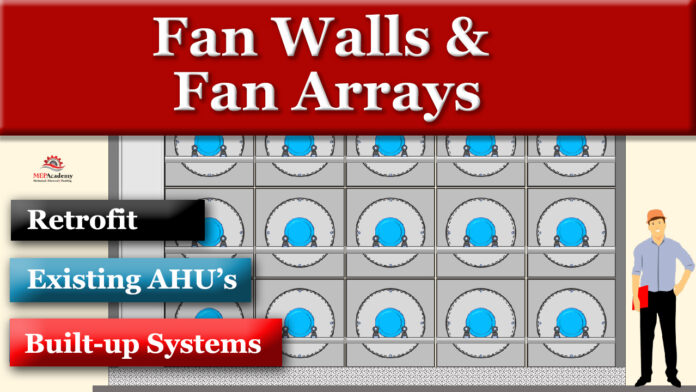

How Fan Walls or Fan Arrays Work. Fan walls are fans configured in stackable or wall mounted modules that can be designed in various arrays to form a larger fan system. They have a host of benefits over traditional fans used in the HVAC industry that we’ll cover in this article. One of those benefits is their simple modular design which replaces the single larger, heavier fans of earlier designs.

If you prefer you can watch the Video of this presentation by scrolling to the bottom or clicking on the following link “How Fan Walls or Fan Arrays Work“.

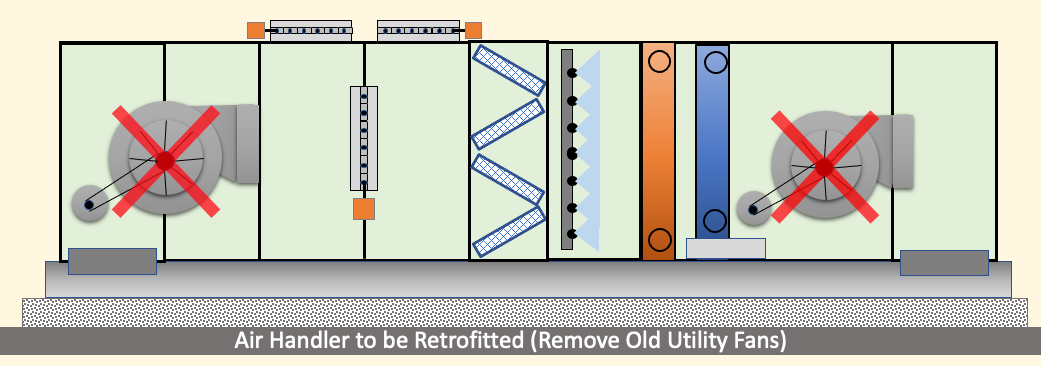

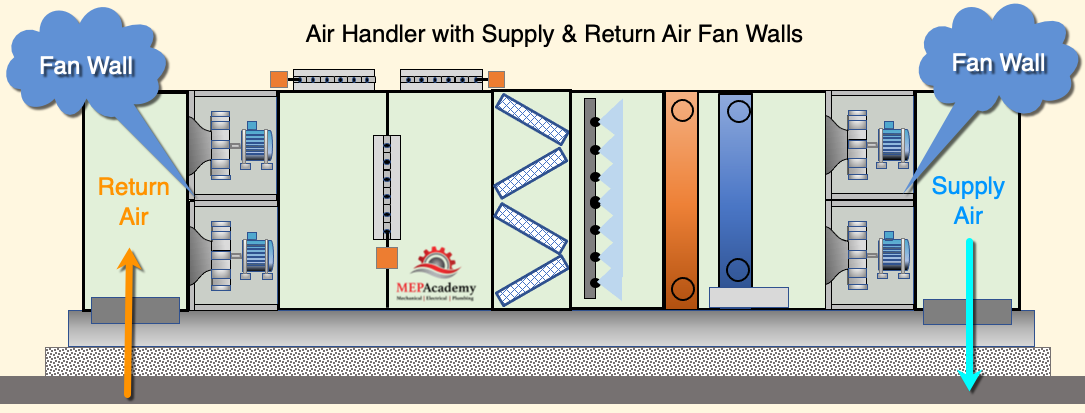

We’ll first show you how an air handler gets renovated with a new Fan Wall System. Here we show a large air handler with one large utility style fan inside. The system will be shutdown and the fan will be removed. You can see here that the fan was removed from this air handler so that a new bulkhead sheet metal wall could be installed to hold the new fan arrays. So that is what we’ll do here.

