Steam Heating System Basics. Learn how steam systems work and where they’re used in the HVAC Industry. We’ll show you three systems that use steam for heating.

If you prefer to watch the Video of this presentation, than scroll to the bottom or click this link. Steam Heating System Basics.

Steam heating systems are found in Commercial, Residential, and Industrial Facilities. They can be found in central plants of large University Campuses and in District Steam Distribution systems.

Steam is used in laboratories, breweries, food processing, industrial plants, in hospitals for sterilization, and in the production of electricity through steam driven turbines. There are two basic system types, direct and indirect steam systems.

We’ll discuss the basic indirect steam heating system.

Steam is moved through the system of pipes by the pressure created when water is vaporized into steam. There are no pumps required, as the higher pressure within a steam system causes it to move through the pipe, valves, and equipment.

We can witness this on any stovetop when a tea kettle whistles. As the water turns to steam it seeks to escape the tea kettle through the small opening and whistles as it escapes.

Condensate from the steam condensing needs to be brought back to the system for reuse unless the steam is used for a process. The condensate can be brought back by gravity or with the use of a condensate return pump.

When heat is added to water its temperature will rise until it hits the point of evaporation, at this point it changes from a liquid into a vapor or steam. This occurs at 212 Fahrenheit or 100 degrees Celsius at normal atmospheric pressure.

If we enclose the water within a steam boiler with no opening to the atmosphere, the steam will increase the pressure within the system as the molecules move faster and faster, colliding into each other and the walls of the boiler looking for a lower pressure escape route like the hole in the tea kettle.

If we connect piping to an opening in the steam boiler the steam will exit the boiler into the piping without the need of a pump, but just by the pressure created by the steam.

