VRF Heat Recovery vs VRF Heat Pump. VRF stands for Variable Refrigerant Flow, a method of varying the volume of refrigerant circulated in the system in relation to demand. As demand drops so does the volume of refrigerant circulated by the compressors. The compressor can slow down and pump less refrigerant to meet the current demand of the system. We’ll explain the differences between a VRF Heat Recovery System and a VRF Heat Pump.

If you prefer to watch the Video of this presentation than scroll to the bottom or click on this link. VRF Heat Recovery vs VRF Heat Pump.

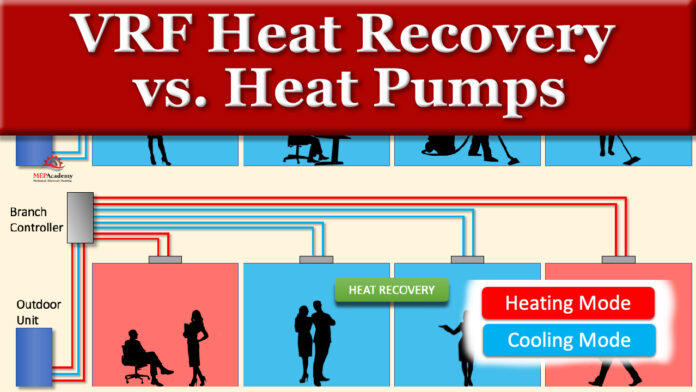

One of the big differences between a VRF Heat Pump and Heat Recovery system is that with a VRF Heat Pump system all the units must be in the same mode. Either cooling or heating.

