What is IPLV (Integrated Part Load Values)? It is based on part load chiller efficiency values. The IPLV is calculated on the weighted percentage of assumed operational hours at each operating condition. So there are four operating points that are going to be measured. This is an average efficiency of a single chiller. A lot of chiller installations will have multiple chillers. So this is a rating for a single chiller.

If you prefer to watch a video on this topic, scroll to the bottom of this page for link.

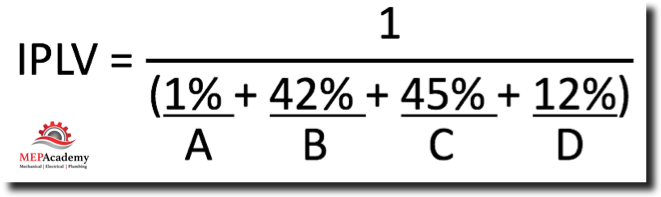

The IPLV formula is one over the four operational points that we are calling A, B, C & D. These will be the efficiency of the chiller at the different partial loads, which we’ll get into next. Were going to take condition “A” at 1%, condition “B” at 42%, condition “C” at 45%, and condition “D” 12%. This means that the chiller runs at condition a 1% of the time and 42% of the time at condition “B” and so on.

Checkout these BTU Meters

So what does “A”, “B”, “C” and “D” stand for? We are going to take these four data points for the chiller under review. Data point “A” is 1% of the chiller conditions running at 100% full capacity. The four data points are as follows:

Four Data Points Used in IPLV Calculation (EER)

“A” 1% of the time Chiller is running at 100% Capacity

“B” 42% of the time Chiller is running at 75% Capacity

“C” 45% of the time Chiller is running at 50% Capacity

“D” 12% of the time Chiller is running at 25% Capacity

These values will be put into the calculation

“A” = COP or EER at 100% Capacity

“B” = COP or EER at 75% Capacity

“C” = COP or EER at 50% Capacity

“D” = COP or EER at 25% Capacity

So, when the chiller is running at 100%, 75%, 50% and 25% we’ll put in the EER that corresponds to that datapoint.

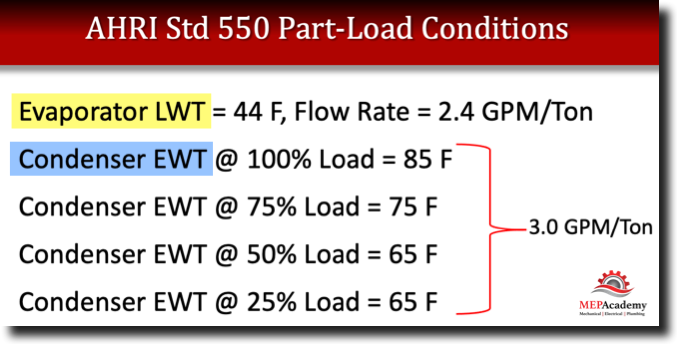

Step 1 is to determine Part-Load energy efficiency values for the chiller running at these four datapoints as discussed previously as 100%, 75%, 50% and 25% load. These operating points are the AHRI (Air Conditioning, Heating and Refrigeration Institute) standard-550 conditions. Standard-550 specifies the conditions under which these datapoints are measured.

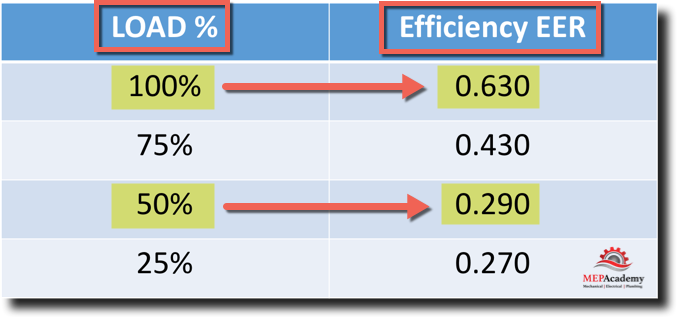

Step 2 is to insert the four data points into the IPLV formula. So now all you need is a sample of the EER for a particular Chiller that you want to analyze. We have a sample of the EER (Energy Efficiency Ratio) of a particular water-cooled chiller as shown here.