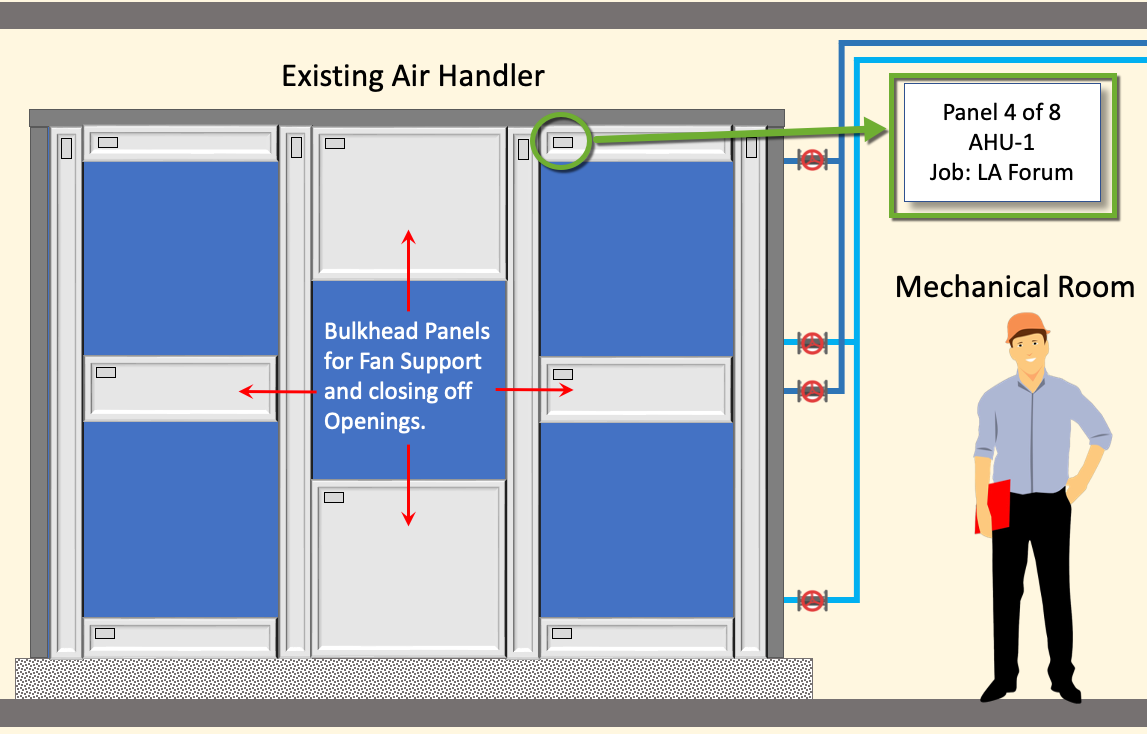

We’ll install the bulkhead walls, including vertical and horizontal panels, which leaves us an opening in the bulkhead for the fans. Each panel will come from the factory with a sticker that identifies which air handler it applies to, and where the panel is to be installed according to the manufacturer provided assembly drawing.

