In this article, we break down two essential smoke control strategies designed for large commercial spaces. First, we cover a targeted smoke control method tailored for hotel guestroom floors, keeping hallways and exit routes safe during an emergency. Then, we explore how an atrium smoke control system works to keep open, multi-story spaces clear of smoke by using smoke exhaust fans. These are just a couple of the many approaches used to manage smoke effectively and maintain safe evacuation paths.

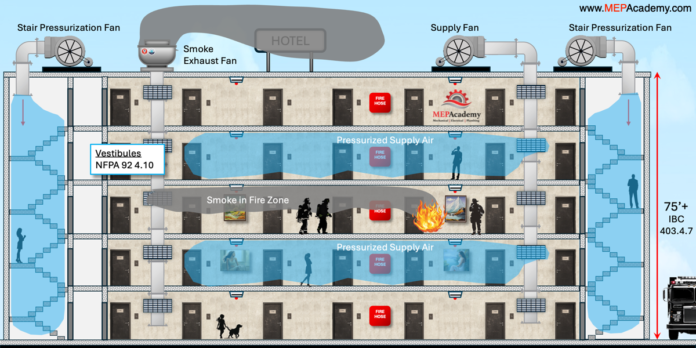

Hotel Zoned Smoke Control System

A Highrise hotel can use a zoned smoke control pressurization system to keep smoke from spreading across guestroom floors during a fire, ensuring that hallways, stairwells, and elevators remain safe for occupants to evacuate. Here’s how the system typically works:

When smoke is detected on a guestroom floor, the smoke control system activates automatically. In a dedicated smoke control system, the equipment is only used for smoke control and will require frequent testing.

The supply fans pressurize areas critical for evacuation, such as stairwells, elevators, and corridors, by pumping in fresh air. This pressurization creates a pressure differential between these escape routes and the potentially smoke-filled spaces, which forces smoke back into the affected areas and prevents it from entering escape paths.

The Sandwich Technique

The sandwich technique is a zone smoke control method used in high-rise buildings to contain smoke to the fire floor and prevent vertical spread. It works by exhausting smoke directly from the fire floor while pressurizing the floors immediately above and below with supply fans, creating a pressure “sandwich.” This differential pressure keeps smoke isolated to the fire floor, ensuring that adjacent floors remain smoke-free.

The floor above and below the fire zone is positively pressurized, while the floor with the fire is under negative pressure created by the smoke exhaust fan. There are smoke control dampers on each of the supply and exhaust ducts that are opened or closed depending on the floor or fire zone. The exhaust damper is opened only on the fire floor, and the supply dampers are opened on the floor above and below the fire floor. This is just one strategy. By venting smoke directly from these spaces, the system reduces smoke density at the fire source and improves visibility for both occupants and emergency responders.

This is a dedicated system where the smoke control equipment is used only during emergency and is not part of the regular HVAC system.

Stairwell Pressurization

Most building codes will require that the stairwell in a high rise be pressurized to keep the smoke out. This allows the occupants a safe egress out of the building without having to breathe in smoke. A dedicated fan system supplies clean air into stairwells, creating a pressure differential that prevents smoke infiltration. The pressurization created by the fan must be significant enough to prevent smoke from entering the stairwell but also allow occupants to open the stairwell door.

In a high-rise, a vestibule is often used for smoke control with stairwells or elevator lobbies, to act as a buffer zone between areas with different pressures. These enclosed spaces are pressurized with fresh air during a fire to prevent smoke from entering, ensuring that stairwells and elevator shafts remain safe for evacuation and firefighter access.

