How Steam Traps Work. We’ll explain the important job of steam traps and how the three most common steam traps work. We’ll also show you examples of where they’re used in the HVAC industry.

if you prefer to watch the video of this presentation scroll to the bottom or click on this link. How Steam Traps Work.

When steam gives up its heat it turns into condensate, which must be removed from the system. The rate of heat transfer through the heat exchanger is highest when the heat exchanger is full of steam. If condensate wasn’t drained out of the system, and it collected in the heat exchanger, then the rate of heat transfer would drop.

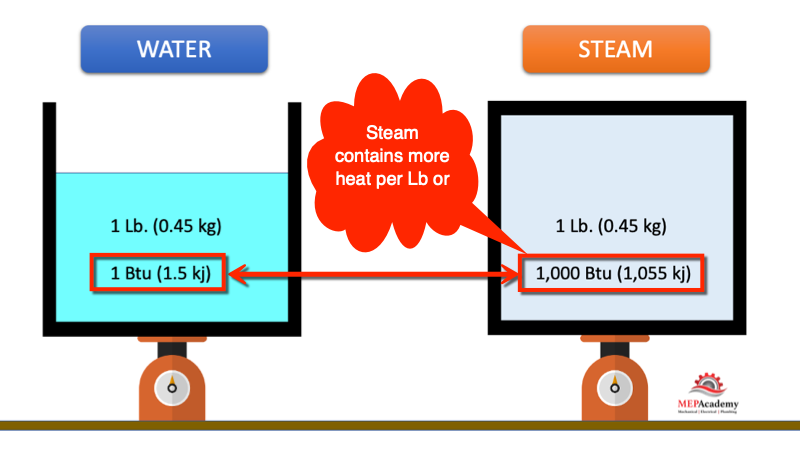

Remember that a pound (0.45 kg) of water or condensate holds 1 Btu (1.5 kj) as it gives up its heat one degree (0.55 K), and that steam gives out approximately 1,000 Btus (1,055 kj) for every pound (0.45 kg).

if condensate is allowed to sit in the heat exchanger the system will lose capacity. Therefore, it’s important to make sure that the condensate is quickly removed while not allowing the steam to escape without first transferring its heat.

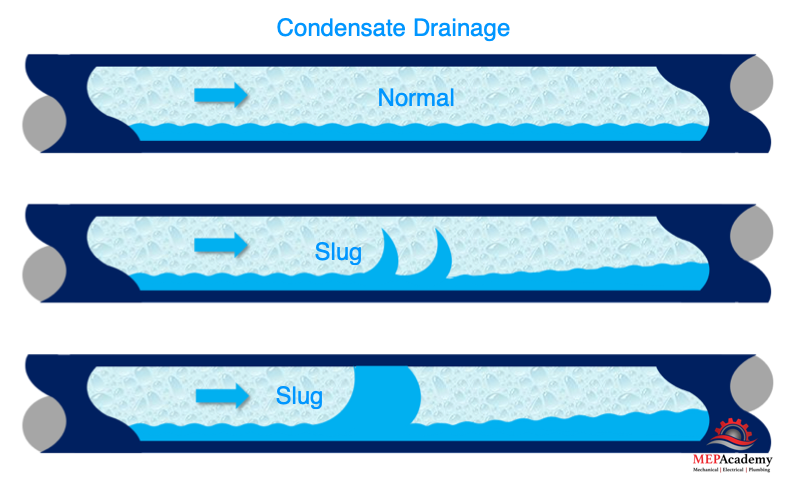

Condensate Water Hammer

Condensate if left to collect in the pipes could cause problems such as water hammer noises, where a high velocity slug of condensate water is slammed against fittings or equipment. This is like a tidal wave in the pipes. The energy is dissipated onto the piping components and is noticeable by the noise it makes or the rattling of the pipes.

When the steam boiler starts the system will be full of air and non-condensable gases that need to be vented out of the system. If a steam trap fails to remove air from the system, the air and non-condensable gasses will reduce the heat transfer rate of the heat exchanger. Non-condensable gases behave like an insulator, thereby reducing the heat transfer rate.