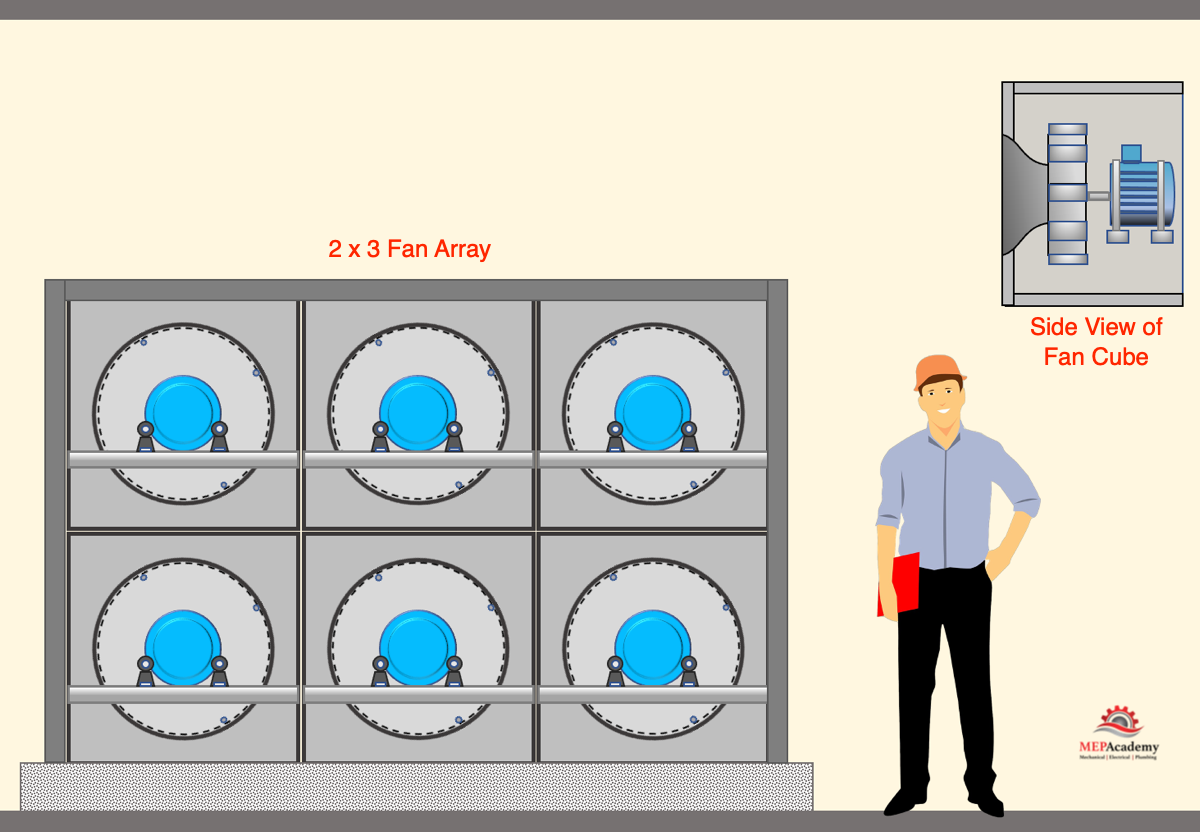

Next the fans will be installed. Here we show what the fan might look like from the side view. Each manufacturer provides similar looking fans with various modifications. Next, we put another fan, until all five are installed.

