The electronic expansion valve controls the precise amount of refrigerant that flows into the evaporator. This is based on the demand which causes a step motor to open or close the valve to achieve a certain superheat that avoids liquid refrigerant from entering the compressor.

You will find expansion valves in most refrigerant circuits from refrigeration and air conditioners to chillers. The need for increased accuracy, precise temperature control, better energy efficiency and remote monitoring has brought about an evolution in expansion valves. (See below for YouTube video on Electronic Expansion Valves)

Checkout these Electronic Expansion Values hereWe will cover the main components including the superheat controller, electronic expansion valve, pressure transducer and temperature sensor, along with a brief explanation of superheat.

The expansion valve is one of the four main components found in refrigerant circuits. If you missed our video on Refrigerant Circuits you can find the link here.

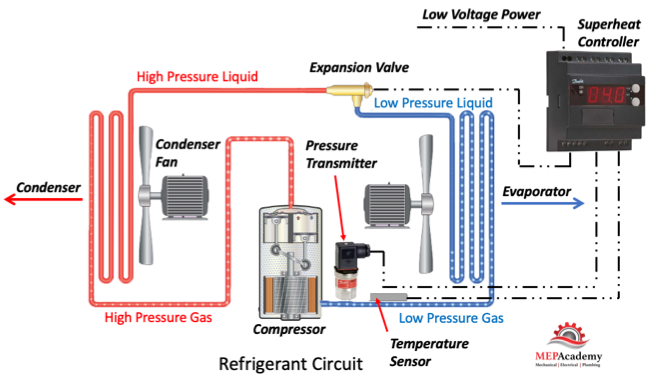

All refrigerant circuits need a way to control the amount of refrigerant that can pass from the high side of the system to the low side. The refrigerant passes through the expansion valve in a liquid state. Once this refrigerant passes the expansion valve it ends up going through the evaporator where the liquid refrigerant absorbs heat from the air or water that passes over the evaporator. This causes the refrigerant to evaporate, going from a liquid to a gas.

Depending on the demand for cooling, the expansion valve acts to control the proper amount of refrigerant needed.

With the superheat controller monitoring the superheat and adjusting the expansion valve to maintain an optimally low superheat value that results in higher COP values. A higher COP translates into energy savings.

There are various manufactures and types of expansion valves and variations on how they function. We’ll cover some basics about the electronic expansion valve and some of the components that allow it to operate. First we’ll cover the various components that you’ll find in some of the electronic expansion valve setups and how they function.

What is Superheat

It’s all about maintaining the correct amount of superheat. Making sure you have a minimum amount of superheated refrigerant leaving the evaporator before it enters the compressors is important for the protection of the compressor and for accurate demand control. Compressors are not made to handle liquid refrigerant, so it’s important that only gas/vapor enters the compressor, otherwise you can damage the compressor.

The superheat controller allows you to adjust the parameters and set which refrigerant is being used in the system. Each refrigerant has different characteristics of pressure, temperature and superheat values.

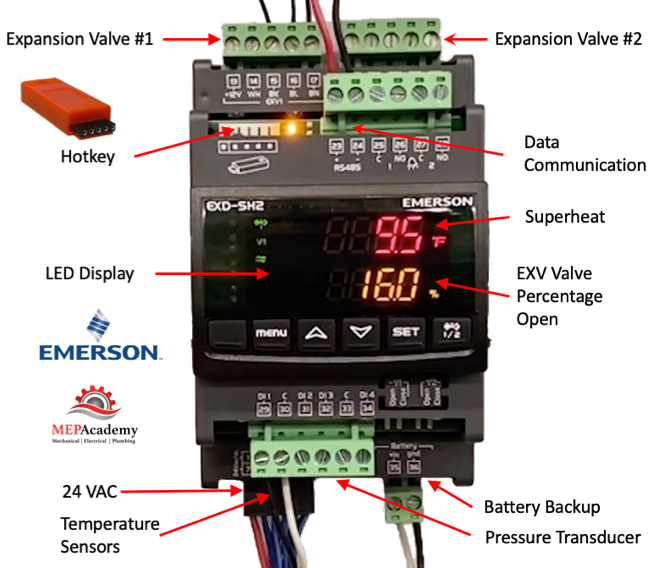

Checkout these Electronic Expansion Values hereUsing the two buttons on the superheat controller with the visual display is easy for technicians to make any setting required or view system states such as superheat, temperature sensor value and evaporating temperature. The display and its readouts will save the technician from having to retrieve service gauges and thermometers to determine these values.

