Water source heat pumps are versatile and energy-efficient HVAC systems widely used in commercial and institutional buildings, such as office spaces, schools, and healthcare facilities. These systems utilize a centralized water loop to transfer heat between individual heat pumps, making them ideal for buildings with diverse thermal demands across different zones.

If you prefer to watch the video of this presentation, then scroll to the bottom.

How Water Source Heat Pumps Work

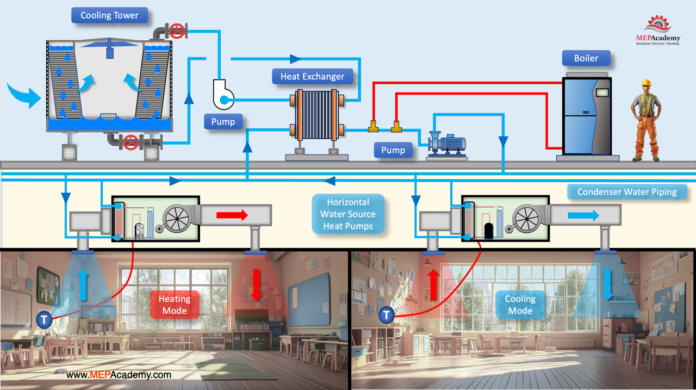

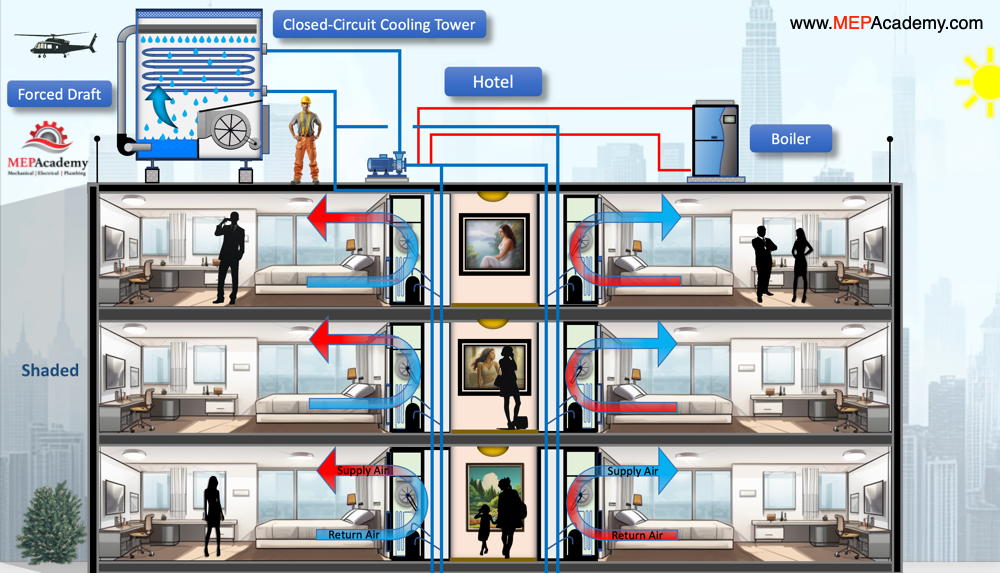

Water source heat pumps use the refrigerant cycle to either absorb or reject heat. Each unit connects to a water loop that serves as a medium for heat exchange. During cooling, the heat pump transfers heat from the indoor space to the water loop. Conversely, during heating, the heat pump extracts heat from the loop and delivers it to the indoor space. Each zone has its own water source heat pump, and they’re all connected to the same water loop.

Interaction Between the Fluid Cooler and Boiler

The water loop in a Water source heat pump system requires temperature regulation to ensure efficient operation. Two key components that facilitate this are the fluid cooler and the boiler:

Fluid Cooler

During peak cooling conditions, the water loop temperature rises due to heat rejection from various zones. The fluid cooler dissipates this excess heat to the outside air, maintaining the water loop within the desired temperature range.

Boiler

During heating seasons or when the water loop cools down excessively, the boiler adds heat to the loop, ensuring it remains warm enough to support heating operations across zones.

Typical Water Loop Temperatures

The water loop in a Water source heat pump system is typically maintained between 70 degrees Fahrenheit and 90 degrees Fahrenheit (21C to 32C). This range ensures efficient operation for both heating and cooling modes, balancing the energy requirements of all zones while optimizing the performance of the heat pumps.

Heat Contribution and Removal in Different Building Zones

In a Water source heat pump system, different zones can either add or remove heat from the water loop based on their heating or cooling needs:

Heat Addition: Zones requiring cooling transfer heat into the loop, raising the loop temperature.