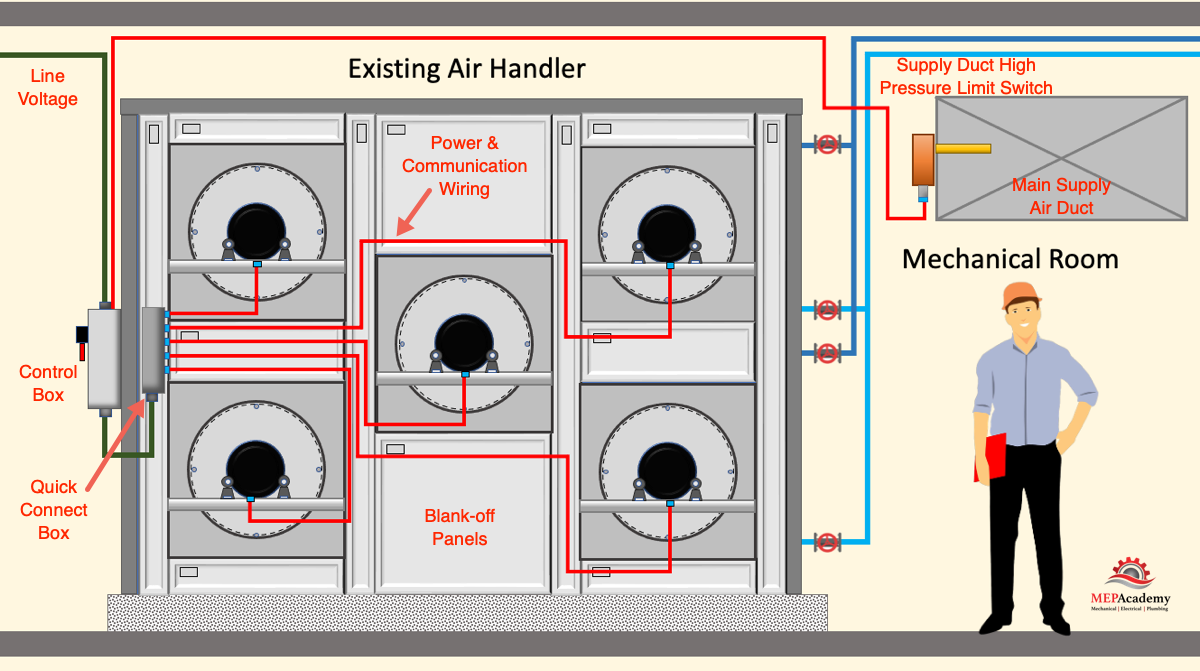

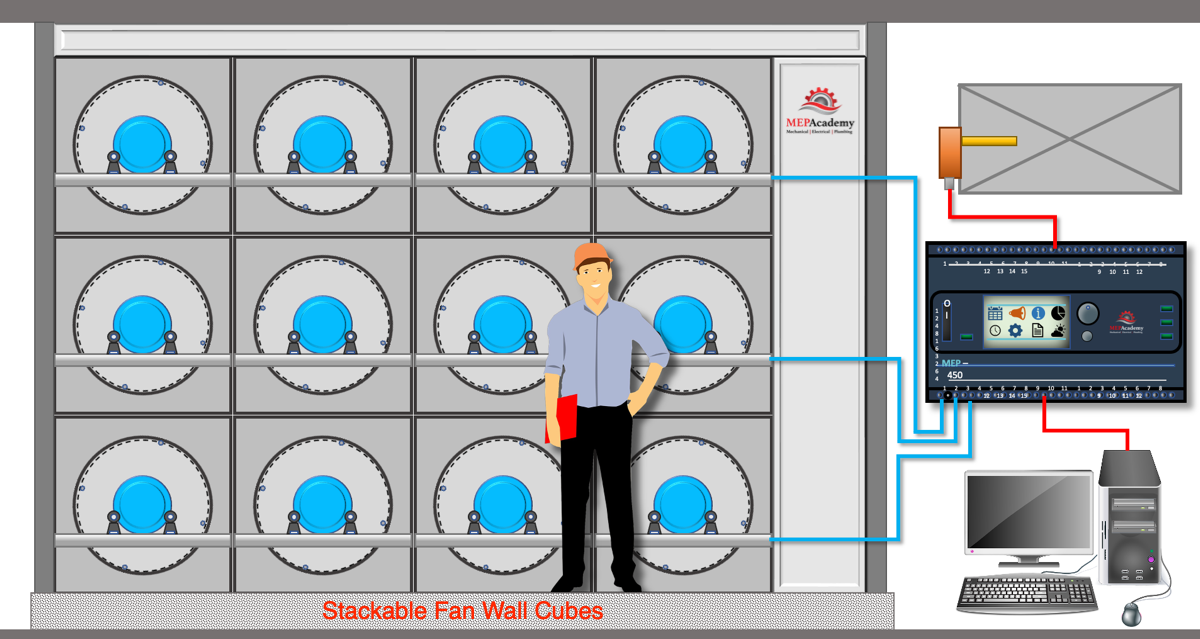

A quick connect box is installed inside the air handler. The quick connect box connects directly to the bulkhead wall and provides quick connection points for all the cabling coming from the fans. Each fan has power and communication wiring connected to the quick connect box. This part of the installation can be done without an electrician as the connections are just plugged into receptors at each end.

