How Waterside Economizers Work. In this video we will learn How Waterside Economizers work, also known as Free Cooling. We’ll learn how to connect an economizer into a water-cooled and air-cooled chilled water system. A 100% free cooling allows for the chiller to be shutoff and the cooling tower along with a heat exchanger to do all the cooling. We will show you three waterside economizer configurations using a plate and frame heat exchanger.

If you prefer to watch the video of this presentation than scroll to the bottom or click on this link. How Waterside Economizers Work

In our previous video we demonstrated how an air side economizer is based on the ambient dry bulb temperature, and now we’ll show you that a waterside economizer is based on the ambient wet bulb temperature using evaporative cooling. The purpose of a water-side economizer is to reduce or eliminate the hours the mechanical cooling equipment must run, such as a chiller.

Integrated vs Non-Integrated Economizers

There are several methods of operating a waterside economizer. One is for it to be integrated with the operation of the chiller, hence operating simultaneously, or non-integrated, where the chiller is completely off and the economizer has full responsibility to meet the demand of the load.

Integrated Waterside Economizer

The use of an integrated waterside economizer allows for the simultaneous use of both the chillers and the reduced energy consumption aspects of a waterside economizer as required by ASHRAE 90.1

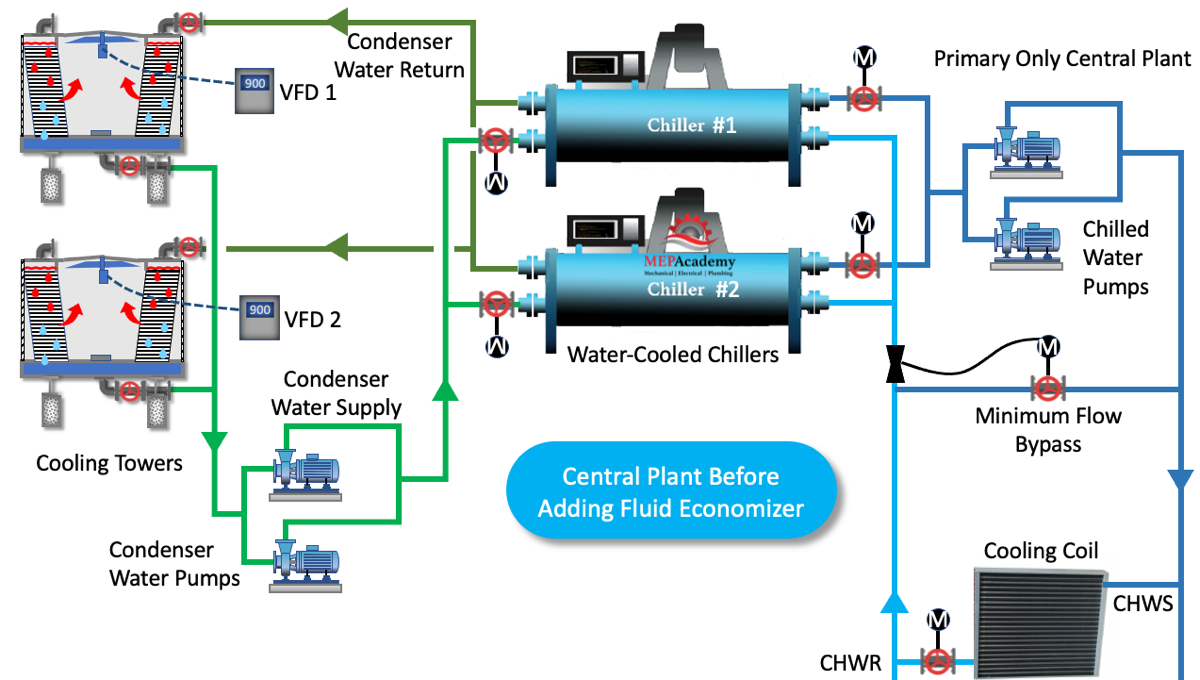

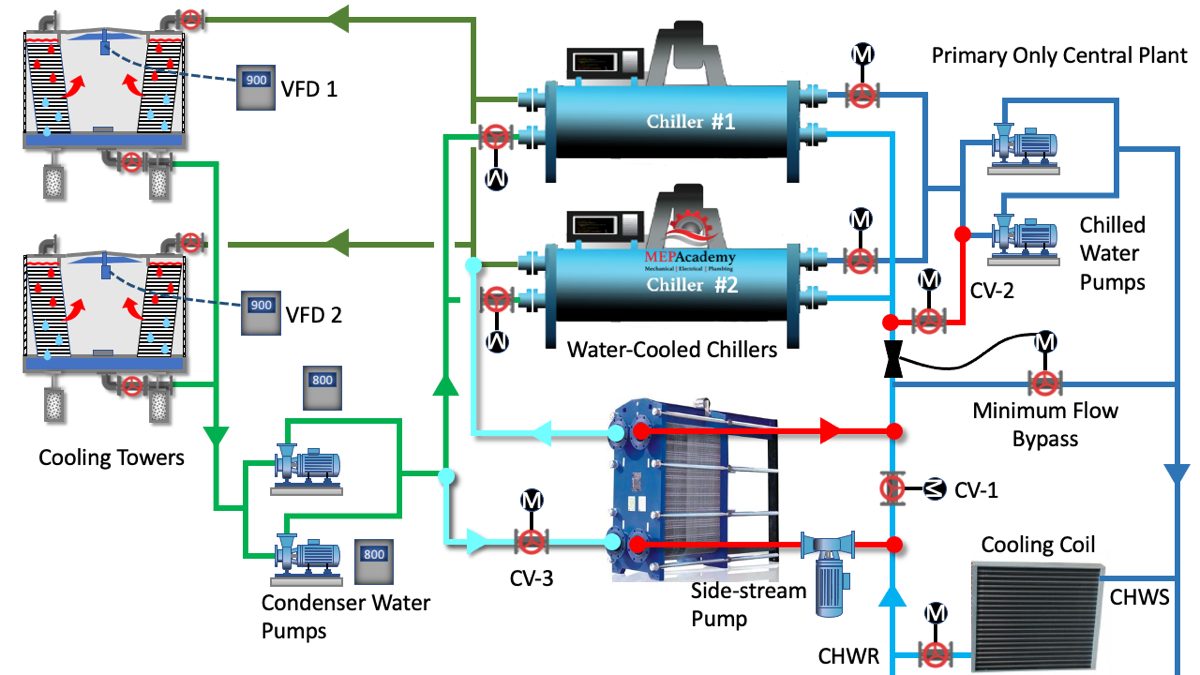

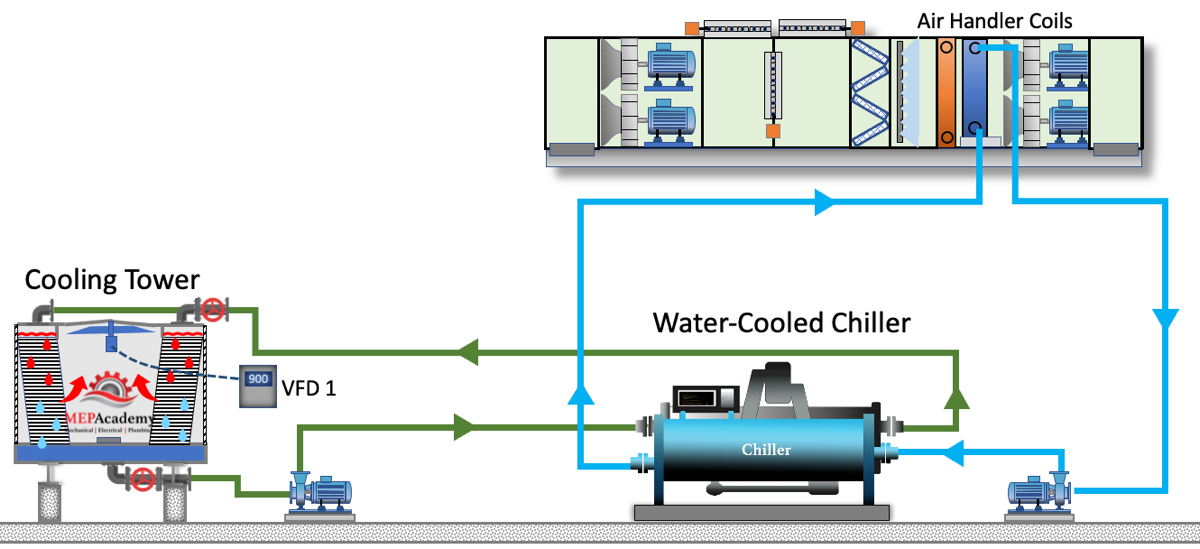

This is a typical primary only chilled water central plant layout, where the primary chilled water pumps serve the chillers and the building load, represented here as a cooling coil.

A plate and frame heat exchanger will need to be added in series with the chillers on the chilled water side for the transfer of thermal energy between the condenser water and chilled water sides. For an explanation of How Plate and Frame Heat Exchangers Work see our previous video.

We will tap into the chilled water return piping and connect to the heat exchanger to precool the chilled water return before sending it onto the chiller. To do this we’ll need to add a control valve (CV-1) to divert the flow, and force the chilled water return to go through the heat exchanger.

The waterside economizer can lower the chilled water return temperature before it arrives back at the chiller for mechanical cooling.

This reduces the load on the chiller in an integrated system. When in full waterside economizer mode we need to add a bypass line so that all the water avoids going through the chillers in order to save on pump energy. We’ll add a control valve (CV-2) to open fully while both chiller control valves will be closed to prevent water from going through the evaporator coils.

This completes one side of the heat exchanger which is the hot side. For the cold side of the heat exchanger we need to connect the condenser water piping in parallel with the chillers, and pipe the cold water coming from the cooling tower basins so that it flows into our heat exchanger, where it will absorb the heat through the plates from the chilled water return. The heat will then be carried by the condenser water to the top of the cooling tower where it will reject the heat to the atmosphere. We need to install a control valve (CV-3) to prevent the flow from entering the heat exchanger when it’s not in economizer mode to avoid additional pressure drop on the pumps.

At the same time, the condenser water pump can reduce its speed and water flow with the use of a Variable Frequency Drive (VFD) to compensate for the reduction in demand on the chiller because of the economizer, if the minimum flow is maintained through the chiller.

When the chiller is at partial load in an integrated economizer system, the condenser will require the manufacturers required minimum flow for head pressure control. The cooling tower will also have a requirement for minimum flow that will need to be adhered to.

There is the option to use a 3-way control valve instead of a 2-way valve, or an option to use a side stream pump to pull the chilled water return through the heat exchanger.

