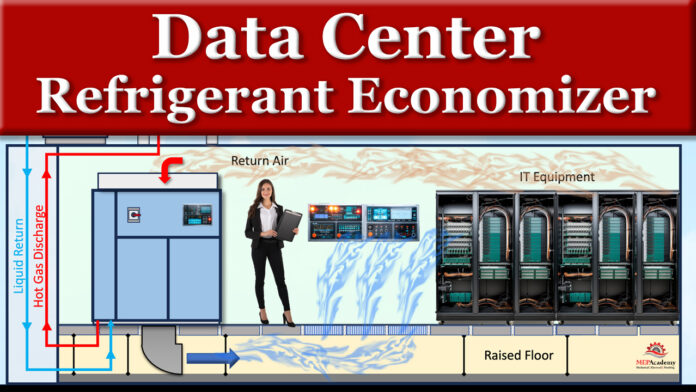

We’ll explain how a free cooling system with a refrigerant economizer works in a data center. Unlike air economizers, which use outside air for cooling, refrigerant economization systems operate differently. These free cooling systems come in a split system or packaged unit version with multiple configurations.

If you prefer to watch the video version of this presentation, please scroll to the bottom.

Data centers are energy-intensive building types that consume 10 to 50 times the energy per floor space than a typical commercial office building. There are many energy saving strategies for data centers, with one of them being economizers. You have probably heard about air and water-side economizers, but we’ll look at a refrigerant economizer system.

Refrigerant Pump

The heart of the refrigerant economizer is the refrigerant pump. This isn’t the compressor, but a separate pump used to circulate the refrigerant during economizer function. Pumps use less than one-tenth the energy of a compressor, allowing for energy savings. The pump is located below the receiver and condenser.

The pump takes the high-side sub-cooled liquid leaving the condenser and moves it to the expansion valve while maintaining a differential pressure for proper operation. When outside air conditions are unfavorable, the compressors come on and the pumps are bypassed.

Economizer Differences

Refrigerant allows for greater heat absorption capacity than either of air or water. Refrigerant carries as much as two times the heat of water, and 40 times as much as air. This allows for smaller pipes, and the avoidance of large air ducts and contaminated air coming in and out of the building with an air-side economizer.

Modes of Operation

There are three basic modes of operation with these units. One is that the data center unit runs in full compressor mode without the use of an economizer. The second mode is to be in full refrigerant pump mode under economizer operation, and where the compressors are fully off.

And the last method is to use both the compressor and pump in a mixed mode operation. The mixed mode method requires that there are two circuits. This allows one circuit to be pumping refrigerant in economizer mode, while the other circuit is using a compressor.

