Overview

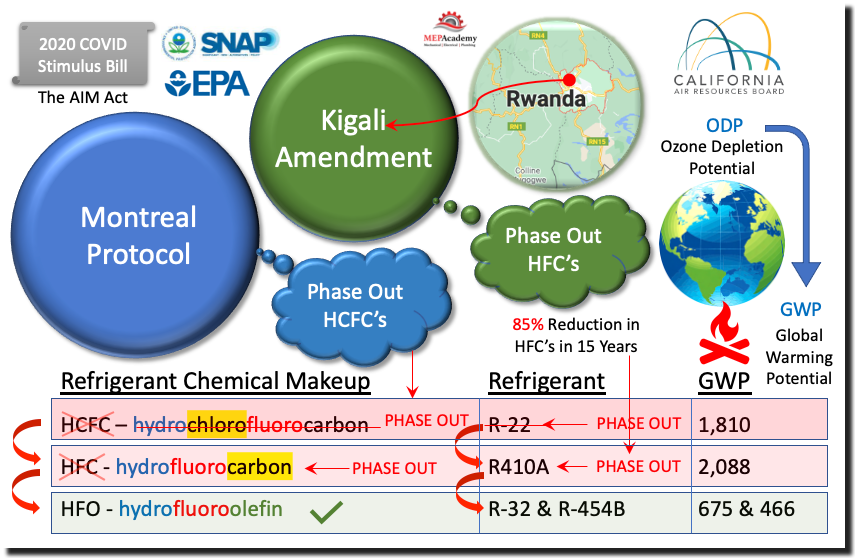

The push for lower global warming potential (GWP) refrigerants is causing a shift in the refrigerants that will be used in future equipment. The recently passed legislation of the American Innovation and Manufacturing (AIM) Act, which was part of the December 2020 COVID stimulus bill, has given the EPA authority to regulate refrigerants based on GWP.

The proposed new regulations and standards will mean additional training for technicians doing the installations as the flammability of the proposed replacement refrigerants are slightly higher than what is currently being used.

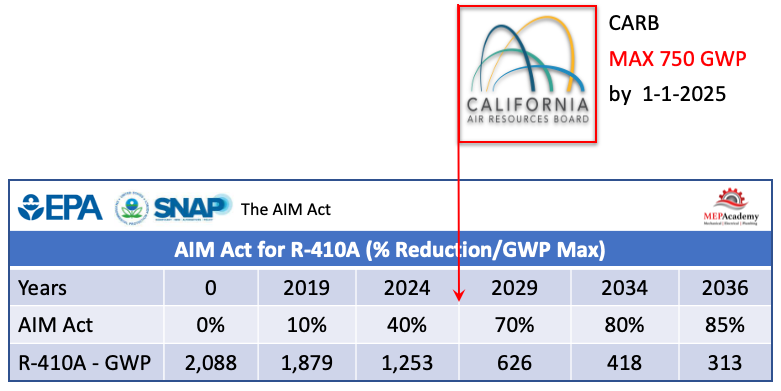

For those in California, one of the more progressive states for energy and the environment, these phaseout dates may come faster than a federal mandate. The California Air Resources Board (CARB) is looking at January 1, 2025 for the implementation of a maximum GWP of 750, which would eliminate the widely used R-410A in most unitary and split systems.

