Air Handling Units. How they work and how they’re built.

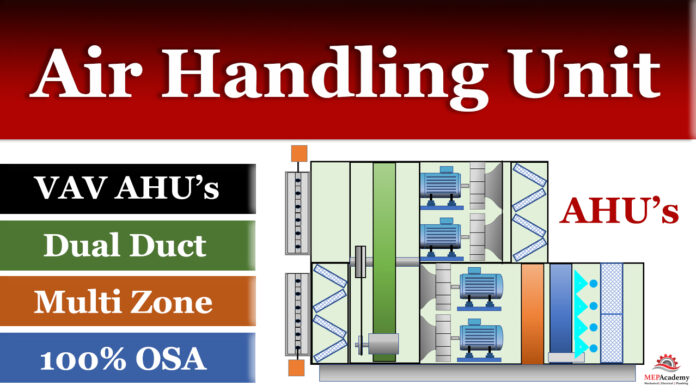

In this presentation we’ll be learning how Air Handling Unit (AHU) works within various commercial and healthcare buildings. We’ll show you how custom Air Handling Units are built with the selection of various options such as humidifiers, heat wheels, heating and cooling coils, dampers, economizers, UV lighting and the various types of fans being used.

We’ll explain the different types of air handlers used including VAV, CAV, Dual-Duct, Multizone and 100% Outside air units.

For the YouTube video of this presentation, scroll to the bottom.

The Basic Air Handling Unit Configuration

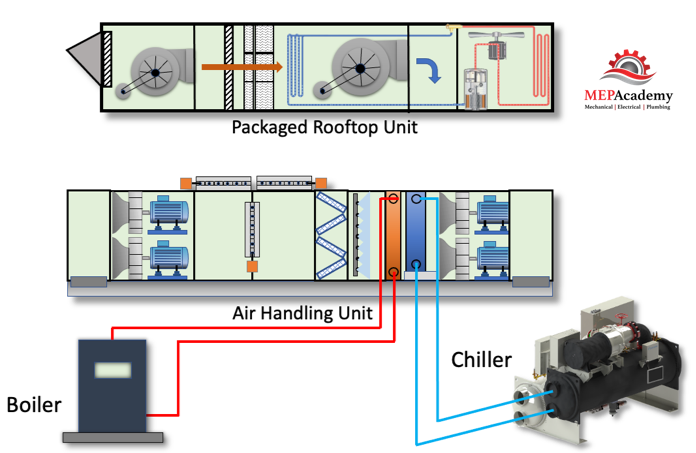

The main differences between an air handling unit and your typical air conditioner is that the air handler doesn’t provide the source for heating or cooling. Also, air handlers are available in much larger sizes up to and over 400,000 CFM . Air handling units also allow greater customization to fit project specifics.

The air conditioner has the refrigeration cycle as part of the equipment, where the compressor circulates the refrigerant that does the cooling and/or the heating. The air handling unit will do its cooling using chilled water from a chiller or refrigerant from a remotely located compressor, and do its heating using heating hot water or steam from a boiler.

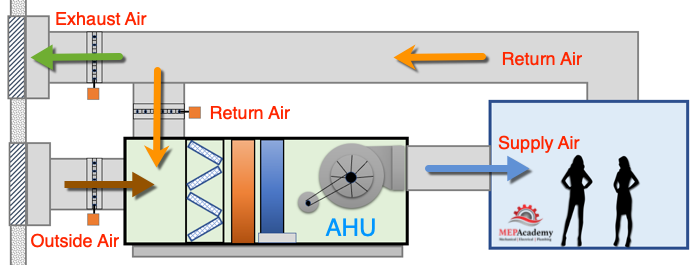

As you can see the Return air system has two options, it can return air back to the inlet of the supply, or it can exhaust the air outside. The rest of the air systems only have one option as shown by the directional arrows.