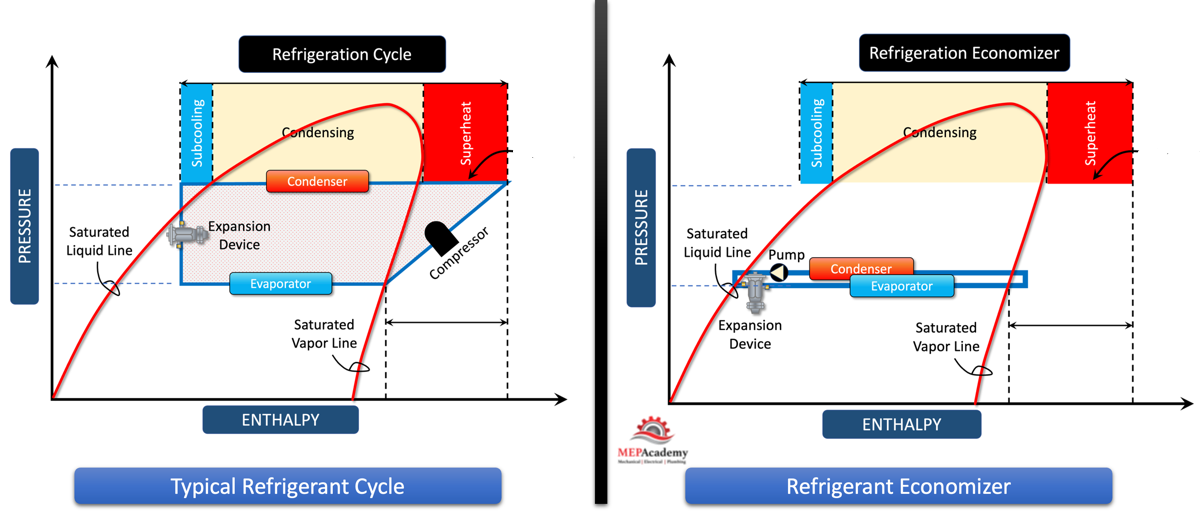

For those that love the engineering aspect, here is a look at what the refrigerant chart says the system is doing in economizer mode. As you can see during the normal refrigerant cycle the compressor raises the pressure significantly. That doesn’t occur during the refrigerant economizer cycle when the compressor is off.

Since there is no compressor to raise the pressure our line flattens out on the vertical pressure line. The compressor is gone, and a pump is added to cycle the refrigerant around the system. See our video on How to Read Refrigerant Charts for a better explanation.