Heat Removal: Zones requiring heating extract heat from the loop, lowering the loop temperature.

This dynamic exchange creates an efficient, self-balancing system where zones in cooling mode can offset the energy needs of zones in heating mode, reducing the overall demand on the fluid cooler and boiler.

Open vs. Closed Loop Systems

Water source heat pump systems can operate with either an open loop or a closed loop configuration:

Open Loop

In this setup, water is drawn from a natural source, such as a lake, river, or well, and is cycled through the system. After the heat exchange, the water is discharged back into the source. Open loops are highly efficient but may require permits and careful water quality management.

Closed Loop

Here, the water circulates within a sealed piping system, transferring heat to or from the fluid cooler or boiler. Closed loops are easier to maintain and protect against contamination but may involve higher upfront costs for piping and installation. Additionally, closed loop systems protect the heat exchangers of the water source heat pumps from contamination, enhancing their longevity and performance.

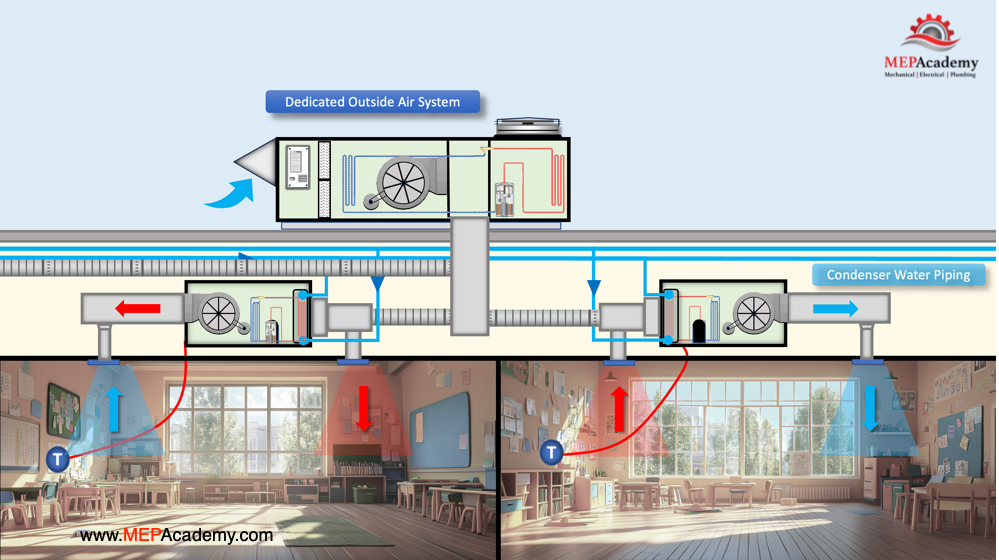

The Role of a Dedicated Outside Air System (DOAS)

To comply with building codes and provide fresh air, many Water source heat pump systems incorporate a Dedicated Outside Air System. This unit provides ventilation air that is conditioned independently of the Water source heat pumps, improving indoor air quality and ensuring compliance with ASHRAE standards.

A Dedicated Outside Air System may:

Pre-condition incoming air by heating, cooling, or dehumidifying it before distribution.

Work in tandem with Water source heat pumps to manage latent and sensible loads more effectively.

