In this article, we’ll explore one effective method for managing VAV systems in laboratory settings, focusing on the sequence of operations that ensures a safe and energy-efficient environment.

If you prefer to watch the video of this presentation, then scroll to the bottom.

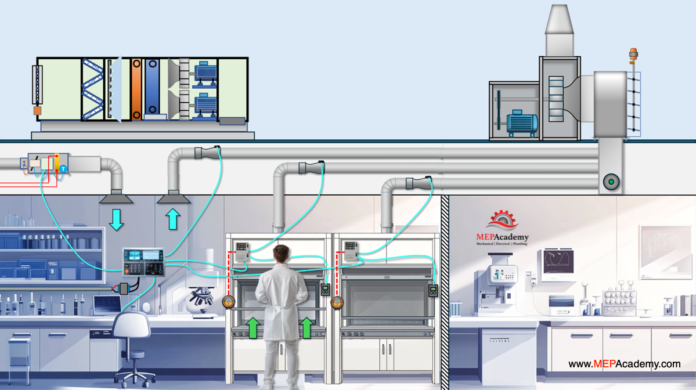

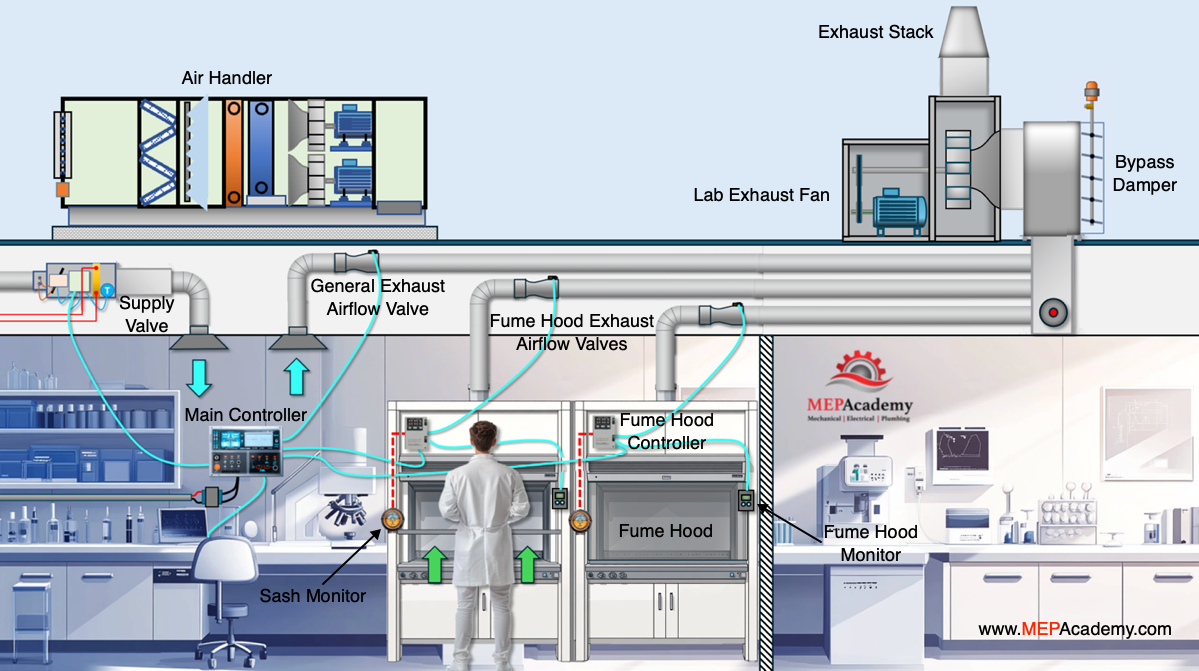

A common strategy for addressing exhaust and supply requirements while minimizing energy consumption is to implement a variable air volume (VAV) lab control system. This system can be as straightforward as a single exhaust fan connected to two variable-volume fume hoods, or it can scale up to include multiple fans that activate based on laboratory demand.

No matter the size of the lab, each VAV fume hood is equipped with an exhaust airflow control valve to regulate airflow through the hood. Typically, hoods used for standard research are connected to a manifolded exhaust duct that leads to roof-mounted fans. Additionally, the laboratory space is supplied with fresh air through a duct with a modulating damper to control the air’s volumetric flow.

A VAV lab system is managed to maintain a safe environment by use of the following.

Space Pressurization

Laboratories typically operate under negative pressure to contain fumes and odors. To achieve this, the control system is configured to exhaust more air than is supplied. The amount of exhaust air required is directly related to the Air Changes required, Fume Hood airflow capacity, and or the amount of conditioned supply air needed based on heat gain driven labs.