The steam traps job is to remove condensate, air, and non-condensable gases, while preventing steam from leaking past it in a steam system. For the basic understanding of a steam system see our video on Steam Heating System Basics.

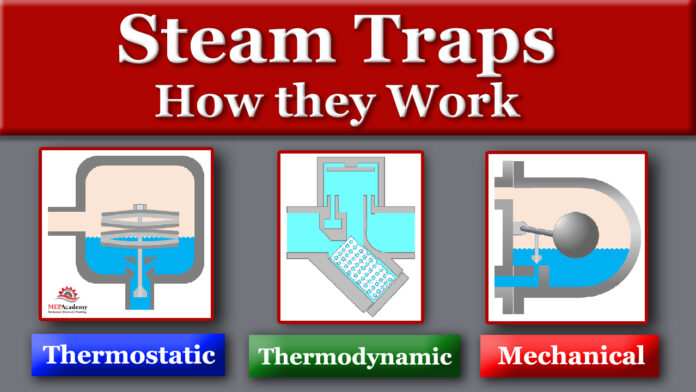

There are three main types of steam traps, but they all require a differential pressure between the inlet and the outlet of the steam trap. We’ll cover how each of the three steam traps categories work.

Mechanical Steam Traps

The density difference between the steam and condensate is how a Mechanical steam trap works. Steam in the form of vapor is less dense than that of liquid condensate which makes the use of a float as an effective means of control. The float and thermostatic (F&T) trap and the inverted bucket trap are the two most common mechanical steam traps. These traps use floats that rise, and fall based on the amount of condensate, and either open or close the trap.

When the condensate level is high in a float & thermostatic trap, the float rises and opens the trap to allow condensate to flow out. When the condensate level drops, so does the float which causes the trap to close.

With an inverted bucket trap, steam will push the bucket upward closing the trap, while condensate will pull the bucket down opening the trap.

These steam traps open and close based on the density of the steam and condensate being different. With the F&T trap the heavier condensate lifts the float, while with the Inverted Bucket the heavier condensate sinks the float.

Thermostatic Steam Traps

The temperature difference between steam and condensate is how a thermostatic steam trap work. It’s based-on temperature. After the condensate forms its temperature drops below that of the steam, and after a certain drop in condensate temperature the trap opens. When steam first condenses its temperature is the same as the condensate. This will require that the condensate cool further before the trap opens.

There are various substances used as the controlling element in thermostatic steam traps, such as fluids and metals.

The bimetal type thermostatic steam traps uses the differing coefficients of expansion of various metals. When two metals are attached together, and one expands at a different rate then the other based on temperature, this can be used to open and close a steam trap. As more and more steam enters the trap, the bimetal heats up and expands while pulling up on the stem of the valve that closes the steam trap, and when it cools down it opens the trap. The presence of steam will cause the bimetal to bend in a certain direction and close the trap, while the cooler condensate will contract the bimetal to open the trap.

When the boiler starts up after being off, the air, condensable gases, and the condensate in the system will be pushed through the open steam trap.

Thermodynamic Steam Traps

The Velocity difference between steam and condensate is how a thermodynamic steam trap works. Steam moves at a greater velocity than condensate. The only moving part in this thermodynamic steam traps is the disc, which moves up and down, opening and closing the port for condensate to flow through.

When the steam system is started, the cool condensate and air is pushed by pressure into the trap, causing the disc to move upward, allowing the condensate and air to pass through.

As hot condensate moves through the steam trap some of it flashes into steam, causing the pressure to drop below the disk, which causes the disk to drop.

As the condensate heats up and flows through the trap it cause steam to flash under the disc, which drops the pressure causing the disc to drop lower towards the seat or opening. As this is occurring the flash steam on top of the disc is pushing the disc closed. This traps the flash steam in the upper chamber, which causes an equalization of pressure on both sides of the disk, preventing any more condensate from passing through.

Flash steam in the upper chamber condenses, causing the disc to be forced up, while allowing condensate to enter. This process repeats itself over and over again.