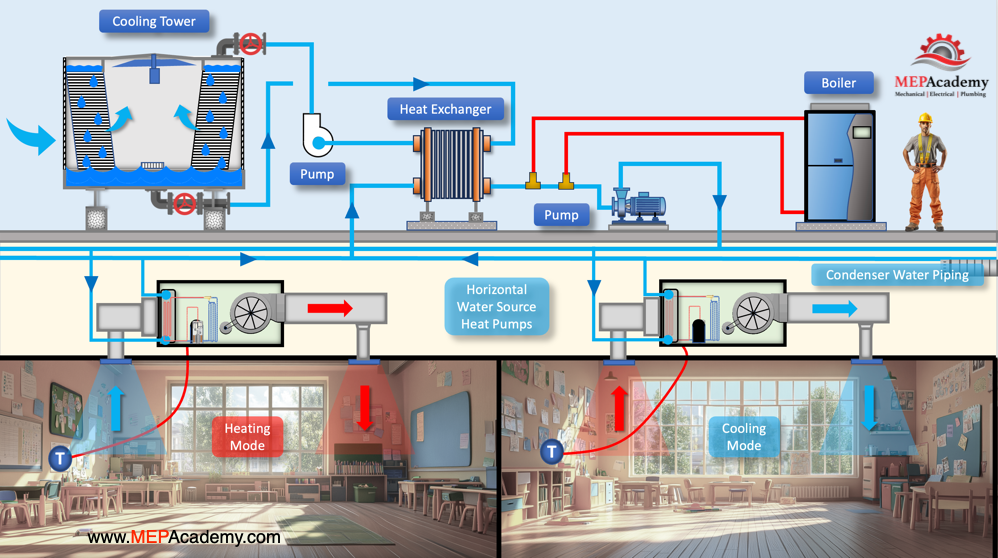

A Plate and Frame Heat Exchanger is a critical component in Water Source Heat Pump systems when utilizing an open-source cooling tower. It is installed between the open-loop (cooling tower) and the closed-loop (water source heat pumps), effectively creating two separate water loops.

Function of the Plate and Frame Heat Exchanger

Separation of Water Loops:

The open loop consists of water circulating between the cooling tower and the plate and frame heat exchanger. This water is exposed to the atmosphere, making it susceptible to dirt, debris, and biological growth.

The closed loop contains clean, treated water circulating between the plate and frame heat exchanger and the water source heat pumps inside the building.

Protection of Water Source Heat Pumps:

Cooling towers are prone to biological growth, scaling, and debris accumulation. If this contaminated water were to circulate directly through the water source heat pumps, it could foul or clog their internal heat exchangers.

By using a plate and frame heat exchanger, the open loop contaminants are isolated from the water source heat pumps, reducing maintenance and extending equipment life.

Heat Transfer Process:

The heat exchanger transfers heat between the open and closed loops without mixing the water.

When in cooling mode, heat from the closed-loop water is rejected through the heat exchanger into the open loop, which then carries it to the cooling tower for dissipation.

In heating mode, heat is absorbed from the closed-loop water and transferred to the water source heat pumps for space heating. If the loop water is too cold then the boiler is activated to bring the minimum water temperature up to set point.

Cost vs. Benefit

Added Cost: Installing a plate and frame heat exchanger introduces additional upfront costs, including the cost of the heat exchanger itself, piping modifications, and additional pumps.

Reduced Maintenance & Increased System Longevity: The cost is justified by the long-term benefits, as it:

Prevents fouling of the heat exchangers inside the water source heat pumps.

Reduces chemical treatment needs for the closed-loop water.

Lowers maintenance costs by preventing scaling, biological growth, and corrosion in the closed-loop system.

While adding a plate and frame heat exchanger increases the initial investment, it significantly enhances system reliability, efficiency, and lifespan by keeping the closed-loop water clean and free from contaminants. This setup is a best practice when using open cooling towers with water source heat pump systems to prevent fouling and ensure optimal long-term performance.

Basic Controls for the Fluid Cooler and Boiler

Effective operation of the fluid cooler and boiler relies on an integrated control strategy that maintains optimal water loop temperatures. Key controls include:

Temperature Sensors: Measure water loop temperatures to determine when to activate the fluid cooler or boiler.

Set Point Controllers: Maintain the water loop temperature within the desired range (e.g., 70 degrees Fahrenheit to 90 degrees Fahrenheit)(21C to 32C). The set point temperature can vary based on building load, outdoor conditions, and efficiency goals. A greater temperature difference in the loop improves overall system energy efficiency but reduces efficiency at the individual zone level heat pumps. If you widen the Delta T from 60 to 90 degrees Fahrenheit (15.5C to 32C), that gives the system level a 30-degree temperature difference, meaning the boiler will run less often, but the water source heat pumps requiring heating may run less efficiently due to the cooler water temperature.

Staging Controls: Enable or disable stages of the fluid cooler or boiler based on real-time demand.

Seasonal Mode Switching: Automatically switch between heating and cooling priority based on outdoor temperatures or building load profiles.

Water source heat pumps also work with other water sources such as lakes and streams, see our other video on “How Geothermal Heat Pumps Work”, or “How Heat Pumps Work” to better understand the reversing valve, and our video on Dedicated Outside Air Systems.

Conclusion

Water source heat pumps provide an efficient and flexible solution for modern HVAC needs, especially in buildings with diverse heating and cooling requirements. By leveraging a balanced water loop, supplemented with a fluid cooler and boiler, these systems optimize energy use across different zones. When integrated with a Dedicated Outside Air System and managed by robust control strategies, Water source heat pump systems deliver exceptional performance while meeting energy efficiency and ventilation standards.