Air Filters and Filter Housing Basics. In this article we’ll review air filters, filter housings, filter ratings, and how to use a VFD to maintain flow when filters get dirty. Most people spend the majority of their time indoors, so knowing all about filters is important for good air quality and health.

For the YouTube Video of this presentation, scroll to the bottom.

The purpose of air filters is to remove dust and particles from the air stream, not only to protect HVAC equipment, but to also to protect people, and products. This could be people in a residence, office building or hospital, in addition to protecting products during manufacturing, like computer chips and pharmaceutical drugs.

Checkout these Air Filters here

Think of a museum and the expensive paintings hanging on the wall that cost millions of dollars. Contaminated air carrying by products of combustion can damage the artwork. Selecting the correct filter is important in protecting equipment, people, or product.

The museum may need three levels of filtration to protect the expensive artwork. This could include a 30% pleated filter, then a 65% synthetic bag filter, and then the final filter could be a 95% synthetic bag filter.

There are also filters for removing odors and gasses. We’ll first cover air filters for particle and dust removal and then for gasses and odors. A renewed concern includes viruses, bacteria, and microorganisms.

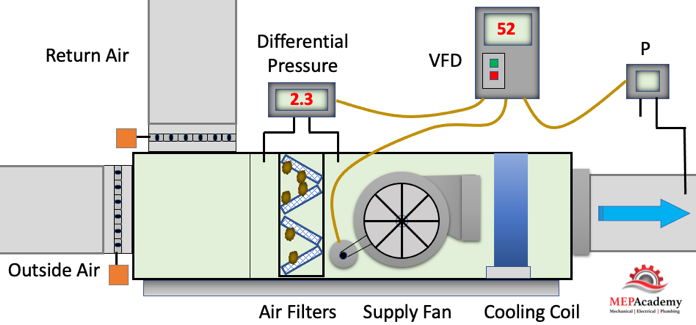

VFD Control of Dirty Filter Conditions

This air handler has a differential pressure transmitter measuring the pressure drop across the filters. When the filters become dirty, there will be an increase in the pressure across the filters, which will cause a loss in flow or CFM if nothing is done to correct the problem. Here we use a Variable Frequency Drive (VFD) to adjust the fan speed for any loss in pressure across the filters.

When the differential pressure reaches a certain static pressure the VFD will go into action and speed up the fan to compensate for the additional pressure drop created by the dirty filters. A set of contacts can be made that sends an email alert to the facility engineer to notify them of the dirty filters.

Checkout these Air Filters herePollutants to Be Removed

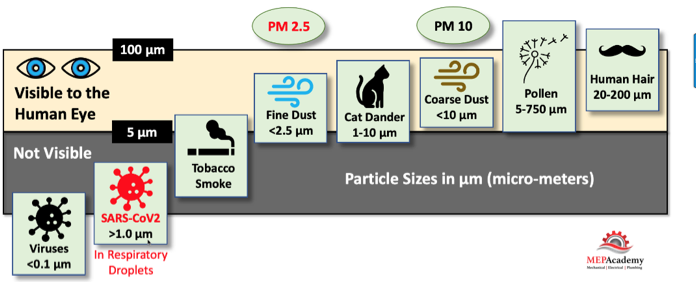

So, some of the items we want to filter out, everything from human hair, which is in the visible zone. The pollen to coarse dust that’s a larger particle sizes, cat dander, pet dander, fine dust which is smaller particles, tobacco smoke, some is visible, some of the particles aren’t, and then the SARS virus in respiratory droplets is about 0.1 micrometers, and then viruses 0.1 micrometer and smaller.

