Humidifiers

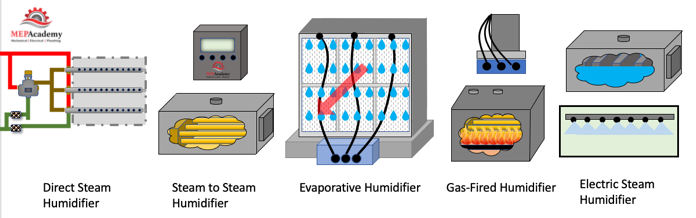

Humidifier Types and Humidity Basics. Humidifiers vary as to the source or energy that provides the final product produced for humidification whether that’s steam or mist. You can use Steam, Electricity, Gas, Air or Water as the main source of humidification. We’ll explain each of these humidification systems. Humidifiers can be installed within Air Handlers, ductwork or open areas.

If you prefer to watch the YouTube Video of this presentation, scroll to the bottom.

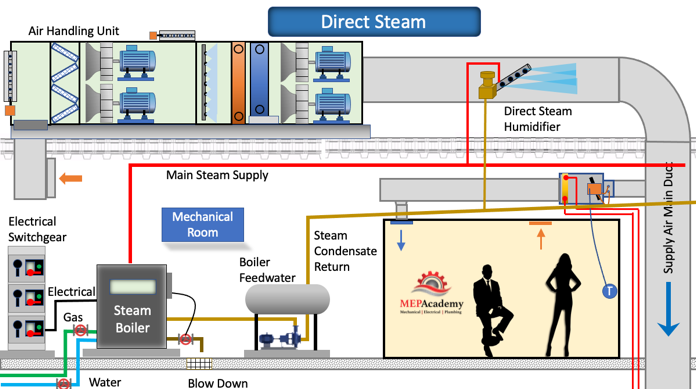

Direct Steam Humidifiers

Using steam directly from a steam boiler eliminates the need for additional steam generating equipment. The steam will be delivered from the steam boiler to a manufactured provided direct steam humidifier.

Checkout these Humidifiers here

The direct steam humidifier will have the capability to remove dirt and scale particles by straining the incoming steam. There will be a separating of the condensate from the steam, directing the steam condensate to the drain outlet. The steam leaves the humidifier in an all-vapor state where it mixes with the air stream.

Using a direct steam humidifier reducing the need for maintenance as required with other method of humidification as the steam at 212°F (100°C) provides a natural method of steam cleaning the components of the humidifier.

If the facility is existing and already has a steam boiler than this might be the cheapest alternative, depending on where the existing steam pipes are in relationship to where the steam is required.

Steam Distributors

Inserted in the air stream within the supply duct will be the steam distribution tubes that have perforated holes running along its length. The steam exits these holes along the tube, injecting steam into the air stream.

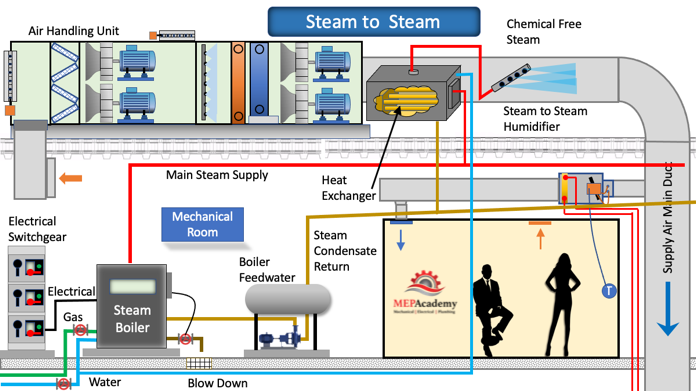

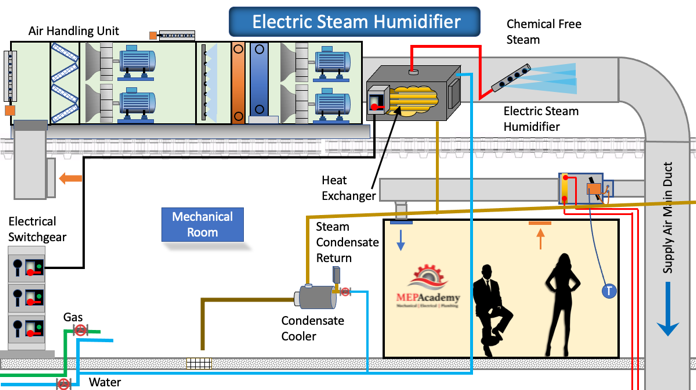

Steam to Steam Humidifiers

Unlike the direct method where steam from a boiler is used directly in the air stream, the steam-to-steam humidifier uses a heat exchanger. This separates the steam generated by the steam boiler from the steam that enters the air stream. This avoids the concern of using treated steam boiler water and the adverse health effects associated with chemicals being brought into the air stream from the boiler.

