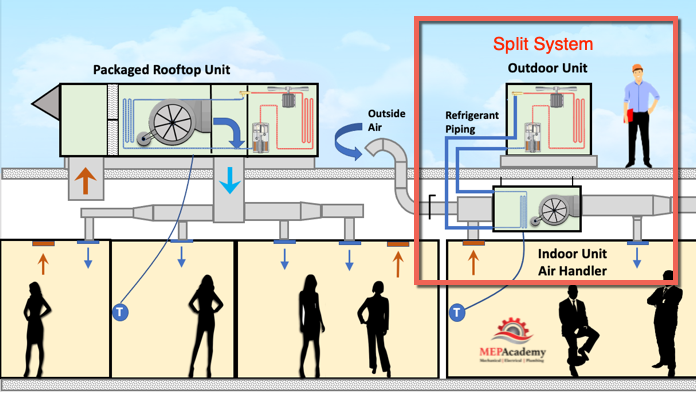

How HVAC Split System Air Conditioners Work. Using a Split System Air Conditioner or Heat Pump is common in residential and commercial applications. It’s called a split system because the indoor and outdoor components are separated or split from each other and are connected by refrigerant piping and control wiring. This differs from a self-contained rooftop packaged unit which houses both indoor and outdoor components. We’ll see different designs using split systems.

If you prefer to watch the YouTube Video of this presentation, scroll to the bottom or click on this link >> How HVAC Split System Air Conditioners Work

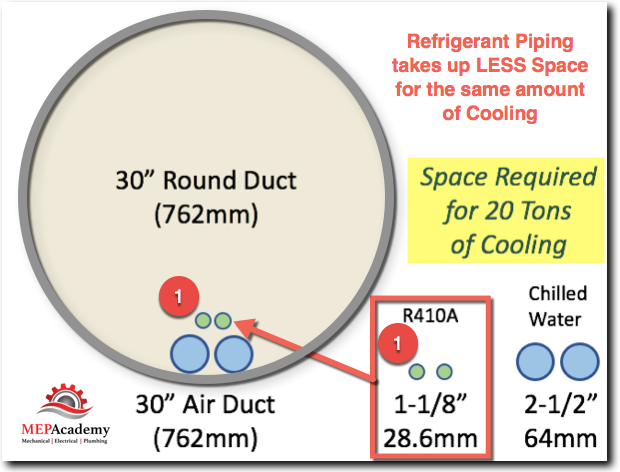

HVAC Split systems are convenient to use with existing buildings because it’s much easier to route small refrigerant piping to the indoor coil, then to run much larger air ducts using a rooftop packaged unit. As you can see the rooftop unit needs large openings for the supply and return ducts to enter the building. The split system uses smaller copper tubing and requires a small opening in the roof or wall.

Refrigerant Piping Size vs Ductwork Size

Refrigerant carries more heat capacity then air, which allows small refrigerant piping to easily maneuver through building structures and components as opposed to large air ducts. This is what gives split systems their advantage, except when it comes to ASHRAE 62.1, ventilation air requirements, which we’ll discuss later.

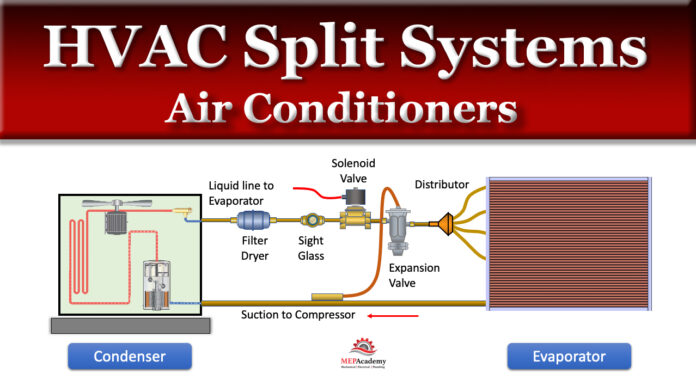

The split system is made up of the Outdoor unit, often called the condensing unit, because this is where the refrigerant condenses from a gas back into a liquid, and an indoor unit where the evaporator is located. The indoor unit can be called an Air Handling Unit (AHU), Fan Coil or a Furnace with Coil.