How to Build a Custom Air Handling Unit

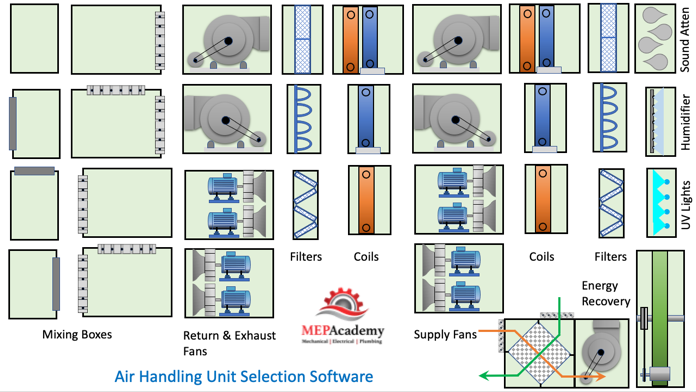

Let’s build a custom air handler like the manufacture would using the engineers project requirements and the available air handler sections.

The air handling unit manufacture will use their software program to assemble a unit based on the project specifics. Looking at a screen of options the air handlers engineering team will start building the air handler maybe starting with the inlet options.

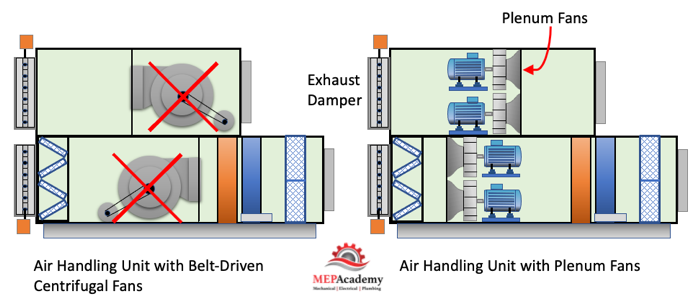

We’ll build our air handling unit using plenum fans because they provide better acoustics and allow for some redundancy incase a fan burns out. As you can see we added them on the supply inlet and on the exhaust.

Since this is an operating room will add a UV (Ultraviolet) lighting system to kill any bacterial, viral or fungal organism in the air and on or near the cooling coil, including the drain pan where water accumulates before draining.

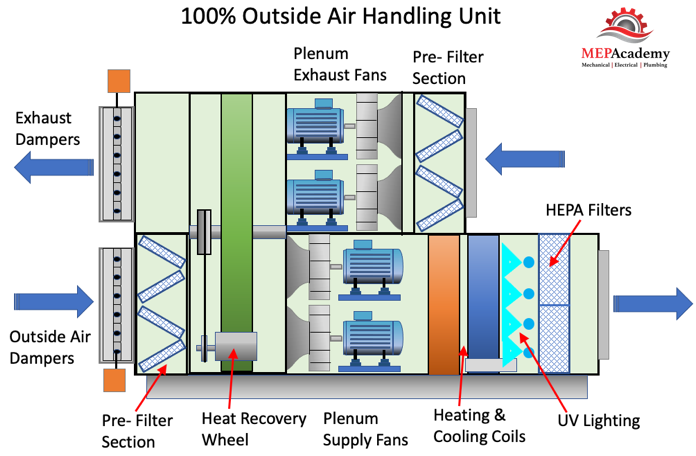

We added an energy recovery wheel to save energy and capture the heat that is being wasted. Using 100% outside air is energy intensive as we are spending energy to cool the air and then we are exhaust all of that air out of the building. To capture this energy there are several choices like the heat recovery wheel, heat exchanger or a run around coil. We’ll explain these in another video. We also added filters on the exhaust stream to keep the energy wheel clean.

100% Outside Air Handling Unit

The first section will be our pre filter section to clean the air that’s coming in, and then the Heat Recovery Wheel, then our supply fans. The fans are what pull the air from the outdoors and push the air into the operating room. Then we’ll have a hot water and chilled water coil to temper the air, the UV Lighting system, and finally we’ll have a HEPA filter to clean the air as there’s additional requirements for the operating room, since you’re cutting people open the air has to be super clean. And then on the exhaust side we need an exhaust damper and an exhaust fan to take the air from the room and exhaust it out.

