The refrigeration cycle is the heart of the HVACR industry. Just like the heart in the human body which circulates life giving blood, the refrigeration cycle circulates refrigerant using a compressor. Before we explain the refrigeration cycle we need to explain a few principles of physics to help you better understand and retain the information.

Moving Heat

The purpose of the Air Conditioner or Refrigerator is to MOVE heat from one space to another. In the case of an Air Conditioner, you want to move the heat out of the building. Those in the HVACR industry are professional movers of Heat, either by moving heat out of a building or bringing heat into a building. One of the ways to do this is with the refrigeration cycle.

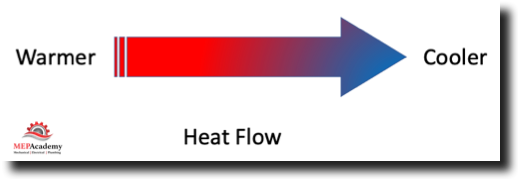

Heat Flow

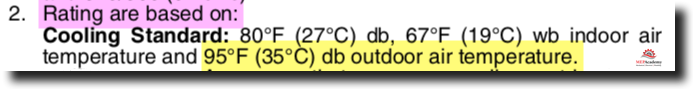

Heat flows from the warmer medium to the cooler medium. So for the condenser to reject its heat to the outdoors using an air-cooled condenser the temperature of the condenser has to be greater than the surrounding outdoor air. This is why during really hot summer days when the temperature is above the temperature rating of the condenser, which is usually rated for 95 Degrees, the cooling capacity is reduced.

The greater the outdoor summer temperature above 95 degrees the worse your air conditioner will operate as it makes it difficult for the condenser to transfer its heat to the outdoors when the temperature difference is reduced.

See the notice located in the Air Conditioners manufactures literature for the performance of the Air Conditioners rating as shown below, the outdoor temperature is figured to be 95 degrees. Which means anything above that will reduce the tonnage (reduce cooling) of the AC Unit.

Heat seeks to equalize with the medium around it by transferring some of it heat to the cooler medium until they equalize. You can’t transfer heat to something that is warmer, only something cooler.

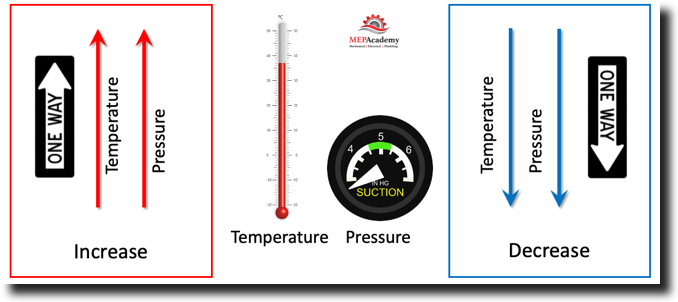

Temperature and Pressure Relationship

To understand the compressor, you’ll need to understand the relationship between Temperature & Pressure. It’s very simple as they act in the same direction in the refrigeration cycle. If you increase the pressure than the temperature also increases. If you decrease the pressure the temperature also decreases. Pressure and Temperature move in the same direction like a one-way highway.

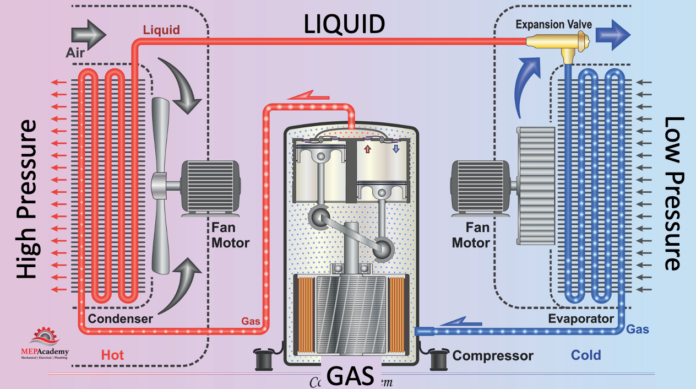

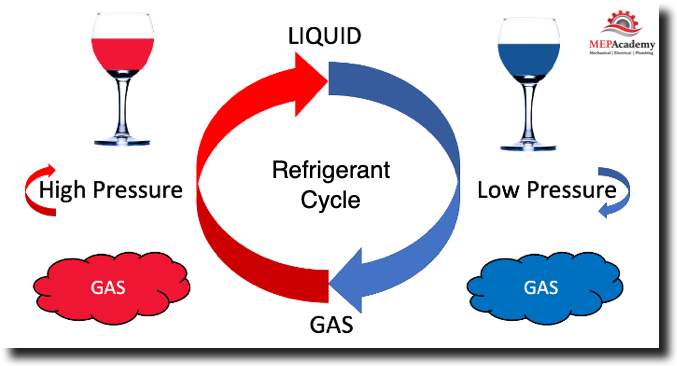

In the refrigerant cycle we have the LOW & HIGH pressure sides. The high side is shown in red, while the low side is shown in blue in the following pictures. There are two sides, like in martial arts or Tennis. You have the Low Side & the High Side which is created by the compressor.

