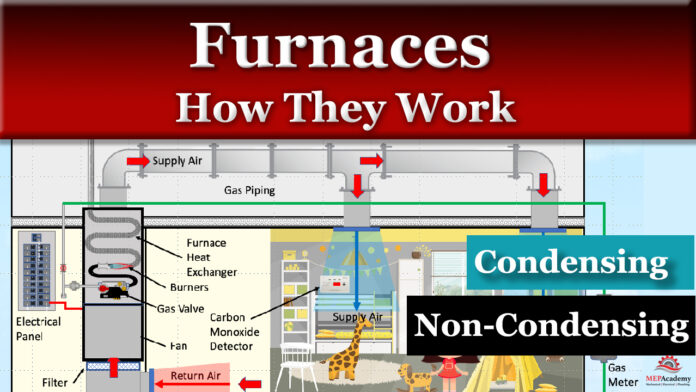

How Gas Furnaces Work. In this presentation we’ll cover how a furnace works and explain the various components, including the different types of furnaces that are used mostly in residential spaces, but also used in various commercial applications. Natural gas is the mostly used fuel for furnaces. We’ll explain the difference between a condensing furnace and a non-condensing furnace. We’ll discuss how furnaces are rated for energy efficiency and the type of flues used for each type of furnace.

If you prefer to watch the video of this presentation, then scroll to the bottom or click this link. How Gas Furnaces Work

Construction of a Furnace

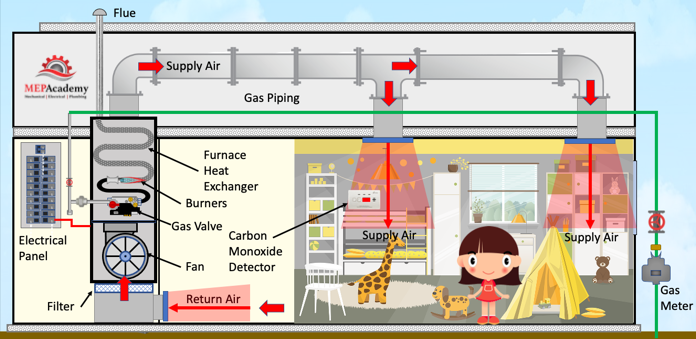

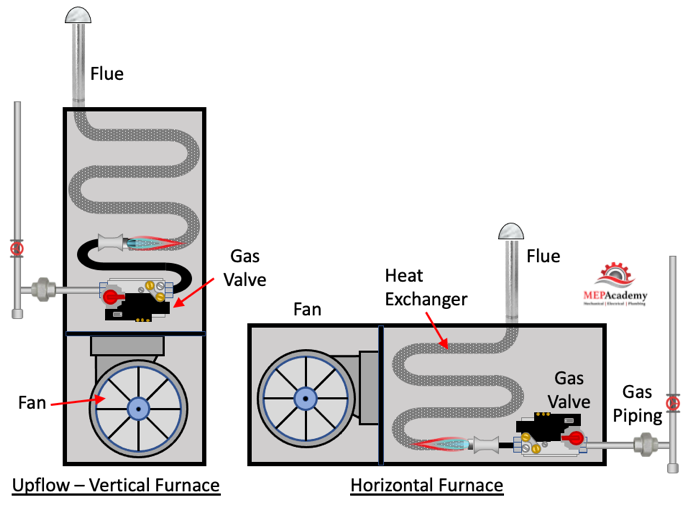

The furnace can be installed vertically or horizontally in a closet, basement, attic, crawl space or equipment room.

Checkout these Gas Furnaces hereThe furnace is housed in a sheet metal casing. The latest models use a variable speed fan to blow air over the heat exchanger. These types of fans have direct drive ECM motors that are much quitter and run more efficient than traditional fans. The fans don’t handle a lot of static pressure, often a maximum of 1” W.C. (0.249 kPa). Warning “Installation and Service should be performed by a qualified installer, service agency or the gas supplier”.

