Fan Filter Units FFU, and how they work. In this article we’re going to cover the fundamentals of how fan filter units work and there use in a cleanroom environment. We’ll show you four different fan filter unit system configurations and how they differ.

If you prefer to watch the video of this presentation, then scroll to the bottom or click on the following link. Fan Filter Units FFU

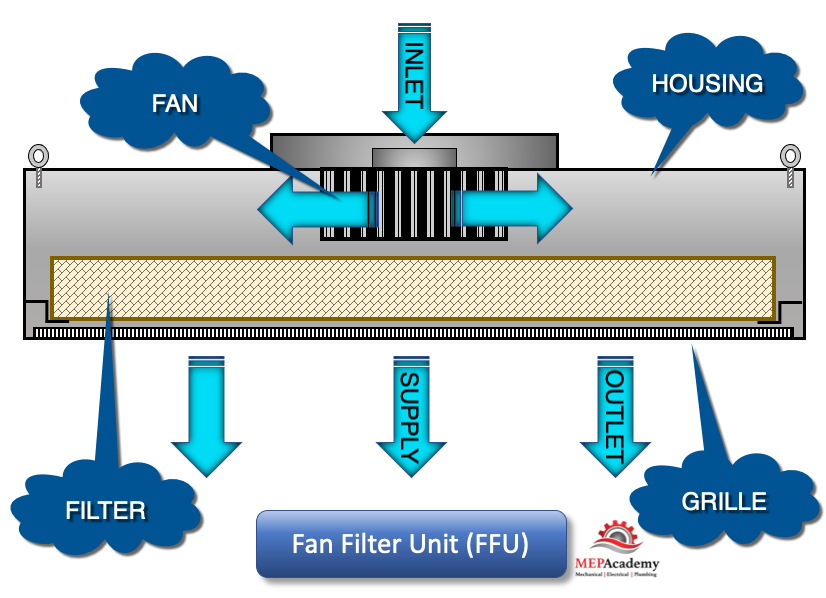

A Fan Filter Unit (FFU) is a device used in cleanrooms and other controlled environments to provide high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filtration. It consists of a fan, a filter, and a housing unit. The primary purpose of an FFU is to circulate and filter air to maintain a clean and particle-free environment.

Here’s how a FFU typically works

Fan: The FFU contains a fan that draws air into the unit using various system configurations. The fan is usually an electronically commutated (ECM) or direct current (DC) motor that operates quietly and efficiently. The most common sizes are 24” x 24”, 24” x 36”, and 24” x 48” fan filter units.

Checkout these Fan Filter Units hereAir Handling Unit & Fan Filter Unit System #1

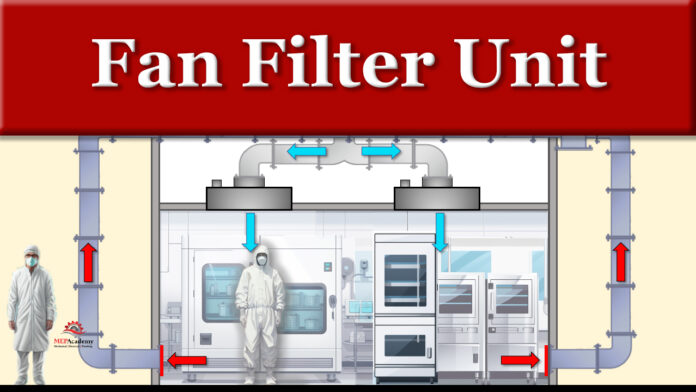

Here we show an Air Handling Unit directly feeding the fan filter units, with the return from the space going directly back to the air handler.

Filter: The air passes through a high-efficiency filter, such as a HEPA or ULPA filter within the Fan filter unit housing. These filters are designed to remove particles as small as 0.3 micrometers (HEPA) or 0.12 micrometers (ULPA) with high efficiency. They capture airborne contaminants, including dust, pollen, bacteria, and other particles, ensuring the air leaving the FFU is clean and free from harmful substances.

Housing Unit: The fan and filter are housed in a sealed unit, preventing air leakage and maintaining the desired cleanliness level within the controlled environment. The housing unit is typically constructed with materials that minimize particle generation and are easy to clean.