Phases of Refrigerant

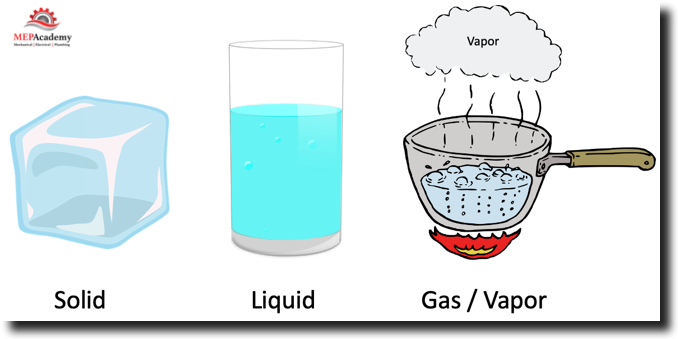

Now we need to know what phases the refrigerant is found in within the system. You’re familiar with water so we’ll use that as our initial example. Water basically has three phases that it can be found in as follows;

- Solid: Ice

- Liquid: Water

- Gas: Vapor, Steam

In the refrigeration cycle the refrigerant will only exist in two phases, as a LIQUID or a GAS. This is what it’s all about. The refrigerant just keeps going in a circle from Gas to Liquid, then back to Gas again. This is the basic refrigerant cycle, the continuous changing of the state of the refrigerant from gas to liquid, liquid to gas, over and over again while in the process of moving heat around. The high pressure side is related to heat, while the low pressure side is related to cooling.

Checkout Refrigerants here

So this is how we will find the refrigerant inside a Refrigerator, Air Conditioner or Chiller. Its either on the low or high side and in either liquid or vapor form. There are only four possibilities. LOW, HIGH, LIQUID or VAPOR.

Components of Refrigeration Cycle

Before we explain the refrigeration cycle, we need to understand the four basic components which are:

- Compressor

- Condenser

- Metering Device

- Evaporator

Compressor (From Low Pressure Gas to High Pressure Gas)

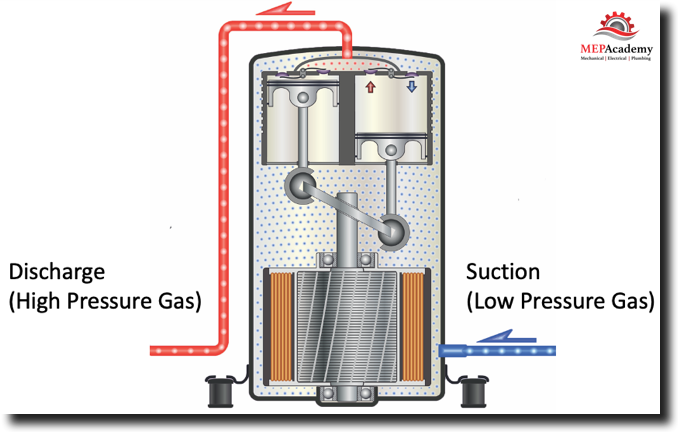

The compressor is what does most of the hard work in a refrigerant cycle. It pumps the refrigerant around the system. It does this by creating a pressure difference between one side of the compressor and the other side. The compressor is what creates the low and high sides of the system.

There are different types of compressors which will cover in another video, but the purpose is to move the refrigerant around the system. The compressor will only work with GAS, no liquid, so its important that only vapor enters the compressor inlet or suction line.

The compressor takes low pressure refrigerant and increases it to high pressure refrigerant. And as we learned when the pressure goes up so does the temperature of the refrigerant.

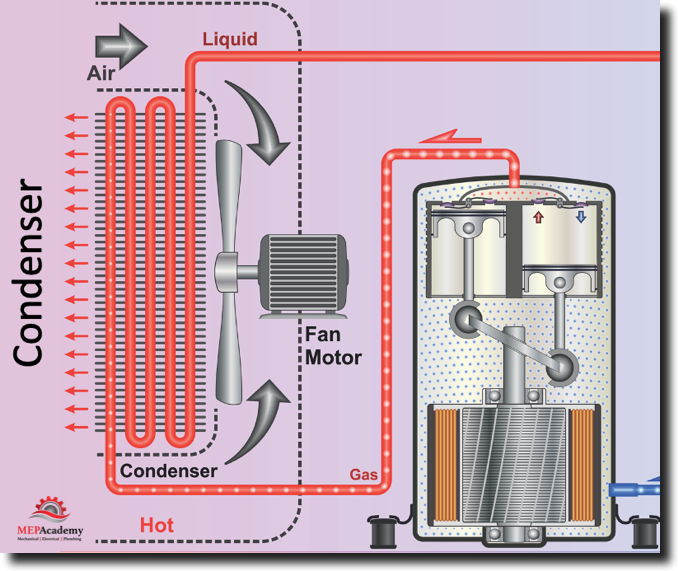

Condenser (From High Pressure Gas to High Pressure Liquid)