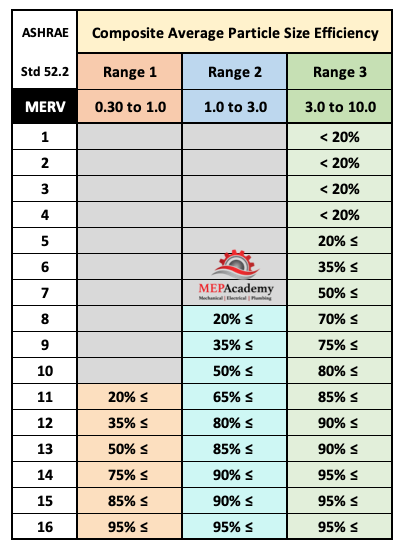

So, you’re looking for a filter that’s going to take out what it is you’re looking to take out. Now this shows ASHRAE standard 52.2 which is a standard used for testing filters. There’s three ranges of sizes, this is 0.3 to 1.0 micrometer, 1 to 3, and 3 to 10.

MERV – Minimum Efficiency Reporting Value

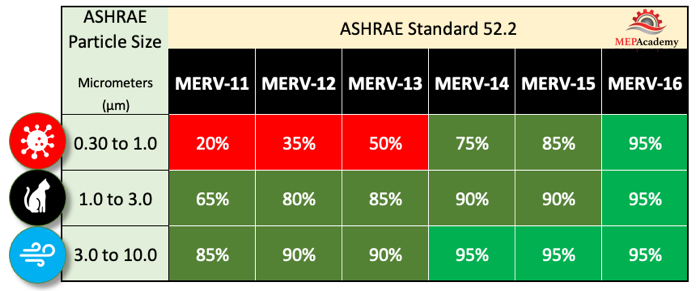

The different sizes of microns, as you can see the MERV rating here, these filters in the beginning here, don’t take out much on the smaller particle sizes, and not that great on the larger particle sizes. So, you really want to stay in the MERV 11 and higher rating, and we’ve reduced the chart to 11 and greater, and you can see on the small particles 0.3 to 1 the MERV 11, 12 and 13 is 50% an under efficiency.

So, if you move to a 14 you’re going to get 75% efficiency, and as you can see on the larger particles all the filters do better. It’s a little easier to catch a large particle than it is a very small one. You can see the MERV 16 is rated for 95% efficiency in all size ranges. Of course that’s a more expensive filter, so you might want to stay with a MERV 14 filter if possible, or a MERV-13. It’s depending on what particles you’re trying to capture. If it’s all large particles, then basically anyone of these filters is going to be pretty good.

Checkout these Air Filters hereFilters are rated based on their ability to remove particles from the air stream in a single pass. MERV is the industry standard indicating the effectiveness of the filter. The higher the MERV number the greater the filter is at removing contaminants and dust particles from passing through the filter.

The particle sizes are in three micro-meter ranges (0.3 µm to 1 µm, 1 µm to 3 µm, and 3 µm to 10 µm). There are 25,400 micro-meters in an inch, so were talking about small particles. The air filters are assigned a MERV number based on how they perform in one or more of these three particle size ranges. The higher the MERV rating, the higher the filtration efficiency. There are similar rating systems in other parts of the world, and some hardware stores like Home Depot have their own rating system.

When shopping for filters you should be looking at the MERV rating and what you want to remove from the air stream, such as cat dander, fine dust, coarse dust, tobacco smoke, odors, pollen or even viruses.

The cheaper filters and lower MERV values are not very good at removing small particles which can be dangerous to your health.

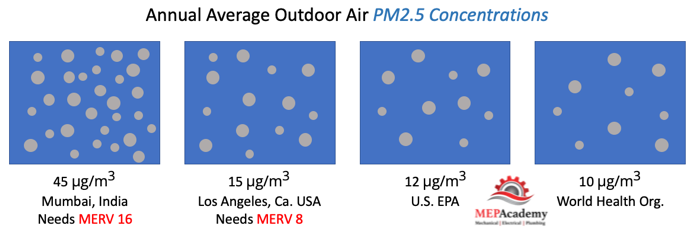

PM 2.5 Concentrations

Why bother filtering outdoor air? PM2.5 refers to particles two- and one-half microns or less in width. Particles 2.5 microns and smaller are considered dangerous to human health as they can bypass many of our body’s defenses.

Over 3,000,000 pre-mature deaths worldwide were found to be correlated with outdoor air pollutant particles 2.5 microns and smaller. People are exposed to these particles indoors where they spend most of their time, so filtration is very important in maintaining indoor air quality.

