In this article we’ll discuss BTU Meters, also known as Energy Meters, which is a device used to measure the amount of thermal energy (heat) consumed or transferred in a system. These meters are commonly employed in various applications where accurate measurement and billing of heating or cooling energy are essential. Here’s how a BTU meter works and some applications for their use.

If you prefer to watch the video of this presentation, then scroll to the bottom.

How a BTU Meter Works

Temperature Sensors

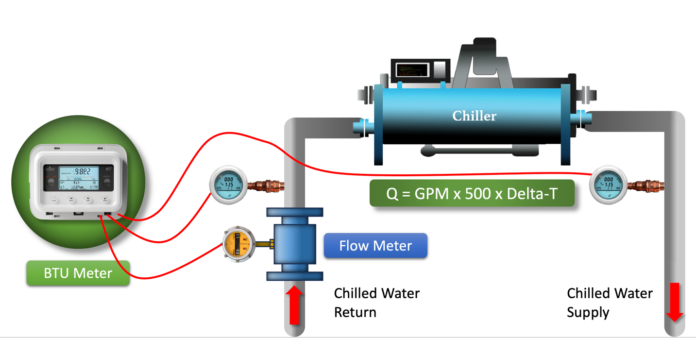

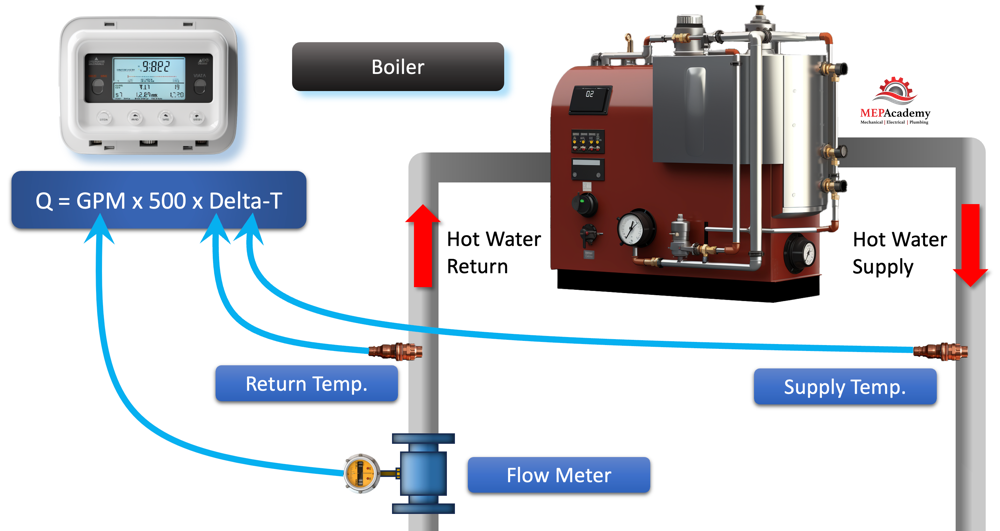

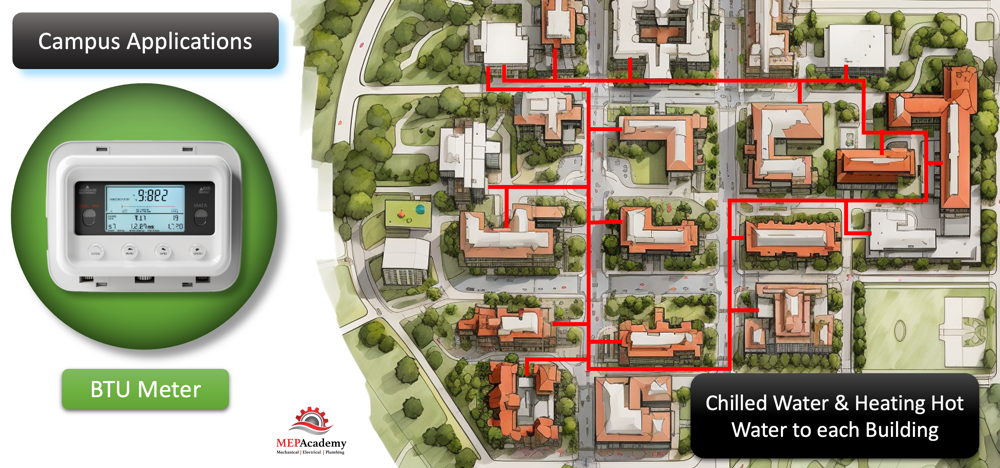

BTU meters typically consist of two temperature sensors, one placed at the inlet and the other at the outlet of a heat exchange system, which could be a chiller, boiler, air handler or the heating hot water and chilled water service lines feeding one of many campus or district buildings. These sensors measure the temperature of the fluid before and after it undergoes the heating or cooling process.

Flow Sensor

A flow sensor measures the rate of flow of the fluid within the system. This is essential for determining the volume of fluid passing through the heat exchange system.

Heat Calculation

Using the temperature difference (ΔT) between the inlet and outlet, along with the flow rate, the BTU meter calculates the amount of thermal energy transferred or consumed. The specific heat capacity of the fluid is often considered in this calculation.

The formula for calculating the energy consumed is Q = GPM x 500 x Delta-T

Q represents the total amount of energy in BTU’s, while GPM is the volume of water flowing through the pipes, 500 is a constant, and the Delta-T measures the difference between the supply and return temperatures.

Display and Data Transmission

The calculated energy value is then displayed on the meter’s interface, and/or is transmitted to a building automation system.

Applications of BTU Meters

Heating and Cooling Systems in Buildings

BTU meters commonly used in residential, commercial, and industrial buildings measure the energy consumption of heating and cooling systems. This includes applications such as central heating, air conditioning, and district heating or cooling networks.

District Heating and Cooling Networks

In large-scale district heating or cooling systems, BTU meters are essential for accurately measuring and billing customers based on their actual energy consumption. This is common in urban areas where a centralized plant supplies heating or cooling to multiple buildings.

Industrial Processes

BTU meters find applications in various industrial processes where precise measurement of thermal energy is critical. Industries such as manufacturing, chemical processing, and food production use these meters to monitor and manage energy consumption.

Renewable Energy Systems

BTU meters used in solar thermal systems, geothermal systems, and other renewable energy applications to quantify the thermal energy harvested or produced. This information is crucial for assessing the efficiency and performance of these systems.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial buildings often utilize BTU meters to monitor the energy used for space heating and cooling. This helps in optimizing system efficiency and identifying opportunities for energy savings.

Utilities and Billing

Utilities use BTU meters for accurate billing based on actual energy consumption. This is particularly important in situations where tenants or customers are individually responsible for their energy costs.

Energy Efficiency Assessments

BTU meters used in energy audits and assessments to evaluate the efficiency of heating and cooling systems. Measuring actual energy consumptions generates recommendations for energy efficiency improvements.

In summary, BTU meters play a crucial role in measuring and managing thermal energy in various applications, providing accurate data for billing, optimizing system performance, and promoting energy efficiency.