When bidding on a plan and specification project designed by a third party engineer, it’s imperative to read through the specifications for those items that will affect your normal way of constructing a project. Every contractor has a preferred way of building a project based on their own preference for materials and methods which might not line up with what the engineer has specified.

So it’s important to read the specifications thoroughly to determine where the specifications differ from your own companies standards, so that you can adjust your price accordingly.

Your company may have a preference for building their ductwork with certain seams and joints according to the equipment in the fabrication shop, or which is owned by the fabricator you purchase your ductwork from.

Knowing what to look for when reading the specifications comes from years of experience, and being familiar with the lexicon used in the trade to describe various materials and methods of construction.

An experienced estimator should be able to quickly read the pertinent sections of the specifications to discern any deviations from his company’s standard methods of construction.

Specifications can be provided in book form, electronically or printed, or they could appear only on the drawings. Either way, make sure to read them carefully.

Specification Review

Not everything that is found in the specifications maybe applicable to the project you are bidding, as engineers use templates for their specifications. This means that they most likely purchased a pre-written technical specification which requires them to personalize it for the particular project, but often they are lazy and the specifications are not applicable or mention systems that don’t exist on the bidding documents.

But you still must read the specifications as they will become part of the contract and you can be held to anything that is specified.

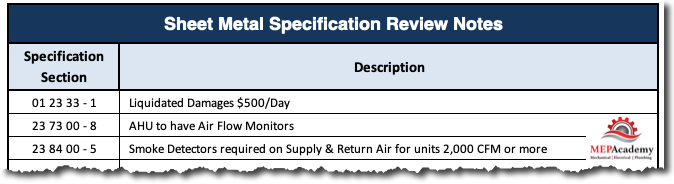

You need to record or highlight the important section of the specification for referencing during estimating review meetings or for the project manager if you are successful in winning the bid.

When recording the specification number onto any of the forms used for documenting, write out the full spec section description, such as: 23 73 00 – 8, 3.4 A. This identifies specification section 23 (HVAC Trade), section 73 00 (Air Handlers), – 8 (page 8), paragraph 3.4A. This will help you when you need to refer back to that section, saving you valuable time looking for the same section.

If you are using Blue Beam or Adobe Reader, then you can bookmark that page and section in the program. The idea is to record those items that differ from your standards and which will have a cost impact that you need to cover in your bid, in addition to risk factors to be aware of, risk such as liquidated damages. Liquidated damages are assessed against the contractor usually for not finishing the project on the scheduled completion date, and for each day they’re after a daily fine is assessed.

Reviewing the specifications is a very important step in the process of bidding a project. The specifications will set out the requirements of the materials and equipment that you will be responsible for providing along with the methods and standards of construction. This is not a step that you can avoid.

There are methods once you become familiar with the layout of specifications, in which to save time by looking where you know the most pertinent information is located, that which has the greatest impact on cost and risk.

Specifications are assembled in three parts as defined below.

Part 1 (General)

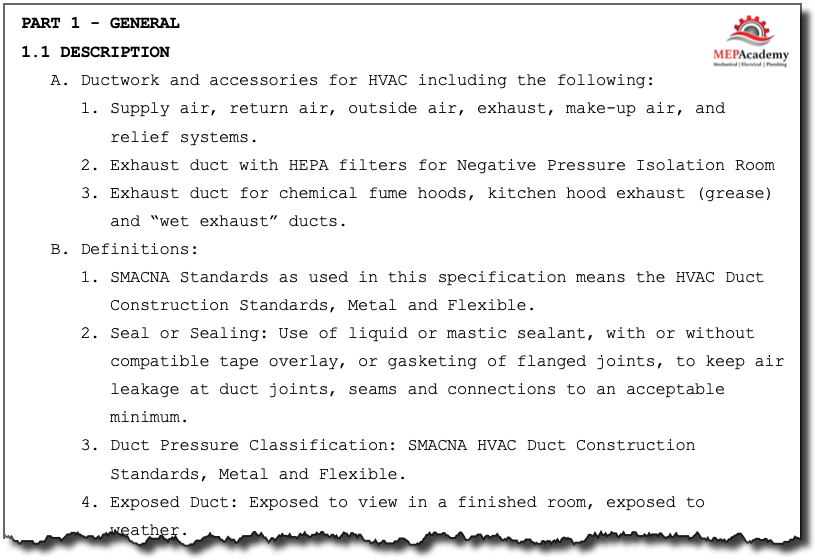

Reading any part of the technical section of the specification will begin with part 1, the General section. The general section of the specifications usually begins by giving a description of the scope of work contained within the section of the specification. This may include a brief outline of the equipment or materials contained in that section (see spec below). The requirements for shop drawings or submittals could also be stated in this section. It might also list related work in other sections of the specifications.