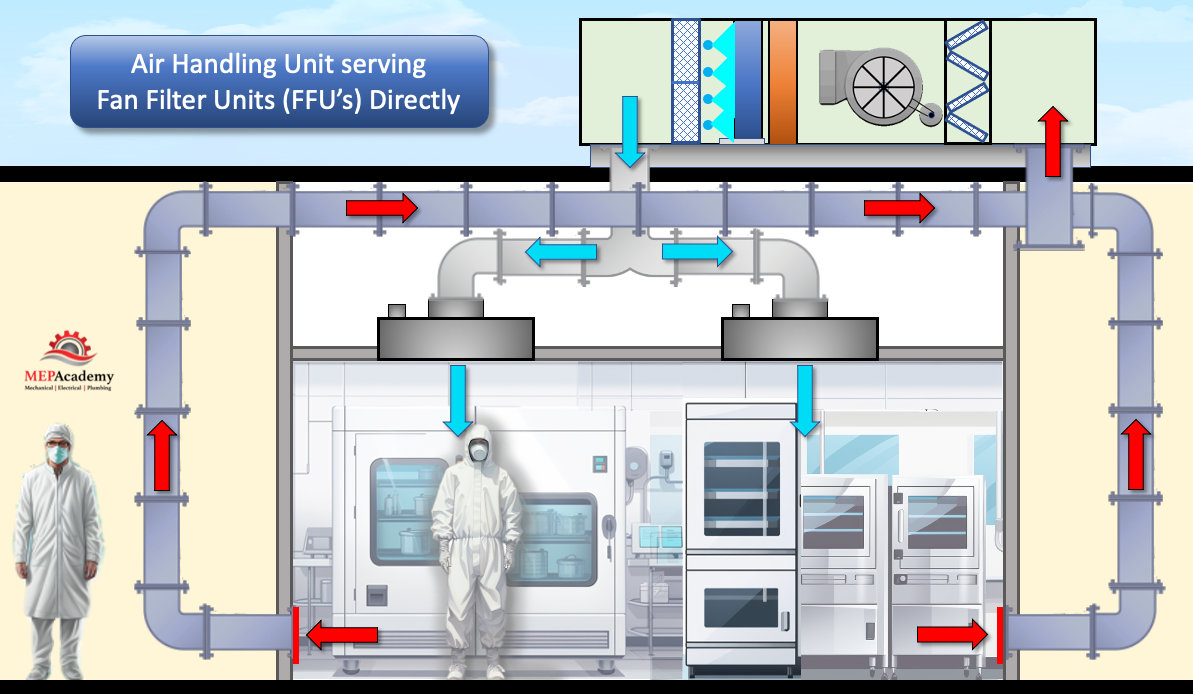

Air Handling Unit & Fan Filter Unit System #2

With this second configuration the air handler feeds the fan filter units as in system #1, but the return air goes directly to the fan filter unit instead of the air handler. The air handler provides the required conditioning and outside air, while the fan filter units provide the required air changes to achieve the cleanliness level for the specified space.

Air Distribution: The clean, filtered air is then discharged uniformly and evenly through the outlet of the FFU. The airflow pattern depends on the specific design and installation of the FFU, which can vary based on the requirements of the cleanroom or controlled environment.