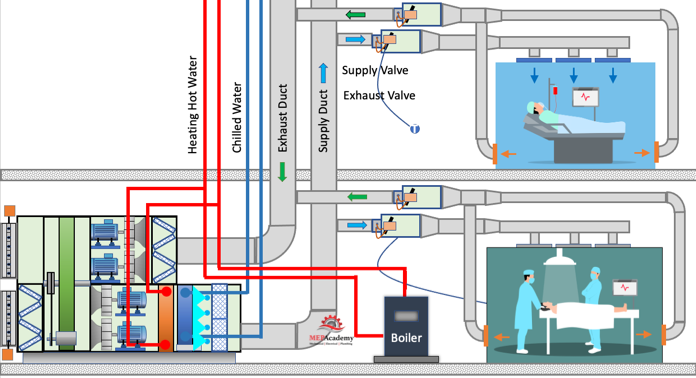

Now we’ll take this air handler that we’ve built and put it in the mechanical room in the hospital. You see we got our two operating rooms. We’ll set our Air Handler that we just built, and then the HVAC contractor will run the main ducts, exhaust and supply mains, and from there they’ll tie into branches through exhaust and supply valves feeding the operating room with laminar Flow grilles and low return.

Then the contractor will rig and set in a boiler, hook up all the hot water piping to the hot water coil, and then make a connection from the chiller to the chilled water coil, or if you’re using a compressor you can run DX refrigerant piping.

We just showed you how you can customize any air handler according to the project requirements, now we’ll show you a few more systems where air handlers are used.

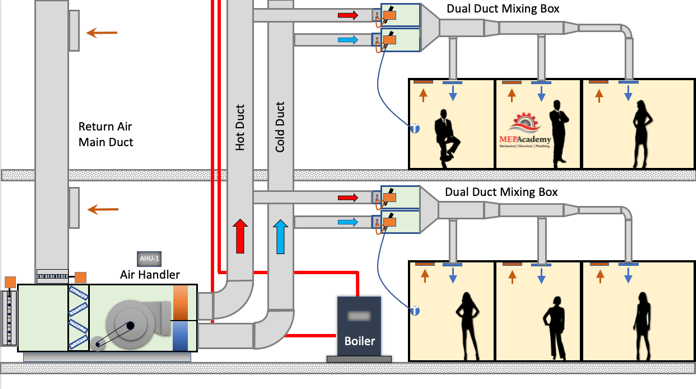

Dual Duct Air Handling Unit

This is a dual duct air handling unit that provides Cold air and warm air to travel down two different main supply ducts to dual-duct VAV mixing boxes. After the Dual Duct mixing box the air leaves in one common duct with the correct mixture of cold and warm air to satisfy the temperature setting of the space.

The air handler supply’s air over the cooling and heating coils simultaneously and the dual-duct boxes decide how much of each to open depending on the requirements of the room temperature sensor. One dual duct mixing box could be providing cooling while another is providing heating.

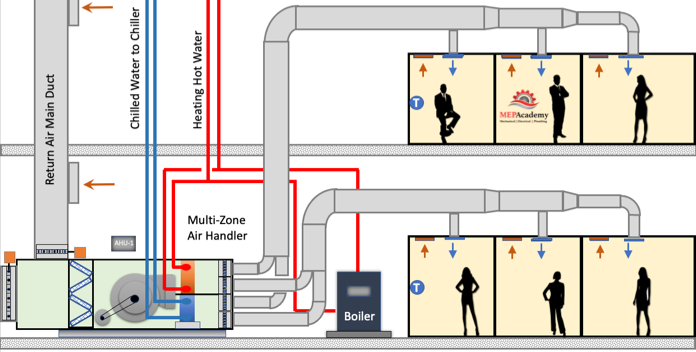

Multi-Zone Air Handling Unit

This is a multi-zone air handling unit. Each of the zones has a hot and cold deck damper at the air handler unit, which is different than the dual duct air handler we just showed you. Each zone has its own supply air damper at the heating coil and another at the cooling coil.