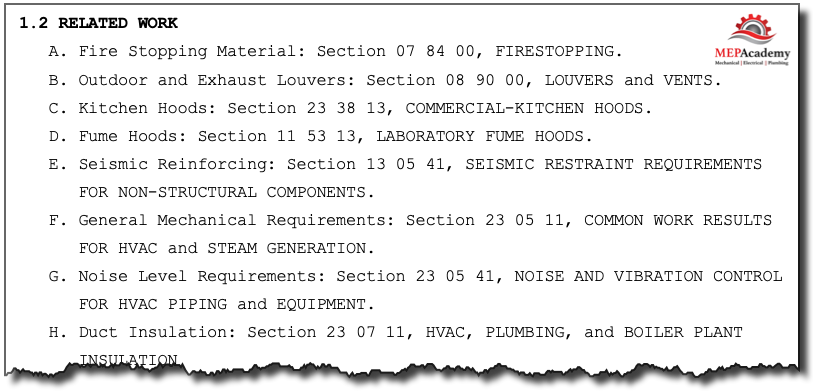

Section 1.2 Related Work

In part 1 of the general section of the specifications you will find section 1.2 “Related Work”. This portion covers other areas of the specifications that have related sections, some of which will be within your scope of work and others within other trades that isn’t part of your scope but needs coordination.

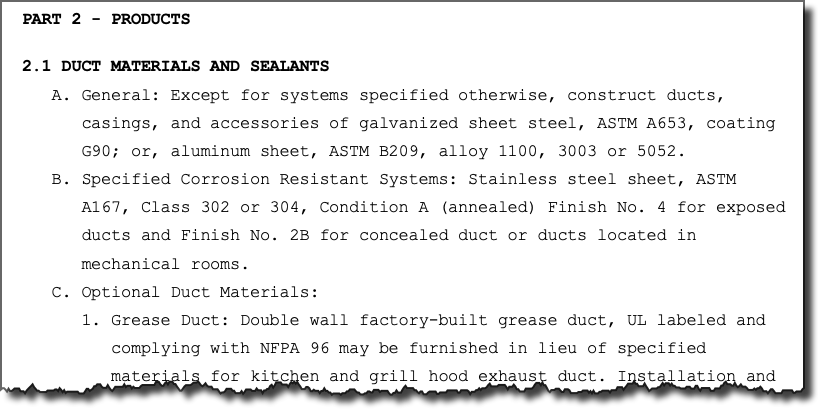

Part 2 Products

In part 2 will be the description of the technical requirements of the equipment or material. The performance, ratings and criteria that must be net if a substitute piece of equipment will be allowed. The equipment or material could be referred to by manufacture and model number, or generically described. Acceptable manufactures could be listed, those other than the one on the equipment schedule.

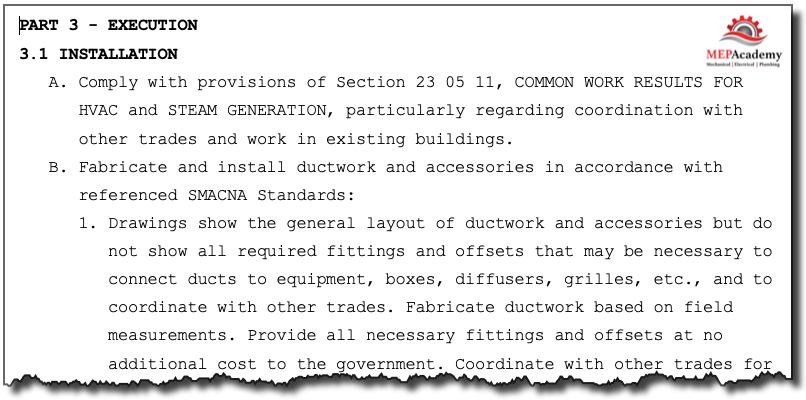

Part 3 Execution

Part 3 is the last part of the specifications and it describes the methods and quality of construction required. It could mention the start and test requirements for a boiler or that the equipment being installed has to be installed according to manufacture suggested methods of installation. It could mention the requirements of adjusting and cleaning of the equipment.

SMACNA Standards

The areas of concern for the sheet metal trade will be the construction standards specified for the air ducts and accessories. You will need to know the thickness of the material required for the various sizes of duct, and what type of seam and joint is mandated.

Often the specifications will cite SMACNA as the construction standard to follow when fabricating and installing the ductwork and accessories. SMACNA is the industry trade association that publishes construction standards in addition to other works related to the industry.

Construction Specifications Institute

Specifications are broken down by sections that correspond to the different trades. The Construction Specifications Institute (CSI) puts out specification division definitions that classify various trades into easily identifiable numbered sections and subsections.

