Spiral vs Flexible Duct. In this presentation we’ll look at the advantages and disadvantages of spiral versus flexible ductwork. Ducts are used to provide a path for air to travel from one place to another. There are important factors to consider when designing the layout of a duct system which we’ll cover here.

If you prefer to watch the Video of this presentation, then scroll to the bottom or click on the following link. Spiral vs Flexible Duct

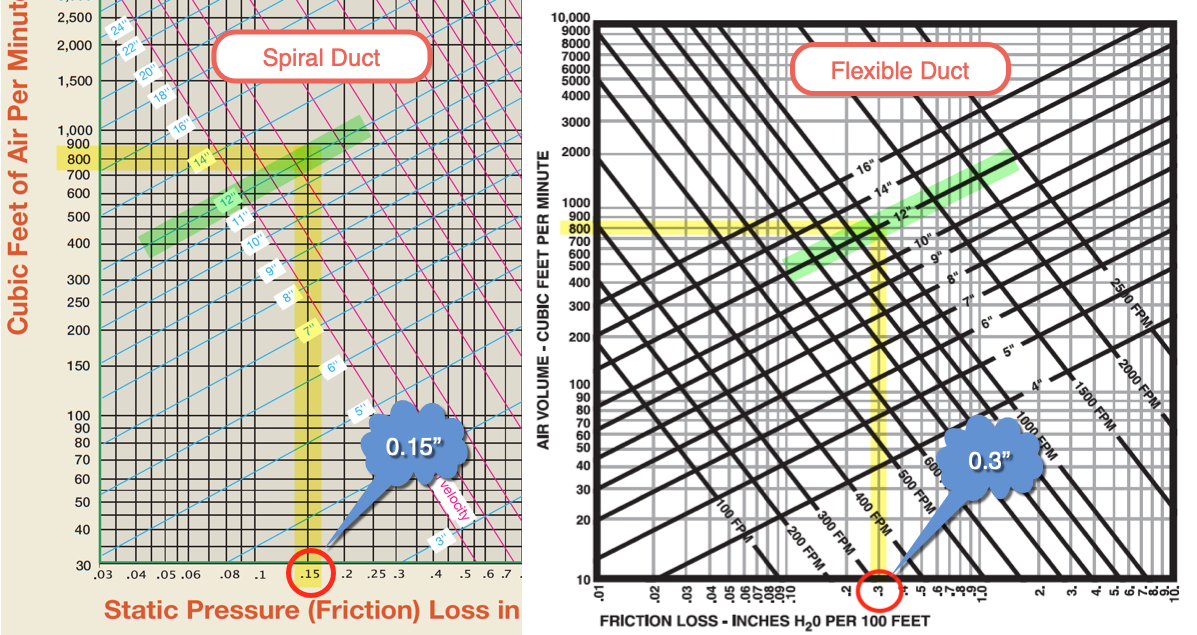

Pressure Drop in Spiral and Flexible Duct

The first consideration which has an impact on the fan energy is the pressure drop difference between spiral and flexible ductwork. Spiral ductwork is rigid and has mostly a smooth interior which is good for air flow. Flexible ductwork is not as smooth as spiral which creates a higher resistance to airflow and increased pressure drop. Additional static pressure is added to the system fan when using flexible ductwork.

For example, a 12” spiral duct at 800 feet per minute has a pressure drop of 0.15”/100 feet. The same size flexible duct at the same velocity would have a pressure drop of 0.30” per 100 feet, which is twice the amount.

Checkout these Flexible Ducts hereEase of Installation

Flexible ducts are more flexible and lightweight, making them easier to install, especially in tight or hard-to-reach places. They can be easily bent and adjusted to fit various configurations, which can simplify installation in complex layouts. Because spiral ducts are rigid, they may require a more unobstructed path, and additional space.

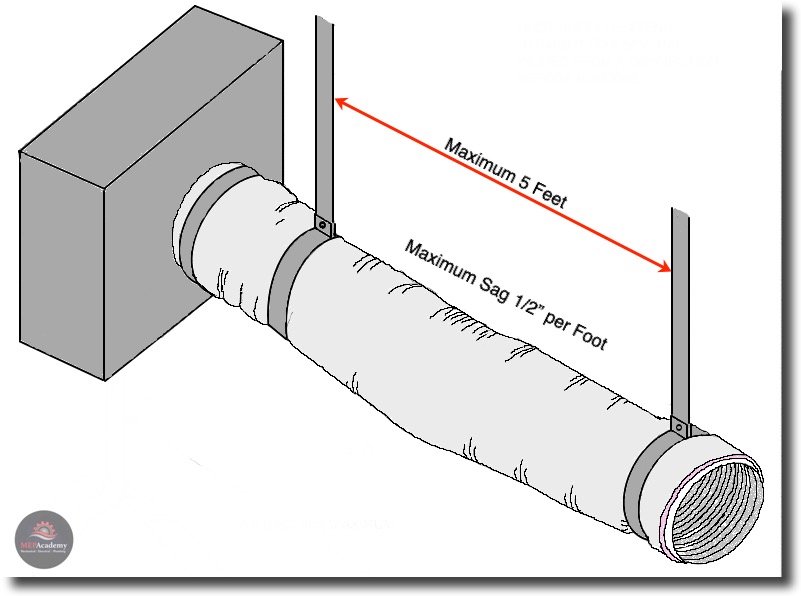

Hanger Spacing

Flexible ductwork will require more hangers per code. For example, a 12” flexible duct may require a hanger every 4 feet, while spiral can require one every 12 feet maximum. Also, flexible ductwork is restricted on how much sag can occur between hangers.

Durability of Spiral vs Flexible Duct

Spiral ducts are rigid and maintain their shape, which can lead to better airflow and minimize pressure loss. Flexible ducts are more prone to damage from sharp objects or rough handling. They can collapse or kink, leading to reduced airflow efficiency. Flexible ducts have a shorter lifespan compared to rigid spiral ducts, especially in commercial or high-traffic environments.

Checkout these Flexible Ducts hereCost of Spiral vs Flexible Duct

Flexible ducts are generally less expensive to purchase and install compared to rigid spiral ducts. Flexible ductwork comes prefabricated wrapped in insulation, while most spiral will need to be insulated after installation including fittings. Flexible duct can avoid some fittings by its ability to flex to achieve various angles, while rigid spiral would need a sheet metal fitting.