Split systems are available from less than one ton to over 100 tons of refrigeration capacity. Split systems come in two basic configurations, either as cooling only or as a Heat Pump, which we’ll explain later.

Heating in HVAC Split Systems

Heating can be in the form of a gas furnace, electric strip heater, electric heat pump, hot water, or steam. Here we show two ways of getting heat to the occupied space using a split system. First you can use a split system heat pump, which works to cool the space in summer, and heat the space in winter. See our video on How Heat Pumps Work to understand how they work.

Furnace with DX Coil

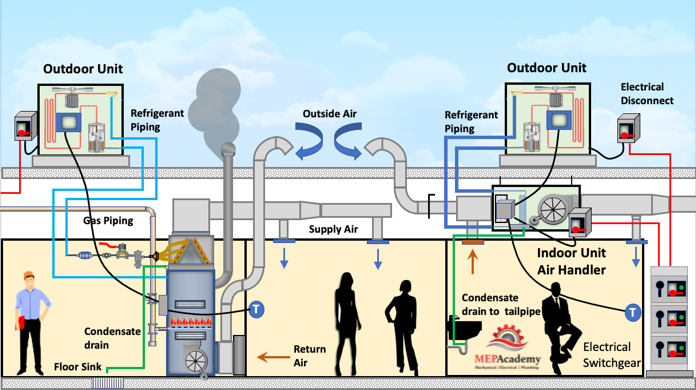

The other option is to install a furnace with a coil. The furnace will require some form of fuel such as natural gas for heating. Cooling will be accomplished by installing a evaporator coil on top of the furnace, which is connected to an outside condenser.

The furnace will require combustion air inlet and a means of exhaust combustion gases outdoors. It’s important that the discharge flue remain a minimum of 10 feet away from any air intake, check your local code for the proper distance.

You’ll need to install a condensate drain pipe from the cooling coil drain pan to an approved receptor, like a floor sink or the tailpipe of a sink.

Electrical will need to be installed from a breaker panel to a disconnect switch located near the equipment. The disconnect switch is a safety device that allows any technician working on the equipment to lockout the electrical power feeding the HVAC equipment.

Heating Hot Water Coil

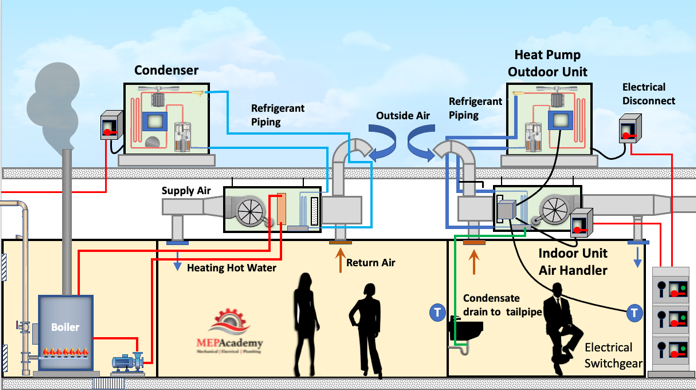

Another option is to use a boiler to provide heating hot water to a coil located inside the air handler. The boiler will need a source of fuel for combustion, in this case natural gas. The heating hot water will need to have a pump to circulate the water to all of the Air handlers in the building.

Here we only show one air handler getting heating hot water, but it could also be dozens more in larger buildings. The heating hot water piping will need to be insulated, most likely with some form of fiberglass pipe insulation to prevent the loss of heat from the pipes. Not shown is makeup water and any other accessories like expansion tanks. This could also be a steam boiler with a steam coil in the air handler to provide heating.

