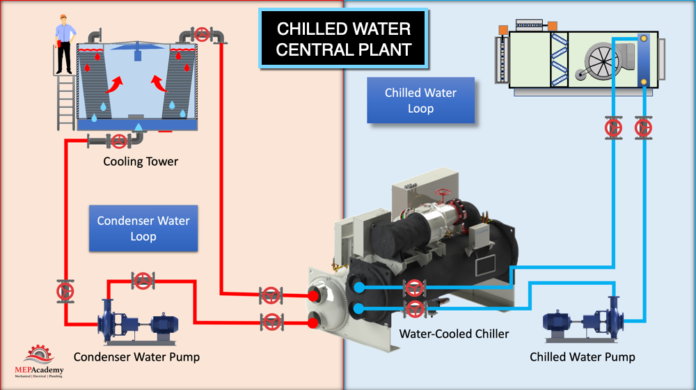

In this article we’ll discuss the basics of a chilled water central plant. The main pieces of equipment include a water-cooled chiller, cooling tower, air handler, controls, and the chilled-water and condenser water pumps.

If you prefer to watch the Video of this presentation than scroll to the bottom or click on the following link. Chilled Water Central Plant Basics.

We covered chillers in another video, but we’ll go over the basics here. The chiller contains a refrigeration circuit with the typical components found in a standard air conditioner. There is a compressor that circulates the refrigerant, a condenser, and the evaporator.

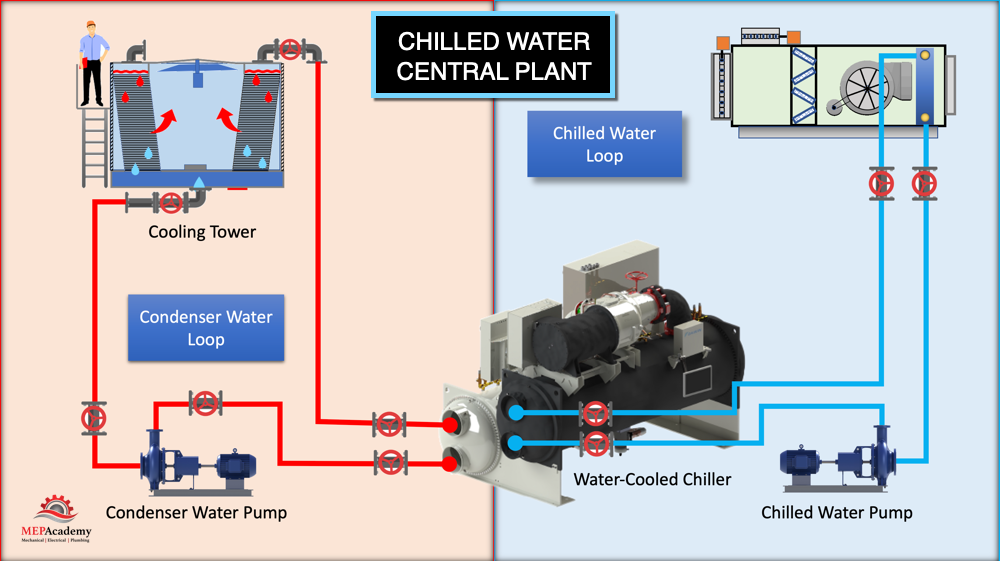

There are two main loops of water fed from the chiller, one comes from the evaporator and the other from the condenser. The chilled water pumps circulate water from the chiller’s evaporator to the air handler through piping, this comprises the chilled water loop. Then there is the condenser water pump that circulates water from the chiller’s condenser to the cooling tower, this comprises the condenser water loop.

These makeup the two main water loops found in a water-cooled chiller plant. The chilled water loops purpose is to absorb the heat from the building. The condenser water loops purpose is to reject that heat to the atmosphere.