Particles less than 1 micron can stay suspended in the air for a long time. Poor indoor air quality can contribute to a wide range of health problems, including Asthma, lung, nose and throat irritation and complications.

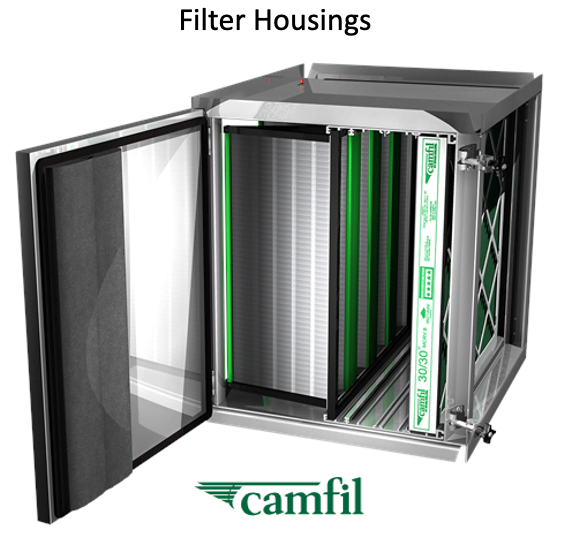

Filter Housings

Filter housings provide an enclosure for the filters and can be installed indoors or outdoors in new systems or used for a retrofit project.

Here is a filter housing manufactured by Camfil that can be used outdoors and has a 25” deep side access which accommodates a 2” or 4” deep prefilter, one 2” or 4” deep intermediate particulate or carbon filter, and a 6” or 12” deep rigid or pocket final filter.

V-Shaped filter housings allow for additional filter area using this arrangement. Housing are available for pre-filters, final filters, HEPA’s and roll filter housings.

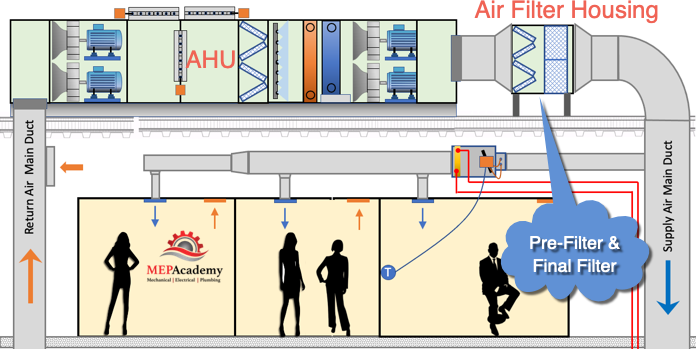

We can easily retrofit this air handler with a filter housing. First we cut into the main supply ductwork, then install some transition that match the size of the housing connections, then we install the filter housing, and support legs. This filter housing has a prefilter and final filter. The prefilter catches the larger particles and protects the more expensive final filter.

Filter Location and Identification for Replacing

Filters are mostly located on the return side of the HVAC equipment for residential and commercial systems, except for some special applications where there will be supply side filters, which we’ll discuss later.

This can be at a return grille mounted in the ceiling or on a wall. If not located in either of those two locations, then it will be found at the HVAC equipment. You would need to access the equipment and remove the filter access panel or filter rack to locate the filter. On the side of the filter should be the size and MERV rating.

If there is no existing filter or the information isn’t available, then you can measure the opening size. You would measure the height, width and depth of the filter. For a custom fit, make a 1/4” reduction in the height and width for a proper fitting.

Filters can be partially loaded and still a certain percentage of people will perceive the downstream air from the filter dissatisfying. This can occur even before the filters are fully loaded. Contrary to reasonable thinking the filters can be the source of sensory pollution when the filters begin to retain dust and particles.

Depending on where you live, you may need higher levels of filtration to bring down the concentration of these particles.

Contaminants can also be generated within the building from gas burning appliances, burning of candles, cooking, fireplaces, etc. This means it’s critical that you understand what generates a harmful environment in your home and how to increase the indoor air quality. See our video on the “Top 12 Ways to Increase Indoor Air Quality” for ideas.