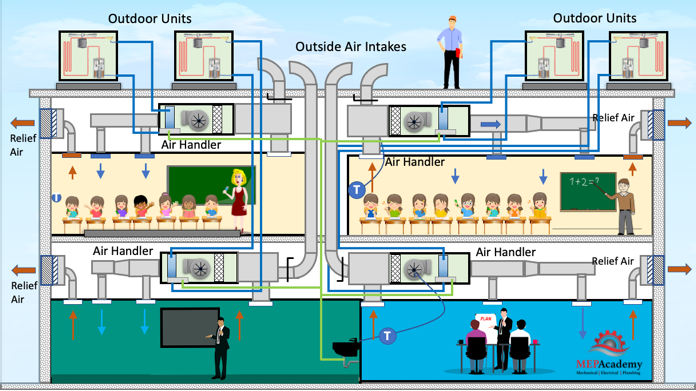

Ventilation Air per ASHRAE 62.1

One of the challenges for split systems is providing the required ventilation air to each of the air handlers. Ventilation air will need to be provided to each space or indoor fan coil or air handler per ASHRAE 62.1. This requires a duct from the outside or from a DOAS unit to the space or fan coil. See our video on “Dedicated Outside Air Systems” for a better understanding.

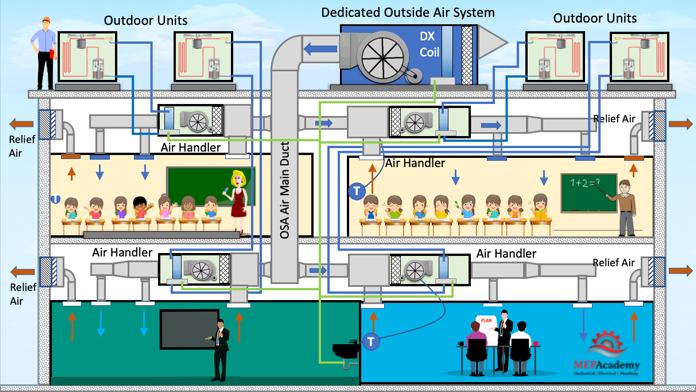

Dedicated Outside Air System

This Dedicated Outside Air System filters and conditions the outside air before the fan sends it to each of the air handlers. The Dedicated Outside Air System handles the latent load of the ventilation air so that the air handlers won’t need to be upsized for this additional load.

Each air handler will receive the required amount of ventilation air per ASHRAE 62.1 based on the occupancy level, size of the room and space usage type.

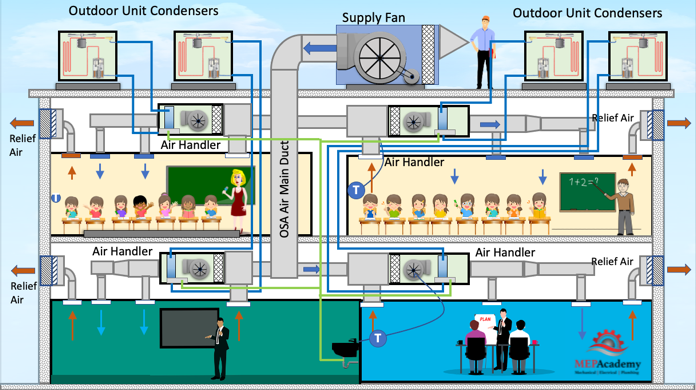

Supply Fan with Filtration

Another option is to provide ventilation air using just filtration and a supply fan, but no conditioning of the outside air. This relieves the indoor air handlers fan from needing to pull in outside air. The disadvantage is that the air handler will need to handle the additional heating and cooling load for the ventilation air.

Separately Ducted Outside Air Ducts

The lowest first cost option would be to duct the ventilation air individually from each indoor air handler. This would require additional energy of the air handler fan and coil. This would require a lot of small ducts running through the building from each air handler, unless you required an economizer for your indoor air handler because it meets the threshold of your energy code, then the ducts would be much larger and may not make sense.