Refrigerant Safety Codes and Standards

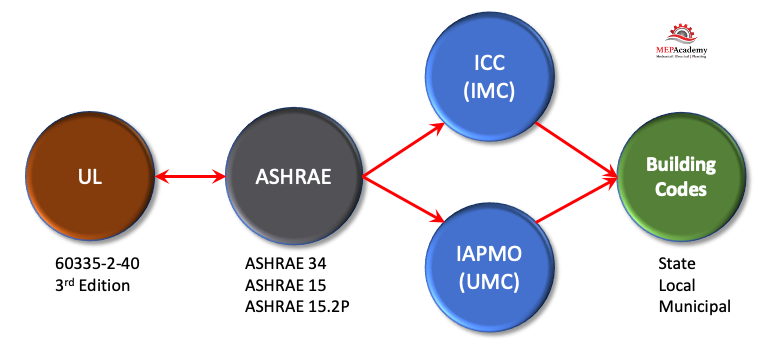

The use of these new A2L refrigerants will require that the building codes of state, cities and municipalities be updated before the wide spread adoption. The majority of these requirements will be written into UL 60335-2-40 3rd edition, ASHRAE 34 and ASHRAE 15 – 2019. (ASHRAE 15.2P – Residential).

The new ASHRAE 15.2P for residential application is set to be ready for the January 1, 2025 transition.

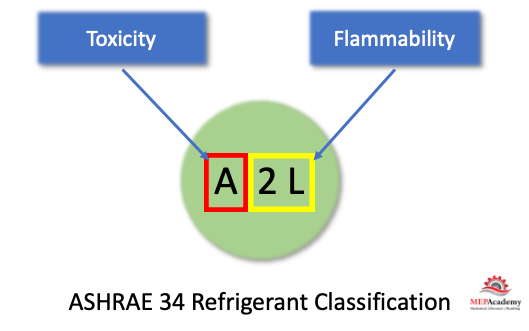

Mechanical ASHRAE 34

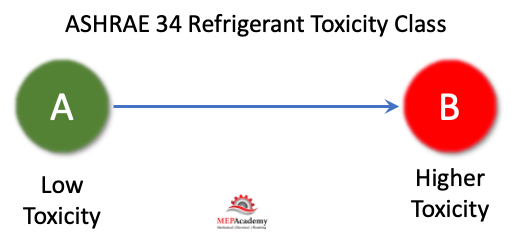

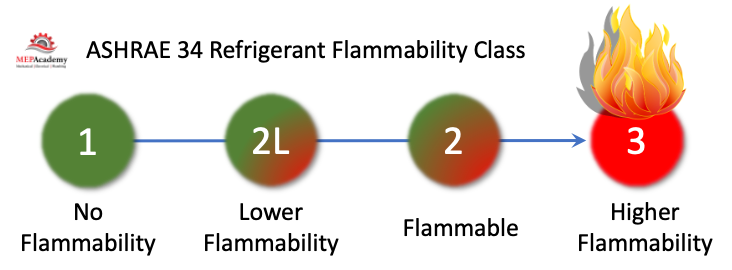

ASHRAE 34 classifies refrigerants for safety. The first letter as shown below represents the toxicity class of the refrigerant. The second number/letter identifies flammability.

There are two classes of toxicity, class A or B, with B considered more toxic.

Flammability has four classes (1, 2L, 2, or 3), with 3 being the highest flammability.

ASHRAE 15

Those familiar with ASHRAE 15 for commercial projects are aware of the requirements, but what about the new proposed ASHRAE 15.2P for residential projects. ASHRAE Standard 15 is a Safety Standard for Refrigeration Systems in the event of a catastrophic leak. ASHRAE is getting close to finalizing the standard that will apply to residential buildings (ASHRAE 15.2P), but there are still the state and local code authorities that will need the standard adopted into their code, during their code cycles.

The desire for ASHRAE is to have a model standard (ASHRAE 15.2P) adopted by building codes, thereby giving guidance on the safe application of the use of A2L refrigerants in residential settings.

Checkout Refrigerants hereThe slight increase in flammability with the proposed use of A2L refrigerants like R32 & R454B will require additional safety measures to ensure that a catastrophic leak will not cause harm to the occupants. This hazard can be mitigated by making sure that the amount of refrigerant charge is limited based on floor area or that some form of ventilation is activated when a leak is detected.