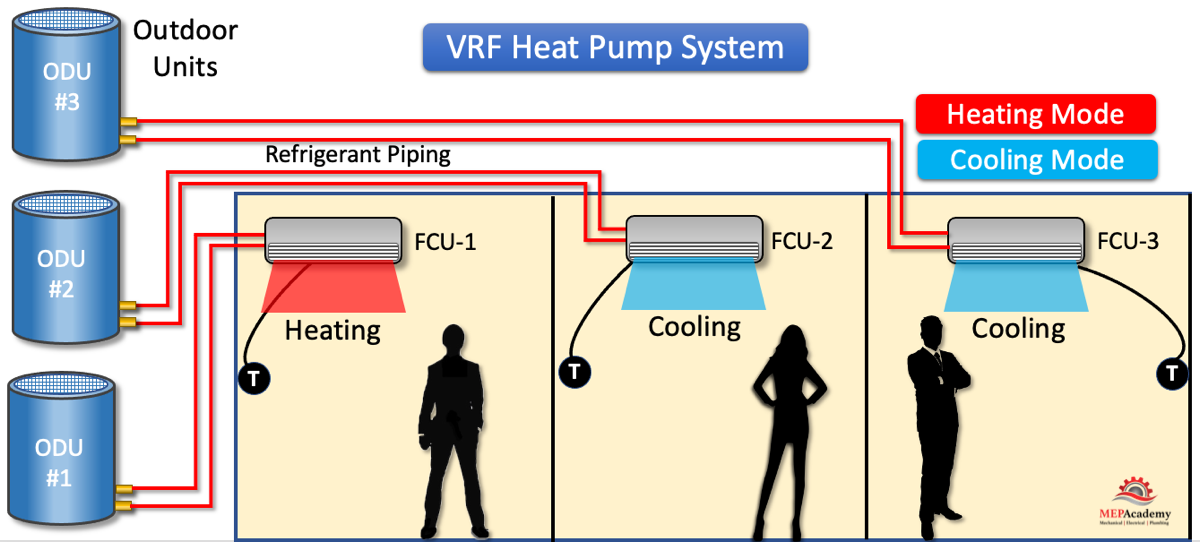

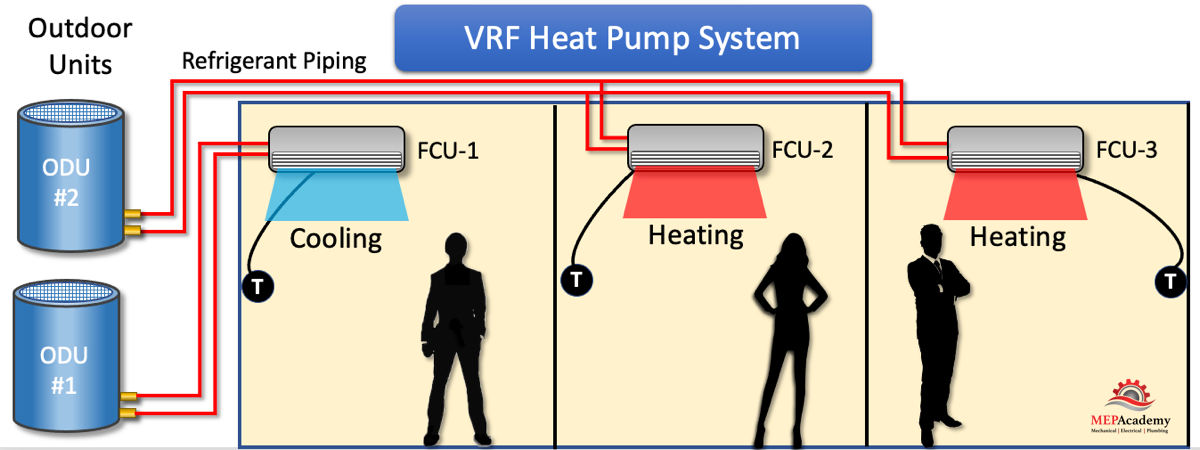

As seen here this one outdoor unit can feed many indoor units, but all the indoor units need to be in the same mode, such as heating as shown here, or all in cooling. With a VRF Heat Pump system if each zone or office wanted to control whether to heat or cool their space, then each would require their own outdoor unit.

Here we have an Executive in Office #1 wanting heating, while the second office wants cooling, each indoor fan coil will require a separate outdoor unit, and the third office is also calling for cooling and will have their own outdoor unit.

To reduce the number of outdoor units, the engineer will group together those zones that have similar load profiles. So, indoor Fan Coil #2 and #3 have similar load profiles, so we can get rid of one of the extra outdoor units and its piping and connect Fan Coil #3 together onto the outdoor unit #2, this saves on outdoor units.

Now whenever Fan Coil #2 and #3 switch modes of operation they will always be in the same mode as they’re on the same outdoor heat pump system, as shown here now in heating mode together, while the outdoor unit #1 can be in any mode separate from the other system.

The benefit of using a VRF Heat Pump system over the traditional split system heat pump is that you have inverter compressor and multiple indoor fan coils all working together to achieve a lower energy consumption.

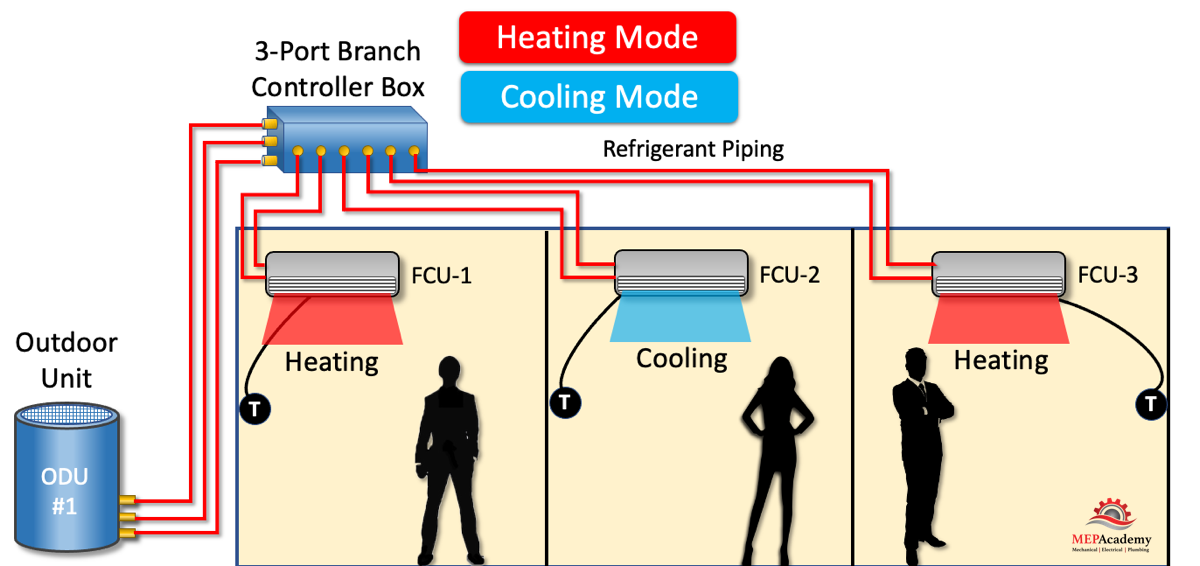

The disadvantage when we look at the VRF Heat Pump versus the VRF Heat Recovery as shown here is that if we install a 3 port Branch Controller Box and connect the refrigerant piping to the outdoor unit, we can then connect fan coil #1 to the branch controller allowing that office to choose to be in heating or cooling mode, in this case heating.

