Modern HVAC systems aim to balance energy efficiency, indoor comfort, and operational simplicity. One of the most effective energy-saving techniques in HVAC systems with Direct Digital Control (DDC) is the Supply Air Temperature Reset Strategy. This strategy optimizes the operation of air handlers serving Variable Air Volume (VAV) terminal boxes by adjusting the supply air temperature dynamically based on demand.

If you prefer to watch the video of this presentation, then scroll to the bottom.

What is a Supply Air Temperature Reset Strategy?

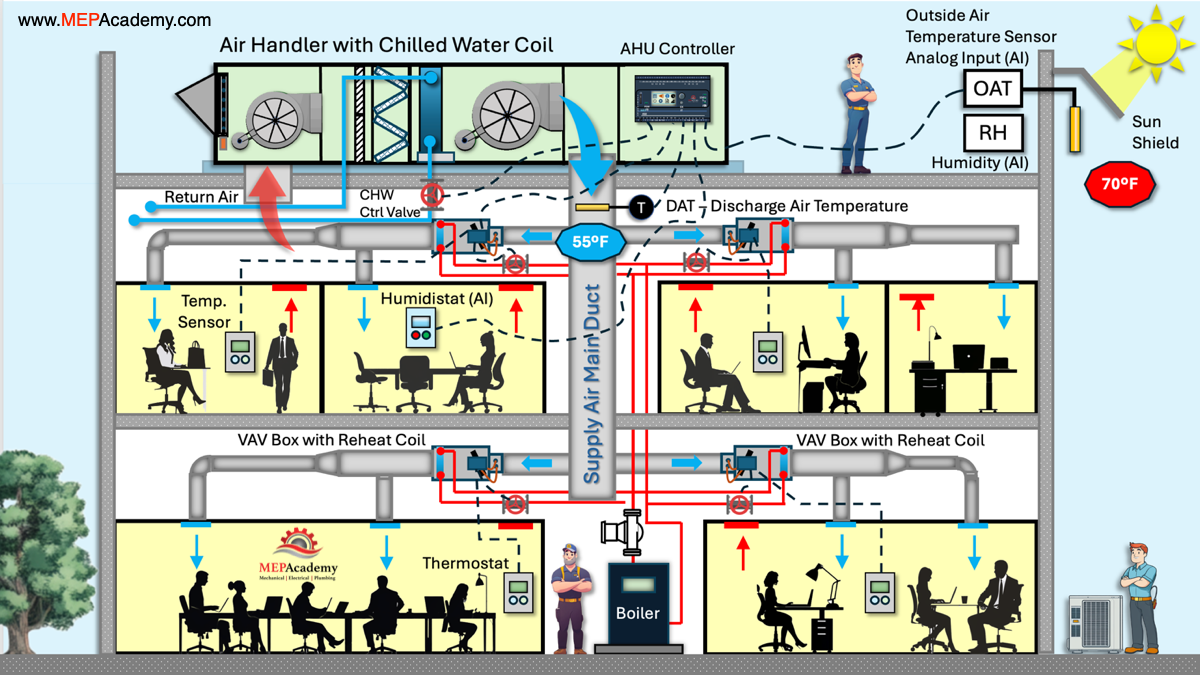

In an air handler serving VAV terminal boxes, the SAT reset strategy dynamically adjusts the temperature of the air supplied to the duct system during part-load conditions. Instead of maintaining a fixed SAT 55°F (12.7°C), the system modulates this temperature based on real-time building conditions, such as outside air temperature and damper positions. The 55°F (12.7°C) is required to meet the peak load, but the building operates more often at less than peak demand during milder weather.

Supply Air Temperature Reset using Outside Air Temperature

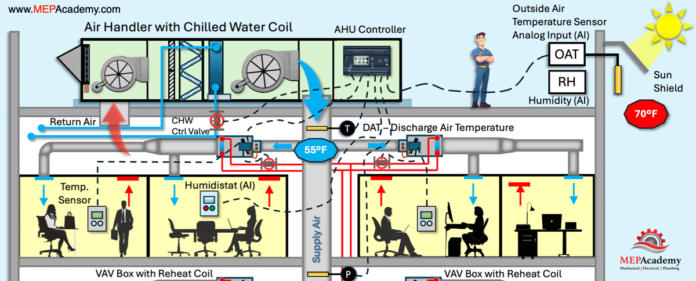

The supply air temperature reset will require that there is a DDC controller mounted on or near the Air Handler that will have various input and output devices connected to it. The AHU Controller will use an outdoor temperature sensor to provide an analog input of the ambient outdoor temperature. The AHU controller will also receive an input signal from a discharge air temperature sensor indicating the current supply air temperature.

When outdoor air temperatures are mild or cooler, indicating lower cooling demand, the DDC system incrementally raises the SAT set point to reduce the cooling load on the air handling unit which saves energy.

For example, as the outdoor air temperature drops below a pre-defined threshold, such as 70°F (21°C), the SAT is gradually reset upward from its baseline value such as 55°F (12.7°C), toward a higher limit such as 65°F (18.3°C), typically in 1 to 2°F increments. This reset process continues as outdoor temperatures decrease, ensuring energy savings by reducing the load on the chiller’s compressors. Several things can happen when the supply air temperature is increased that needs to be monitored such as the maximum static pressure available, the ability for dehumidification and increased airflow. We’ll cover all three of these.

What happens to the System with higher Supply Air Temperatures?