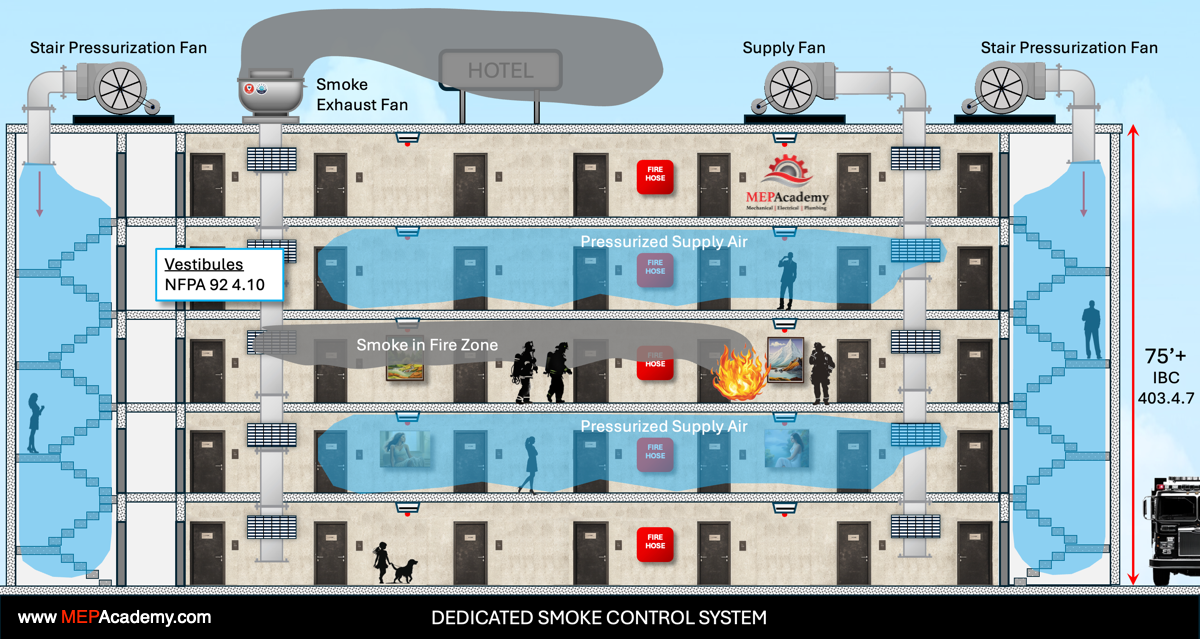

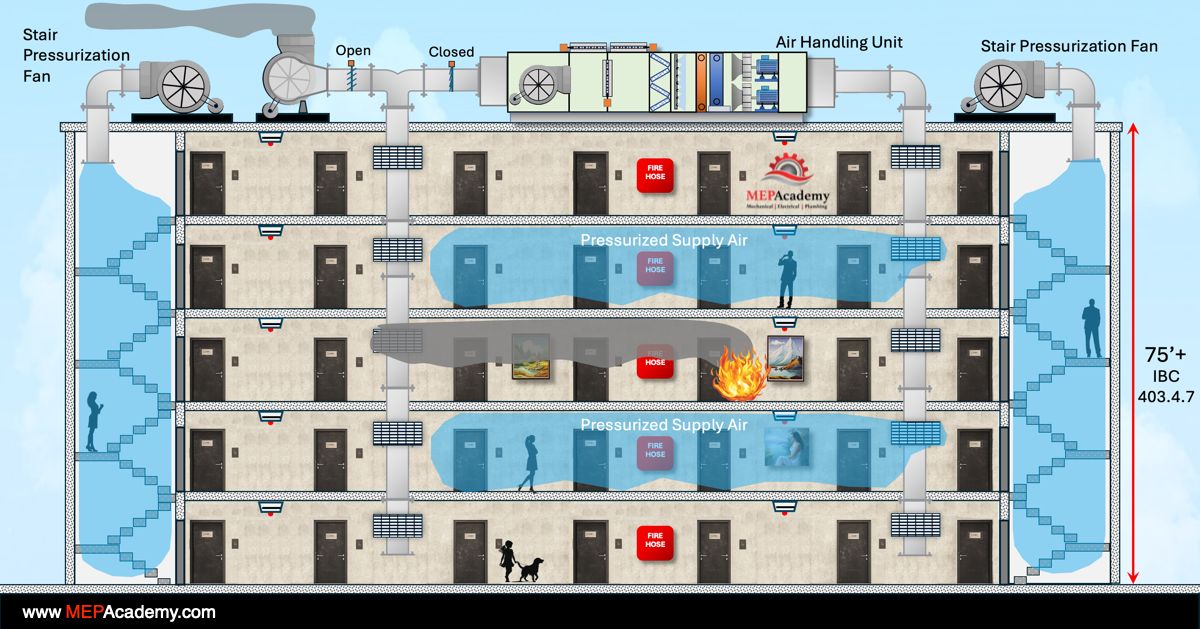

Non-dedicated Smoke Control System

Here is how a non-dedicated smoke control system in a high-rise hotel using existing HVAC air handlers that supply and return air on each guestroom floor during normal operation, with each floor designated as a separate fire zone:

Upon fire alarm activation on any guestroom floor, the smoke control system engages, signaling the HVAC air handler for the affected floor to switch to smoke control mode. The dampers in the air handler switch to smoke control by shutting the return damper and opening the outside air damper. The air handler serving the fire floor closes the supply air damper on that floor to prevent spreading the fire to other areas. The supply dampers on the floors above and below the fire floor open to pressurize and sandwich the fire floor to prevent smoke infiltration.