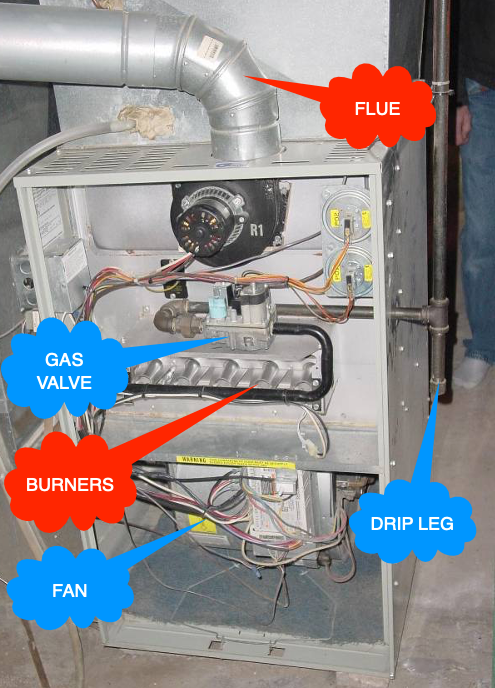

Gas piping will be installed from the gas meter, or from a branch off the main gas line, and connect to an internal Gas Valve and manifold in the furnace. A gas shutoff valve should be provided at the furnace for isolation of the gas. The shutoff valve needs to be in a visible location close to the furnace for ease of use in an emergency or for maintenance. Between the shutoff valve and the furnace should be a union and drip leg. The union provides for the gas piping to be removed from the furnace if required.

A Drip leg should be installed to trap any condensate in the gas piping and prevent it from entering the furnace. The drip leg should be located away from where it could freeze. After the piping is installed, it will need to be pressure tested to ensure there are no leaks. The pressure test can be done using compressed air or an inert gas like nitrogen. Never use oxygen to pressure test gas piping. The use of an electronic leak detector can help identify any leaks indicated by a failed pressure test. Obviously, a flame would never be used to find a leak.

Pipe size depends on the volume of gas required and the size of the furnace, but for a small residential unit the gas piping might be just a 1/2”(20mm) pipe. The gas valve controls or modulates the flow of gas to the burners. The burners convert the fuel and air into heat that enters the heat exchanger.

Furnace Heat Exchangers

With a condensing furnace there will be two heat exchangers, a primary and secondary heat exchanger. With non-condensing furnaces there is only one heat exchanger. The heat exchanger is where the room air absorbs heat from the burning fuel. By having two heat exchangers, the condensing furnace allows for additional heat transfer and lower flue gas temperatures. The secondary heat exchanger will most likely be made of stainless steel to prevent corrosion as condensate will occur at lower flue gas temperature.

Checkout these Gas Furnaces hereCombustion Air

The combustion air will go up through the heat exchanger and to the outdoors, while the blower fan sucks in return air and blows it through the heat exchanger, then out to the spaces to be heated. The air delivered to the spaces and the burning fuel with its combustion gases are on opposite sides of the heat exchanger wall and never encounter each other. Some manufactures provide removability of the heat exchanger for easy serviceability.

Combustion and flue exhaust will need to be provided. With a condensing furnace this is accomplished by installing a combustion inlet pipe to the outside (direct venting) or inside (non-direct venting), and a combustion flue exhaust to the outside. If using a condensing furnace, then vents can use 2” to 4” PVC as the flue gas temperatures are much lower on these types of furnaces. For non-condensing atmospheric furnaces its common to use “B” vent, check the furnace manufacture and local code authority for venting requirements.

There will be a direct spark ignition or hot surface ignition system for the lighting of the gas when heating is called for. Along with the direct spark ignition is a remote sensor that confirms that the gas is burning. This is a safety device to prevent gas from being released if no flame is sensed.

Condensate from Condensing Furnace

A condensate pipe will need to be installed for any condensing furnace installed. Condensing furnaces are more efficient, but the byproduct is condensate that needs to be routed to a drain. The drain will have to run through a neutralizing filter because of the acidic nature of the condensate. This neutralizing kit can be provided by the manufacture or bought separately.

Newer models will have integrated circuit control boards that could contain dip switches for easy setup adjustments.

Electrical

Electrical conduit and wire will be run from the breaker panel to the furnace. These furnaces require only 115 volts, single phase power to the unit. Inside the unit should be a transformer that reduces the 115 volts down to a lower control voltage.

There will be a safety switch on the cabinet door leading to the blower, so that when the door is opened the blower is shutoff. This prevents someone from getting injured from a moving fan wheel and motor during service.

Filters

Filters can be provided on the bottom or side inlet to the fan housing by adding a filter rack if one isn’t provided. Remember that the furnace should never be run without a clean filter in place. See our video on “Air Filters and Filter Housing Basics” to understand filters and how they’re rated.

Smart Thermostat

Look for furnaces that have some form of communication with a smart thermostat to provide system information and alerts to system problems. There are also mobile apps that allow for notification and setting adjustment remotely, including routine maintenance alerts. The thermostat should allow for modulation of capacity. There will be a control wire access port for the thermostat wiring coming from the conditioned space.

When the thermostat sends a signal to the furnace to provide heat, the combustion air fan will start to ensure proper air for the combustion of the gas. Then to confirm that the combustion fan is running there is some form of pressure switch that picks up pressure created by the fan which then energizes the hot surface igniter. After a preset time, the hot surface ignitor will allow gas to flow to the burners. After another preset time that the burners are operating, the blower fan will start and blow air out of the furnace into the space. If the system fails to lite the burners after various attempts, then shutoff the system and contact a service company to determine why.