The steam from the boiler is under pressure, while the secondary steam is often under atmospheric pressure. Having a second source of water increases the concern for impurities in the water and the havoc it can create This increases the need for frequent cleaning.

The time to satisfy a demand for humidification is slower than the direct steam method because the water must be brought to a boil before it can be used.

The indirect steam humidifier provides tight control of output using a modulating control valve, positioning from closed to open based on demand. This allows for a quick response to any space demand for humidification.

Checkout these Humidifiers hereElectric Steam Humidifiers

If there isn’t a steam boiler at the facility, then there is the option of generating steam with a water source and electricity.

Using electrodes to pass electricity through water is one method, and the other would be to use immersed resistance heating elements to boil water for steam supply. Water quality will be important with the use of electrodes while water quality won’t affect the immersed heating element type humidifier. With both of these types the need to boil water makes it less responsive for quick control.

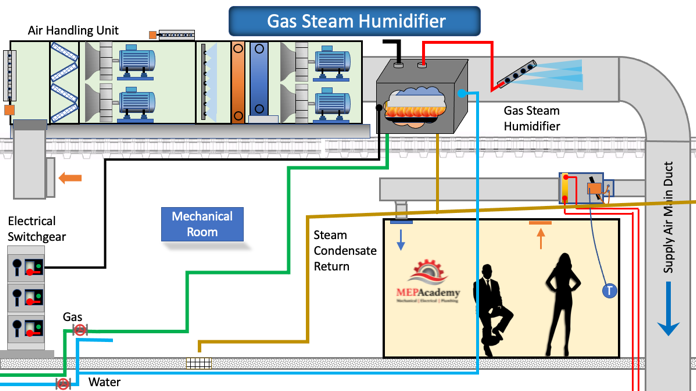

Gas-Fired Steam Humidifiers

Gas fired steam humidifiers use ionic beds of fibrous mediums that heat the water using gas instead of electricity. The fibrous medium will absorb several pounds of solids in the water and will require replacement when the medium is fully loaded. This leads to reduced time cleaning the tank as the fibrous medium collects a lot of the solids in the water.

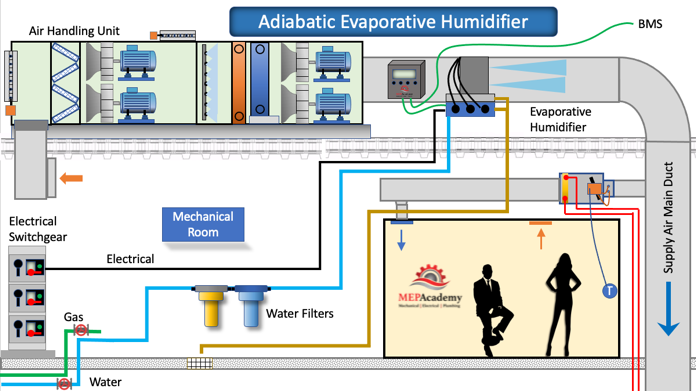

Evaporative Humidifiers

Another option is to use an evaporative humidifier, that can be installed in an air handler or in supply or exhaust ductwork. Air passes over media as water trickles down over it, causing the air to be cooled while increasing its relative humidity.

Moisture is evaporated into the air passing over the wet media, proving an increase in the water content of the air. Sensible heat from the supply air is used for evaporation of the water into vapor, this provides for cooling of the air while also adding moisture. This reduces energy consumption without the need for boilers or gas fired units that burn fossil fuels for the evaporation process.

The HVAC contractor will install the evaporative humidifier in the duct as shown here, then connect the electrical to power the water pumps and controls, then install the water piping to the unit. Its important to provide some form of water filtration to keep the unit from clogging or minerals from depositing on the equipment.

We’ll need a drain line to remove any unevaporated water. Also available is the ability to remotely monitor the system through a BMS system. You can monitor or make changes to the settings; this is typical with most of the humidification systems.