ASHRAE now requires continuous or intermittent outdoor air by mechanical methods for residential buildings. In residences whole house fans are being installed to bring in outdoor air while also using cooler outdoor air instead of running the compressor. The only problem with this method is that the air entering the home is not being filtered, and depending on where you live, this could be bringing into the home poor quality air. Certain places in the world have higher concentrations of these pollutants and need higher levels of filtration like, parts of eastern and southern Asia, parts of western and northern Africa.

The U.S. EPA has set a maximum annual average ambient PM2.5 concentration of 12 µg/m3, while the World Health Organization maintains a guideline of 10 µg/m3

As you can see for Mumbai, India occupants to achieve the U.S. EPA guidelines of 12 µg/m3of PM2.5 concentrations, a MERV 16 filter would be required, while Los Angeles would only need a MERV-8.

Filters are rated based on a range of velocities flowing through them.

What to Consider when Choosing an Air Filter

Pressure drop needs to be considered as this could adversely affect the flow (CFM) of the system if the fan can’t handle the additional restriction or pressure drop created by the filters. Be sure to compare the pressure drops for various filters and there corresponding MERV rating.

The MERV rating or HEPA cleanliness rating. The higher the rating the better the performance. This defines the efficiency of the filter to capture particles of various sizes. Be sure to understand what it is that you want removed from the air stream, such as particles or gasses. Are you providing filtration for a home, operating room, paint booth or welding station?

The filters holding capacity for the filter is considered dirty and needing to be replaced.

Pressure Drop

Air filters create pressure drops, with the thicker filters creating more pressure loss than its similar thinner version. Pressure drop is to be considered in the design of any HVAC system to ensure that the fan can push the required amount of air (CFM) to the space. If the pressure drop is greater than the system can handle there will be a loss of air flow (CFM).

Fans used in residential systems usually have low static pressure capabilities, so adding high pressure drop filtration would reduce the CFM, or air flow to the rooms. There is a tradeoff between increased filtration and energy consumption. The greater the filtration, the greater the pressure drop, the more fan energy needed to overcome the static pressure drop across the filters.

Dirty Filters and Notification

Dirty filters provide another challenge for the HVAC system, because as the filters do their job of entraining dirt and particles their pressure drop increases. This increase in pressure effects the air flow, so it’s important to change filters when they get dirty. How do we know if the filter is dirty or getting dirty without opening the unit and visually looking at them to see if they are dirty? This is where magnehelic gauges become important for notification of the filter’s cleanliness or level of dirtiness.

Fans Response to Dirty Filters

With the use of Electrically Commutated Motors, (ECM) motors and VFD’s, fans can now respond to an increase in pressure drop caused by a dirty filter. As the filter gets dirty or as the pressure drop increases, the fan can speed up to maintain the same volume of airflow, because as we already learned, the air flow or CFM will diminish as the pressure drop increases.

We the use of various differential pressure measuring devices, the increase in pressure drop across the filters can be used to send a message to the fan to speed up. This ensures that any critical spaces receive the design airflow required.

Types of Filters

Filters are available in various thicknesses, sizes, and MERV values. Panel filters and high-performance cartridge filters. Filters come in low efficiency, medium efficiency, high efficiency, and HEPA type filters.

Pad and panel type filters are usually low efficiency types with efficiencies in the 30% range, removing particles 10 microns and larger. Medium efficiency filters will run between 40% and 60% and are usually of the bag or box type removing particles in the 3-to-10-micron range. These filters can be used before the high efficiency filters to increase the life span of the more expensive high-efficiency filters. High efficiency filters range from between 80% and 90% efficiency using a bag type or box type filter, and a particle removal rate of over 70% for particle sizes of 0.3 micron and larger.

Filter Material Construction

Backings can be welded wire or expanded metal with welded wire be more expensive but offers better performance.

Beverage board frames, cardboard or a kraft paper frame, with the beverage board frames being the more expensive one. The beverage board frame can be chemically treated to resist moisture, bowing, or collapsing providing a better performing frame then the other two.