Chemical Fume Hood Flow

The VAV fume hood is equipped with a fume hood monitor, sash position indicator, controller and an airflow control valve that adjusts the airflow based on the position of the sash. While exhaust velocities vary by application, the use of 100 feet per minute is often used. If you have a 6-foot fume hood with an open sash height of 24 inches, then the volume of air would be 6-feet times 2-feet equals 12 square feet times 100 feet per minute, equals 1,200 CFM. An 18-inch open sash would equal 900 CFM. In a lab that measures 64 feet in length by 32 feet wide with a 10-foot ceiling at least 2,048 CFM would be required to achieve the 6 air changes required for this lab. If you want to learn more on how to calculate air changes per hour see our other video.

Lab Airflow Valves

A VAV laboratory controller maintains negative pressure by dynamically adjusting the fume hood exhaust valves, general airflow exhaust valves, and supply airflow valves in response to real-time conditions.

Fume Hood Exhaust Valves

The controller modulates the fume hood exhaust valves based on the sash position. When a sash is opened, the valve opens further to increase the exhaust airflow, ensuring that fumes are effectively captured and removed.

General Airflow Exhaust Valves

These valves control the overall exhaust from the lab space, beyond just the fume hoods. The controller adjusts these valves to maintain the desired negative pressure in the lab, ensuring that air flows from adjacent areas into the lab, preventing contaminants from escaping. If the fume hoods are not being used, then the General Exhaust valve will increase its airflow to maintain a negative pressure based on the position of the supply valve.

Supply Airflow Valves

To maintain balance, the controller also modulates the supply airflow valves. As exhaust airflow increases or decreases, the supply airflow is adjusted to ensure that the lab remains at a slightly negative pressure. This ensures that the lab draws in clean air from adjacent spaces, rather than allowing potentially contaminated air to escape the lab.

By coordinating the adjustments of these three types of valves, the VAV laboratory controller effectively maintains a consistent negative pressure, ensuring a safe and controlled lab environment.

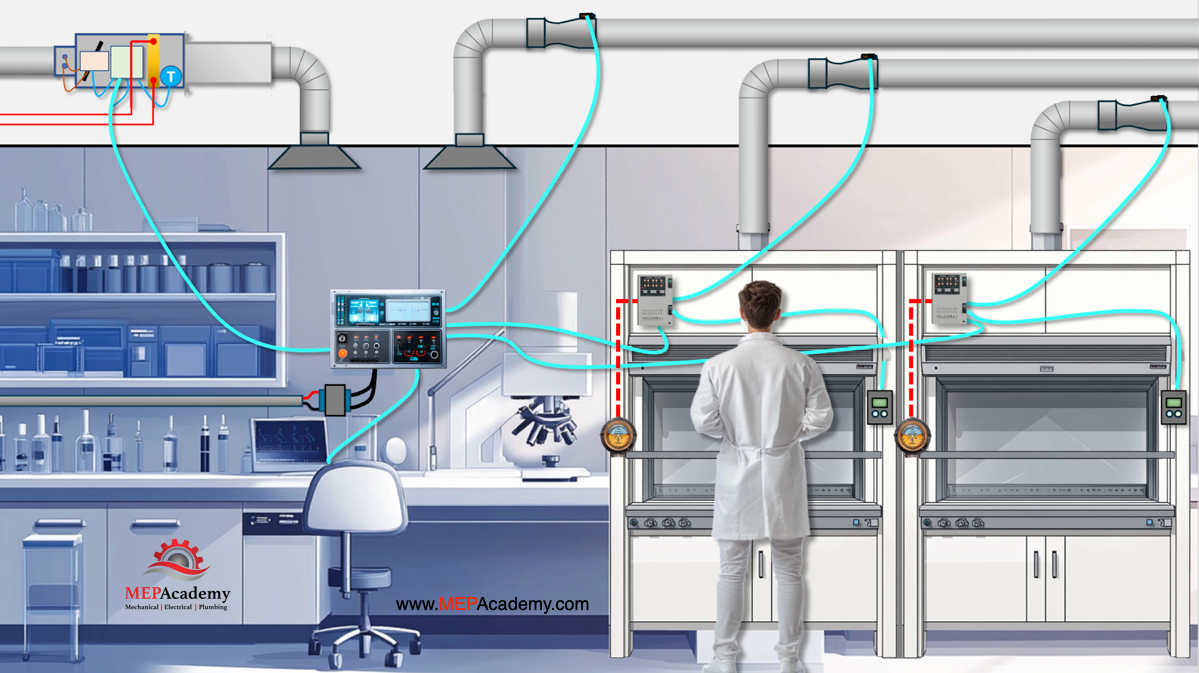

Sash Position

As the sash opens, the sash sensor detects the change and signal the fume hood controller to adjust the exhaust airflow control valve to open, ensuring the desired airflow and maintaining a safe hood velocity. When the sash closes, the valve adjusts to a specific level to sustain the required face velocity. As the sash is moved to a new position the controls will respond within seconds to reposition the exhaust airflow control valve to maintain the required face velocity. This requires that the exhaust airflow control valve be able to adjust flow (CFM) from full load to the minimum required. The valves are pressure independent and will maintain the required flow when the overall system pressure fluctuates.