The condenser does just as the name implies, it condenses the refrigerant from a High Pressure Vapor back into a High Pressure liquid by removing the heat either to the air stream or through a water-cooled heat exchanger. Remember heat wants to balance its self out, so that everything is the same temperature, it does this by transfer heat to a cooler medium. From the hot refrigerant to the cooler air blowing over the condenser coil.

The air blowing over the condenser comes in contact with the hot surface of the copper coil (pipe) as represented in the image. This causes the refrigerant vapor in the condenser coil to condense back into a liquid.

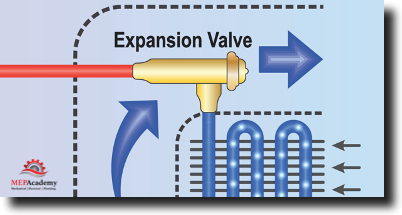

Metering Device (Expansion Valve) (From High Pressure Liquid to Low Pressure Liquid)

The metering device only allows as much liquid refrigerant that is required to pass through from the high side to the low side. The metering device is like the Parking Cop at the Professional Ball Park, only allowing as many cars to pass as there are parking stalls available in that area. The metering device only allows refrigerant to get through according to the cooling requirements.

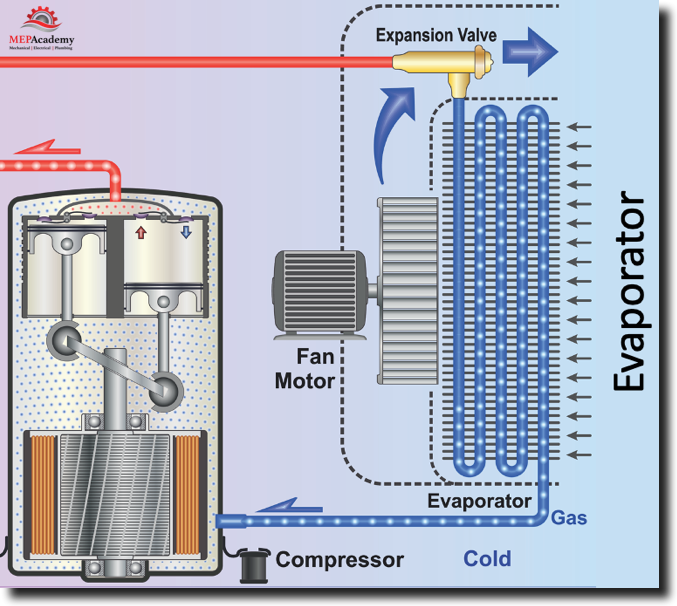

Evaporator (From Low Pressure Liquid to Low Pressure Gas)

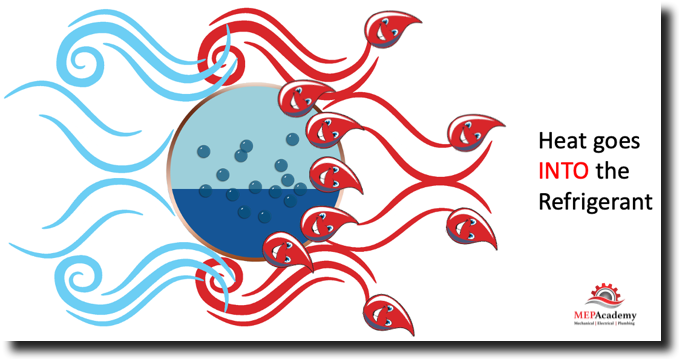

The evaporator does as its name implies, and it evaporates the liquid into a gas.

As warm air passes over the Evaporator coil the heat is absorbed by the liquid refrigerant causing the refrigerant to boil off into a gas. The air leaving the coil will be much cooler as it has given up some of its heat to the refrigerant. See diagram below.

As the liquid refrigerant passes through the evaporator the warm air passing over the evaporator gives up its heat to the liquid refrigerant passing through the coil tubing of the evaporator causing the refrigerant to evaporate (convert from liquid to gas). The air gives up some of its heat, thereby becoming cooler. Remember as long as there is a temperature difference between two items, the warmer one will transfer some of its heat to the cooler one.