As shown before, each air handler has a condensate drain going to the tailpiece of the sink.

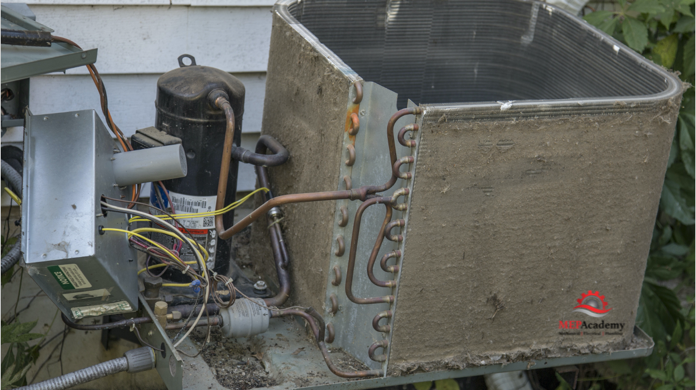

Condensing Unit

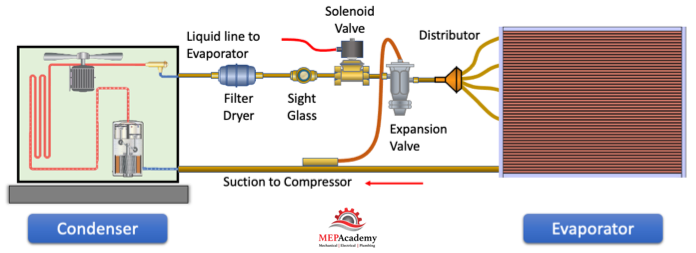

The condensing unit contains two major components, the compressor, and the condenser coil. The compressor is the heart of the unit and pumps the refrigerant around the piping circuit. The condenser coil provides a means of rejecting the heat to the outdoors using a fan blowing air over a hot coil.

In this picture we can see that this condenser hasn’t been maintained and is covered with dirt. This will reduce the capacity of the unit, so be sure to check your outdoor coil at least once or twice a year to ensure its clean.

We can see the hot gas discharge piping coming off the top of the compressor and feeding the condenser coil which is responsible for rejecting the heat from the building. But in this poor condition it won’t be working. Here is the filter drier that’s on the hot liquid line leaving the condenser and sending liquid to the expansion valve at the evaporator. Here is the suction piping that has arrived from the indoor evaporator section and is entering the compressor below the discharge piping.

This is the ugly insides. Here is what the condenser may look like from the outside.

There will also be some controls on the outdoor unit that communicates with the indoor unit and provides various safety components to protect the compressor and the other system parts. The communication from a thermostat or space sensor is typical for a residential unit, while in commercial installation there could be the addition of a BACnet card that allows communicating with a Building Automation System (BMS).

Outdoor units will contain one compressor for smaller sizes and multiple compressors for larger systems.

The condenser can also be air-cooled, water-cooled or evaporatively cooled.

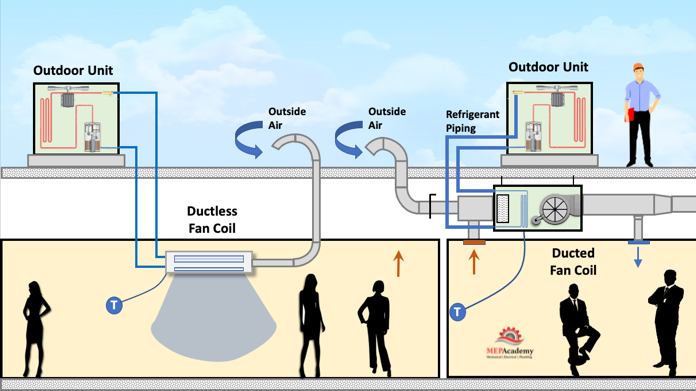

Indoor Unit Air Handler (DX Fan Coil)

The Air Handler contains the indoor fan and evaporator coil. The evaporator coil is where the refrigerant absorbs the heat from the building air that is being blown over the coil. This causes the refrigerant liquid in the evaporator to evaporate while cooling down the building air, see our video on “Refrigerant Cycle 101” to better understand how a refrigeration cycle works. The expansion valve or metering device separates the high side from the low side and modulates the amount of refrigerant that passes through it in relationship to demand.