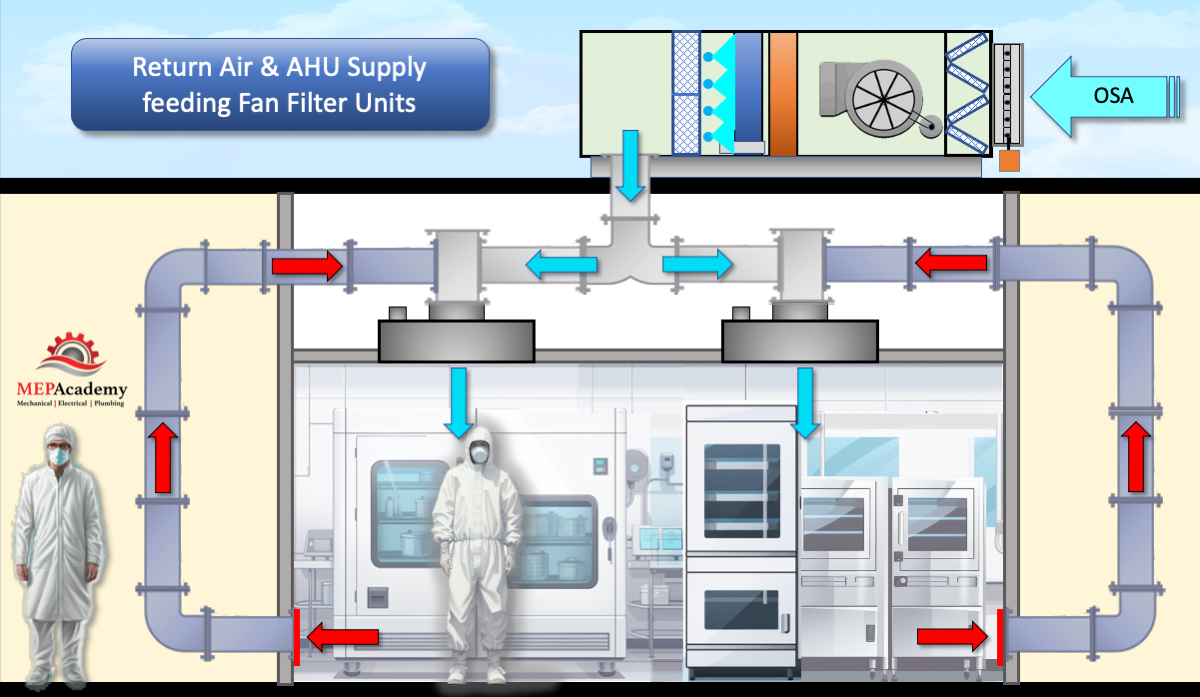

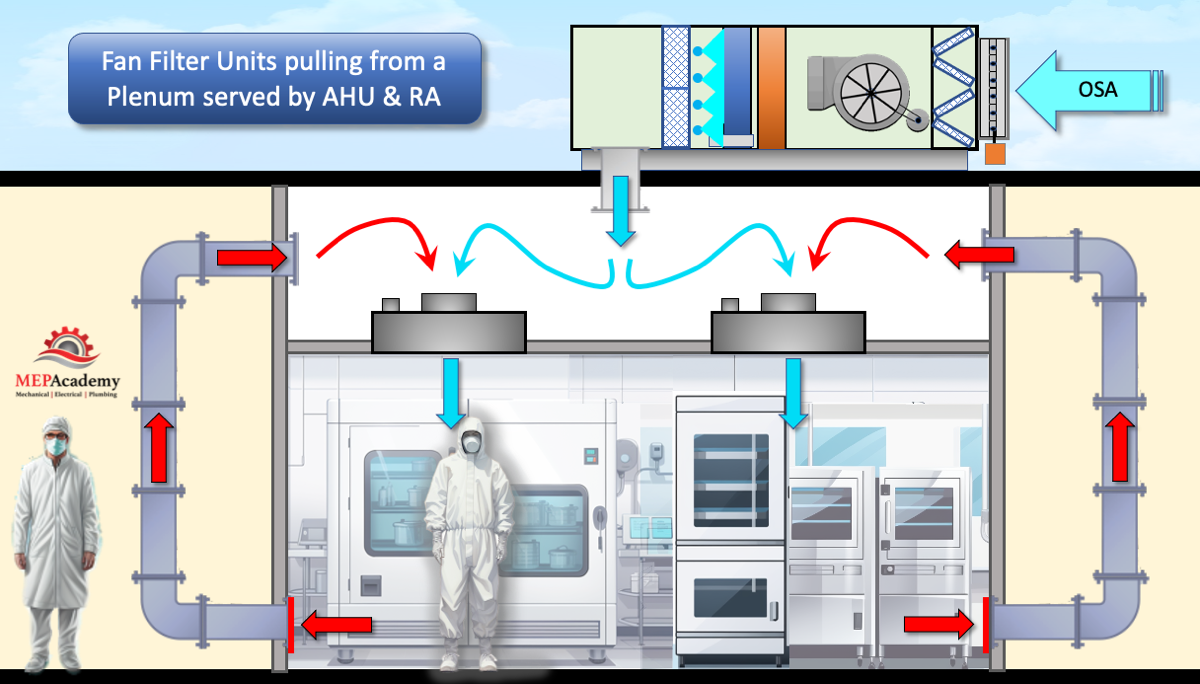

Air Handling Unit & Fan Filter Unit System #3

In this third system configuration, the air handler dumps its supply air into a sealed plenum area where the fan filter unit draws air from. The return air is drawn into the plenum space by the fan filter units.

FFUs are often used in conjunction with a ceiling grid system or other mounting methods to create a grid of clean air within a cleanroom. Multiple FFUs can be installed in a modular fashion to cover the entire ceiling area, providing consistent air cleanliness throughout the space.