We show this evaporative humidifier installed in the supply ductwork, but they’re also made for installation within the air handler or on the exhaust side with the use of an energy recovery heat exchanger. There are other versions of the evaporative humidification process used for non-ducted applications.

Checkout these Humidifiers hereAtomization Humidifiers

Atomizing humidifiers don’t require a boiler or steam piping as they basically spray water through nozzles to create a mist. That is why they are the most energy efficient type of humidifier. Compressed air and water intersect to create a mist that absorbs heat from the air stream for evaporation into a vapor. This will cause a cooling of the air and will take energy from the air in the form of heat. This would require a larger heating system if using humidification and heating at the same time. If there is insufficient heat in the air stream, then moisture or water could accumulate on the surrounding surfaces of the ductwork, causing damage as water leaks out into the space. Along with direct steam, atomization is quick to respond to a demand for humidification. These systems are best served by deionized water (DI) or reverse osmosis water.

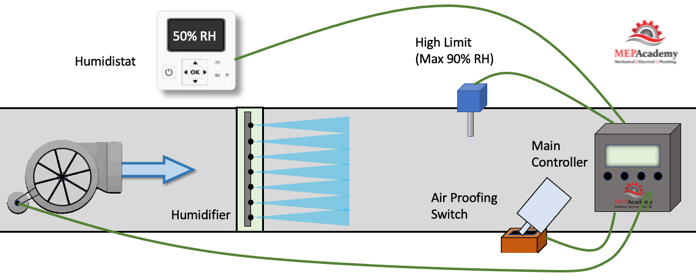

Humidifier Controls

There are several controls that are used for the proper functioning of an humidifier.

High Limit Sensor. This insure that the humidity doesn’t exceed a certain maximum. We’ve set this one for 90% relative humidity as it serves a VAV systems.

Airflow Proving Switch. The humidifier must be shutoff if airflow is not blowing through the duct and over the dispersion tubes. To ensure air is moving over the dispersion tubes an airflow proving switch is proved in the duct downstream of the dispersion tubes. This can be done by using a sail switch, which has a sailboat like sail in the air stream that will rotate on a shaft to make an electrical circuit.

Humidistat. This will control the on and off of the humidifier based on the set point. It works just like a thermostat except that the controlled element is humidity.

Humidifier Controller. Humidifier manufactures provide various levels of controllers with touch screens and LED displays. There are options to have remote monitoring, where you can see what is happening with the humidifier and make changes. It’s possible to have multiple humidifiers connected to one main controller.

Hygroscopic Materials

This is the process whereby materials will absorb water from the atmosphere by absorption or adsorption. Hygroscopic materials like paper are water lovers that absorb water, which can be a problem for a lot of industries. A museum with expensive artwork is sensitive to rapid changes in relative humidity. If the relative humidity is too low than moisture can be pulled or evaporated out of the hygroscopic material such as that which paintings are rendered on. If it can absorb moisture it will be capable of losing moisture content.

Drain Coolers

Many local codes and municipalities don’t allow the draining of 212F (100C) condensate into the sewage system. This will require the use of a drain cooler, which injects domestic cold water to mix with the steam condensate to drop the temperature of the water before it enters the drain.

Steam Boilers

Using direct steam for humidification creates a concern for the air quality when the boiler water is treated with chemicals. These water treatment chemicals can end up in the air, therefore indirect steam to steam is used as a barrier to this issue. Using Indirect steam avoids evaporating the anti-corrosive additives into the air stream, which has been known to cause health problems and the deterioration of paintings and exhibits in museum.

What is Relative Humidity?

The Relative Humidity defines the amount of moisture in the air at the current temperature compared to the amount it could hold at that temperature when 100% saturated. Relative humidity is always expressed as a percentage.

