Top 6 HVAC Control Strategies to Save Energy. In this video we’ll learn the top 6 Control Strategies for reducing energy consumption. These are control strategies to reduce cost and save energy. The control strategies are programmed into the sequence of operation for the control of HVAC systems.

We’ll learn about using trim and respond (T&R) setpoint reset logic for controlling chillers and air handlers. The energy savings from these strategies vary by geographical area and building types.

If you prefer to watch the YouTube Video of this presentation, then scroll to the bottom or click on this link. Top 6 HVAC Control Strategies to Save Energy

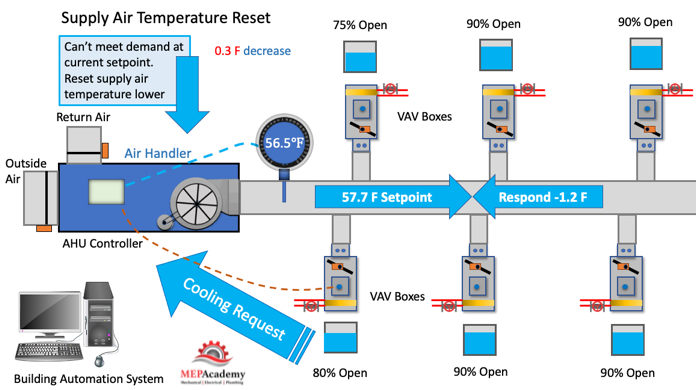

#6 Supply Air Temperature Reset

To save energy the supply air temperature can be reset higher when the demand is reduced. This will save on compressor energy use and allow more time for the use of the air side economizer.

Using Trim and Respond control logic if no request for cooling is sent to the air handler controller, than the supply air temperature is trimmed by a set value that is determined by the programmer. Let’s say that if no request is made the supply air temperature is reset 0.2°F, this would move our setpoint to 55.2°F. Every two minutes or whatever duration is set by the controls programmer the trimming of the supply sir temperature will occur until a request is made from a zone.

The VAV zone boxes can be programmed to make a request when any VAV box damper reaches 90% open. When the request is sent, the supply air temperature will respond by decreasing by a certain value, chosen by the programmer, let’s say by 0.3°F. If our temperature was trimmed up to 58°F, before a request was made, the request would decrease our supply air temperature to 57.7°F.

If multiple VAV boxes send request at the same time, then the value is multiplied by the number of request. If 4 VAV Boxes sent a request for more cooling, then the Supply Air Temperature could be reset by 4 times 0.3°F, for a total of 1.2°F decrease. The controls programmer will limit how much the supply air temperature can be decreased at any one time, no matter how many request are sent for additional cooling. This allows system stability.

Systems using an air-side economizer will have more time when the economizer is in use because of the supply temperature being set higher. This allows the outdoor air to be used instead of the compressor to provide cooling, which saves on energy.

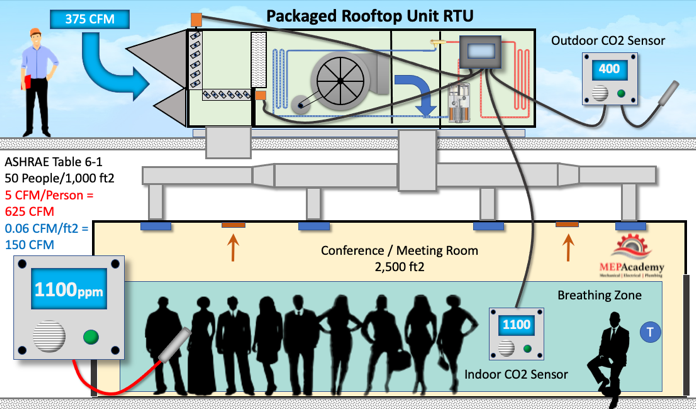

#5 Demand Control Ventilation

The reason it’s called Demand Controlled ventilation is that it controls the amount of ventilation based on the demand. Demand changes with occupancy levels, so some form of occupancy monitoring will be used as the control strategy. Ventilation air is required by ASHRAE standard 62.1, but providing ventilation air is energy intensive and costly. Providing only what’s needed can save on energy and money.

With ASHRAE 62.1 the ventilation requirements or outdoor air is increased based on the number of occupants and square footage of the space. Demand controlled ventilation is based on providing outdoor air in proportion to the occupancy level.

Energy is wasted in the form of conditioning excessive amounts of ventilation air when the occupancy level is less than the design maximum. By using demand-controlled ventilation, the occupancy level can be monitored, and the quantity of ventilation air adjusted downward according to actual occupant levels. Tracking the occupancy level with DCV reduces energy consumption by only bringing in enough ventilation air to satisfy the current level of occupants, not the design maximum.