The exhaust air damper on the fire floor opens, while the exhaust dampers on all other floors close. This will create a negative pressure on the fire floor preventing smoke from exiting the floor. The smoke will be exhausted out the air handler or in this setup a smoke exhaust fan is provided.

The HVAC air handler on the floors directly above and below the fire floor activate in pressurization mode, supplying fresh air to create a positive pressure barrier.

This pressurization prevents smoke from migrating vertically, confining it to the fire floor. Stairwells, corridors, and elevator shafts are pressurized separately to keep them free of smoke, allowing safe evacuation routes for occupants and access for firefighters.

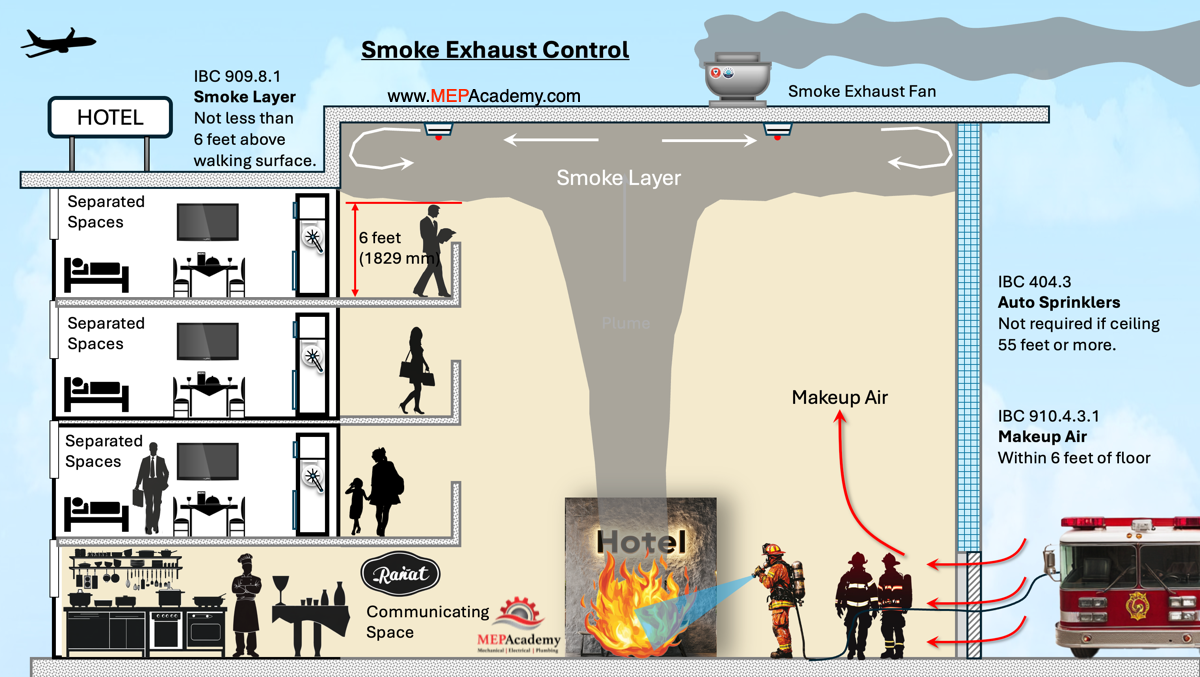

Atrium Smoke Control

When a fire ignites, it begins to consume nearby materials, releasing heat, smoke, and toxic gases. The combustion process produces high temperatures, causing hot air to rise. Flames reach upward, creating a vertical plume of heat and smoke above the fire source. The intensity and spread of the fire depend on fuel type, oxygen availability, and surrounding materials.