Then without having to install another outdoor unit we can add fan coil #2 to the branch controller and that office can be in cooling mode. The same for fan coil #3, we just pipe the fan coil to the branch controller box and that office can choose any mode of operation, in this case heating.

This can all be done using one outdoor unit with a 3-port branch controller, which is one of the advantages of using a heat recovery system as opposed to a VRF Heat Pump System. The heat Recovery system also makes great use of the heat being rejected. The heat rejected from fan coil #2 can be used to heat the spaces serving fan coil #1 and #3.

Cost of VRF Systems

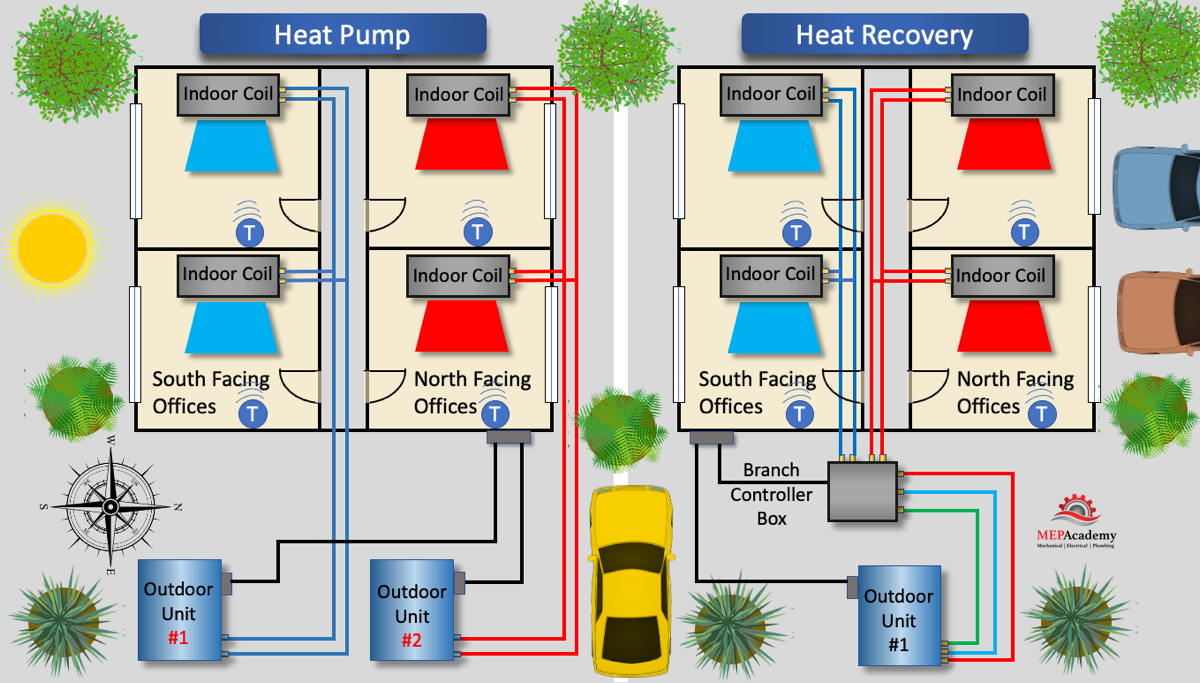

To determine which system is more expensive an analysis will have to be done. If we have two small identical office buildings as shown here, with the first building using a VRF heat pump system. The heat pump system would require at least two outdoor units, one for the South exposure and the other for the North exposure.

The Heat Recovery system is perfect for this type of balanced zoning, and will require only one outdoor unit, but will need a Branch Controller box to route heating or cooling to the indoor units.

The total amount of piping, fittings and insulation cost will need to be determined between the two designs.

All of the outdoor units and the Branch controller will need electrical power. All of the indoor fan coils will have their own controller, so there is no difference in cost between the two systems here.