A control box will be installed on the outside of the air handler. Then the electrician will run line voltage power to the control box, and then over to the quick connection box located inside the air handler.

There are cable ties for quickly securing all cabling tight to the wall. The location of these ties is clearly shown on the drawings.

Then we install safety devices such as smoke detectors or pressure sensors. A high pressure limit switch prevents excessive pressure from occurring in the main duct. This will be wired to the control box, and if high pressure is sensed in the duct a signal is sent to the control box to shut-off the fans This could also be any fire/life safety device such as smoke detectors. If smoke is detected, a signal is sent to the fans control box and the fans are shut-off, this prevents smoke from being blown throughout the building.

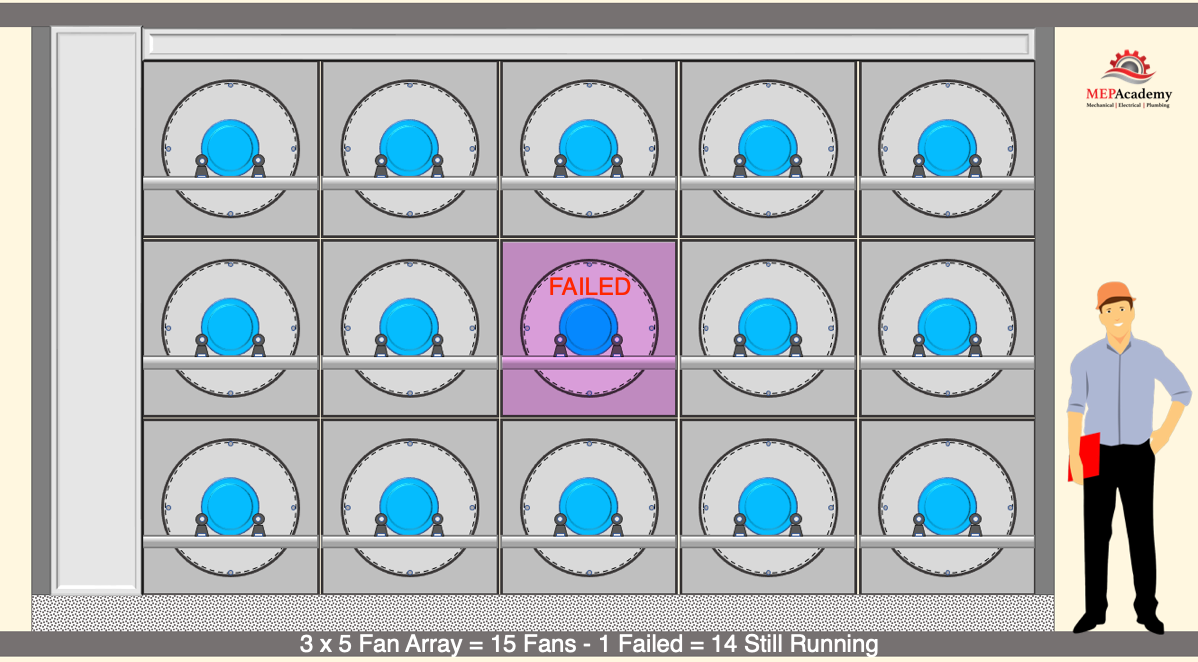

If one fan breaks down and needs to be removed, just replace it with a blank-off panel until the new fan arrives. This allows the system to remain running using the remainder of the fans. If this were a single utility or vane axial fan that burned-out, the whole system would be down until a new fan was installed. This allows for redundancy with multiple small fans compared to one large fan.

Built-up Fan Wall or Fan Arrays

Fan walls or fan arrays can be used for built-up systems also. They can be provided in stackable cubes in various configurations. We can have a 1 x 2 array, that is one fan high by two fans wide, or a 1 x 3, or a 2 by 3 fan array. As you can see you can increase the required airflow by increasing the number of fans in the system. All you need is the space for the fans.