The use of antimicrobial agents on air filters help reduce the proliferation of microbes.

Built-up Filter Banks

In large commercial buildings you can find very large built-up filter banks that require supplemental steel for support.

Electrostatically Charged Air Filters

Carbon Air Filters

In commercial buildings where odors are a problem, the use of activated carbon filters can help. Activated carbon filters can remove molecular contaminants such as bio-effluents, volatile organic compounds (VOS’s), and organic-based odors, while also reducing ozone exposure. Carbon filters don’t increase in resistance as they are used, which is opposite of your standard air filter.

AHU Filtration

There are various quantities and qualities of filters used in air handlers. Of course, air handlers that serve a hospital operating room would have greater filtration requirements than that of an office building. Operating rooms may require three separate filter banks, a pre-filter, final filter, and HEPA filtration., while an office may have one or two filter banks, a pre-filter and final filter.

Looking at the air handler we can see that the first set of filters are pre-filters and are used before the coils. These filters are important to ensure that the coils remain clean, as any dirt on the coils will cause a loss in heat transfer.

Commercial filtration differs from residential filtration in that in commercial buildings the ventilation rate is often much higher, meaning that a greater amount of outside air is brought in the building through a commercial filter than residential ones.

Air Changes per Hour

Another factor effecting the use of filters and their longevity is the amount of air changes per hour they receive. In your typical single-family homes, the recirculation of the air happens whenever the unit is on. Various commercial and medical buildings will have special rooms that dictate the amount of air changes for ventilation and for recirculation. Cleanrooms vary in their classification with some rooms being very clean and requiring the majority if not all the ceiling to be filters. This you may find in factories that fabricate computer chips or pharmaceuticals, where the air needs to be super clean, as any tiny particle can ruin the computer chip or spoil the drug being produced.

How Air Filters Work

There are four basics methods by which dust and particles are captured by the air filter media: Straining, Impingement, interception and Diffusion. Watch the YouTube Video of this presentation to see an animation of these methods. Air Filter Video

Straining occurs when the dust or particle is larger than the gap between filter fibers. This is one of the common methods of removal in low efficiency filters.

Impingement occurs when a large, dense particle collides with the filter fibers directly, not be able to follow the air flow around the fiber. The fibers can be coated with an adhesive to assist in retaining the particle. This is also one of the common methods of removal in low efficiency filters.

Interception occurs when the dust or particle rides the air stream through the filter media and at some point, leaves the air stream and attaches to the media fibers. This method is used for particle removal in medium efficiency filters.

Diffusion occurs when very small particles are influenced by air molecules, colliding with them, causing them to move erratically through the air stream. This allows the small particles to become attached to the filter media, which is a method used in high efficiency filters.

Electrostatic occurs when particles are given the opposite electrical charge as that of the filter. The particle will then be attracted to the filter when passing through it.

Filter Performance

There are a few metrics for measuring filter performance including Efficiency, Dust-Holding Capacity and Resistance.

Efficiency defines the percentage of dust and particles that the filter will remove.

Dust-Holding Capacity defines the amount of dust and particles that the filter can hold before being changed.

Resistance defines the amount of pressure drop created by the filter in the air stream.

ASHRAE Standard 62.1 and 62.2

This is the commercial 62.1, and residential 62.2 standard for the minimum requirements for HVAC particle filtration efficiency. To meet the minimum ventilation requirements in areas of the world where the outside air is highly polluted is challenging.

The difference between residential and commercial filtration, is that the home HVAC system doesn’t run most of the time, while in commercial buildings some form of air and ventilation is required whenever the building is occupied. Filters are used all the time in commercial buildings and less often in residences. Also, overall system efficiency drops when air bypasses the filter due to gaps in the filter racks or tracks. Be sure that the air is traversing the filter and not finding its way around the filter through cracks and poor filter rack design.

Filter Maintenance

Maintenance of filters involves reading of the filter resistance gauges, visual inspections, and scheduled filter replacement. A filter that fails or gets clogged can cause damage to products, bypass infiltered air, and increase energy usage.