The VRF Heat Recovery systems will most likely require the greatest initial investment when compared to VRF Heat Pump or traditional air conditioning systems. The additional cost for the VRF Heat recovery system comes from having more components and a higher level of installation and commissioning cost.

The initial cost of a VRF system should be analyzed based on life cycle cost which will be impacted by the energy cost and savings factors.

If you are an HVAC contractor or Engineer that tracks the cost of VRF Systems, then the VRF Wizard has a VRF System Cost Spreadsheet for keeping track of these types of projects. To get this spreadsheet click on this link >> VRF System Cost Tracking Spreadsheet.

Mode of Operation

All air conditioning systems including VRF systems are made to move heat from one location to another depending on the mode of operation. Heat is either brought into the building or rejected out of the building.

Using a VRF Heat Pump in cooling mode, heat is absorbed into the refrigerant from the warm indoor air blowing over the coil. The heat is then circulated by the compressor to the outdoor unit where the heat is rejected through the outdoor coil into the outdoor air. For a complete understanding of the refrigeration cycle see our video on “Refrigerant Cycle 101”.

The heat pump has a reversing valve which changes the direction of flow to each of the two coils. In Heating mode, the indoor coil now becomes the outdoor coil. So during the cold winter, the outdoor coil acts as the evaporator and absorbs heat from the cold outdoor air. You’re properly wondering how there is any heat in the cold winter air.

Well, this is the magic of refrigerants, as R410A is commonly used in VRF systems, and this refrigerant boils at -55.3F (-48.5C). That means this refrigerant circulating in the VRF System can still absorb heat from the cold outdoors and send it to the space to be heated. See our video on “How Heat Pumps Work” for a better explanation.

So it’s easy to remember, one coil absorbs heat (takes it in) and the other rejects heat (throws it out) all with the magic of refrigerants.

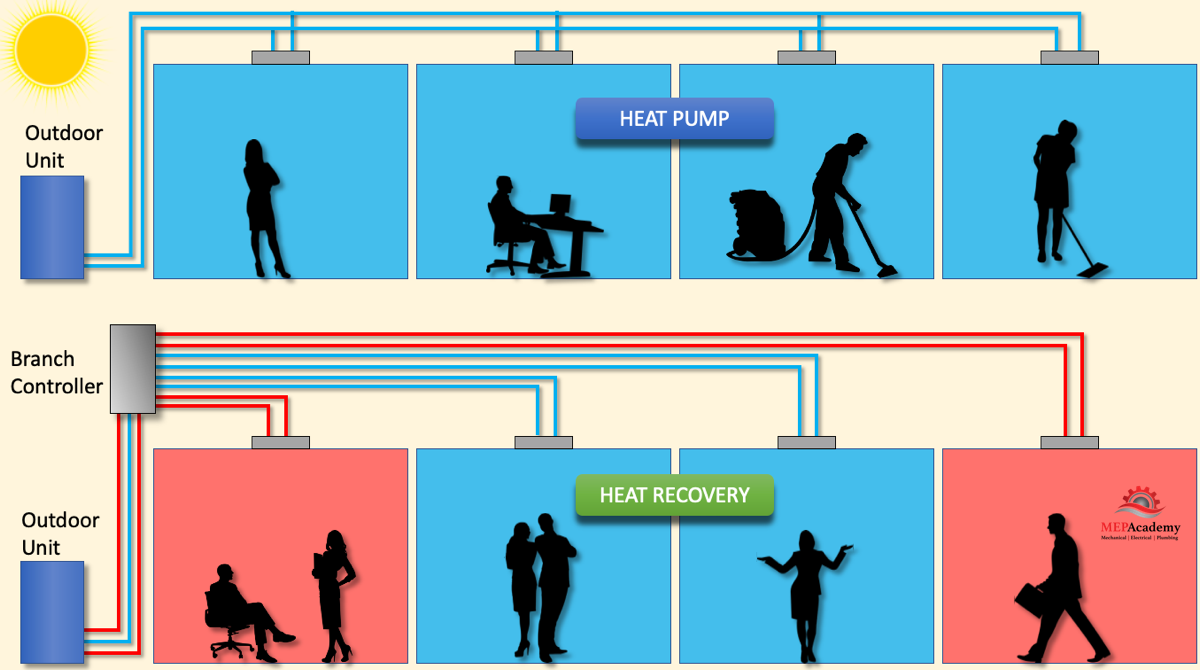

A much better and more efficient use of the heat being removed is to use it for some purpose, such as for a room needing heat while another zone is in cooling mode, this is what a Heat Recovery system is good at.