Why hasn’t ASHRAE standard 15 applied to residential properties before? The classification (A1) by ASHRAE Standard 34 of the refrigerants currently used in residential properties were considered safe if a leak occurred within the occupied space. The assumption was that the acute toxicity exposure limit would not be exceeded in a catastrophic leak. The proposed new classification of refrigerants (A2L) to be used in residential properties are considered slightly flammable to a greater extent.

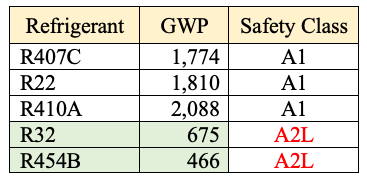

The move to the A2L refrigerants is driven by the desire to have a lower global warming potential (GWP) refrigerant.

So what will be some of the new requirements? Since the new A2L refrigerants are slightly more flammable, there needs to be a way to mitigate any chance of a fire.

ASHRAE Standard 15.2P

This standard will cover the safe design and installation of residential refrigeration systems. Historically residential refrigerant system were considered safe because they use class A1 refrigerants and the level of acute toxic exposure wouldn’t be exceeded in a catastrophic leak.

The push for lower global warming potential (GWP) refrigerants has manufacturers proposing refrigerants classified as A2L (Low toxicity & Low flammability), such as R32 or R454-B. Currently the widely used R410A in packaged and split systems is classified as an A1 (Low Toxicity & No Flammability) refrigerant. This increase in flammability is what has generated the additional concern and need for additional safety measure.

Refrigerant Tool Compatibility

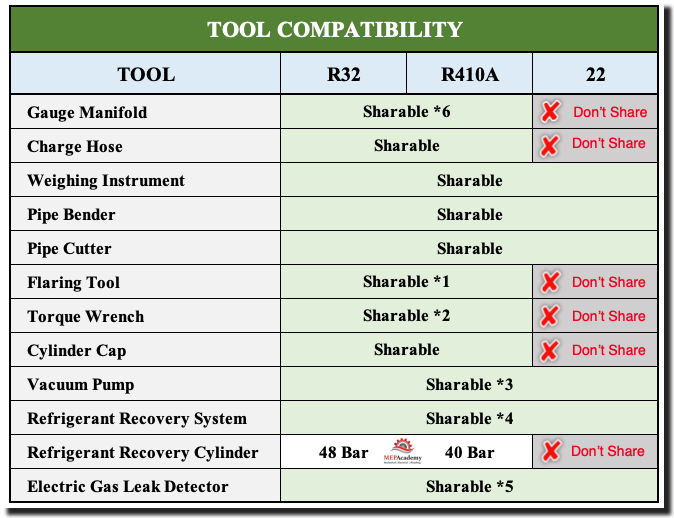

Can you use the same tools that you have been using for R-22 and R-410A with the newer refrigerants?

Changing from R22 to R32

R32 operates at a higher pressure than R22, and R32 uses a different type of oil. The oil from the R22 system could cause sludge or other issues, therefore all the tools used for your R22 systems should not be used for R32, such as gauge manifolds and hoses. Have a dedicated manifold and hoses just for your R32 systems.

Changing from R410A to R32

Since R32 uses has similar operating pressures and oil properties as R410A, so the use of separate manifolds and hoses isn’t required if so stated by the tool manufacture.

So, you won’t be able to replace just one component of an R-22 system with that of an R-32. If you replace an R-22 Outdoor unit, you’ll need to replace the coil, but you maybe able to use the refrigerant piping.

- *1: R22 type can be used for R32 & R410A by changing the work process.

- *2: Dimension of width across flats of flare nut is different between R32 & R410A and R22 (4/8″ & 5/8″ only. Other flare nuts can be shared)

- *3: When using an R22 type for R32 & R410A, use with a reverse flow preventive adapter.

- *4: HFC recovery systems can be shared if they have been certified by the manufacturers to be supporting the relevant HFC’s.

- *5: Even if a detector supports R22, if the detector does not support HFC (R32, R410A), it cannot be shared. Always check with the tooling manufacturer.