Controlling superheat is an accurate method of ensuring that you have the proper amount of refrigerant, not too little or too much refrigerant, but an energy efficient amount to meet the demand.

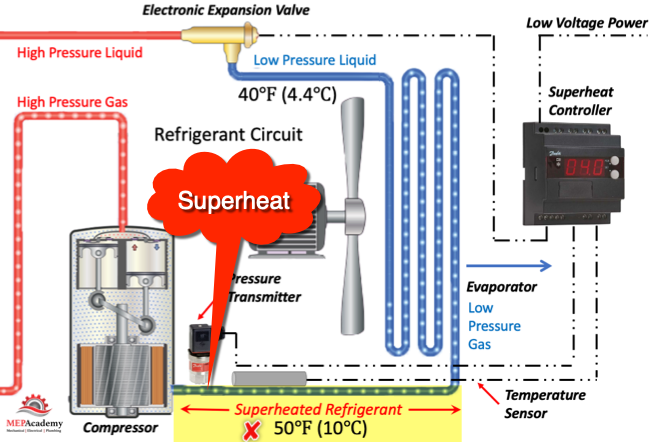

Superheat occurs when the refrigerant in the evaporator has completely evaporated into a gas and then additional heat is added to the gas. The initial heat caused the liquid refrigerant to turn into a gas. By adding additional heat after the refrigerant has completely changed into a gas the temperature of the refrigerant gas becomes superheated.

Superheat = Temperature of Gas entering compressor – Boiling Point/Saturation point of refrigerant.

For example if your refrigerant boils at 40 degrees (4.4 C) in the evaporator, the point at which the refrigerant liquid turns into vapor, then adding more heat will cause the temperature of the vapor to rise, let’s say to 50 (10 C) degrees. This would give you 10 degrees (5.6 C) of superheat.

Typical control is based on superheat set point but an additional temperature sensor may be used to measure discharge water or air temperatures. This air or water temperature may be controlled directly, as long as superheat remains at a level sufficient to prevent floodback.

The job of the expansion valve is to make sure that the evaporator has the optimum amount of refrigerant injected into it no matter what the load or demand is at any time. This is done by using a Superheat Controller, Pressure Transmitter/Transducer and a Temperature Sensor with the electronic expansion valve to constantly sense the superheat in the evaporator. We will cover each of these components now.

Expansion Valve Superheat Controller

The Expansion Valve Superheat Controller calculates the superheat, after which it sends a signal to open or close the expansion valve opening to allow an accurate amount of refrigerant into the evaporator based on demand.

This precisely controls the amount of refrigerant allowed through the valve based on the superheat of the refrigerant. The controller requires low voltage power and wired connections for the various input or output signals such as the pressure transducer, temperature sensor and or remote monitoring by the building automation system.

Alarm

The controller can send notification of any alarm set off by the system such as high or low superheat, bad pressure transducer or temperature sensor, minimum or maximum temperatures. This is done by the controller providing an error code on its LED display which corresponds with the manufactures trouble shooting literature to identify the problem area.

Hotkey

Look for the feature of a hotkey that allows you to program one controller and, than upload those setting to a hotkey where you can than easily transfer the settings to all other controllers needing the same settings by plugging the hotkey into all other controllers.

Remote Monitoring

This feature allows you to connect to your building automation system so that overview of the controller can be done remotely.