You could set the supply air reset temperature higher, such as 65 to 70°F (18.3 to 21°C), but setting the supply air temperature at an upper limit can introduce several drawbacks and concerns, including:

Reduced Dehumidification

The higher SAT may not cool the air enough to reach the dew point, leading to inadequate moisture removal and higher indoor humidity levels, especially in humid climates. To prevent the Supply Air Temperature reset strategy from compromising dehumidification and ensuring the required relative humidity levels are maintained, several control strategies and hardware devices are typically employed:

A humidistat (or humidity sensor) can be integrated into the control strategy. If the indoor RH exceeds a set threshold (typically around 60%), the system can override the SAT reset and maintain a lower SAT, ensuring that sufficient dehumidification occurs to maintain comfort and meet code requirements.

Outdoor air humidity sensor can help the system determine whether outside air is suitable for cooling and dehumidification. In humid climates, the system may rely on outdoor enthalpy rather than just temperature to control SAT and ensure effective dehumidification.

When a higher SAT is implemented, the system continuously monitors the outdoor or indoor humidity levels via sensors and humidistats, or both. If the RH exceeds the preset limit, the system either halts the SAT reset strategy or adjusts the SAT to a lower value to maintain effective dehumidification.

Increased Airflow Requirements

To maintain the same sensible cooling capacity, airflow (CFM) must increase as Delta T (temperature difference between supply and room air) decreases, potentially overloading fans and ductwork. Higher airflow requirements to meet cooling loads can lead to increased fan energy consumption, offsetting the intended efficiency gains of SAT reset.

What Happens to the CFM Delivered to the Space?

When the supply air temperature is reset higher due to a lower outdoor air temperature, the air delivered to the zones becomes warmer. Using the sensible heat load equation, (Q = CFM x 1.1 x Delta-T), a higher SAT reduces (Delta T) (the difference between room temperature and supply air temperature). To maintain the same sensible heat removal capacity (Q), the airflow (CFM) must increase to compensate for the reduced (Delta T). This ensures the HVAC system continues to meet the cooling load in the space, despite the warmer supply air.

What Happens to the Static Pressure?

The static pressure limits in an HVAC system directly influence the maximum supply air temperature reset by determining the system’s ability to deliver sufficient airflow (CFM) to offset reduced cooling capacity from higher SATs.

Effect on the Economizer

A higher supply air temperature setpoint increases economizer use because it allows the HVAC system to utilize outdoor air for cooling over a broader range of outdoor temperatures. With a higher SAT, the air handler does not need to cool the air as much, so outdoor air at moderately warm temperatures can still meet the cooling requirements without activating mechanical cooling. This expands the economizer’s operating range, maximizing free cooling and reducing energy consumption.

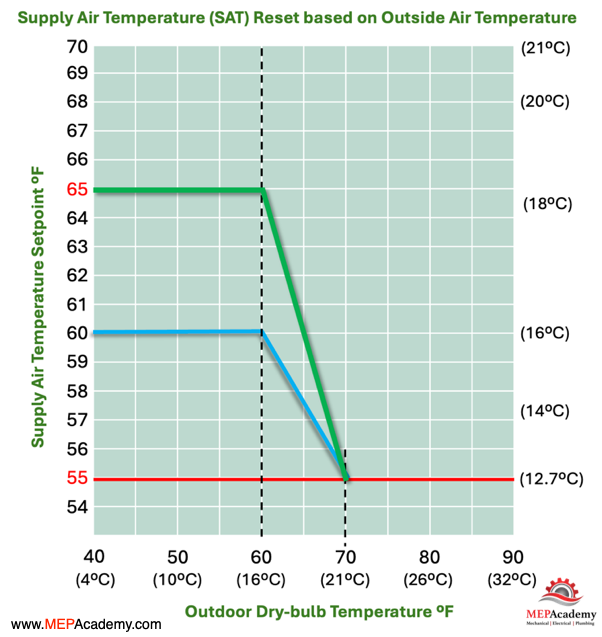

Supply Air Temperature Reset using Trim and Response

The supply air temperature reset sequence using trim and response logic based on VAV box damper positions begins with the Direct Digital Control (DDC) system continuously monitoring the damper positions of all VAV terminal boxes served by the air handling unit. If the majority of the dampers are less than a specified open percentage, such as 60%, indicating reduced cooling demand, the system gradually raises the SAT set point in small increments, typically 1 to 2°F, to save energy by reducing the cooling load.

Conversely, if a significant percentage of dampers, such as 20% or more, are nearly fully open such as above 90%, indicating higher cooling demand, the SAT set point is lowered incrementally to provide sufficient cooling to meet the zone requirements. The system uses real-time feedback from the damper positions to continuously adjust the SAT dynamically within predefined minimum and maximum limits, typically between 55°F and 65°F. This approach ensures that the SAT is optimized to balance energy efficiency with occupant comfort, responding dynamically to varying cooling demands across the served spaces.

Consider a commercial office building with an air handler serving 10 VAV terminal boxes. During peak summer afternoons, all VAV dampers are close to fully open, indicating high cooling demand. The DDC system maintains the SAT at 55°F (12.7°C) to meet this load.

In the early evening, as occupancy decreases, none of the dampers remain fully open. The DDC system resets the SAT to 65°F (18.3°C). This

Reduces chiller and fan energy consumption.

Maintains comfort as the zones with reduced occupancy now require less cooling.

Conclusion

A Supply Air Temperature Reset Strategy is a powerful tool for improving the energy efficiency of HVAC systems while maintaining comfort in buildings. By leveraging modern DDC systems, building operators can implement this strategy to reduce energy costs, enhance equipment longevity, and contribute to sustainable building operations.

Adopting this strategy is not just an upgrade, it’s a commitment to smarter, more efficient, and environmentally conscious building management.