The indoor unit can be ducted or ductless.

Residential systems are relatively simple and smaller, while the commercial versions can be very large and have many other options installed within their housing. Commercial air handlers can be packaged, custom made, or built-up with individual components selected and field erected. See our other video on “Air Handling Units” for a better understanding.

Compressors

The smaller residential units under 10 tons will most likely have 1 compressor, while commercial units 10 tons and over can have two or more compressors. Compressors vary in their ability modulate capacity. Smaller system will use a hermetically sealed compressor with a scroll compressor. Larger systems can use semi-hermetic, reciprocating, and scroll compressors in 1 or more configurations depending on size.

Most compressors use oil for lubrication and that oil travels around the refrigerant circuit continuously during operation. It’s important that the oil returns to the compressor at the same rate that it leaves, as the compressor needs to remain lubricated at all times.

Heat Pumps

In addition to the cooling only split systems, there are Heat Pumps which reverse the refrigerant cycle to provide heating also. There is a move in some states and countries to go all electric, such as in California. Heat Pump are all electric so there is no burning of a carbon-based fuel. See our other video on “How Heat Pumps Work” for a better understanding.

One of the differences between a Heat Pump and other cooling only units is that of the metering device. The metering device separates the high-side from the low-side and controls the amount of refrigerant passing through it. The Heat Pump uses a special “Reversing Valve or 4-Way Valve” that allows refrigerant to change direction based on whether in heating or cooling mode. The indoor coil is used as an evaporator to provide cooling during summer, and as a condenser to provide heating during winter. Therefore, you shouldn’t call the outdoor unit a condenser when dealing with a Heat Pump, as it acts as both a Condenser and Evaporator depending on the mode of operation (Heating or Cooling). With a cooling only Air Conditioner, the outdoor unit is always the condenser.

Split System Sizing and Mixing and Matching

Splits systems are often chosen where the outdoor and indoor unit tonnage match, but that is not always the case. Split systems can have the outdoor unit slightly larger or smaller than the indoor unit. By upsizing the outdoor unit, this will allow more latent heat for the indoor unit. The tonnage of the indoor unit can be larger than the outdoor unit to increase the sensible heat ratio and airflow (CFM). Providing an indoor unit that is one size larger or smaller than the condenser maybe safe, but check with the AC Manufacture when mixing outdoor units and indoor unit capacities. This is not allowed with most Heat Pumps.

Residential systems commonly use split systems of 5-Tons and under or multiples of these sizes for larger homes. You might find a 3-Ton unit serving the first floor and another 3-ton unit serving the 2nd floor in a two-story home.

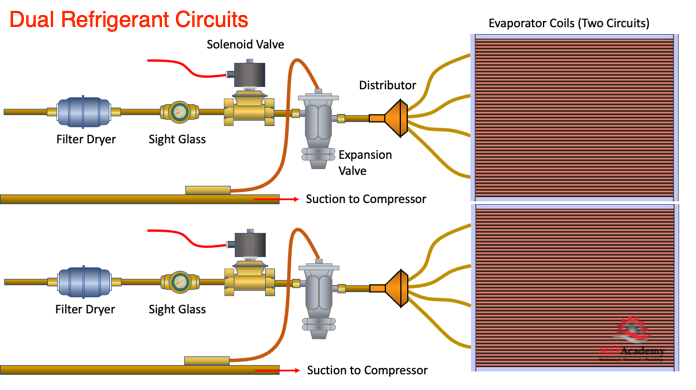

Refrigerant Piping and Number of Circuits

For small split systems where the indoor and outdoor units are relatively close and the pipe routing simple, the use of line sets maybe used. Line sets are available in a coil of ACR copper and are pre-charged with refrigerant, in lengths of 15, 25, 35, 50 or 100 feet. This saves on labor by avoiding field brazing of joints for fittings and couplings. Piping distances are often restricted by equipment manufactures so be sure to check the literature for these requirements if your distances exceed 100 feet or more.