The rising heat from the fire generates a vertical column of smoke and hot gases known as the smoke plume. This plume carries particulates, toxic gases, and intense heat toward the ceiling. As the plume rises, it pulls in the surrounding air, growing in size and cooling slightly. The plume’s upward motion spreads smoke and heat vertically, reaching ceiling levels quickly, especially in tall spaces.

A smoke control system for an atrium is specifically designed to manage and exhaust smoke from the large, open space of an atrium during a fire. Atriums are common in modern commercial and institutional buildings like hotels, shopping malls, and office complexes, where they provide open, multi-story gathering spaces that are visually appealing. However, their large volume and vertical open design present unique challenges for smoke control, as smoke can accumulate and spread quickly throughout multiple levels. A well-designed atrium smoke control system prevents smoke buildup, enhances visibility for evacuation, and keeps pathways clear for firefighters.

Ceiling Jet Stream

Upon reaching the ceiling, the hot smoke and gases spread outward, forming a layer just below the ceiling, this is called the ceiling jet. The ceiling jet moves horizontally, carrying intense heat and smoke across the ceiling surface.

When the ceiling jets hits the wall, it turns back thickening the smoke layer. This jet is key to triggering fire detection systems, as smoke detectors and sprinklers respond to the elevated temperatures in this layer. The ceiling jet influences the spread of heat and smoke to other areas and guides smoke control strategies.

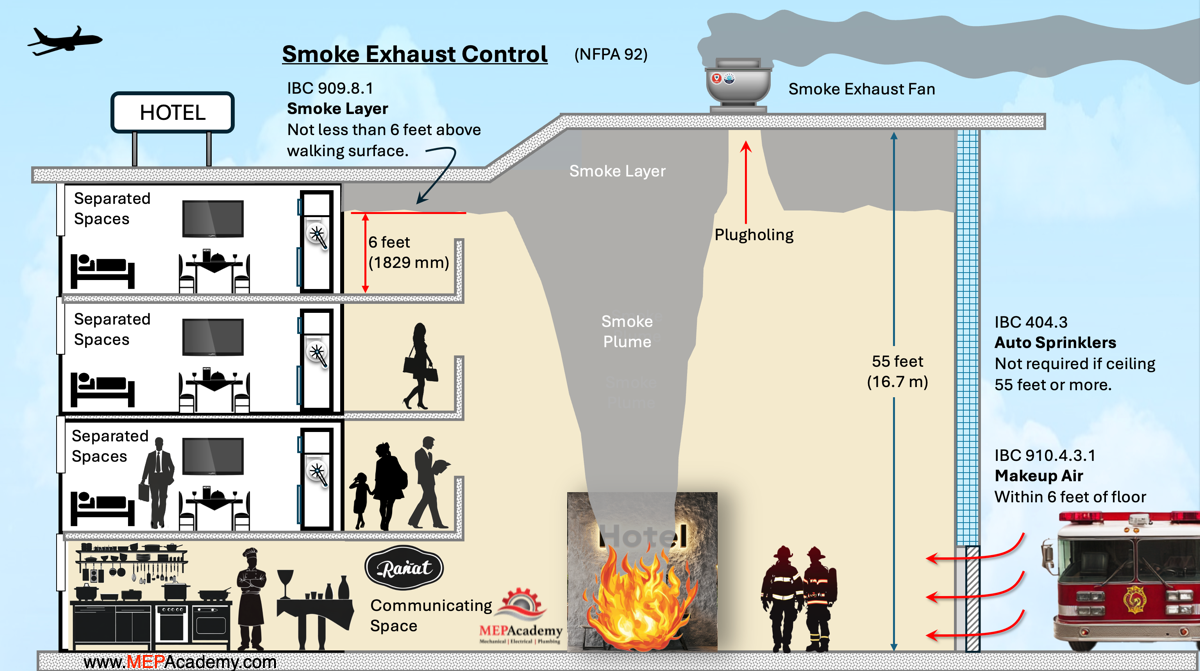

Smoke Layer

As the ceiling jet spreads, smoke accumulates, forming a hot, dense smoke layer beneath the ceiling. This smoke layer thickens as the fire burns, moving downward over time and reducing visibility in the space. The smoke layer is hazardous, containing toxic gases and reducing breathable air near floor levels as it descends. Smoke control systems aim to slow or halt the smoke layer’s spread to maintain visibility, protect egress paths, and aid firefighting efforts. The international building code section 909.8.1 states that the lowest horizontal surface of the smoke layer must be maintained at 6 feet (1829 mm) above any walking surfaces that is part of an egress within a smoke zone.