Using a conference room for our example. If the meeting room was designed for 125 people, but only the presenter is currently in the room waiting for attendees. The CO2 monitor would pick up the low quantity of carbon dioxide and close the outside air damper to match the occupant level. As more attendees arrive to the meeting, the level of CO2 increases, and the CO2 Monitor picks up this increase and sends a command for the Outside Air Damper to open wider, allowing more outside air into the space. As, the occupants leave the system will begin to close the outside air damper. This is a basic explanation of how DCV works, for a further explanation see our video on Demand Controlled Ventilation.

#4 Optimal Start

HVAC equipment has often been setup to use a time clock or time-of-day schedule to turn the system on and off based on a proposed occupancy schedule. The time clock will be set to start the HVAC system equipment before the occupants arrive and to shut it off at a preprogrammed time when the building is scheduled to be vacant. The schedule of when to turn on the HVAC equipment in the morning to ensure the space is comfortable for the occupants is often based on the worst summer or winter conditions. This creates an opportunity to save energy by providing an optimal start time when conditions are not at these peak conditions.

With an Optimal Start strategy the building automation system will select the best, or optimal start time based on the conditions existing for that day. The buildings control system will determine how much time, or how early the HVAC equipment needs to be started to ensure the space is comfortable for the occupants when they arrive. The building automation system will prevent the HVAC equipment from starting too early, which is a waste of energy. The controls will ensure that the system is started with just enough time to have the space conditioned when occupants arrive, no sooner.

Using the capabilities of a building automation system to track historical data and use that data for current conditions is how this strategy is implemented. The controls system receives input from space sensors on the current temperature and compares this to the setpoint temperature. With historical trending data the building automation system can determine how long the HVAC equipment needs to run to make up the difference between this setpoint and the current space temperature. The greater the Delta-T, the earlier the HVAC equipment will be started.

This control strategy saves energy by optimally starting equipment and avoiding conditioning spaces to setpoint temperatures earlier than required. This saves on operational hours of the HVAC equipment, allowing the equipment to last longer.

#3 Shorten HVAC Schedule

Often HVAC schedules are set for longer time durations then the actual occupants require. Shortening the HVAC schedule works well with an optimal start and stop control strategy. This strategy avoids turning on HVAC equipment before they are needed and quickly turns them off when occupants are not scheduled to be in the building. The building automation system learns with historical trending data when it’s the best time to turn equipment on. The controls system uses outdoor air conditions, indoor temperatures and set points for heating and cooling during occupied mode.

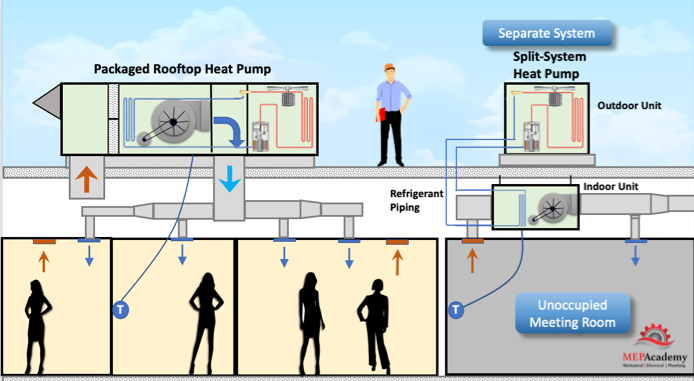

There may be spaces within the building that operate only on specific days of the week. If this space is on the same system as the regularly scheduled equipment, it might payoff to provide a separate system or method of controlling the conditioning of this space.

Working with optimal start to determine the best time to start the equipment, including night setback temperatures, this strategy ensures that the equipment is only running when the building is occupied.

#2 Minimum VAV Box Damper Flow Reductions

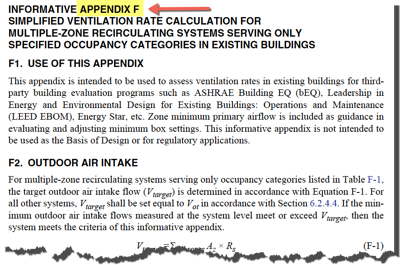

Systems using Variable Air Volume boxes have their dampers set to a minimum open position to ensure that there is always ventilation air per ASHRAE 62.1. Often this minimum open setting is greater than the actual CFM required of the space, as the space will most likely be influenced by the internal load which will drive the damper wider open, negating the minimum setpoint. Set the VAV box damper open to the minimum mandated to meet ASHRAE standard 62.1 for ventilation and no more. See ASHRAE 62.1 Appendix “F” for a Simplified Ventilation Rate Calculation for multiple zone recirculating systems.