This air handler has a mixing box that allows for return air and outside to mix. The outside air damper will modulate to maintain the minimum amount of ventilation air as required by code. It’s possible to control the outside air using a CO sensor in the space being served by this air handler, to allow for energy conservation.

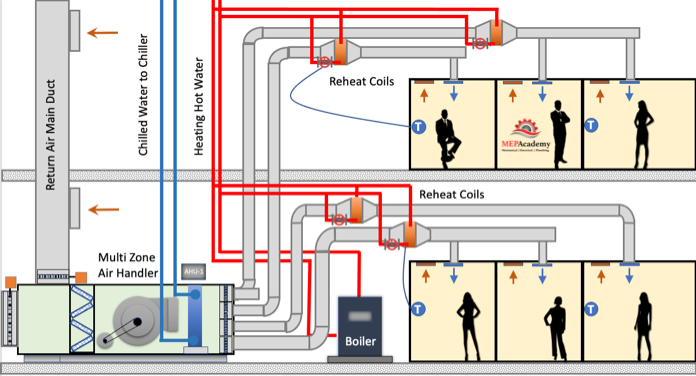

This is another version of the multi-zone air handler, except instead of a dual duct system with two coils in the air handler, this unit uses only a cooling coil. The heating if required is provided by an in-duct reheat coil.

VAV Air Handling Unit

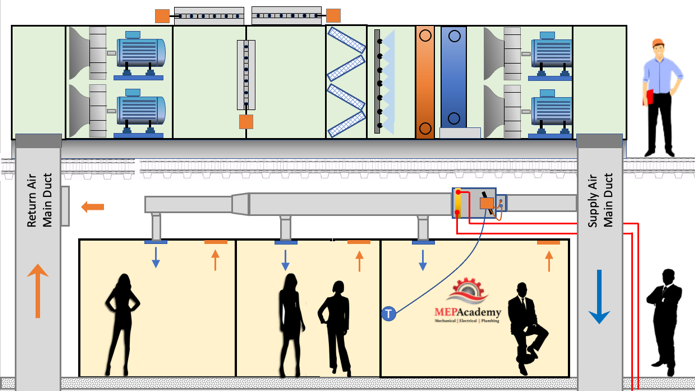

Here is a Variable Air Volume VAV Air Handler mounted on a roof. The VAV Air Handler is probably the most common system used in medium to large commercial buildings.

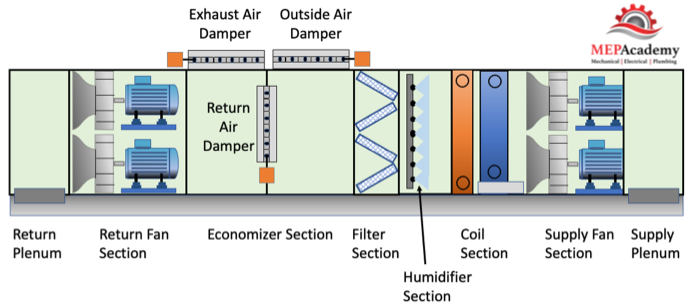

This custom air handler starts with the return air section, then travels through the return air fans. The air next enters the economizer, where the air can be exhausted out of the building or returned to the system. The next set of dampers is the outside air dampers that work with the economizer to bring in code mandated ventilation air. As the outside air damper opens to let more ventilation air in, the exhaust damper will open approximately the same amount to let air out.

Economizers save energy by using the outside air to cool down the building when the temperature is lower than the return temperature or some set value.

Next the air enters the filter section to clean the air. Various quality of filters can be used depending on the cleanliness requirements of the air. Next the air travels through a humidifier to add moisture to the air stream before entering the coil section and then through the supply fan that will push the air through the ductwork to the VAV boxes at each zone. The VAV boxes will open and close their damper to satisfy the temperature in this space.