With a VRF Heat Recovery System, the Branch Controller will either send the heat absorbing or heat rejecting refrigerant to any space depending on whether the space wants heating or cooling, based on the demand of the controller.

So, if heat is absorbed into the refrigerant from a space needing cooling, it can be rejected by the refrigerant into a space needing heating. This is the basic principle of a VRF Heat Recovery System. We’ll cover these systems in more depth in other videos.

When should you use a VRF Heat Pump versus a VRF Heat Recovery System?

The decision will be based on several factors, one of which is what do we want to do with the heat that is recovered from a space. Do we want to throw it away, like we do in a traditional air conditioner, or do we want to use it somewhere else?

The main difference between the VRF Heat Recovery and Heat Pump system is that the VRF Heat Recovery uses the heat which allows for simultaneous heating and cooling.

The VRF Heat pump system allows for only one mode of operation at a time. This means that you have the choice to have all the zones in heating mode or all in cooling mode. If you have one space calling for heating and another for cooling, the one with the controller will determine the mode of operation. The heat pump uses a reversing valve to change the direction of the refrigerant flow. See our video on “How Heat Pumps Work”.

Therefore, VRF Heat Pump systems need to be designed with zones having similar load profiles, such as all spaces have exterior South facing offices.

The VRF Heat Recovery System uses a Branch Controller to send cooling or heating to any of the zones connected to the system. The branch controller acts like a Flight Controller, directing traffic. This allows for the heat rejected from one space to heat another space on a different zone.

Heat is removed from a space requiring cooling and rejected through the indoor coil into another space requiring heating. This is the efficient use of energy as its utilized instead of with traditional air conditioners where this heat gets rejected to the outdoors.

In an all-air system, heat is moved from one coil to another. This means in a heat pump system there is an indoor and outdoor coil, so heat is either entering the outdoor coil or exiting the coil. With a VRF Heat Recovery system this same heat can be entering or exiting any of the indoor coils, allowing for either heating or cooling at the same time.

The designer will need to review the owners’ requirements, how the building is oriented, the need for simultaneous heating and cooling, zoning layout, ventilation requirements, and accessibility for routing of piping and or ductwork including available space for new equipment.

Simultaneous Heating and Cooling with VRF Heat Recovery System

The decision on which system to use comes down to whether the zone can take advantage of simultaneous heating and cooling. This requires that the cooling and heating loads are balanced. Another consideration is the cost, as the initial cost of the VRF Heat Recovery System is higher.

Its possible to provide VRF Heat Pumps for each zone, but if you have a lot of zones that are balanced then it probably makes more sense to use a VRF Heat Recovery system, as this can save energy and reduce the number of outdoor units required for the total tonnage.

Depending on the configuration of the spaces and the orientation of the building, the use of a VRF heat pump system can reduce cost and installation and commissioning time by simplifying the install and commissioning process.

Here is a simple example of the differences with an analysis of a building that has the same north and south exposure areas. There are two options.

First, we can install a VRF Heat Pump Systems, one for the North Zone and another for the South Zone. That way when the North calls for heating all the North zones can be in heating mode, while at the same time the South Zones is in cooling mode. Two separate systems operating in two different modes. This requires a minimum of two outdoor units and at least two indoor units.

VRF Heat Pump System

Outdoor Units required = 2

Indoor Units required = 2 minimum

With the VRF Heat Recovery System this can be accomplished with just one Outdoor Unit and two indoor fan coils or more depending on the zone size.

VRF Heat Recovery System

Outdoor Units required = 1

Indoor Units required = 2 minimum

Controller Box = 1 minimum

As our example shows, we’ll need two outdoor units when designing for a Heat Pump system, and only one for a Heat Recovery System.

The engineer needs to determine what the owners project requirements (OPR’s) are and how to best accomplish those. How the building is zoned, the type of spaces and the operating schedule of the various spaces will need to be considered. Do the spaces share the same orientation to the sun?

You can see in the image below that with a Heat Pump system you’ll have all zones in Heating or Cooling, there is no simultaneous heating and cooling. You can switch to all cooling or all heating.