Based on the information obtained from the chiller manufacture as shown in the chart above, we can see that the chiller running at 100% as an EER (Energy Efficiency Ratio) of 0.63, and when running at 50% it has an EER of 0.29.

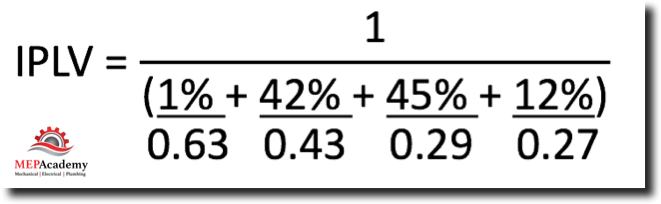

We take the information from above an insert it into our IPLV formula to derive at the IPLV number.

Remember that the chiller runs at full load only 1% of the time, so in the above example the 0.63 EER goes in the first column of the formula, followed by the EER of the chiller at 75% load and so on. You can see that the chiller has the worst EER at full load capacity and the best EER at 25% capacity. That’s why multi chiller plants may run several chillers at low load than to run one chiller at full load.

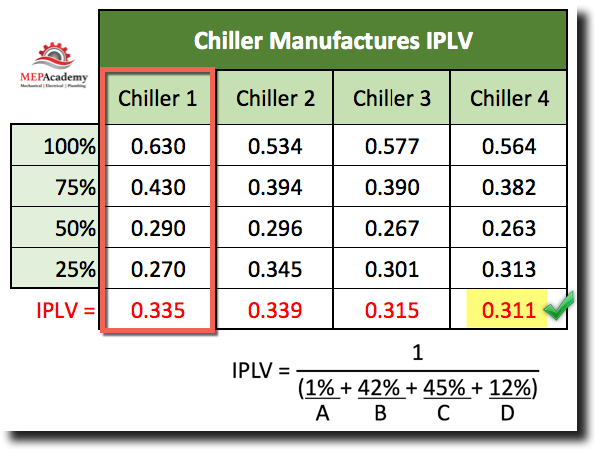

Below is a spreadsheet that we made to show various chiller manufacturers and how they compare in their total IPLV (Integrated Part Load Value).

You can see that the IPLV for chiller #1 comes out to be 0.335, while chiller #2 is 0.339 and the most efficient of the chillers is #4 at a IPLV of 0.311

AHRI Standard 550

AHRI (Air Conditioning, Heating and Refrigeration Institute) specifies the operating conditions under standard 550/590 that chillers are rated for as follows. According to AHRI the purpose and scope of the standard is as follows;

1.1 Purpose. The purpose of this standard is to establish for Water-chilling and Heat Pump Water-heating Packages using the vapor compression cycle: definitions; test requirements; rating requirements; minimum data requirements for Published Ratings; marking and nameplate data; conversions and calculations; nomenclature; and conformance conditions.

2.1 Scope. This standard applies to factory-made vapor compression refrigeration Water-chilling and Water-heating Packages including one or more compressors. These Water-chilling and Water-heating Packages include:

- 2.1.1 Water-cooled, Air-cooled, or Evaporatively-cooled Condensers

- 2.1.2 Water-cooled heat recovery condensers

- 2.1.3 Air-to-water heat pumps

- 2.1.4 Water-to-water heat pumps with a capacity greater or equal to 135,000 Btu/h. Water-to-water heat pumps with a capacity less than 135,000 Btu/h are covered by the latest edition of ASHRAE/ANSI/AHRI/ISO Standard 13256

You can see that the AHRI standard has the evaporator LWT (Leaving Water Temperature) at 44 F and various condenser entering water temperatures (EWT) for the various percentages of chiller loads corresponding to the four data points.

If a chiller is to run at other than AHRI Standard 550/590 conditions then its considered NPLV (Non-standard Part Load Values).

IPLV Calculation is Based on a single chiller. Data shows that 80% or more of the central plants have multiple chillers. This would then indicate that IPLV doesn’t accurately represent multi-chiller plant operating conditions. The use of energy analysis tools will provide a better solution. The use of the IPLV is used to compare unloading characteristics of similar chillers in a situation when there is only one chiller.

A chiller doesn’t run at full load most of the time. Chillers run less than full load most of the time, so this calculation is a better indicator of the chillers most likely operating efficiency.

Checkout these BTU MetersResources: