Welcome to the course that will teach you how to Estimate HVAC Sheet Metal for the commercial industry. If you are mostly working in the HVAC residential industry, then this course will allow you to see what is involved to enter the commercial industry, while also giving you good estimating practices. In this course we will cover the steps needed to complete an HVAC Sheet Metal Estimate from material takeoff to field laboring.

The first section will cover the requirements needed to read engineered drawings, and what to look for in the plans and specifications that are applicable to the HVAC estimate. This includes understanding how to read the symbols used on drawings, and how to read the various CAD generated lines and the basic drawing layout. The building should be built just as its shown on the drawings and as indicated according to the specifications.

At the end of each section, there will be a short quiz to help you remember the material that was covered in that section.

The drawings that are used to bid the project will become part of the contract if your company is the winning bidder. So it’s important that you read through the drawings and specifications completely to ensure that you have all the cost covered to make for an accurate bid, one that will provide a profit for your company.

There are several different sets of drawings created for the construction or renovation of a building. The one that we will be focusing on are the Mechanical set, specifically the HVAC portion of the mechanical drawings.

Who are the Players in a Construction Project

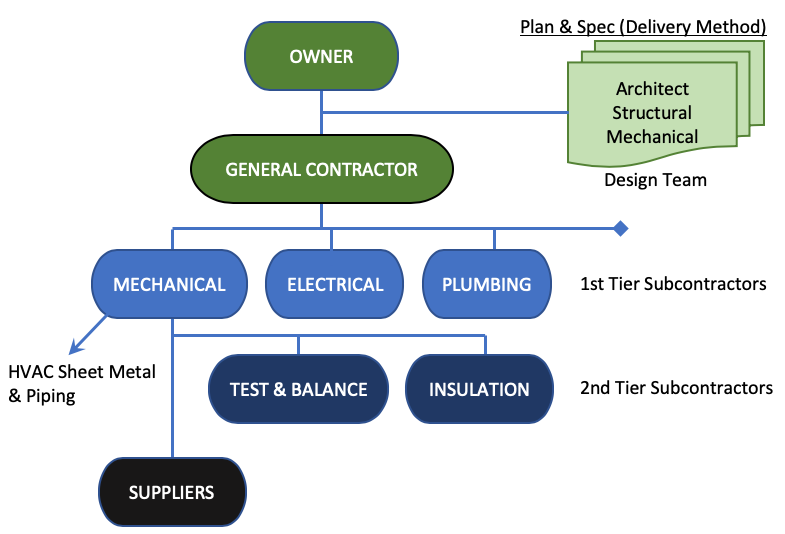

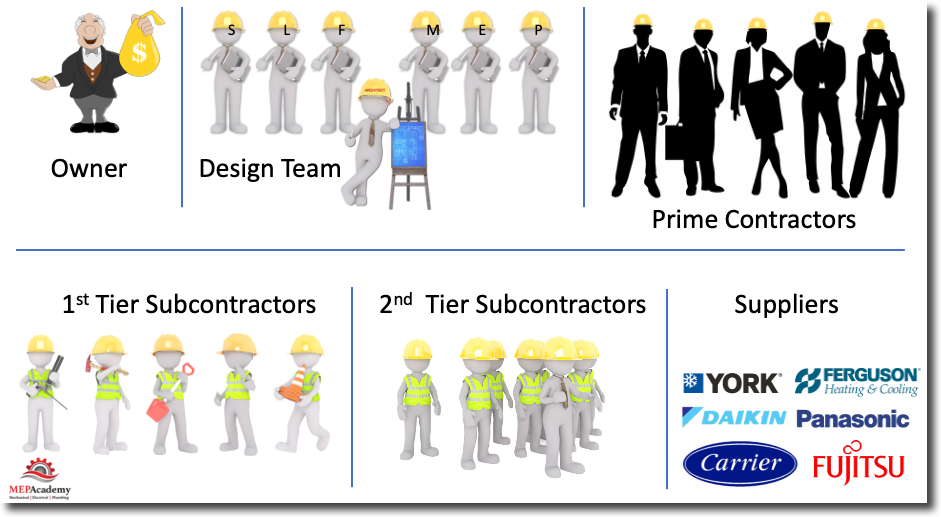

There are various players in any construction project. Depending on the delivery method, which there are three that are mostly used in construction: Plan and Spec, Design/Assist, and Design/Build. The parties to a construction contract are as follows.

Project Owner (Private or Public)

The owner can be a public or private entity and is the one behind the reason or purpose for building or renovating a construction project. In the private sector this could be an individual or more likely a corporation. For the public sector this is usually your local, state or federal government which has more stringent and regulated bidding requirements then the private sector.

The owner provides the money or can secure the funds for the project. They will hire the design team under the Plan and Spec delivery method, which includes the Architect and the associate trade engineers such as the Mechanical, Electrical, Plumbing and Structural engineers.

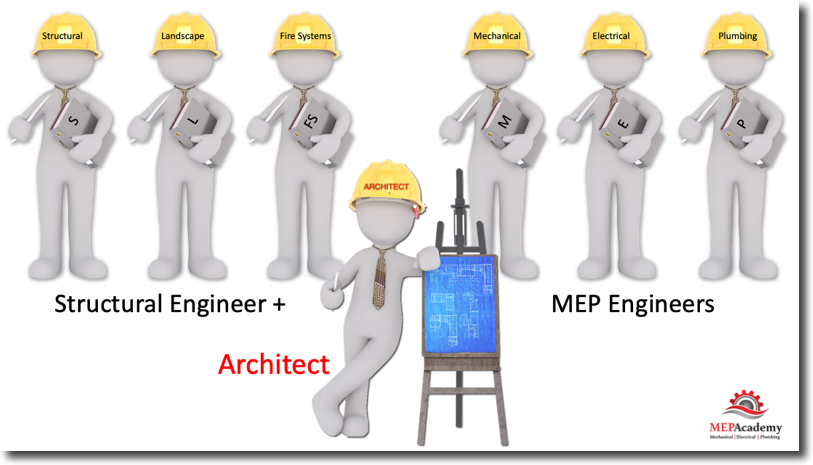

Design Team

Under a plans and specification delivery method, the private sector owner will hire an architect to carry out the design according to the owners directive and needs. The architect will hire all the other designers needed to provide a complete set of engineered drawings. These drawings will then be sent out with an (RFP) request for proposals from a list of approved general contractors.

General Contractors (Prime Contractors)

The General Contractor will manage the construction project, using some or none of their own labor, and for which the owner contracts with for the construction of the project. The General Contractor will invite 1st tier subcontractors to provide bids on their respective trades, this would include the MEP (Mechanical, Electrical, Plumbing) trades, in addition to all the other trades.

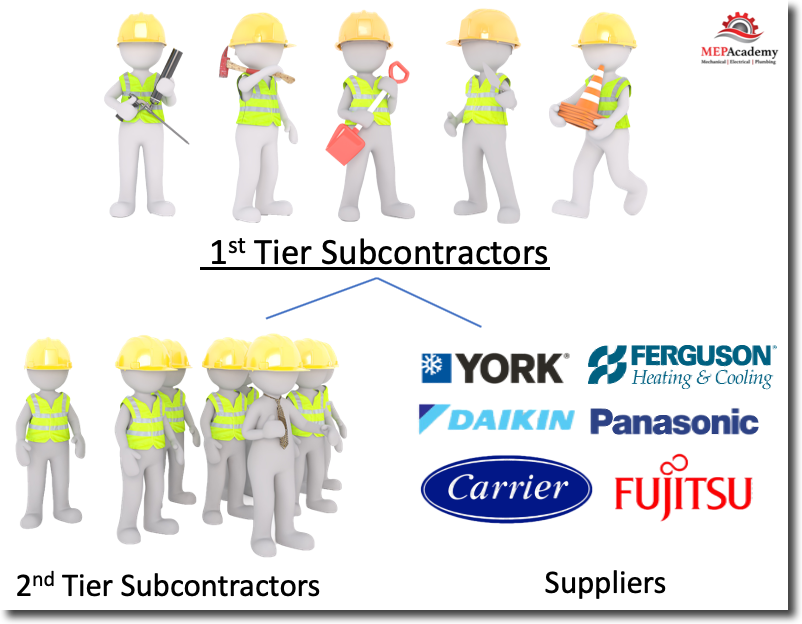

1st Tier Subcontractors

This is the level where the mechanical, electrical, plumbing and all other trade contractors will receive their subcontract agreement from the general contractor. There are instances when the contract will be directly with the owner, but in the most cases a General Contractor will be used in a plan and spec delivery method. This is the first tier of subcontractors to the general contractor, the next tier will be the subs of the subs.

2nd Tier Subcontractors

These are the contractors that get hired by the first tier subcontractors, which makes them the second tier subs to the general contractor as shown in the diagram. If you are the mechanical contractor, then you might hire an Water and Air balance company or an insulator to insulate the air conditioning ducts and piping.

Suppliers

You will also have agreements in the way of purchase orders with suppliers for the purchase of the equipment and materials needed to carry out the mechanical portion of the scope of work. During the bidding process they will provide quotations based on the plans and specifications as designed by the mechanical engineer.

Estimating by Construction Activity/Construction Work Element

Before estimators can create a detailed estimate, projects must be broken down into smaller parts, so each part can be individually estimated. A subset of material, equipment, and labor estimates is created for each construction work element.

For example to install a 50 foot section of duct in a high bay area would require the following:

- (Material) The material estimate identifies required quantities of duct, fittings, air distribution, and any sheet metal accessories.

- (Rentals) The sheet metal estimate identifies that a scissor lift is required to install the hangers and ductwork.

- (Labor) The sheet metal takeoff provides the quantity of hours and the number of man-days required to perform work.

- (Fabrication) The takeoff identifies the pounds of sheet metal that has to be fabricated or purchased.

Items required for Estimators

The following items should be provided to you by the salesperson or the general contractor, or whoever is responsible for bringing in the documents.

- Drawings and specifications (Plans and Specs)

- RFP (Request for Proposal) and a narrative description of the project’s scope

- Bid Forms if applicable

- Project schedule

- Bid conference or job walk date

- Bid date and time

- Method of delivery for bid

What makes a Good Estimator?

The estimator must;

- Visualize the separate operations of the job as the work would progress through the various stages of construction

- Read, conceptualize, and obtain measurements from drawings

- Have knowledge of mathematics, previous construction experience, and a working knowledge of all branches of construction

- Have good judgement when determining what effects numerous factors and conditions will have on the construction of the project and what allowances should be made for each of them including labor adjustments.

- Do accurate work and present it in a complete and organized format for an estimate review and handoff to operations if the project is successfully won.

SMACNA Company Spotlight – Black & McDonald

Black & McDonald, a Canadian based multi-trade contractor with offices across Canada and the United States. Watch this video to learn a little about how an experienced HVAC contractor conducts business. You can see their fabrication shop is setup to be efficiently run.

Prequalifying The Bid

It’s not feasible to bid everything that is available, as you will spend a lot of time and money chasing after work that you have very little chance of winning. This is why it’s important that you have some method to determine whether a certain project is worth the time and money to pursue.

Prequalifying is a set of questions that you ask of the opportunity to determine if it rates high enough to warrant pursuing it further. Here are some questions you might ask about the opportunity before you make a decision to pursue it.

Bid Risk Assessment

Having some form of rating system will help you make a decision whether or not to bid a project based on some form of evaluation of the opportunity for success, such as the MEP Academy “Bid Risk Assessment” form which is part of the MEP Academy Estimating Spreadsheet.

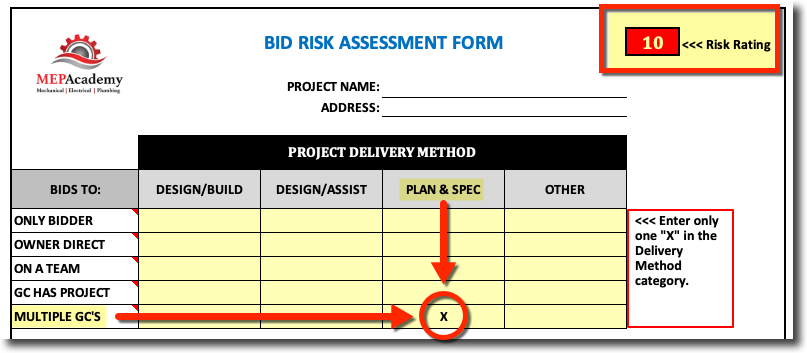

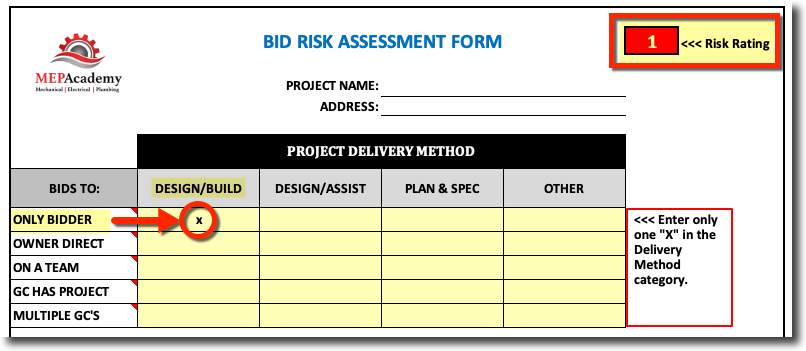

Project Delivery Method

There are several delivery methods from Design/Build to Plan & Spec. Each delivery method has more or less risk associated with it. The delivery method runs horizontally across the top header, and the entity accepting the bids runs vertically on the chart.

Design/Build means that you are responsible for the design and construction of the project. This means you either hire the mechanical engineer to be part of your team or you have in-house engineers that will design the project. This would make you the design-build contractor.

Design/Assist means that there is a 3rd party engineer that you will assist in the development of the materials and methods of construction and any value engineering ideas you have to make the project meet the owners budget and performance objectives.

The Plans and Specifications mean that there is a 3rd party engineer that designs the project and then mechanical contractor compete to build the project according to those plans and specs. You the contractor have no responsibility of the design, and should receive a change-order for any changes or corrections to the drawings that add cost to the project execution.

Design/Build projects allow you better control of the design, materials and methods of construction and so they usually allow for better margins or profits. This would be considered less risky and earn a lower score, meaning less risk on the assessment form and a better opportunity.

Plan and spec projects are usually more competitive and the opportunity for making profits that are comparable with the design-build delivery method are less, so this would rate a higher risk value.

Projects Bids to

The vertical column assesses who your competition is and who you are bidding to. Being the “Only Bidder” as shown on the top row would of course be the best position to be in as a bidder, so this would rate a low value or low risk factor.

The last row shows having “Multiple GC’s”, that is there would be more than one general contractor that you would have to submit your price to in order to have the greatest chance of winning the project. With more general contractors, there will be more mechanical contractors bidding, as each general will invite their typical three or more regular mechanicals to bid. This is the worst case scenario as the competition will be high and the margins driven lower in order to compete and win the project, so this gets the worst score in this category.

Looking at the above “Bid Risk Assessment Form” you see that bidding on a project that is Plan and Spec’s with Multiple GC’s will get you a high score of “10” points, which isn’t good. The risk assessment score is like a golf score, the lower the score the better, or in this case the less the risk the lower the score. Looking at the same form shown below, but this time we are bidding a Design-Build project and we are the only bidder, this gives you a score of “1”, which is good. Obviously this opportunity has less risk in the way of being the successful, which is what this form was created to determine.

- How many other Sheet Metal bidders are there? You don’t want to be bidding against a large pool of bidders, unless you think that you have a lower overhead cost then the competitors.

- How many General Contractors are bidding the project? If you are bidding to a general contractor, then you will need to know if they are bidding against a pool of other general contractors. The more general contractor there are bidding the project, the less chance you have of winning the project.

If there are four generals bidding and each one of them invites four mechanical contractors to bid the project, then it’s possible that you are one bidder out of sixteen possible sheet metal contractors. What’s the chance that you will win against fifteen other bidders. If you do win, what’s the chance you’ll make money having been the low bidder out of sixteen bidders?

- Does the project have funding approved?

- Is the schedule reasonable and do you have the field labor to perform the work when required?

- Is the decision based on low price?

- Are there any non-union bidders? If you are a union contractor trying to compete against non-union contractors you could be at a disadvantage on labor cost, unless the union grants some form of concession.

- Do you have a relationship or experience working with the general contractor or owner?

Estimates that Lose Money

If you are an estimator long enough, you will have estimates that don’t make a profit as anticipated at time of the initial bid. This can be caused by many reasons. Some of the most common include;

Errors. Some of the causes of errors include not reading all the specifications for the requirements, or reviewing all the details and notes on the drawings. Errors can occur because of being rushed to get a project bid without the time to do your due diligence with all the bid documents.

Labor Productivity in the field may not have produced according to the assumption made at bid time. This could be due to unforeseen project conditions that increased the difficulty for the installers to hit the labor productivity factors assumed at bid time in the estimate.

Was the estimate short on material or equipment cost?

Was there adequate rental equipment cost in the bid, including the proper duration or the time required for its use?

Was the project schedule extended, requiring additional cost for extended general conditions?

Whatever the reason, you should have a closeout meeting with the project management team to determine a better approach on the next project that poses similar risk possibilities.

Sometimes it’s just not possible to predict how a certain general contractor or owner will manage the construction project, and how that will impact your labor. By having a strong project management team on the project to ensure that any legitimate change order is procured can help minimize or mitigate the risk of poor management of the construction by the general contractor or owner.

Bidding on Federal Construction Projects

All GSA (General Services Administration) design and construction contracting opportunities are advertised on the Federal Business Opportunities (“FedBizOpps“). To receive drawings and specifications for projects, contractors must be registered in the System for Award Management (SAM) system and in FedBizOpps, as drawings and specifications are usually issued electronically there. Announcements will contain instructions on obtaining classified drawings and specifications which are not distributed through FedBizOpps. The following areas are included in construction.

Beginning an Estimate

Deciding on whether to bid a project or not is sometimes beyond the estimators role. Often, a salesperson, contract executive, construction manager, Vice President, owner or some other individual will make the decision of whether or not to proceed on a bid. Some of the factors that go into the decision could be;

- What is the availability of our staff to run this project?

- What is the projected availability of field personnel to install the project according to the project schedule?

- Who is the competition?

- Who are you bidding to?

- Do they pay on time?

- Do they manage a project in a proficient way?

- Are there multiple general contractors?

Once the decision has been made to proceed with a project it is best to begin by following the procedures outlined in this course, you will ensure that each and every estimate that you assemble will be done in the most efficient and fail safe method, thus avoiding costly mistakes.

Bid Schedule

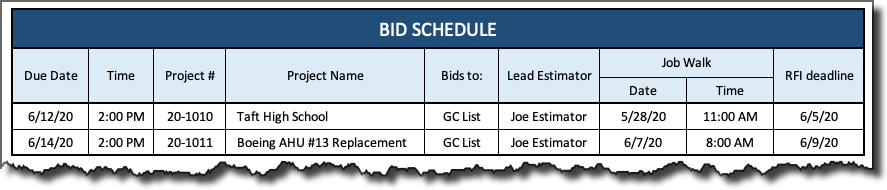

After the decision is made to pursue a project, then there should be somewhere that the name, date and time is displayed for the estimating team and for vendors that visit your office.

Below is the minimum information that you should have when tracking bids and their due dates.

Due Date & Time: When is the bid due and at what time? Depending on whether the bid is public or private can make a big difference on the actual submission time. Most public entities won’t accept bids that are submitted a minute late, while private companies have more leeway.

Project Number: This should match the project number entered on the bid log above in order to track all the records related to the bid.

Project Name: Usually this is the name on the drawings and specifications and what everyone will referred to, especially working with your vendors and subcontractors.

Bids To: List who the bid will be sent to. If it’s a public bid then there could be specific instructions in the bid documents on how to address the envelope and how many copies are required.

Lead Estimator: If you have multiple estimators, then list the estimator assigned to lead the estimate.

Job Walk: List the date and time of any job walks. There are some job walks that are mandatory in order to submit a bid. At these job walks or project conferences there will be a sign-in sheet to confirm to everyone who was present at the mandatory meeting.

RFI Deadline: You will need to study the drawings and read the specifications to derive at any questions that you might want to submit as an RFI (Request for Information). RFI’s help clarify items on the drawings, specifications or from the job walk site visit.

Bid Log

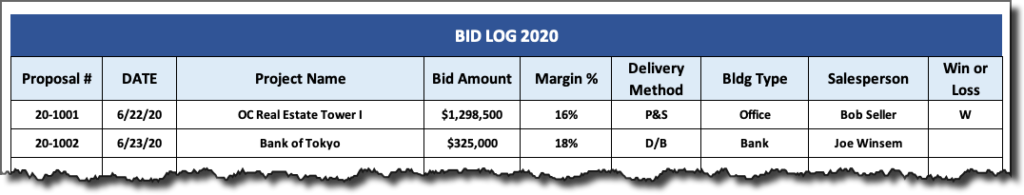

Next you will want to record the project into an estimate log and assign it a proposal number. This will allow you to provide a year-end report on various parameters related to success ratios, project types and delivery methods.

Estimating Bid Log

After you finish the estimate, you should record the pertinent information into a bid log. If you are using one of the many software programs for tracking bids, then this would be automated with that program.

The bid log should be something similar to the above. The bid log is used to keep track of the order in which projects arrive into the estimating department and for reference when looking back to check an old estimate.

Proposal #: Put the estimate number on all documents related to that bid, especially the estimate spreadsheet and proposal. The numbering system shown above includes the last two digits of the year, followed by the number of the project bid in that year. As shown in the example above (20-1001), this bid was the first bid in the year 2020. You should create a estimate tracking system to keep track of the estimates that you work on. This will make it easier for you to reference at a later date.

Date Received: Enter the date you received the documentation and the name of the project.

Bid Amount and Margin After the project bids you can enter the bid amount, margin and latter if you won or lost the project. You can include any information that you deem important for your company to track.

Delivery Method: P & S is the abbreviation for Plans & Specifications and is your typical Design-Bid-Build process of construction. D/B would indicate Design-Build, a much different process than plan and spec. This course will cover the P&S (Design-Bid-Build) process, but many of the procedures are applicable to both. See our other course on Design/Build.

Building Type: Tracking the building type is for historical reasons. Often your looking for a project to compare an estimate that is of a similar building type.

Salesperson: Indicate the individual that brought the project into the estimating department or the individual that is responsible for presenting the project proposal to the company receiving the bids.

Wins and Losses: The bid log will help to total the dollar amount of the projects won and loss for the year, and the success ratio.

Bid Notification

There are a lot of software programs available that automate vendor and subcontractor notification.

List the name of the project, the engineer and the bid date. The reason the engineer is important is because some vendors assign their salespeople according to who the engineering firm is. The vendor bid notification should be filled out early in the process, so that everyone that needs to provide pricing has a reasonable amount of time to do so.

Poor estimating practice is to notify the vendor and subcontractors late in the bidding process, forcing them to be hurried in preparing their bid. The less time you give your vendors and subcontractors to prepare the more likely that their price will be uncompetitive.

Introduction to Sheet Metal Estimating (Free Course)

- Chapter #1 – Introduction to Sheet Metal Estimating

- Chapter #2 – How to Read the Specifications

- Chapter #3 – Understanding the Front End Documentation

- Chapter #4 – Sheet Metal Estimating Standards

- Chapter #5 – Labor and Material Databases

- Chapter #6 – MEP Estimating Software