Battery Backup

If the system doesn’t have positive shutoff capabilities or use a solenoid valve to prevent refrigerant migration during non-operating periods such as during a power outage, then some means of power backup should be provided. That’s where this feature provides connectors for a battery backup or UPS (Uninterrupted Power Supply).

Pressure Transducer

The pressure transducer or transmitter will provide the expansion valve controller with the current pressure at the discharge of the evaporator on the suction line to the compressor.

Checkout these Refrigerant Sensors here

Temperature Sensor

The temperature sensor provides the other information needed by the electronic expansion valve controller in order to calculate the superheat of the refrigerant in the system.

Checkout these Refrigerant Temperature Sensors here

With the temperature from the sensor and the pressure from the pressure transducer the controller can determine the superheat of the refrigerant and make an intelligent adjustment to the electronic expansion valve.

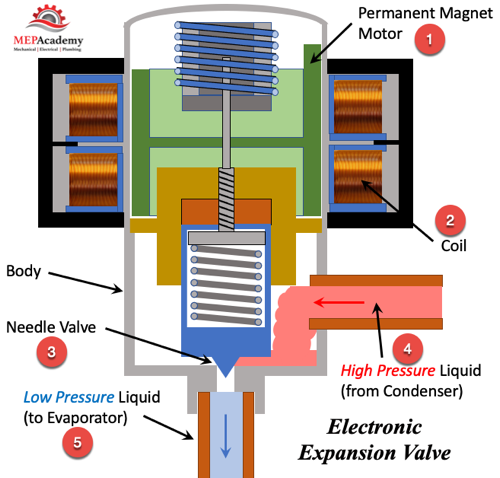

Electronic Expansion Valve

The control of the amount of refrigerant flowing through the expansion valve is more accurate using an Electronic Expansion Valve EEV. This accuracy increases the efficiency and energy performance of the system by preventing wasteful amounts of refrigerant getting passed the expansion valve.

There are various manufacturers of EEV’s, such as Emerson, Danfoss, Sporlan or Carel, each with their respective benefits and features, but the premise is the same. The desire to control superheat to protect the compressor and provide an efficient amount of refrigerant is at the heart of the design of an expansion valve.

Some of the components of this particular electronic expansion valve are the #1 Permanent Magnet Motor and #2 Electric Coils that work together to adjust the #3 Needle Valve allowing #4 High Pressure Liquid Refrigerant to pass into the evaporator where it becomes #5 Low Pressure Liquid.

The step motor in electronic expansion valves doesn’t rotate continuously like your typical fan or pump motor. The step motor takes small steps in either direction to precisely control the amount of refrigerant going through the expansion valve. Baby steps in the tune of 200 to 400 steps per second, or a total of 2,500 steps to over 6,000 steps for larger models. One complete rotation could be 24 to 100 steps (15 to 3.6 degrees/each step) depending on the design of the valve.

Checkout these Electronic Expansion Values hereSightglass

Parker’s Sloan Electronic Expansion Valve models SERI & SEHI have a built-in sightglass that can indicate the moisture level of the refrigerant, flash gas present upstream of the valve, and provides a visual confirmation of valve piston movement. This can be a useful feature for system refrigerant charging, service and diagnostics.

Checkout these Refrigerant Sight Glasses here

Steps to Take when selecting an Electronic Expansion Valve

- Determine Refrigerant to be used

- Determine capacity required for the valve

- Determine pressure drop across valve

- Determine the liquid temperature of the refrigerant entering the valve

- Select valve from the capacity tables of the valve manufacturer

Features and Benefits

- Energy Savings

- Accurate Control

- Optimized Superheat Control

- Optimally charged Evaporator

- Precise Minimum Stable Superheat (MSS) Control

- Improved Part Load for Variable Speed Systems

- Works with all common Refrigerants

- Intelligent Superheat algorithm with Safety Features

- * Compressor Protection

- * Fewer Compressor Breakdowns

- *Stable Operation

- Easy to Install

- Controller works with a Modbus interface or as a stand-alone