When the minimum damper position is set too high, then fan and cooling energy is wasted. Too much cold air is being sent into the space, requiring additional energy to reheat the air. This can be avoided by reducing the minimum setpoint, and by using this Minimum VAV Box Damper Flow Reduction strategy. This will of course depend on the space type and usage.

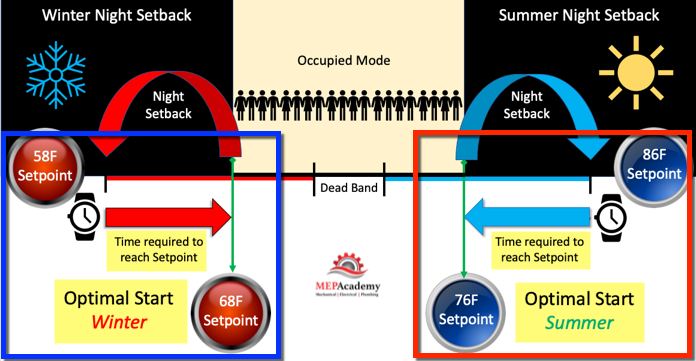

#1 Wider Dead Bands and Night Setbacks

On average, this was the #1 way to save energy.

DeadBand

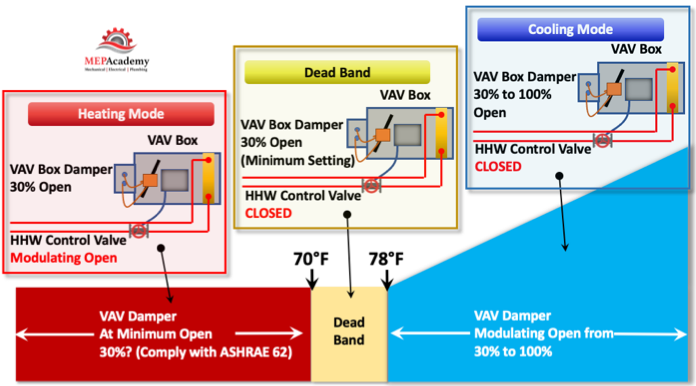

The deadband is the temperature range when the HVAC system is neither calling for heating or cooling.

By widening the dead band, the amount of time that the HVAC system would save energy would increase. In California zonal thermostats that are used to control both heating and cooling shall be capable of providing a deadband of at least 5°F.

Night Setback

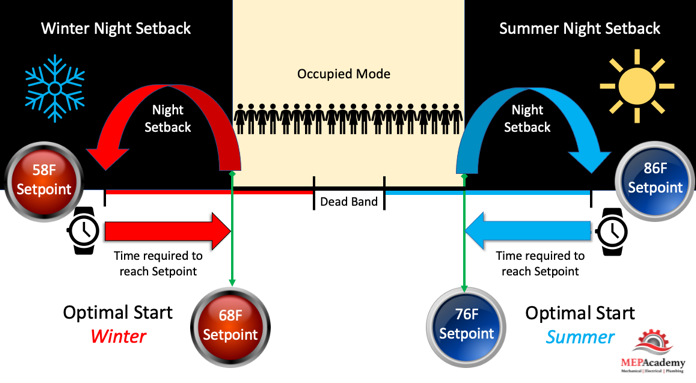

When the building is unoccupied during the nighttime hours, the HVAC system temperature can be setback in the range of 6° to 10°F. This allows the building to become warmer or cooler at night then during the day, but avoids letting it get too far from setpoint. By allowing the HVAC system to increase or decrease from the setpoint, depending on whether in cooling or heating mode, the system will come on less during the night when the building is unoccupied, thereby saving energy.

The system will come on only to avoid extreme temperature conditions. For instance, if your normal daytime setpoint for cooling is 76°F, you could program the DDC system to bring on the HVAC equipment to cool the space after hours or off schedule if the building temperature reached 86°F.

You can see that this works directly with the Optimal Start Control Strategy which is to ensure there is enough time in the morning to cool the space down to its normal setpoint. This is because it was prevented from maintaining normal setpoint temperature of 76°F during the night, hence night setback.

It’s important the system be put in the unoccupied mode; this is to ensure that the outside air dampers are closed. Bringing in ventilation air in unoccupied mode can increase energy consumption unless outdoor conditions are in the economizer range for free cooling of the space in summer.