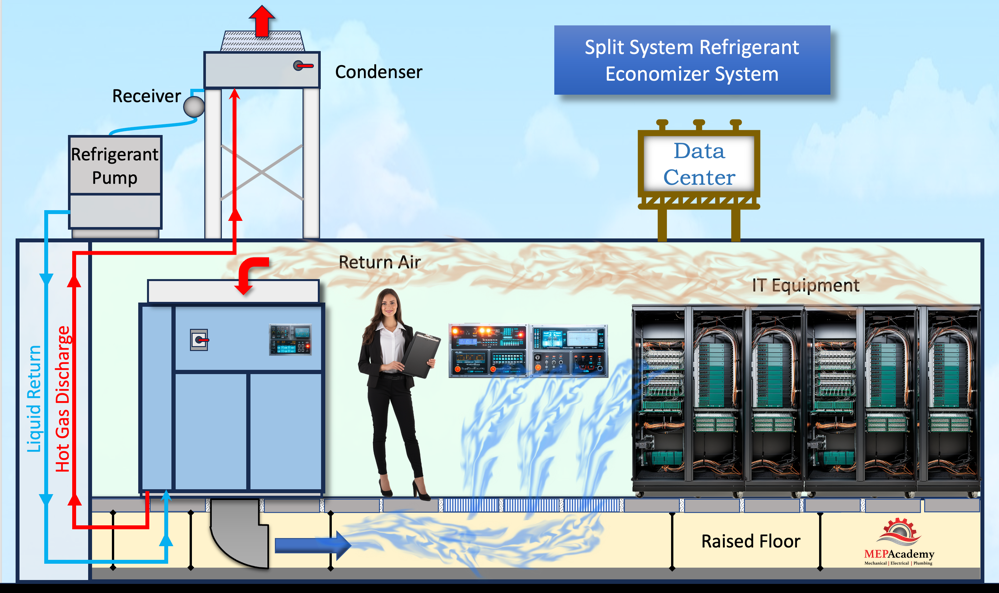

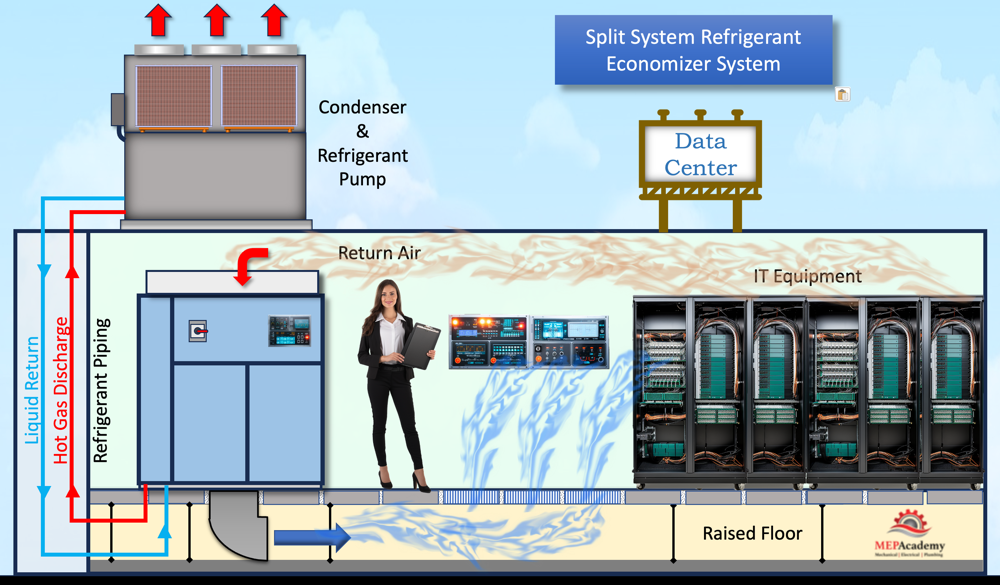

Split System

The first option is the use of a split system where the condenser sits on a stand on the roof. There is a an additional piece of equipment that houses the refrigerant pump. A refrigerant receiver collects liquid coming from the condenser and feeds it to the refrigerant pump. During economizer mode, the pump will circulate the refrigerant while the compressors are off, or during mixed mode both could be operating on separate circuits.

There is also the option to have the refrigerant pump housed with the condenser, but the operation is the same.

The indoor unit will house the compressors and evaporator coil. The liquid refrigerant will go through the electronic expansion valve before entering the evaporator coil. Warm air from the IT equipment racks will enter the top of the unit before passing over filters, than the through the evaporator coil where the heat gets absorbed. The now cooler air will be sent out the bottom of the unit to the underfloor supply plenum, where it will travel through perforated floor tiles and reenter the IT equipment to repeat the cycle.

There are other styles of the indoor unit where there is no need for a raised floor, and where the return air is located on the bottom front of the unit. The supply air will come off the top.

Packaged Units

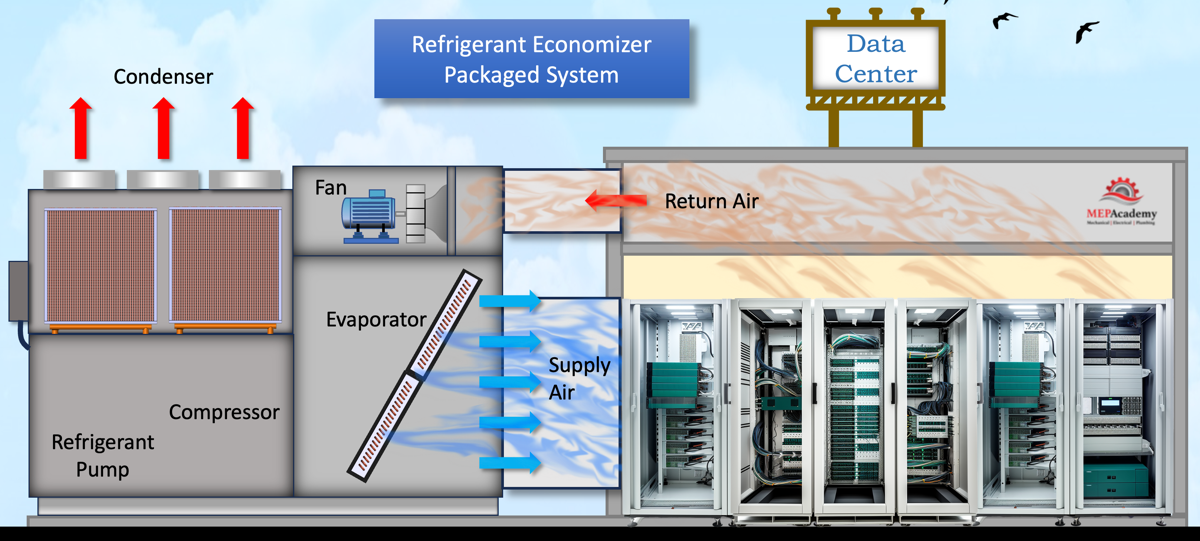

Another configuration is the packaged unit, where the condenser, compressor, evaporator and refrigerant pump are all housed in one larger unit. The unit can be installed on the side of a building and the supply and return air ducted into the data center. Some form of isolation between the supply and return is required to avoid short circuiting of the air.

There is also a packaged unit version that can sit on the roof of the building and be ducted to the data center space. The same consideration needs to be made to ensure that the supply and return air pathways don’t short circuit before entering the IT equipment.

See our other article about Data Center HVAC Systems, or watch the video about Data Center HVAC Systems