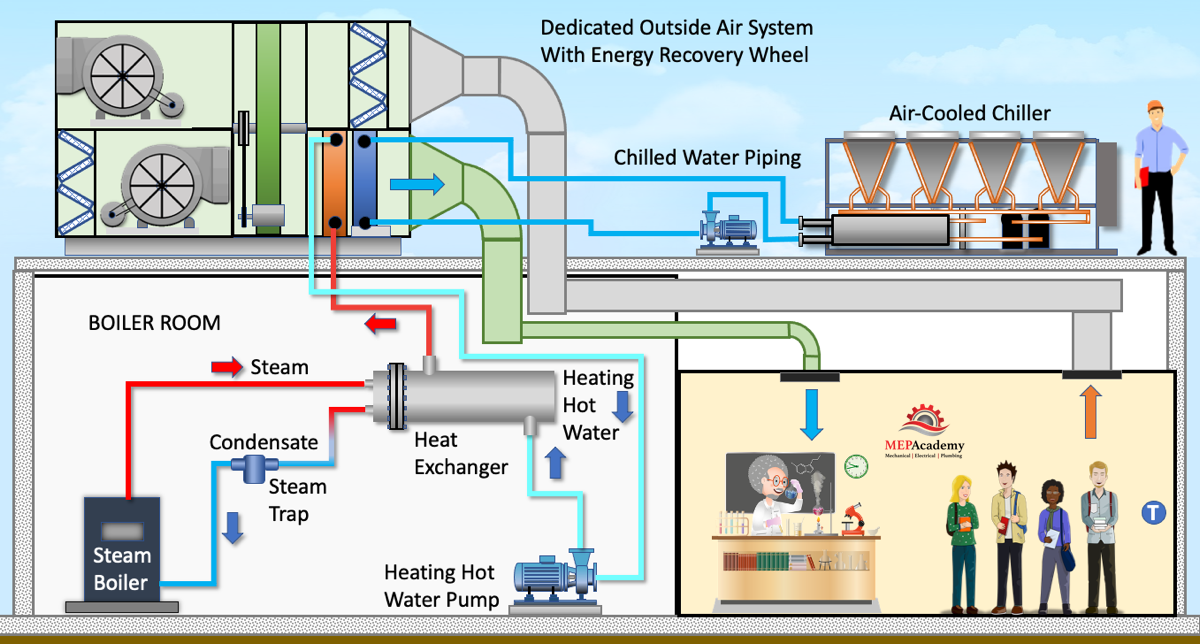

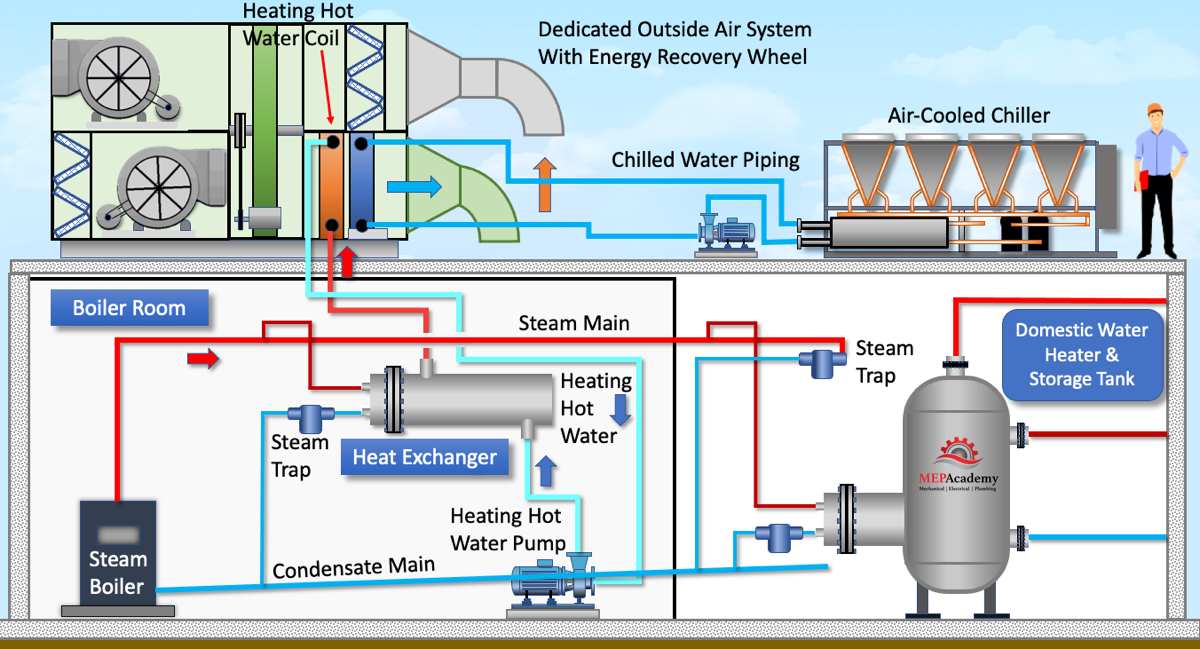

Steam Heat Exchanger for Heating Hot Water

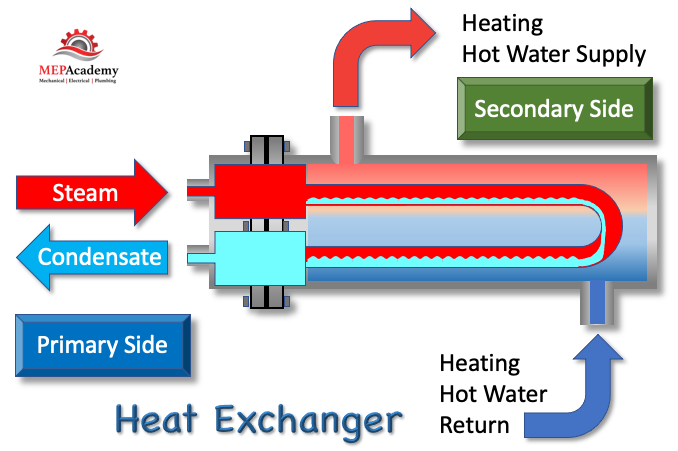

Here we use a steam boiler to feed the primary side of a heat exchanger. The steam will transfer heat to the secondary loop which is feeding the heating hot water coils in Air Handlers. The steam gives up its latent heat and condenses as the heat is transferred to secondary side of the heat exchanger.

To make sure that we are not letting steam into the condensate return we install a steam trap. The steam trap prevents steam from passing through and only lets condensate through. See our video on How Steam Traps Work for a explanation of steam trap types.

On the secondary side of the heat exchanger is a separate loop of water that serves to heating the air in the building air handlers.

If we look inside the heat exchanger, we can see that the primary and secondary piping never mix. The steam enters the heat exchanger as steam and leaves as condensate, while the secondary loop heating hot water is moved by a pump through the system.

The secondary loop heating hot water return enters the bottom of the heat exchanger and picks up heat from the steam and leaves through the top to the air handlers heating hot water coil.

The steam boiler doesn’t need a pump as the molecules are moving fast and exerts pressure on the walls of the boiler and when the piping is connected to the boiler than pressure pushes the steam out of the boiler and into the pipes just like a tea pot that is boiling, and the steam is escaping out of the spout whistling as it exits.

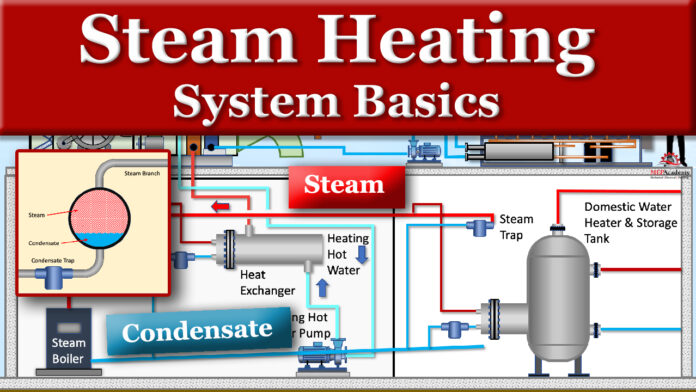

Now we’ll add another piece of equipment requiring a supply of steam.