They can easily fit through doorways and up elevators, making retrofit projects easier. The smaller fan cubes are lighter and easier to handle than single larger fans. This eliminates the need for large cranes or rental equipment.

In retrofit applications, large single utility fans or vane axial fans are often cut apart to allow for easy removal down an elevator, along with any sound traps. Fan Walls run quieter and generate less vibration than the typical fan and are used without sound traps, which also reduces any pressure drop caused by a sound trap.

A 3 x 3 fan array gives us 9 fans. They’re stacked on top of each other and fasten together. Here we have a 3 x 4 fan array shown above. There will need to be a wall that isolates the discharge and suction sides of the fan. This can be done by installing some form of framing on both sides of the fan array and then closing any openings with sheet metal blank-off panels.

Now we have 15 fans running in this built-up system providing air to our building. With all these fans, if anyone was to fail, the system has built-in redundancy as there are 14 other fans still running.

The fan array also provides better laminar flow as the air is spread out across the coil face area and isn’t concentrated in one area as you might get with a single utility or vane axial fan. Retrofits can be done over a weekend when the building is unoccupied, reducing or eliminating any down time for the AC system.

Control Systems for Fan Arrays

Here are a few ways in which these fans can be controlled with the use of a DDC programmable controller that uses inputs and outputs with the option of remote control using a Building Management System. Remember from our other basic controls videos that controllers have internally programmable logic, like mini-computers that house software specifically for the application of the equipment. See our other control videos on “Basic HVAC Controls” or “6 Steps for Designing HVAC DDC Controls”,

They can be controlled by a supply duct static pressure sensor, which attempts to maintain a static pressure set point, or supply CFM control. They can use return airflow control using building pressurization setpoints, or return air fans can be controlled as a percentage of the supply CFM. There are various other methods of control using the controller.

These controllers can be programmed to only run the system during building operational hours by the use of schedules. The controllers can track alarms, scale the CFM of individual fan cells, enable or disable fan cells.

What are some of the Benefits to using a Fan Wall Array?

Some of the benefits to using a Fanwall array is their lighter weight and ease of installation, reduced noise and vibration levels compared to other fan types, reduced building space required, the reduction in downtime due to motor failure because of the use of multiple smaller fans in lieu of a single larger fan installation.

- Easier Installation – Smaller Fan Modules are lighter and easier to handle than one large fan. Easier to move and rig the fan array’s smaller modules which can fit through doorways, hallways, stairways or elevators.

- Reduced Noise & Vibration

- Redundancy – Multiple Smaller Fans prevent full shutdown in case of motor failure in lieu of the use of one large fan motor.

- Saves on Real Estate/Building space – Fan arrays usually require less space than a single large fan which often has a sound attenuator that can be removed.

- Reduced static pressure with the removal of any previously installed sound attenuators.

- Usually less costly to install while improving operational efficiency and saving energy & money

- Eliminates the need for crane rigs or expensive rental equipment or removing walls for equipment access.

- Reduced cost for maintenance and service

- Better laminar flow through the coils.

- Retrofits can be done over a weekend when the building is unoccupied, reducing or eliminating any down time for the AC system.

- Replaces old technology belt-driven forward curved fans or axial fans. Forward curved fans are less efficient than a backward curved fan found on fan Arrays.

- No dust or dirt generated by the motors belts deterioration. Important for spaces requiring clean air.

- EC permanent magnet motor

- Direct drive motor

- High efficiency control system

- High efficiency plug fan

- Smaller fans and motors running at peak efficiencies

Fan Wall arrays can be used to retrofit an existing built-up larger fan system, Air Handler or Packaged DX piece of equipment. When purchased as part of a new AHU or packaged unit all the components will be factory integrated with controllers and motors. This can be small 15 ton air handlers to ones over 2,000 tons that come fully integrated with Fan Wall Array. As part of a retrofit project, you’ll need to demo the existing fan system and install the Fan wall array modules and connect the electrical and control components in the field.