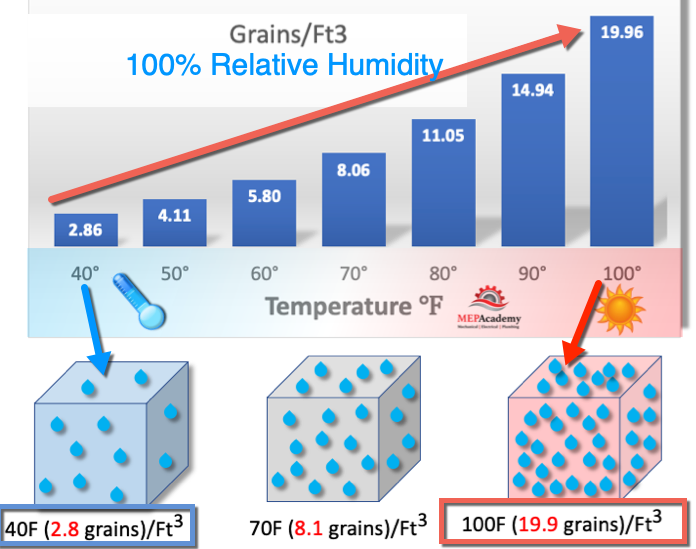

Warmer air can hold more moisture than colder air for the same volume (Cubic Feet) of air. Warmer temperature has a greater capacity for holding water vapor. This chart shows the maximum amount of moisture that can be held in one cubic foot of air at the temperature shown.

At 40F and 100% relative humidity the air can only hold 2.86 grains, but as the temperature increases, say to 70F, the air can now hold 8.06 grains/ft3 of air, and at 100F, the air holds 19.9 grains. So the warmer the air the greater its capacity to hold moisture. Keeping the relative humidity between 40% and 60% for human comfort and safety is the ideal setting.

When relative humidity is at 100%, then the Dew Point Temperature and the Air Temperature are equal. This means that the air is fully saturated with moisture and can’t hold any more moisture. As the dew point temperature rises, the capacity of the air to hold moisture increases.

Relative humidity has been found to be an important factor in the control of airborne infectious diseases, reducing influenza and other viral outbreaks.

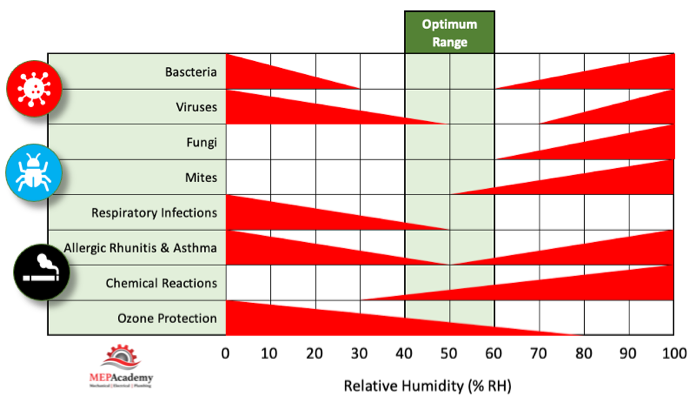

As this chart shows, bacteria and viruses love the humidity to be under 40%, or above 60%. This is where they thrive. The same for respiratory infections and Asthma. This is why controlling relative humidity is important.

ASHRAE recommends relative humidity be kept in the range of 30% to 60% for human comfort and health.

Humidification is the process of adding moisture to the air to improve health and comfort, avoid high static conditions and protect processes or products, like museum paintings. Understanding psychometrics, we know that when cold air is heated, the relative humidity drops, and the air feels dry.

What is the best Relative Humidity for my Home or Business?

The level of relative humidity is dependent on what is being served by the HVAC system. This can be artwork in a museum, or paper manufacturing, office workers or a residential home. ASHRAE recommends a relative humidity range of 30% to 60% for comfort. Yale University has done studies that show a relative humidity range between 40% and 60% reduces the viability of viruses. So, for humans somewhere between 30% and 60% is ideal. For materials and sensitive artwork, the values will differ. There are some cases. Like a burn unit in a laboratory where skin cultures are grown that requires a strict 60% relative humidity within a 1% variance.

Calculating the Humidification Load

Calculating the humidification load is to determine how many pounds of water per hour is required to mee the space conditions. There are three things needed before calculating the humidification load for a space. They are as follows;

- Space Design Temperature and Relative Humidity required to be maintained.

- Volume of air delivered to the space

- Outside Air Design conditions for Temperature and Relative Humidity

Isothermal Steam Humidification

Using steam humidifiers has little effect on the dry-bulb temperature of the supply air serving the space. All the energy required to turn the water into a vapor or steam is handled by the steam humidifier. No heat from the air stream is required to turn the water into vapor, so there is little to no effect on the dry-bulb temperature. Steam is complete water vapor at 212°F (100°C). The steam will mix with the air stream, causing the steam to drop in temperature, bringing it close to the dry-bulb temperature of the air.

If we plot this on a psychrometric chart, the dry-bulb temperature would remain unchanged as the humidification process would send a vertical line up the chart in a pure moisture increase.