Thermostats often allow for two settings. One is auto, which lets the system cycle on and off to meet demand. The other is fan only, with this setting only the fan runs continuously without any heating.

If adding a split system air conditioning unit to the installation, the DX coil will mount on the discharge of the furnace and share the same fan for air flow.

The furnace can weight from 100 to 200 pounds depending on the heating capacity of the unit.

Upflow Furnaces

With up flow, vertical furnaces, the Return air will enter the bottom of the furnace or side, and travel through a filter before entering the fan section where the air is blown through the burner and then the heat exchanger. As the air leaves the furnace it enters a plenum and then through distribution ductwork to deliver the heated air to each room.

Downflow Furnaces

Some buildings use the crawl space for the distribution ductwork and a furnace that provides a downflow configuration. The return air enters the top of the furnace with the supply air exiting at the bottom.

Horizontal Furnaces

When using a horizontal furnace, they can be installed in attics, crawl spaces or an open space. When the furnace is concealed above a ceiling or installed in an attic, there should be an area provided in front of the furnace for maintenance personnel to access the unit.

Checkout these Gas Furnaces hereNatural Gas Regulators

Gas supplied to the building is usually more than the furnace can handle. At the gas meter there should be a gas regulator that reduces the gas pressure from the utility before it enters the meter. The utility company usually sets the downstream pressure between 5 and 7” W.C. (1.2 to 1.7 kPa), or what is required for special equipment. For a gas furnace that is running the pressure can vary by make and model but should be in the 3.5” W.C. (0.87 kPa) range. There are commercial versions that have higher running pressures, be sure to check the name plate for the correct pressure. Also note the maximum pressure rating of the furnace as this value should never be exceeded. For other gas types check the manufactures literature for operating pressures.

Combustion Intake and Exhaust

A sealed combustion furnace is the best option when selecting a furnace. This is when outside air is brought directly to the combustion chamber and exhausted through the flue to the outside. This lessens the chance of combustion byproducts from entering the occupied space. With non-sealed combustion chambers, air is drawn into the unit for combustion and then exhausted through the flue. These high efficiency sealed combustion chamber units exhaust gas that is acidic and can damage old unlined chimneys. In these cases, a new flue may need to be installed or the old chimney needs to be lined.

Combustion air is required for all fuel burning appliances. If the furnace is in an enclosed space, then the proper amount of air will need to be brought into the enclosure to allow for proper combustion. No matter what the enclosure size is, there needs to be provisions for combustion air. Combustion air mixes with the fuel to provide the proper ratio for clean burning of the gas

Gas Venting

Vents are classified into one of four categories. Category I and II vents are for natural draft gas appliances that operate at a negative pressure. They depend on the natural draft of warm air. Most contractors are familiar with Type “B” double wall vent allowed under category I systems. Type “B” flue vent has an inter duct made of aluminum to resist corrosion, with an outer duct made of galvanized steel for strength with an air gap in between. Because high air rises the use of any horizontal flue pipe needs to be slopped at least a 1/4” per foot.

Category III and IV vents are operated at a positive pressure and use a fan to move flue gases out of the system. They require a tighter seal due to the positive pressure.

For condensing furnaces either direct venting or non-direct venting is used with 2” to 4” PVC piping or equivalent as approved by local codes.

Carbon Monoxide Detectors

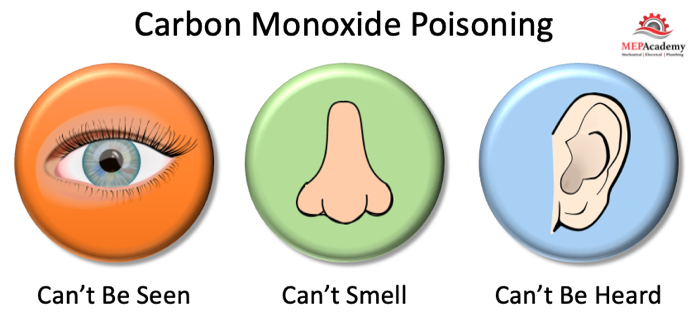

With gas furnaces there is always the chance that the heat exchanger will leak and bypass air into the occupied space. This combustion gas is poisonous and could cause headaches, dizziness, weakness, upset stomach, vomiting, chest pain, confusion and even death.