Fan Array Control Optimization

The fanwalls multiple fan array is optimized for efficiency with controls that vary the speed and quantity of fans in operation at any one time to meet the system requirements.

Each Fanwall manufacturer provides various control packages, from the simple speed controller to the more premium control packages that monitor static pressure and CFM. There may be an option for a fireman’s override, fan RPM, energy usage, individual fan alarm and integration into a BMS system via BACnet.

Variable Frequency Drives

You can add a VFD for each fan or combination of fans to provide for dedicated speed control and a means for on/off fan operation. Various Fan Wall Array manufacturers handle this differently, including one manufacture that includes pre-wired VFD’s, not need for electrician to wire individual fans as they have a simple plug to a local panel

Advantages

Depending on the choice of Fanwall manufactures there are some additional materials and labor required beyond what you purchase from the manufacturer. If your fan wall comes with VFD’s in lieu of ECM motors for speed control, then you’ll need to mount them and wire them to the motors, programming VFD’s and providing electrical to each motor. Fan wall manufactures like Q-PAC avoid most of these issues because they use ECM motors and provide fan power plugs that connect easily to their quick connect panels.

ECM vs VFD Speed Control

Some Fan walls use VFD’s for speed control either with a dedicated VFD per motor or with one VFD handling multiple fan motors.

Some field installed items when using Fanwalls

In addition to the Fans themselves, the following items if provided by the Fanwall manufacture will most likely have to be field installed; VFD’s, BDD’s, Bulkhead walls, Control Panels, Electrical Conduit & Wire, Structural Supports, duct transition (tying into exist systems)

Physical Size

A single fan array can be a 26” x 26” square module approximately 18” deep and weigh 120 pounds. There are fan wall versions that can be completely broken down to get through an existing 19” wide air handler access panel, and then rebuilt inside the unit. With only a cordless drill, wrench, caulk gun and tape measure. According to Nortek it takes approximately 30 minutes to reassemble a single fan cell, and two to three people to move the assembled cells into place.

The cells arrive at the jobsite tagged by the manufacturer as to where they’re to be installed within the air handler. Each cell is bolted to the adjacent cell, while the bottom cells are bolted to the floor. Once all the cells are installed, sheet metal blanking plates are used to cover any top and side openings left over. An electrical chase is provided along the length of the array to protect the power wiring that connects each cell to the electrical power.

Sound Attenuation

Compared to the utility fan or vane axial fan that the plenum fans often replace, the Fan Wall Array is much quieter. Any existing sound traps are removed as the fans are quieter and the cubes that house the fans are provided with acoustic insulation. With multiple smaller direct drive motors the noise levels are less than those of a single large utility style fan or vane axial fan.

Engineering and Supplier Provided Items

If this is a design/build retrofit project for a built-up system, then you’ll need to provide the jurisdictional authority with a set of MEP and Structural drawings showing the new design. This might include structurally engineered drawings showing how the fan array is supported to the structure when using a headwall assembly as opposed to a stackable fan array.

If you are using the Q-PAC fan array system to replace fans in an Air Handler, then you should receive a fully engineered and sized system that fits within the existing air handler. The Q-PAC supplier should provide the following on an Air Handler retrofit:

- Fully Engineered and sized fan array to meet specified CFM and ESP with ECM motors

- Factory supplied/field installed modular fan bulkhead wall assembly with precut fan inlets

- Plug and Play wiring to allow quick connect harness to simply plug into connect panel

- CFM and Static Pressure measurement plastic tubing

- Optional – Blank off panels incase a motor goes down.

- Possibly Factory Supervised Startup.

- 5-Year Parts and Labor Warranty. (Confirm with supplier)

Energy Efficiency

The motors used in a Fan Wall Array have individual on/off control and variable speed control, allowing them to maintain operating efficiently along the demand curve of the system. With the variety of fan sizes and quantity of fans available for a fan wall array making it easier to optimize selection to match the best performance requirements.