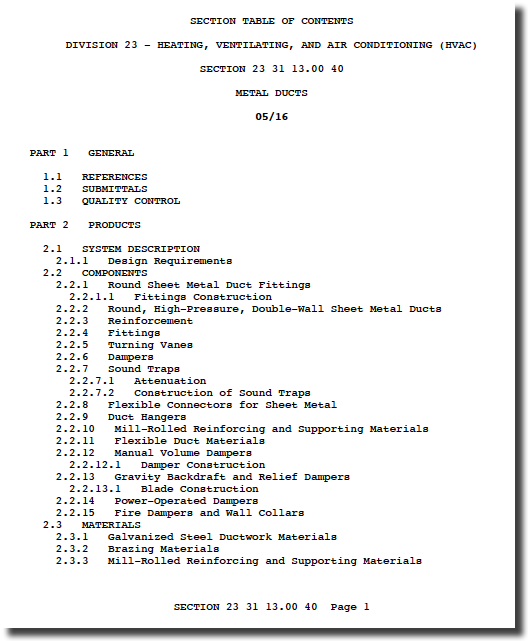

For example under their earlier version there were 16 divisions and the Mechanical Division was specification section number 15. The format was updated to now include 50 classifications of specification sections. Now division 23 is where you will find the specifications for “Heating Ventilating and Air Conditioning” and division 25 for “Integrated Automation”, the specification section for controls. Under division 23 is where you will find the HVAC sheet metal specifications.

Division 23 Heating, Ventilating and Air Conditioning

Within division 23 of the CSI specifications you will find the sheet metal section of the specifications where the information related to the allowable materials and methods can be found. Here are some of the important items to look for in that section of the specifications.

- Which duct seams and joints are allowed for round and rectangular ductwork?

- Are adjustable elbows allowed on round duct or is a more expensive type required?

- Material and gauge of metal required per duct pressure class or system.

- What are the hanger requirements, for both the upper and lower attachments?

- What are the requirements for thermal or acoustical lining of ductwork?

- Type of volume dampers

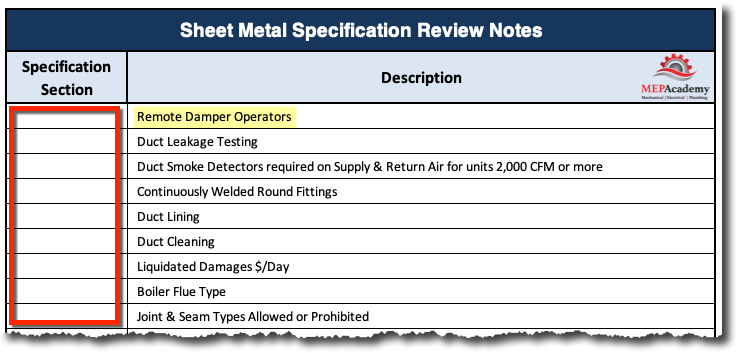

- Are remote damper operators required above inaccessible ceilings?

- Is temporary HVAC equipment required, if doing a renovation project?

- Duct pressure testing requirements

- Duct mounted smoke detectors. Who provides and installs.

- Is cleaning of the ductwork required? SMACNA has three levels of cleanliness.

- Are cost breakouts or unit pricing required?

What you are looking for in the specifications is for those items that have a cost impact and for the construction requirements that deviate from your company standards of construction.

In addition to the Division 23, it’s imperative that you determine if some of these other project requirements are listed under “General Conditions” of the specifications or are located in the projects frontend documents.

General Conditions

Liquidated Damages. This is a clause inserted into the construction contract that provides for a penalty, usually a stated amount per day for not meeting some aspect of the terms, such as the completion date. ($500/Day)

Project Schedule. The duration of the project is important when considering how much labor it will take to get the project completed within the scheduled allotted time frame. If the project schedule is too short, then you may need to work overtime in order to complete it on time. If the project schedule is for an extended period of time, you might have additional general condition cost, such as jobsite offices and rental equipment.

Bonding. Check to see if a performance and payment bond is required. These add cost to your bid, as your insurer will charge a fee to issue these if you are the successful bidder. These bonds ensure the owner that you will pay your bills to those who provide material and labor for company on behalf of this project and that you perform according to the contract. For large companies this cost will be less than 1% of the total cost of your portion of the construction, and for smaller companies this would most likely be greater than 1%.

Risk Management

Reading the specifications, RFP (Request for Proposal) or other documents related to the bidding of a project, the goal is to identify areas of risk. Once you identify those items of risk, then you can either mitigate, avoid or manage the risk with the foreknowledge of risk identification. Early risk identification is smart business practice as opposed to being surprised during construction that a certain risk wasn’t identified and now has to be dealt with.

Additional Personnel

There are some projects that will mandate that certain types of personnel be part of the construction team. These could include the requirement to have a full time supervisor, safety manager or Quality Control Expert. Read carefully through the project personnel requirements and whether they need to be full-time.

Listed Manufacture or Equal

Most engineered projects are designed around a certain equipment manufacture as indicated by the make and model number indicated on the equipment schedule. When reading the specifications you will be looking for the “or Equal” reference where the list of approved manufactures are listed.

Specification Review Checklist

You should have a standard checklist that includes the most common items to look for when reviewing the specifications. The checklist provides a convenient reminder of those items that typically can be found to have a cost impact. Record the specification section and page number for quick reference.

Introduction to Sheet Metal Estimating (Free Course)

- Chapter #1 – Introduction to Sheet Metal Estimating

- Chapter #2 – How to Read the Specifications

- Chapter #3 – Understanding the Front End Documentation

- Chapter #4 – Sheet Metal Estimating Standards

- Chapter #5 – Labor and Material Databases

- Chapter #6 – MEP Estimating Software