If you have a long southern exposure in the northern hemisphere, during the summer the South facing spaces may require cooling, while the North exposure may want heating during various hours of the day.

This could be accomplished with two Heat Pump systems or just one Heat Recovery System depending on the size of the zone. Interior zones are usually in cooling mode to satisfy the internal heat gains from people, lights and plug loads, since they have no exterior exposure.

A Heat Recovery System could be a good option if the load profile is balanced allowing for simultaneous heating and cooling. This allows for the heat that is recovered from the space being cooled to be used in spaces requiring heating, hence the terminology Heat Recovery. For locations that have very cold winters, the engineer must ensure that the VRF system can meet the design load at these extreme temperatures, otherwise supplemental heating maybe required.

Heat Recovery Branch Selector Control Boxes

The VRF Heat Recovery system will require an additional component when compared to the VRF heat pump system. With a heat recovery system there is the need to install a box controller between the outdoor and indoor units. This box controller can handle dozens of indoor units, not just one.

The branch controller box acts like a traffic controller, sending either hot gas to zones requiring heating, or sending cold low pressure liquid refrigerant to those zones needing cooling. You will find that the different VRF manufacturers have different names for this controller box.

These boxes require an electrical connection which adds to the cost of these systems, and depending on which manufacture you use, there might also be the need for a condensate drain.

VRF Indoor Unit Sizing and Style

The heating and cooling load will determine the size of the indoor units. For locations where the winters are extreme the selection may be based on the heating load to make sure that the VRF system can handle the extreme winters. The engineer will size the unit based on the meeting the maximum heating or cooling capacity.

Indoor units come in various styles and configurations. They can be ducted or un-ducted. There are un-ducted wall and ceiling mounted units and concealed ducted indoor units. You can serve more than one space when using the ducted units. With the concealed ducted units there is no visible component expect for the air distribution grille requires for the supply and return air paths from the space. With a ceiling or wall mounted unit, the VRF equipment is visible to the occupants and must be taken into consideration for aesthetic reasons.

Space Allocation Requirements

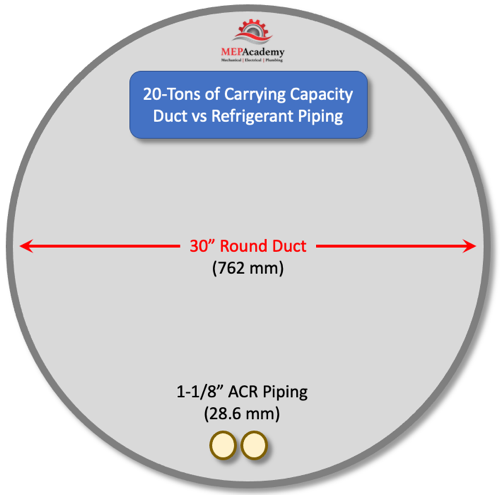

The use of a VRF system is less invasive for renovation projects when compared to an all-air system. The routing of small copper ACR piping is a lot easier than routing larger air ducts to each space when working in an existing building. The capacity of piping to carry the cooling or heating load is much greater than that of air ducts on an area basis. Looking at the chart we can see that the same carrying capacity in tonnage between refrigerant piping and air ducts requires a much smaller piping than air ducts.

If a Heat Recovery system is being installed, then additional space will be needed for the branch controller box.

VRF Electrical Requirements

VRF Heat Recovery systems require three electrical connections, as an additional electrical connection is required at the branch controller box. Traditional split system air conditioners and heat pumps typically have two connections, one at the outdoor unit and another at the indoor unit. If using a rooftop packaged unit, then only one electrical connection is required. On small split systems the outdoor unit may come with cabling that powers the indoor unit.

Packaged AC Unit – 1 Electrical Connection

VRF Heat Pump – 2 Electrical Connections

VRF Heat Recovery – 3 Electrical Connections

Limitations on VRF Piping

The use of a VRF system requires that attention be paid to the distances between all the components. This is to ensure that the system operates correctly. The traditional split system air conditioner also has limitation on the distance piping can be ran, and if that distance is exceeded there could be a drop in capacity and or failure of the system to return any oil required by the compressor.

If we look at one of the VRF manufacturers product data sheets, we can see that there are piping limitations for various distances between components.

The engineer has the option of choosing which systems to use for the different areas of a building. Some areas or floors of the building maybe suitable for a VRF Heat Recovery System, a Heat Pump System, Traditional Air Conditioners, or a central plant of some type. The engineer can mix and match these systems by using more than one type of system within the building.