Make-Up Air System

To ensure the smoke exhaust system works effectively, a make-up air supply is often required to replace the air that’s being expelled. Make-up air helps maintain proper airflow and prevents negative pressure that could disrupt smoke control. This air supply can be introduced from adjacent zones, louvers, or through dedicated air intakes positioned lower in the atrium.

The make-up air system is designed to ensure that fresh air enters the space below the smoke layer, reducing the chance that smoke will be pulled downwards, which could impede evacuation and visibility.

What is Plug holing

In smoke control systems, plug holing is a phenomenon where cool air enters and mixes with the hot smoke layer near an exhaust vent, disrupting the effective removal of smoke. Instead of drawing out hot smoke from the upper layer, the exhaust fan begins to pull in the cooler, denser air from below. This reduces the efficiency of the smoke exhaust system, as it allows smoke to accumulate rather than being fully vented out.

Plug holing is particularly problematic in high atriums or large spaces, where temperature differences between the smoke layer and ambient air can cause this mixing. To prevent plug holing, smoke control systems may use carefully designed exhaust vent placements, larger vent sizes, or specific airflow controls to ensure that only the smoke layer is removed, maintaining clear and safe evacuation paths.

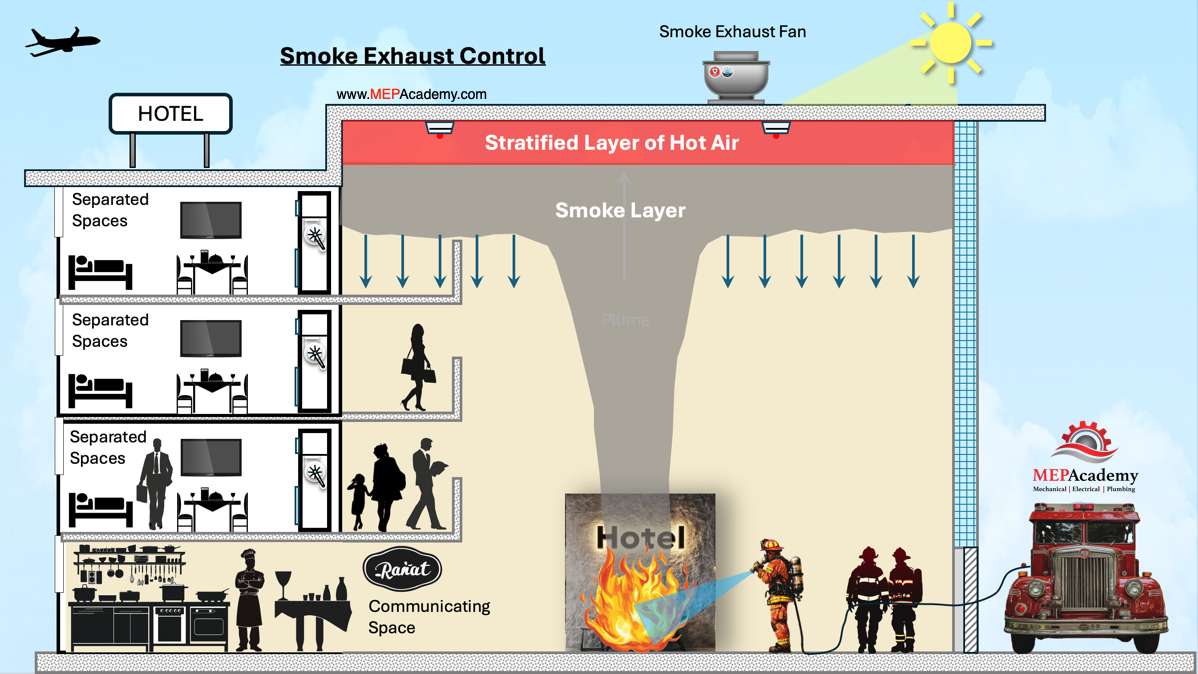

Stratification

Stratification occurs when a layer of warm air forms just below the roof due to solar heating. This layer can interfere with smoke detection and smoke layer behavior.

When the sun heats the roof, the air beneath it warms up and creates a thermal barrier. This warm air layer remains at the ceiling level, preventing cooler air and smoke from rising naturally.