Have you ever wondered what flash gas really is in a refrigeration system? It’s a common term, but rarely explained clearly — and understanding it is key to troubleshooting and system design. In this article, we’re breaking it down in simple terms, with visual diagrams so it finally clicks.

Flash Gas Explained – Refrigeration Basics Made Simple

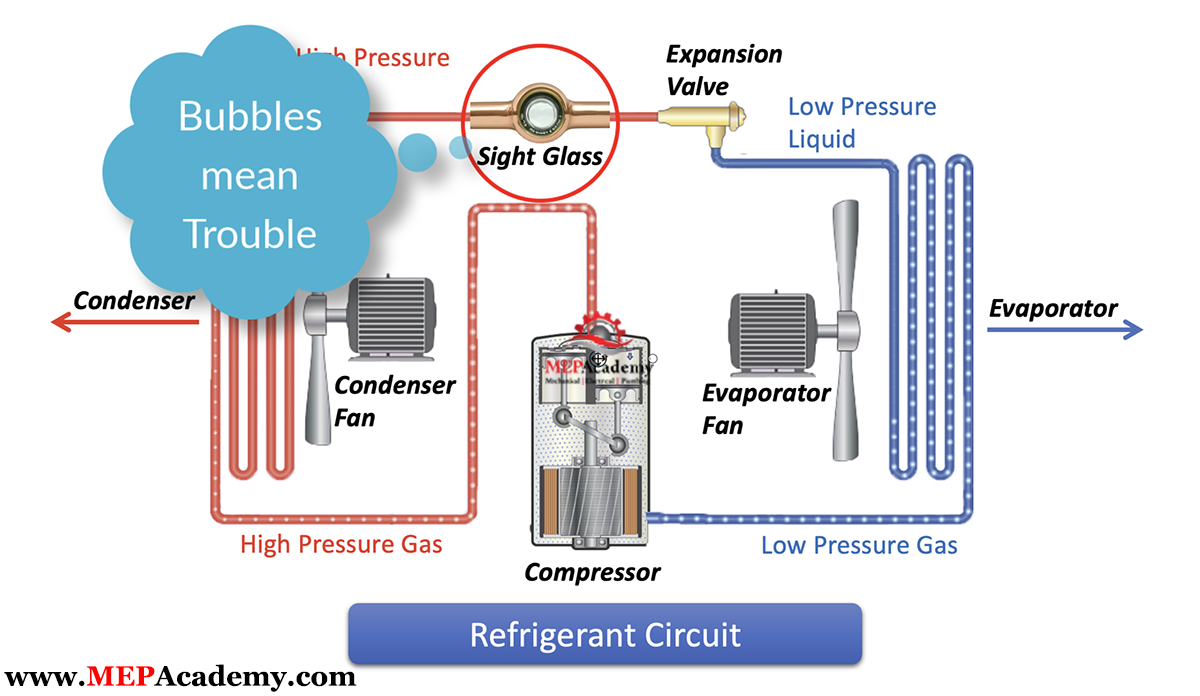

Flash gas is the portion of a refrigerant that instantly boils — or ‘flashes’ — into a vapor when it experiences a sudden pressure drop.

It most often occurs at two critical places in the refrigeration cycle:

- At the expansion valve outlet, and

- In the liquid line, if the system isn’t charged or sized correctly.

Here’s the science: When high-pressure liquid refrigerant exits the metering device and enters the evaporator at a much lower pressure, it can’t stay in liquid form. The drop in pressure causes part of the refrigerant to boil instantly, absorbing heat in the process. That’s flash gas.

But… flash gas can also form where it shouldn’t — in the liquid line — if the refrigerant pressure drops too early. That’s a red flag.

Here on the liquid line, just before the expansion valve, you’ll notice the sight glass. This is a critical inspection point for technicians. When the system is running properly, the sight glass should show a clear, full column of liquid refrigerant — no bubbles. If you see bubbles or foam here, it could indicate flash gas in the liquid line, often caused by a low refrigerant charge, loss of subcooling, or excessive heat gain in the line. Always remember: clear sight glass, healthy system; bubbles mean trouble.

In the evaporator, flash gas is expected — it’s part of the process. But in the liquid line, it’s a big issue.

Flash gas before the metering device reduces cooling capacity and causes erratic operation. You’ll see:

Poor superheat control. Compressor noise. Bubbles in the sight glass

How to Prevent Flash Gas

To prevent flash gas where it shouldn’t be, follow these best practices:

- Ensure proper refrigerant charge

- Insulate long liquid lines in hot environments

- Keep condensing pressures within design range

- Use subcooling to your advantage. See our other video on superheat and subcooling for a further explanation.

Subcooling is key! It ensures the refrigerant stays a liquid until it reaches the expansion device.

So to recap — flash gas is normal in the evaporator, but not in the liquid line. Understand it, control it, and your refrigeration system will thank you.