HVAC Equipment Budgeting and Purchasing Database. Tracking historical HVAC equipment costs can significantly save you time and money on future estimates and purchases, by providing valuable insights on cost, and easy to read comparable data like cost per ton, or cost per CFM.

If you prefer to watch the video of this presentation, then scroll top the bottom or click on this link: HVAC Equipment Budgeting and Purchasing Database

Here’s how and why tracking is important for estimators and purchasing agents:

Accurate Cost Estimates and Informed Budgeting

With a database of historical equipment costs, you can accurately estimate the budget required for future HVAC projects based on past purchases or vendor quotes. Historical cost data allows you to create more realistic and well-informed budgets.

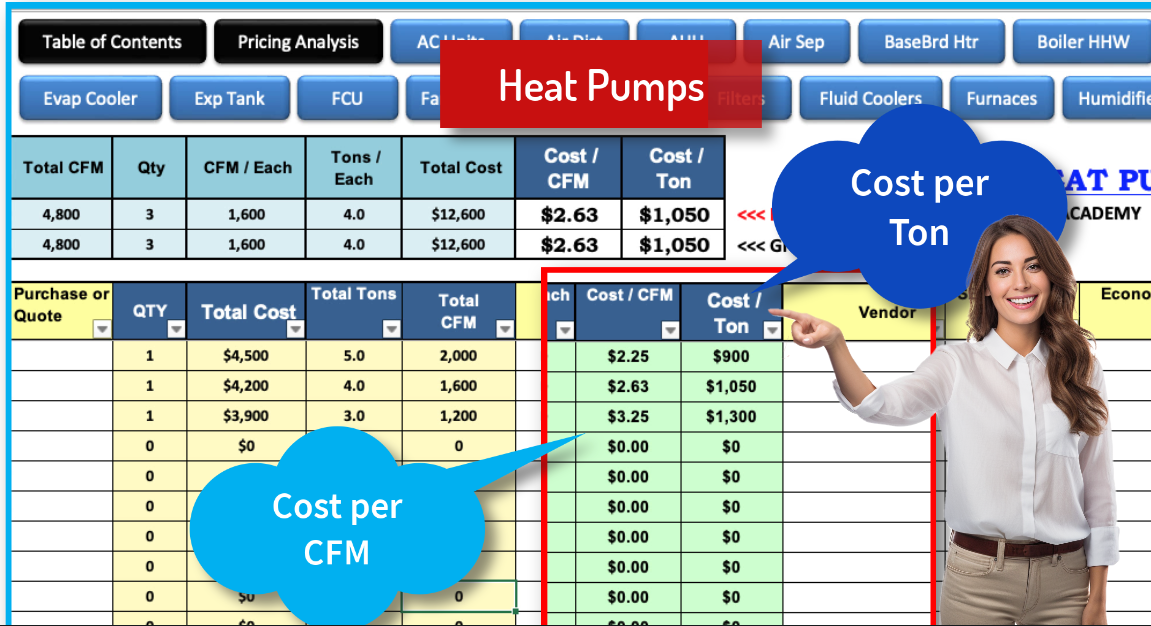

This can be accomplished with the use of a tracking spreadsheet, such as that created by the MEP Academy for this purpose. The spreadsheet tracks the cost of 36 different types of HVAC equipment, from Air Conditioners to VRF Systems.

Looking at the Air Conditioners there are parameters that let us know immediately how much per ton was spent or quoted for a particular AC unit. The information is sortable to allow for quick retrieval of any type of AC unit.

Coils of various types, such as DX, chilled water and heating hot water are easily sorted to determine how much should be paid per coil type, per square feet.

Condenser are tracked for their cost per ton.

36 different types of HVAC equipment are easily tracked and used for budgeting new projects or for purchasing negotiations. Get a copy of this spreadsheet here HVAC Equipment Database.

Vendor Negotiations

Armed with historical cost information, you can negotiate better deals with HVAC equipment suppliers. You have a reference point to discuss pricing and ensure you’re getting fair rates.

Based on previous purchases or supplier quotes, you can quickly know what you should be paying based on what you paid for similar equipment and avoid overpaying for new purchases.

Without historical data, you might unknowingly pay more than necessary for HVAC equipment. Comparing current prices to historical averages prevents overpaying for similar equipment.

Comparative Analysis

Analyzing historical data helps you identify trends in equipment costs over time. This information allows you to make informed decisions about the best times to make purchases, taking advantage of lower-cost periods.

Total Cost of Ownership (TCO) Consideration

Recording both purchase costs and other associated expenses (installation, maintenance, repairs, energy consumption) enables you to calculate the TCO accurately. This comprehensive view guides you in choosing cost-effective equipment that provides long-term savings.

Selecting Optimal Equipment

Historical data can reveal which equipment models and brands have been more cost-effective in the long run. This helps you choose equipment with proven reliability and lower maintenance costs.

Project Planning

When planning new construction or renovations involving HVAC systems, historical cost data helps you project expenses more accurately. This prevents unexpected financial challenges during project execution.

Reduced Decision Time

Instead of researching and estimating costs from scratch for each new HVAC project, you can rely on your historical data. This accelerates decision-making and project initiation.

Minimized Risk of Surprises

Historical data reduces the risk of unexpected cost surprises during a project. You can anticipate potential expenses based on past experiences, ensuring smoother project execution.

Resource Allocation

Accurate historical cost data helps allocate resources more effectively, ensuring that you prioritize projects that align with your budget and financial goals.

Improved Planning

The ability to project expenses accurately leads to better overall project planning. You can schedule maintenance, replacements, and upgrades strategically, optimizing operational efficiency.

Long-Term Savings

Making well-informed decisions based on historical data often leads to choosing more energy-efficient equipment and avoiding costly mistakes, resulting in significant long-term savings.

In essence, tracking historical HVAC equipment costs empowers you to make more informed, efficient, and cost-effective decisions for your HVAC projects. It eliminates guesswork, reduces risks, and helps you plan and budget with confidence. Click on the following link to get a copy of this spreadsheet and start saving time and money.