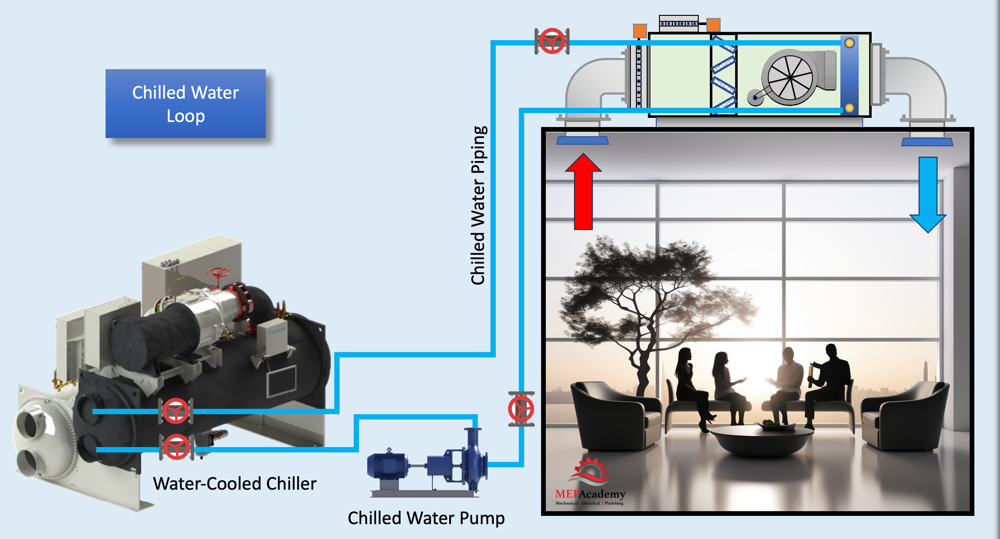

Chilled Water Loop

The chillers evaporator in the central plant produces chilled water. This CHW which is sent to the air handlers cooling coil and fan coils that serve the building occupants.

The air handlers and fan coils circulate warm air over their chilled water coils. The coils cools the air sent back to the occupied spaces. The heat from the spaces is sent back to the chillers evaporator in the chilled water return piping. That heat is absorbed into the chillers refrigerant circuit of the evaporator. The compressor then increases its pressure and temperature before sending to the condenser.

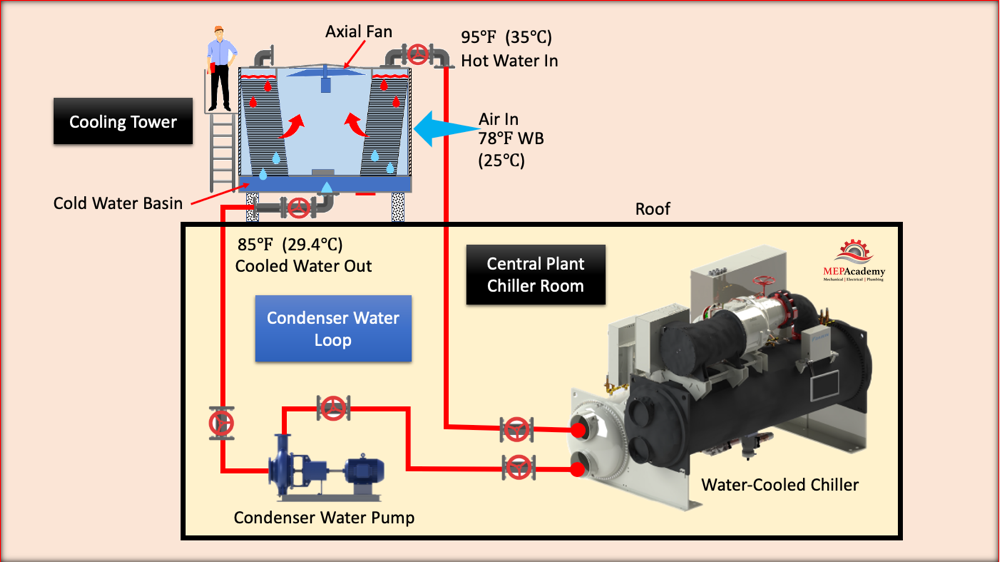

Condenser Water Loop

The cooling tower is responsible for rejecting the heat captured from the spaces. The warm refrigerant in the condenser passes the heat onto the condenser water. The warm water leaving the chillers condenser enters the cooling tower.

The warm water trickles down over the cooling tower fill. The warm water gives up its heat through evaporation to the air be drawn in by the cooling tower fans. The condenser water pump circulates this cooler water from the bottom basin of the cooling tower back to the chillers condenser to repeat the cycle.

This is the basic operation of a chilled water central plant. It includes the production of chilled water used to cool the air that serves the occupants of the building. The pumps circulate that water between the chiller and the other components. The air handlers’ job is to pick up the heat from the space by passing the warm air over the cold chilled water coil.

This is the first in our series on Central Plants and their operation. See our other videos on How Air-Cooled and Water-Cooled Chillers work”, and on “How Cooling Towers Work”.