Energy Efficiency of VRF Systems

The use of VRF systems can save on energy compared to the traditional air conditioners. This is one of the benefits when using VRF. There is one or more compressor in an outdoor unit of a VRF system. These compressors can be digital scrolls or similar that can save energy by matching the compressor output to the cooling or heating demand for the system.

The compressor ramps up and down to match capacity, saving energy by only pumping the volume of refrigerant required to meet the current load. The fans on some of there outdoor units can speed up or slow down to match capacity also. The traditional air conditioner just cycles on and off to meet demand, which is not as efficient as the modulation of these inverter and/or digital scroll compressors.

ASHRAE 62.1 Ventilation Requirements

All occupied spaces require ventilation, that is fresh outside air for the occupants of the building. This is usually done in accordance with ASHRAE standard 62.1, which defines the quantity of ventilation air required based on occupancy levels and area of the space. ASHRAE stands for the American Society of Heating, Refrigeration and Air Conditioning Engineers. They work on establishing standards for the industry and have branches all around the world.

There are several methods for providing outdoor or ventilation air to the occupied space when using a VRF system. Bringing in outside air is energy intensive, especially in hot or humid climates where levels of moisture are high. VRF indoor coils are not efficient at removing a lot of latent loads, as they have high sensible heat ratios.

Sensible heat ratios define the amount of sensible heat to total heat that the unit can provide. The difference between the total and the sensible is the latent load. This means that the higher the sensible heat ratio, the lower its ability to remove latent or moisture from the air.

This means that areas that have high moisture levels will need a way to precondition the air before its delivered to a VRF system. This can be done with a Dedicated Outside Air System (DOAS) unit. The DOAS unit will remove moisture from the outside air and deliver this condition air either directly or indirectly to the VRF indoor unit. See our video on “How Dedicated Outside Air Systems Work”.

Schedule of Occupancy

The time when spaces are occupied is an important factor when engineering a system. Zones with similar occupancy schedules can be combined on the same system which allows for optimal tonnage selection. Spaces with varying occupancy schedules, those spaces that might be used intermittently and not on a regular schedule will require additional analysis and likely a separate system for optimal energy usage.

For instance, small IT closets or areas that require 24 hours a day, 7 days a week operation would not make sense on a larger house system. You don’t want to run a large system off hours to feed a small load. These loads are best off with their own system.

Other spaces like schools and offices usually have a fixed schedule that can be relied upon for accurate programming of a schedule. Spaces that have varying occupancies levels like meeting rooms, conference rooms, and assembly halls can benefit from a dedicated system to meet the unpredictable schedule. Any spaces that produce high levels of moisture will need to be evaluated for their latent load component as the VRF fan coil unit has a high sensible heat ratio (SHR) and doesn’t handle lots of latent load.

When designing a VRF system or any system, occupancy schedule is an important consideration. VRF Heat Recovery systems require similar occupancy schedules to be energy efficient. Its important to balance the heat rejection from the cooling needs with the heating requirements of the system. This allows for the use of the rejected heat to be used for heating simultaneously while cooling is demanded.

Summary

The use of a VRF system can save energy but comes with a higher initial cost. A payback analysis will need to be run to determine the payback period based on the energy savings and the customer required ROI. The use of the VRF Heat Recovery system allows for greater savings if the system has a good balance between the heat rejected for cooling zones being utilized to those zones needing heating. A balanced heat recovery system allows for simultaneous heating and cooling, while heat pumps only allow one mode of operation for the complete coverage area. VRF systems are a good option for renovations because they are less invasive to the existing structure.

The engineer might consider the following when deciding which VRF system to use.

- Does the zone layout benefit from simultaneous heating and cooling by allowing the heat rejected from one space to be used by another?

- Is initial cost the determining factor, as VRF Heat Recovery often has the highest initial investment?

- Does the area have high moisture or relative humidity? This will require the use of additional equipment such as a DOAS unit to remove the moisture or latent heat.

- How will code required ventilation air be provided to the space?

- Are the occupancy schedules of the various spaces similar?

- Is there space for the branch Selector Box if using a Heat Recovery System?

- Where can the outdoor units be located in relationship to the indoor units?

- Is refrigerant monitoring required and do the spaces meet the minimum volume for the ASHRAE 15 requirements?