We’ll have to redo the steam piping to make connections to the domestic system. We’ll install a new steam main and make a connection to the Heat Exchanger making sure to come off the top of the steam main, which we’ll explain why in a minute. Next, we’ll connect the domestic hot water heater and storage tank.

We’ll need a steam trap at the end of any main steam run to allow only condensate to pass through. A main condensate pipe needs to collect all the condensate from any steam systems, here we show a simple system.

Next, we’ll connect the condensate from the heat exchanger to the main condensate line and be sure to install a steam trap to prevent steam from escaping. Allowing steam to escape would be a waste of energy. We’ll also connect the condensate from the heat exchanger that feeds the domestic hot water system and include a steam trap.

We need to connect the main steam line through the steam trap to the main condensate piping going back to the boiler.

Now we can feed the building with domestic hot water, including a return line, and makeup water. This completes a simple layout of a steam heating system. Of course, there are many other components to a steam system which we’ll cover in a more advanced video on steam heating, but this gives you a simple view of what it might look like.

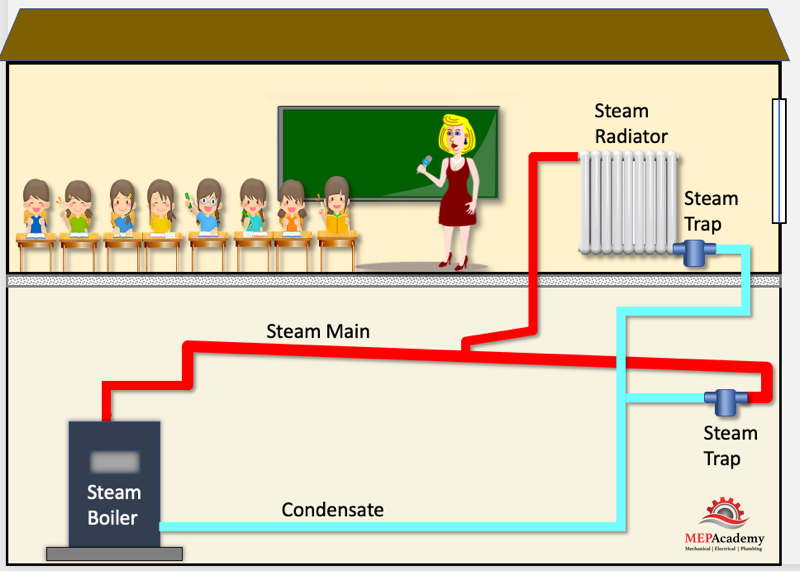

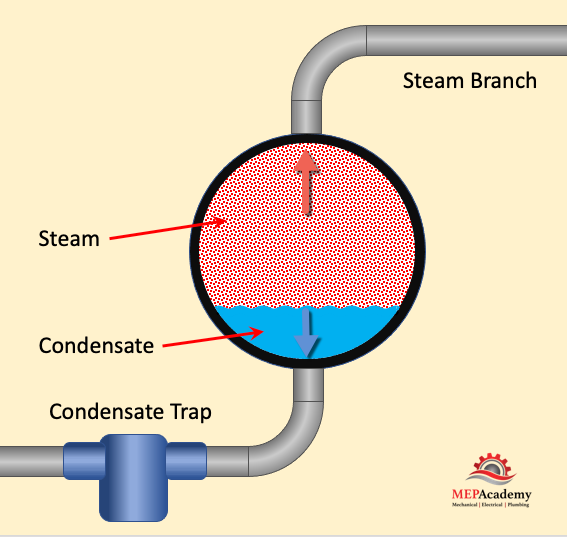

Why Tap Steam off the Top

It’s important that any steam branch line be taken off the top of the main steam pipe in order to prevent pulling condensate into the branch. As you can see the steam will rise to the top because of its lighter density and higher temperature.

For similar reasons you want to make any condensate branch connections off the bottom of any steam line or system to ensure that you are only pulling condensate. And all condensate branches should contain some type of steam trap to ensure that only condensate passes through to the condensate system.

Why use Steam?

Steam has a higher heat content then hot water, which means it can carry a lot more heat in a smaller volume. This heat is in the form of latent heat, which is the change in state from liquid to vapor, and from vapor to liquid. This helps keep the pipes smaller. Steam is water based, so its non-toxic nor flammable, although it’s very hot and will need insulation on the distribution piping to avoid heat loss and prevent someone for getting burned if touched.

The main components of a steam system are the steam boiler, the distribution piping, the steam traps, and the heat exchanger or equipment that requires the use of steam. There will need to be a source of fuel, such as natural gas or fuel oil. A means for makeup water supply, and for boiler blow down to remove unwanted dissolved solids.

This is the basics of a steam system. We’ll get into the details of how each of these components work in other videos.