- *6: Sharable when temperature is recalculated

Additional Safety Measures

These additional safety protocols will fall partly on the installing technician and contractor. This will include additional safety training and site analysis for spaces that maybe too small to handle a catastrophic leak and maintain the maximum exposure limit of the refrigerant. One of the questions becomes, is a refrigerant leak detection system required?

Also keeping track of sources R410A before the 40% reduction occurs in 2024 will be important for servicing existing equipment.

The equipment manufactures need to provide clear installation instructions based on the safety parameters required of their choice refrigerant and the size or quantity of the refrigerant. But how does this work with a split system, where you won’t know the total volume of refrigerant until all the piping has been installed.

Additional Requirements for Technicians

Will the service technicians be required to calculate the total refrigerant in the system to ensure it doesn’t exceed the allowable limits? Will the service technicians be required to calculate the allowable area of the spaces served?

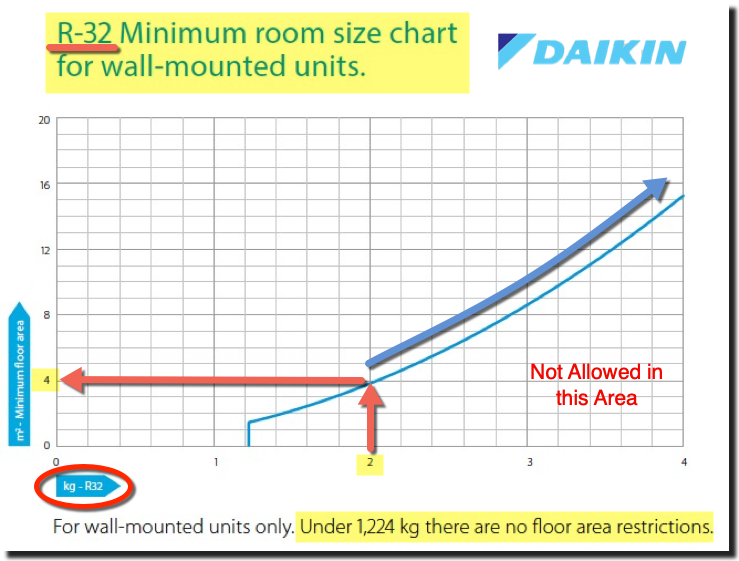

It has been mentioned that there could be lookup tables to help the technician determine the allowable floor area based on the refrigerant charge as shown in this chart for Daikin European model of their wall-mounted unit using R-32 refrigerant.

In the example shown in the chart above, if you have 2 kg (4.4 Lbs) of R32 in the system, then the minimum floor area is shown to be 4 m2 (43 Ft2).

You won’t just be able to change out an old outdoor unit that was using R410A without also replacing the indoor coil, as both must be UL rated for the new refrigerant class A2L. It appears that you will be able to use the existing piping but will have to ensure through a more rigorous testing protocol that there isn’t any existing leaks.

There is still plenty to be worked out before we know exactly what the installing technicians will be required to do in addition to what was the standard protocol using R22 or R410A. How much time will this add to an installation, or how much training will be involved, or for that matter, record keeping?

Refrigerant Safety Training

There is training currently available for flammable refrigerants that you can find provided by the Air Conditioning Contractors of America (ACCA) and by the North American Technician Excellence (NATE) in addition to other trainers.

UL Standards

Here are some for the highlights for the updated UL standard;

- Products using flammable refrigerants are required to be constructed so that any leaked refrigerant will not flow or stagnate near ignition sources such as electrical components.

- Enhanced requirements are applied to the refrigerant tubing, joints and fittings on equipment having a flammable refrigerant, to reduce potential sources of leaks by minimizing the number of joints and additional protection from physical damage.

- Any products using a flammable refrigerant other than a 2L must be factory sealed, factory charged single package units and service ports are not permitted.

- No hot surfaces greater than 700-degree C are allowed in an area that may be exposed to leakage of flammable refrigerants.