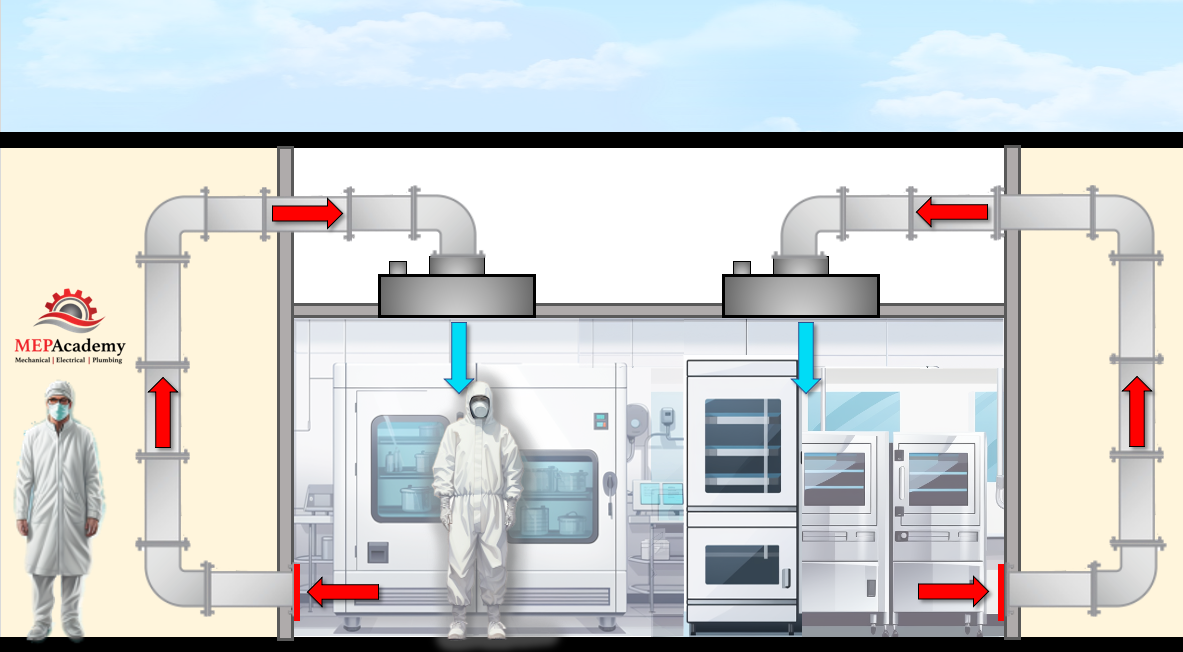

Checkout these Fan Filter Units hereFan Filter Unit System #4

In this system configuration the fan filter units have the return air ducted directly to the unit providing a closed loop within the cleanroom. This may be used where a tight plenum is not available.

Fan filter units are also equipped with wall mounted speed controls that allow for adjustable airflow rates, enabling users to control the air change rate and maintain the desired cleanliness level within the environment. Additionally, some FFUs may include features like alarms, pressure sensors, and filter monitoring systems to alert users when filter replacement is necessary or if there are any issues with the unit’s performance.

Overall, the FFU plays a crucial role in maintaining clean and particle-free environments by effectively circulating and filtering the air, ensuring the air quality meets the required standards.

Fan Filter Unit Applications

Fan Filter Units are commonly used in various types of rooms and environments that require a controlled level of cleanliness. Here are some examples:

Cleanrooms: FFUs are extensively used in cleanrooms across industries such as pharmaceuticals, electronics, biotechnology, healthcare, and semiconductor manufacturing. Cleanrooms maintain low levels of airborne particles to protect sensitive processes, products, or research. FFUs are often installed in the ceiling grid system of cleanrooms to provide a constant supply of clean, filtered air.

Laboratories: Research laboratories, especially those involved in sensitive experiments, require clean and particle-free environments. FFUs can be employed to maintain the cleanliness level required for specific experiments, equipment, or materials.

Data Centers: Data centers require a controlled environment to protect computer equipment from dust and other contaminants. FFUs are utilized to provide clean airflow and prevent the buildup of particles that can affect the performance and reliability of the equipment.

Medical Facilities: In hospitals, clinics, and healthcare facilities, FFUs can be used in areas like operating rooms, isolation rooms, and laboratories to maintain sterile conditions and minimize the risk of airborne infections.

Microelectronics Manufacturing: The production of microelectronics, such as integrated circuits and semiconductors, necessitates extremely clean environments to avoid defects caused by particulate contamination. FFUs are vital in maintaining the required cleanliness levels during the manufacturing process.

Food and Beverage Industry: Certain areas of food processing and manufacturing facilities, such as cleanrooms for packaging or specialized production areas, may require FFUs to control airborne contaminants and maintain product integrity.

Aerospace and Precision Engineering: Facilities involved in aerospace manufacturing, precision engineering, or optics require controlled environments to prevent particles from compromising the quality and precision of their products. FFUs can help maintain the necessary cleanliness standards in these environments.

It’s important to note that the specific cleanliness level and requirements may vary depending on the industry, process, or product being produced or handled. FFUs can be customized to meet the specific needs of different applications, allowing for flexibility in achieving the desired level of air cleanliness.