How to calculate air changes per hour (ACH). How do you calculate how much air or CFM you need to provide to achieve a certain number of air changes? We’ll show you how to determine the amount of CFM or air required for a space based on the required air change rate per hour. Often specifications or standards will mandate a minimum air change per hour for a room for ventilation purposes, odor control, pressure relationship between spaces, or to achieve a cleanliness level like in a cleanroom or operating room.

If you prefer to watch the YouTube video of tis presentation, then scroll to the bottom or click on this link. How to Calculate Air Changes per Hour

Air changes per hour is an indication of how many time the air within the space is exhausted, recirculated through the system, or recirculated within the space.

We’ll cover how to calculate CFM and Air Changes using several different examples, including Hospitals and Cleanrooms.

Air Change Rate per Hour Formula

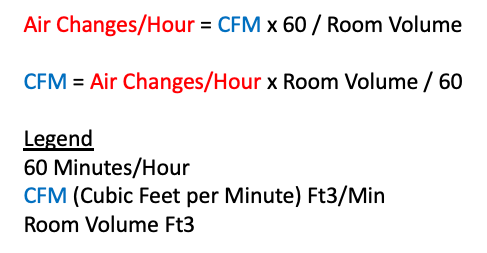

The formula for Air Changes per Hour looks like this:

Air Changes per Hour = CFM x 60 / the Volume of the room

We can express it another way in order to calculate CFM as

CFM = Air Changes / Hour x Volume of room / (60 Minutes/Hour)

High Rates of ACH for Cleanrooms

Cleanrooms are hidden from our view but they are used throughout the industry for businesses such as Food Manufacturing, Pharmaceuticals, electronics manufacturing of computer chips, and any product requiring a clean environment.

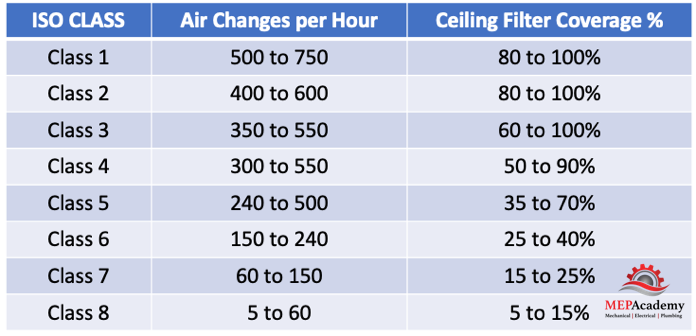

Cleanrooms require large amounts of air to be recirculated through the filters to achieve a certain level of cleanliness. Cleanrooms are classified according to ISO levels 1 through 8, with ISO Class 1 being the most stringent or cleanest.

An ISO Level 1 cleanroom can require in the range of 500 to 750 ACH and require approximately 80% to 100% of the ceiling to be covered in filtration. ISO Class 8 can require in the range of 5 to 60 ACH and have a ceiling coverage rate of 5 to 15%.

For a cleanroom air change rate example let’s use the following information given to use by the owner.

Space is to be a Class 1 Cleanroom

The measurements of the room equal 12 ft x 20 ft x 9 ft

And the Requirements are 500 Air Changes per Hour minimum

Step 1 is to Determine the Volume of the Room

12 ft x 20 ft x 9 ft = 2,160 ft3

This is the volume that needs to be removed from the space every hour multiplied by the number of air changes required in an hour. The thing to remember is that this is in ft3 an hour, and we need to get the units to minutes, as in cubic feet per minute (CFM).

Step 2 – Determine Required Recirculation CFM

CFM = Air Changes / Hour x Volume / (60 Minutes/Hour)

CFM = 500 ACH x our volume of 2,160 ft3/ divided by 60 to get us to minutes, not hours.

CFM = 18,000

For our second example we’ll use a Hospital

Air Changes for Hospitals

The ACH rate is a common design requirement for various rooms within a hospital. Critical spaces within hospitals require that a certain amount of ventilation air be brought into the room every hour in addition to that, there is another requirement to recirculate the full volume of air a minimum number of times through the system every hour.

For example, a Recovery Room may require 2 ACH of ventilation air with a minimum air change rate of 6 for the space. This will require that the volume of outside air for ventilation be two times the volume of the space within an hour and another 4 ACH recirculated through the HVAC system for a total of 6 ACH.

The difference between a hospital room like an operating room and a cleanroom, is that the operating room doesn’t allow the air to be recirculated within the space, as opposed to a cleanroom where the use of fan powered recirculation units are acceptable to achieve the required cleanliness level.

Increased air exchanges reduce odors, increase air quality and cleanliness. There is obviously a cost to increasing the quantity of air changes due to the consumption of fan and or compressor power. Providing the correct amount of air and no more is critical to providing an energy efficient system. When critical spaces are unoccupied, the air change rate should be setback to lower volumes or turned off if allowed.

We used the same volume as the previous example so that you can see what the difference is between the two air change rates.

Hospital Recovery Room ACH

The space Volume is the same as before at 12 ft x 20 ft x 9 ft

The Requirements are 2 ACH of Ventilation with a 6 ACH Minimum

Step 1 again is to Determine the Volume of the Room, which is 2,160 ft3

Step 2 – Determine the Required Ventilation CFM

CFM = 2 ACH x 2,160 ft3/60

CFM = 72

Step 3 is to Determine the Required Minimum CFM

CFM = 6 ACH x 2,160 ft3/60

CFM = 216

Step 4 is to Determine the Required CFM to be Recirculated through HVAC Equipment

Minimum ACH – Ventilation ACH = Recirculated ACH (This can be stated in CFM)

Recirculated CFM = Minimum CFM 216 – Ventilation CFM 72

Recirculated CFM = 144

You can see that the same size room at the two different air change rates makes a huge difference in the volume of air that must be circulated.