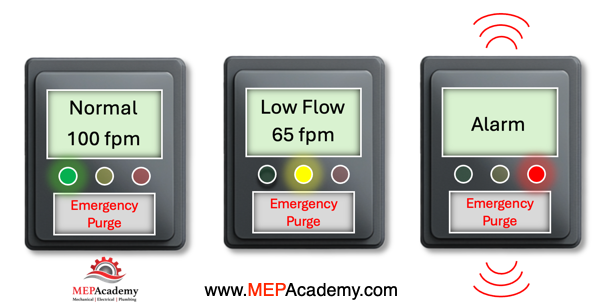

Fume Hood Monitor

The fume hood monitor will indicate the current velocity. There may. be a green light indicating normal operation, and a yellow light when the velocity drops below normal. Once the velocity drops too low or there is a system failure the fume hood monitor will show a red light and produce an audible alarm to alert the room occupants of a potential unsafe condition and to close the sash.

If the user spills a toxic or hazardous substances within the hood, the user can push the purge button on the hood monitor. This will close the sash to contain the contaminants.

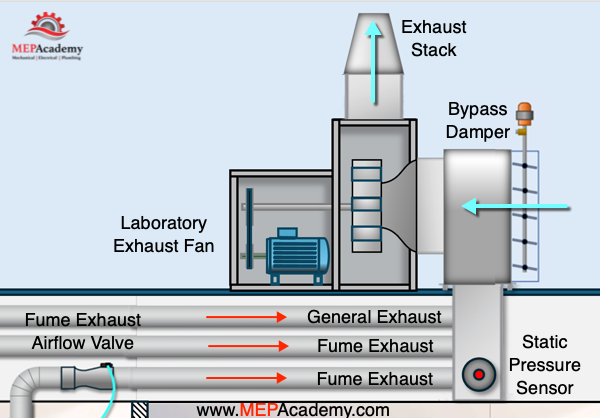

Duct Pressure and Bypass Air

Monitoring duct pressure between chemical fume hoods or other exhaust points ensures the system maintains the appropriate negative pressure. This is to keep the lab space negative, even when VAV hood sashes open suddenly. This pressure monitoring also prevents excessive negative pressure, which could damage the exhaust valves or ductwork.

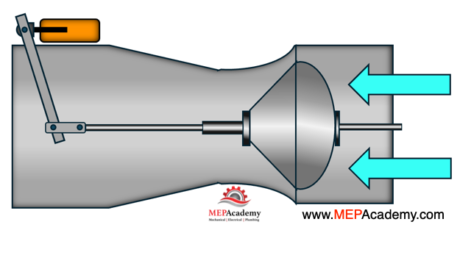

A crucial aspect of controlling duct pressure is adjusting the capacity of the exhaust fan(s) that draw air from the system. While there are various methods to regulate fan capacity, including variable frequency drives. The most common approach is to use a bypass air plenum with a modulating damper.

The bypass air plenum is located either beneath an inline fan or next to a scroll-style centrifugal fume exhaust fan. It includes a modulating isolation damper that disconnects the fan from the duct system when not in use. When sashes are closed and duct negative pressure increases, the bypass damper allows outside air to flow into the fan. This reduces the amount of air pulled from the exhaust system when hood demand is low. The benefits of this setup include:

Lab Exhaust Fan

Stable operation of the exhaust fan, ensuring consistent nozzle velocity and plume rise. Exhaust fan stack velocity is crucial in laboratory fume hood exhaust systems because it ensures that hazardous fumes and contaminants are effectively dispersed into the atmosphere, away from building occupants and nearby areas. A sufficient stack velocity creates a high-velocity plume that carries pollutants to a safe height.This minimizes the risk of re-entrainment into the building’s air supply and reducing the exposure of nearby personnel to harmful chemicals. This helps maintain a safe and compliant laboratory environment.

Quick response to changes in duct pressure.

Energy savings, as reduced exhaust from the lab lowers the demand for tempered supply air

The opposite occurs when the sashes begin to open. As the VAV hood valve opens, the duct pressure becomes less negative, and the bypass dampers begin to close. This adjustment draws more air from the lab exhaust system, while the make-up air increases to maintain proper system pressure.

Summary

Lab exhaust systems are essential for ensuring a safe environment in and around laboratory facilities. However, managing chemical fume exhaust, creating high-velocity plumes, and handling 100% outside air can result in significant energy consumption. By implementing a VAV lab system and providing proper training for lab users to close their sashes when not in use, it is possible to maintain a safe environment while also reducing overall energy usage.