How to Size Bathroom Exhaust

In this article, we’ll walk you through how to size commercial bathroom exhaust fans based on the 2024 Uniform Mechanical Code, the 2024 International Mechanical Code, and ASHRAE Standard 62.1.

We’ll take you step-by-step through real examples for a men’s and women’s public restroom.”

Proper exhaust fan sizing in public restrooms isn’t just about odor control. It’s critical for indoor air quality, moisture removal, and meeting mechanical code compliance.

Undersized fans can cause lingering odors, humidity issues, and even damage building materials over time.

2024 UMC on Restroom Exhaust:

- Light-use public toilet rooms require 50 CFM per water closet or urinal.

- Heavy-use areas like stadiums or airports may require 70 CFM per water closet or urinal.

2024 IMC Exhaust Rates

- 50 CFM per water closet or urinal if the fan operates continuously.

- 70 CFM per fixture if the exhaust system runs intermittently.

ASHRAE Standard 62.1 supports similar rates but emphasizes overall airflow balance and indoor air quality targets.

Now let’s size the fans CFM for a real-world example.

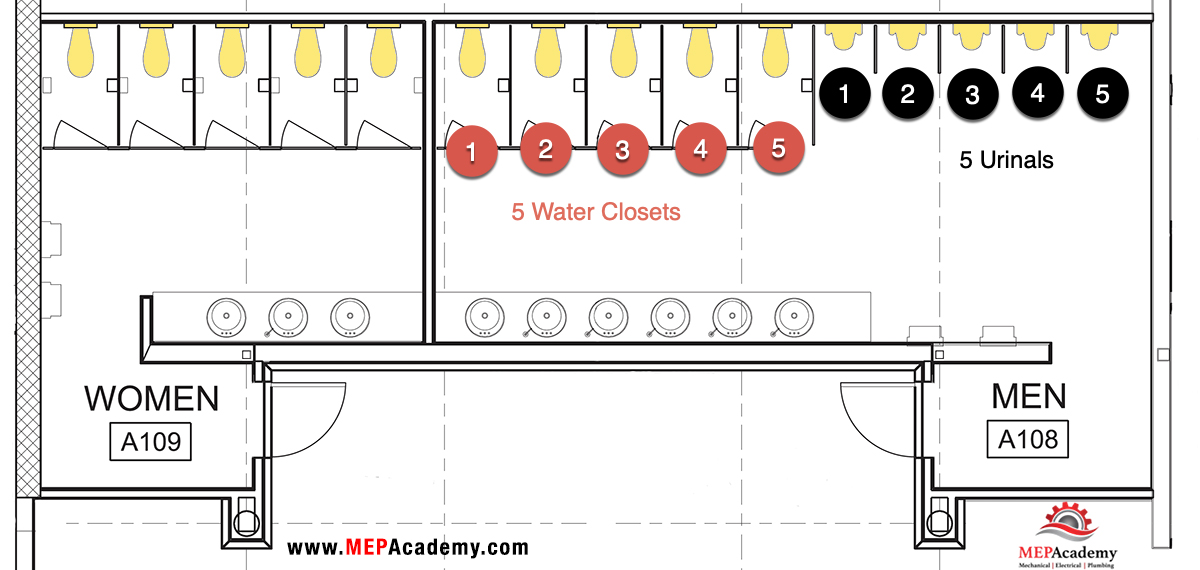

Men’s Public Restroom:

- 5 water closets

- 5 urinals

- Total: 10 fixtures

Women’s Public Restroom:

- 5 water closets

- Total: 5 fixtures

Step 1: Determine which code applies.

For our example we’ll use the IMC 2024 which using the terminology of continuous or intermittent operation. Determine if ventilation will be intermittent or continuous.

In this case, we’ll assume intermittent operation — the fans turn on with the lights or an occupancy sensor.

Step 2: Apply the exhaust rate.

Using IMC 2024 for intermittent operation of exhaust system for the restrooms gives us: 70 CFM per fixture.

Step 3: Calculate the total airflow:

For the men’s restroom:

10 fixtures times 70 CFM equals 700 CFM required

For the women’s restroom:

5 fixtures times 70 CFM equals 350 CFM required

Step 4 Determine Exhaust Makeup Air Method

Providing makeup air for exhausted air is essential to maintaining proper pressure balance. ASHRAE recommends ensuring air doesn’t flow from dirty areas into clean spaces and maintaining a negative pressure. This means providing enough make-up air from adjacent spaces or dedicated systems.

Common Exhaust Makeup Air Methods Include:

- Transfer Air: Air from adjacent spaces flows into the bathroom via door undercuts or grilles.

- Dedicated Conditioned Air: Supplied directly to the restroom through the HVAC system.

- Combination Method: A mix of transfer and limited conditioned air.

Step 5: Select exhaust fans.

Size fan or design ductwork to meet or exceed these total CFM requirements.

To summarize:

For private use restrooms the required exhaust is 25 CFM for continuous or 50 CFM for intermittent system operation.

Size exhaust fans based on fixture count and usage intensity.

UMC 2024, IMC 2024, and ASHRAE 62.1 work together to guide airflow requirements.

Always confirm whether the fans operate intermittently or continuously, and if using UMC, whether the public use is light or heavy to apply the correct rates.