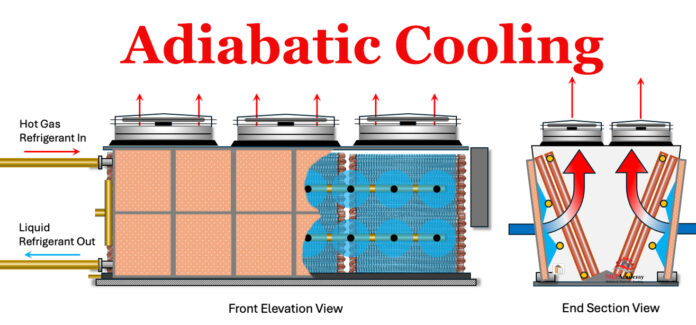

We’ll discuss an adiabatic fluid cooler, an air-cooled condenser with water spray, and an air-cooled condenser using adiabatic cooling.

An adiabatic fluid cooler is a device used for cooling fluids, typically water or a water-glycol mixture, while an adiabatic air-cooled condenser is used to cool a refrigerant based systems. These systems are used in industrial and commercial applications. They operate based on the principle of evaporative cooling combined with a heat exchanger.

If you prefer to watch the video of this presentation, then scroll to the bottom.

How Adiabatic Cooling Works:

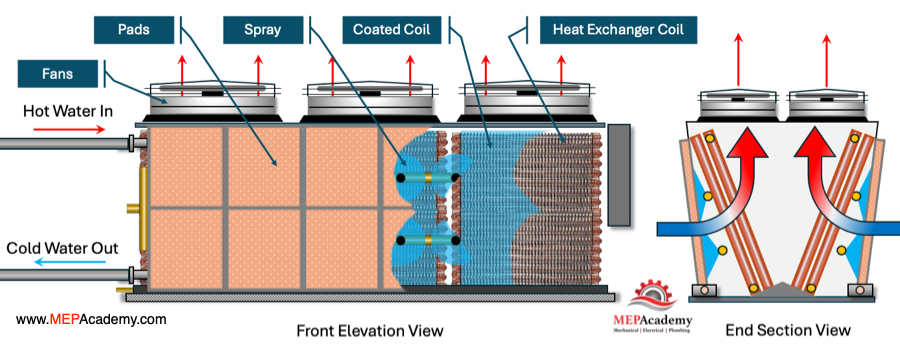

The hot water in an adiabatic fluid cooler flows into the heat exchanger. The heat exchanger consists of coils of tubes surrounded by fins. These tubes are in contact with the hot water. As the hot water flows through them, heat is transferred to the coil surface and fins of the heat exchanger. The heat exchanger can be provided with an epoxy coating to increase corrosion resistance without sacrificing unit capacity.

Water is sprayed or circulated over a pre-cooling pad, to keep it fully wet. This fully wetted medium sits in front of the heat exchanger, and is often made of corrugated cellulose, synthetic material, or fibrous pad. Cool, dry ambient air is drawn through the wetted medium by a fan located on top of the unit, the air becomes humidified as some of the water evaporates into the air, absorbing heat from the surrounding air in the process.

The evaporation of water from the wetted medium extracts heat from the surrounding air, reducing the ambient dry bulb temperature within proximity to the wet bulb temperature. This cooled air then passes over the surface of the heat exchanger where it absorbs heat from the hot fluid inside the tubes and on the surface of the fins. The heat is then discharged to the atmosphere by fans sitting at the top of the unit. As a result, the hot fluid inside the tubes loses heat to the cooled air through the heat exchanger.

The cooled fluid exits the adiabatic fluid cooler and can be recirculated back into the system it’s cooling, such as an HVAC system or industrial process. This effectively transfers the absorbed heat to the adiabatic fluid cooler and then to the atmosphere.

Variable Speed Fans

The variable speed fans inside the adiabatic fluid cooler draws air through the wetted medium and across the heat exchanger to facilitate the cooling process. The speed of the fan(s) can be adjusted to control the cooling capacity of the unit.

By combining evaporative cooling with a traditional heat exchanger, adiabatic fluid coolers can achieve significant energy savings compared to conventional air-cooled heat exchangers, especially in hot and dry climates where evaporative cooling is particularly effective.

Reduces Water Consumption

The Adiabatic fluid cooler can eliminate or significantly reduce water consumption compared to the traditional evaporative systems. They can be operated without water until ambient conditions require additional capacity to meet demand. This reduces water consumption and the cost to treat and dispose of water. There is no water basin to hold water or that can gather dirt and debris. This is because the water passes through once and isn’t recirculated so there is no need for a recirculation pump.

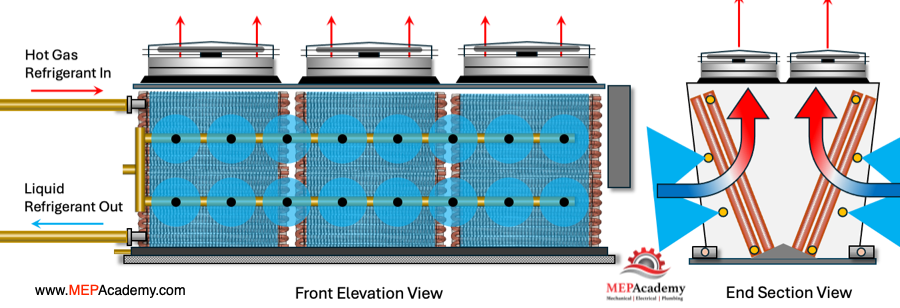

Adiabatic Condenser

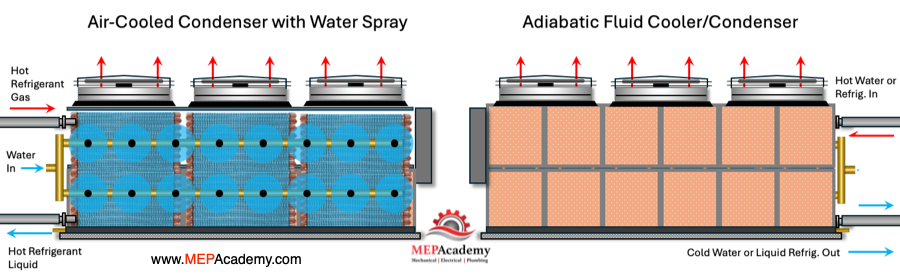

The adiabatic version of the air-cooled condenser uses a fully wetted medium that sits in front of the heat exchanger coil. The air flow and heat transfer process is the same as previously discussed using the adiabatic fluid cooler for water, except now it’s refrigerant as the medium.

Air-Cooled Condenser with Water Spray

For the air-cooled condenser, the refrigerant vapor enters the condenser and leaves as high-side refrigerant liquid. The system will turn on the water spray when it fails to maintain the refrigerant condensing pressure.

The water is sprayed outward away from the coil into the air stream. The air is pulled across the coil by the variable speed fans. The heat from the hot refrigerant is transferred to this cooler air causing the refrigerant to condense into liquid. The condenser will conserve water by running dry and only spraying water when ambient conditions require a lower entering temperature. That’s why these systems are recommended for high ambient dry bulb climates or high temperature applications.

What is adiabatic Cooling?

Adiabatic fluid coolers or condensers operate like dry cooling systems, except they have water running over pre-cooling pads. The air is drawn through the pads depressing the ambient dry bulb temperature of the incoming air. The depressed or reduced dry bulb temperature provides for greater system heat rejection than a dry system.