In addition, there will be a limit to the amount of refrigerant in a system based on the Lower Flammable Limit (LFL) of the refrigerant being used in relationship to the floor area it serves. This is not a problem with small system, but as the Refrigerant system gets larger there will be a corresponding need to ensure that any of the rooms served are large enough to handle a catastrophic leak and stay within the LFL limits.

If you exceed those limits than you’ll need some form of mitigation strategy, like a continuously circulating supply fan to help dilute the leak or you’ll need a leak detection system.

Using a leak detection system will activate several key functions to ensure a safe environment. The leak detector when activated can ensure that the supply fan is locked to run continuously to dilute the space while at the same time turning off the compressor to avoid pushing more refrigerant into the space. Also, close any safety shutoff valves in the refrigerant system to stop the bleeding of refrigerant into the space while opening zone dampers to allow more air circulation. Refrigerant systems located within a closet or whose volume of refrigerant is large may require natural and/or mechanical ventilation.

Refrigerant Leak Detection Systems

When are refrigerant detection systems required? What are the defining characteristics of the HVAC refrigerant system that mandate you install a refrigerant detector? The refrigerant detector needs to indicate the type of refrigerant used.

The refrigerant detector can’t have an adjustable set point to initiate mitigation action. You can see why this could be a problem if it was adjustable. If allowed the ability to adjust, then it’s possible the setting would be set higher than the allowable safe limits.

For spaces that exceed the allowable quantity of refrigerant for the floor area served a refrigerant leak detector that senses a loss of pressure in the refrigerant circuit would be required.

If the leak detector senses a loss of pressure than the controls would activate the supply fan to provide dilution air to lessen the accumulation of concentrated amounts of refrigerant. The HVAC equipment is not allowed to have an internal ignition source due to the risk of flammability of the class A2L refrigerants, per UL 60335-2-40.

Requirements for Refrigerant Leak Detection Systems per UL

- Indicating type detectors are required to be factory installed by the manufacturer with sensors optimally located to detect any leaks.

- Refrigerant leak detector sensor set point is factory set and sealed with no field adjustment permitted. Routine factory inspections are conducted by UL as part of the listing requirements. Detector markings identify the manufacturer and refrigerants used.

- The leak detection system is required to activate at a maximum concentration of < 25% of the LFL of the refrigerant being used in the equipment. This 4-times safety factor helps ensure flammable concentrations are not reached.

- Detectors turn on available mitigation devices such as circulation fans.

- Self-test protocols run every hour to ensure proper operation and function. In the event of detector failure, the circulation fans activate and maintain a required airflow to prevent flammable concentrations from forming. This fail-safe mode is maintained until the detector is replaced.

- The sensor shall not be subject to poisoning due to common household and workplace contaminants that shall not damage the sensor or produce false alarms or nuisance trips per Annex LL of UL 60335-2-40.

Various Refrigerant leak detectors are currently being evaluated by the Air-Conditioning, Heating and Refrigeration Technology Institute (AHRTI). The Institute is assessing the capabilities of currently available refrigerant detectors to meet the response time required by the safety standards, with setpoint(s) determined in a manner to meet the safety standard considering related issues such as upper detection limits, accuracy and calibration, drift over time, sensitivity to environmental conditions (temperature, pressure, humidity and vibration).

Residential installation was simple before this quickly arriving change that will require a safety review of your companies handling and installation practices for these refrigerants.

Some equipment may come with a designated minimum allowed room area right on the equipment label, such as with spot coolers or room air conditioners.

HVAC Equipment Certification

Not to confuse the issue but HVAC equipment manufacturers (US & Canada) will need to certify their equipment to meet the revised addition of UL 60335-2-40, the standard that covers electric heat pumps, air conditioners and dehumidifiers.

System Charge

The allowable amount of refrigerant in the system will depend on the LFL and the floor area of the room that is served by the system.

Resources:

UL Refrigerant Detector Requirements