Remember that carbon monoxide is odorless, so you won’t smell a leak. Therefore, installing a Carbon Monoxide Sensor is so important. Also, carbon monoxide can’t be seen as it’s colorless. It also can’t be heard, so your own human senses can’t be relied upon as your eyes, nose and ears won’t detect anything before the effects of the carbon monoxide could be too late, so get CO sensors installed to protect the occupants.

Gas Ignition System

Whenever there is a demand for heating, the furnace needs to ignite the gas in a safe manner. Large systems will use a two-step process, where the first step is to ignite a pilot flame and once confirmed will initiate the main burners.

Old furnaces used a standing pilot where a small amount of gas was always burning in wait for a call for heating. Current gas ignition designs use some form of automatic ignition device without the need for a standing pilot flame.

Furnace Safety Switches

Safety is paramount when supplying a combustible fuel to an appliance that serves occupied spaces. There are various safety devices contained within the furnace to provide for safe operation, in addition to installation requirements for safety.

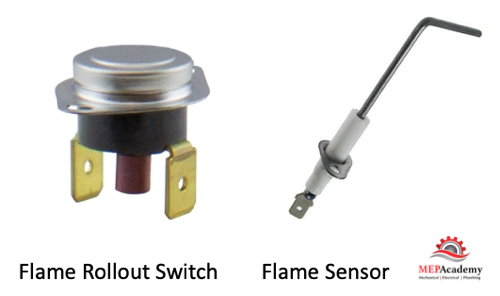

Flame sensors ensure that the gas has ignited and that there is a flame burning. If the flame didn’t light for some reason and the gas valve had opened, the space could fill with gas and cause a possible explosion.

A Rollout switch senses if the burner flame is rolling backwards out of the heat exchanger. The rollout switch senses the flame and shuts off the flow of gas to prevent a fire.

A High Temperature Limit Switch prevents excess temperatures from occurring. Excess temperatures are an indication that something might have failed or malfunctioned. The High Limit switch will shutoff the gas if the discharge air temperature exceeds the limit. The high limit switch will have to be manually or automatically reset. If automatic, then the gas valve will be reopened when the temperature drops below the limit.

Operation and maintenance clearance requirements. Check the furnace manufacturers literature for the clearance requirements around the furnace. These clearances are for safety reason, such as preventing a fire from occurring to the surrounding construction materials. Clearances are also established for proper access to internal components for maintenance personnel.

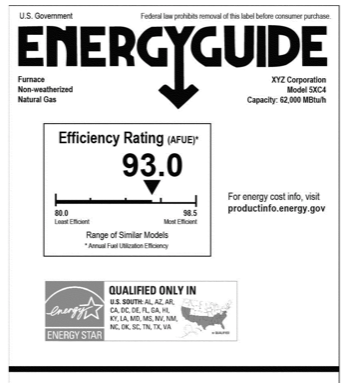

Furnace Rating AFUE Rating

The annual fuel utilization efficiency (AFUE) indicates a furnaces efficiency. The higher the value the greater the efficiency. You can find the efficiency listed on the front of the furnace as its required by the Federal Trade Commission to be posted. The efficiency is given as a percentage, indicating how efficient the furnace is in converting the energy from fuel into useful heat on an annual basis.

The annual fuel utilization efficiency (AFUE) is a ratio indicating the total annual heat provided divided by the total fuel consumed. A ratio of 90% would indicate that 90% of the fuel was efficiently converted into heat, while 10% was wasted. This ratio is for the furnace only and not the distribution of the heat to the space through ductwork, as poorly insulated ducts will reduce the efficiency of the overall system.

Checkout these Gas Furnaces hereMaintenance of your Furnace

Be sure to change your filters often as clogged filters can cause airflow restrictions. With less air flowing over the heat exchanger, it could cause the heat exchanger to become too hot leading to cracking. The cracked heat exchanger would then leak carbon monoxide into the occupied space endangering the lives of the occupants.

Make sure to have your furnace inspected every year including a full-system cleaning, removing all dirt, soot, or corrosion. The inspection will help identify any potential problems with the furnace. Its important that the heat exchanger be inspected for any possible cracking or problems.

Install CO sensors close to all rooms used for sleeping. These can be battery operated or battery backed up versions.

Make sure to regularly check that the CO monitors are operating properly.

Inspect the condition of the flue vent and all connections to ensure a properly sealed system.

Clean and lubricate the fan blower.

Retrofitting Existing Furnaces

A retrofit of an existing furnace can increase it energy efficiency. The additional cost to make the retrofit needs to be evaluated against a new replacement unit. If you plan on adding air conditioning, then a new system is warranted. Remember you’re not only saving on your fuel bill but you’re reducing carbon dioxide emissions.

Before you upgrade your furnace, it’s recommended that you evaluate the potential to reduce the size of the furnace by upgrading to energy efficient windows or adding insulation to the building.