Most small split system have only one circuit, but as the HAVC unit gets larger there are dual circuit units available. Dual circuits will require twice as much piping as a single circuit HVAC unit. There will be two suction lines and two liquid lines running from the indoor unit to the outdoor unit. With dual circuits the ability to control capacity is increased in addition to having a backup or redundant circuit incase a compressor burns out. Each circuit has its own compressor.

The DX coil can also be setup in either a single or dual circuit arrangement. The refrigerant can pass through the coil using one path or two. If you’re using a dual circuit condenser than you’ll have a dual circuit indoor coil. Its possible to have a single circuit condenser and a dual circuit DX coil.

Refrigerant Piping Insulation

This is where most installations that we review are lacking in code compliance and application. The proper application of insulation is important in maintaining a well-functioning HVAC split system. If insulation is poorly applied or if the wrong insulation is used, then there will be a LOSS in capacity of the system. This means that the number of tons of air conditioning that was installed will be less than that. See our video on “Refrigerant Insulation” for the proper installation and type of insulation to be used when installing refrigerant piping.

Condensate Drain

Cooling coils remove moisture from the incoming air, and that moisture condenses on the evaporator coil. The water trickles down the coil and is captured in a drain pan that sits under the cooling coil. The drain pan needs to have some way to empty this accumulation of condensate water. Piping is provided from the drain pan to approved receptor, which could be a floor sink or the tailpiece of a regular sink.

The drain piping needs to pitch in order to avoid overflowing the drain pan. If the piping can’t be pitched per the slope required by the local code, then a condensate pump will need to be added. The condensate pump will raise the level of the water in the piping so that it can meet the required slope or pump directly to the receptor. See our Video on “Condensate Drain Piping”.

Controls

The controls on most split systems are very simple, especially residential split systems. A thermostat calls for heating or cooling and the system initiates startup. For systems with more than one circuit, if the first circuit can’t satisfy the demand then the second circuits solenoid valve would open adding additional cooling capacity to the system. The circuit board for controls is usually mounted in the outdoor unit with control wiring connect the indoor unit to the outdoor unit.

Adding Building Management System (BMS) oversight or connectivity is an option usually implemented on commercial properties. This allows the building engineer or management company complete oversight using graphical interfaces to see what is happening with each system connected to the BMS.

In addition to controlling the overall unit, the system has safety controls that operate to protect the equipment. This could include high and low pressure switches to prevent excessive and minimum pressure levels respectively. There are safety devices to protect the equipment from too much electricity or excessive temperatures.

Advantages and Disadvantages of an HVAC Split System Air Conditioner

One of the biggest benefits is that they come as a packaged unit, already engineered by the manufactured with matching outdoor and indoor units.

Split systems are less invasive for remodeling projects, allowing smaller refrigerant piping to be run to a space instead of larger air ducts. This is beneficial when the indoor space is several floors below the roof, as no vertical duct shafts are required as with a Rooftop unit.

Split system outdoor units weight less than a one piece packaged unit.

Split systems require smaller openings in the structure for refrigerant piping to pass from the outdoor unit to the indoor unit, as opposed to air ducts.

Split System outdoor units are smaller than Rooftop Units, so they are easier to hide. This can be important when the building has large skylights or line of sight code compliance issues.

Split systems usually cost more on new construction projects because they require several points of connection for the electrical and refrigerant piping to connect the outdoor and indoor sections together.

Split systems will require some method of getting the required ventilation air to each space or indoor fan coil per ASHRAE 61.2