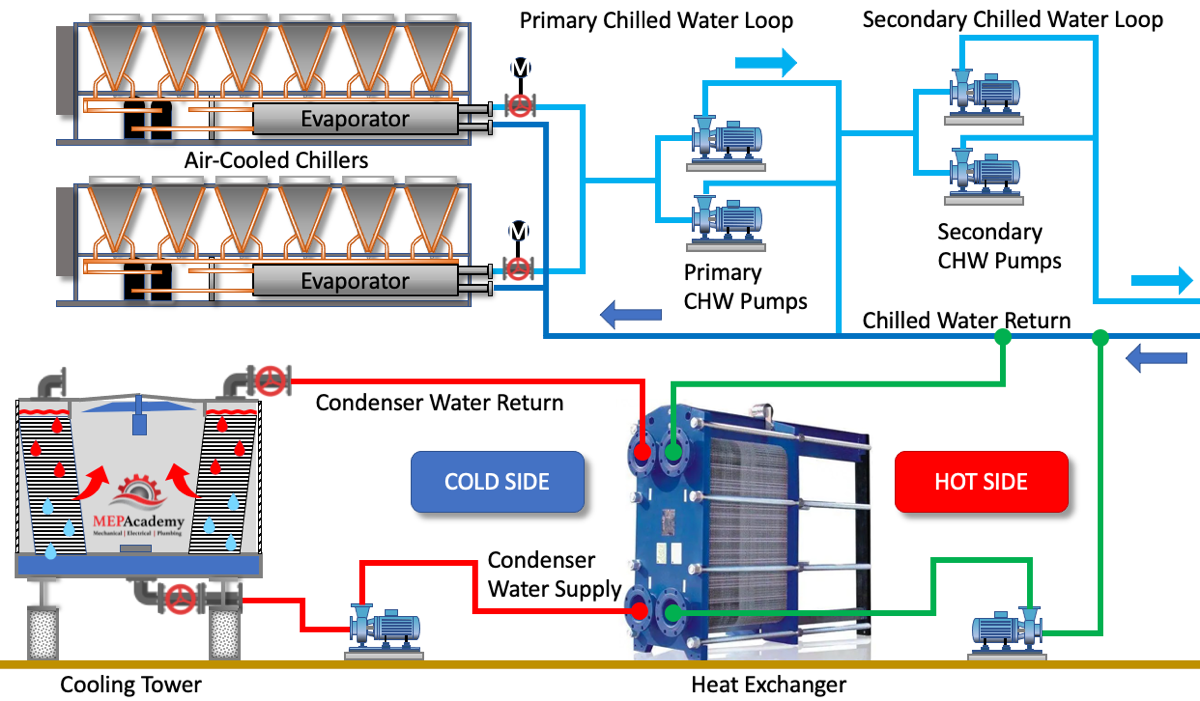

Adding a Waterside Economizer to an Existing Air-Cooled System

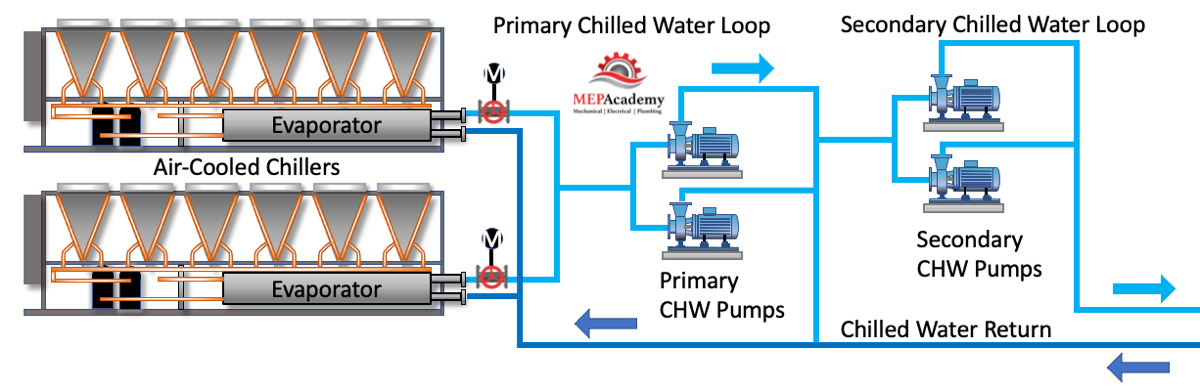

You can retrofit an existing air-cooled chilled water plant with an integrated waterside economizer as we show here. Here we have two air-cooled chillers with primary pumps and variable secondary pumps serving the building load. We can precool the returning chilled water temperature before it enters the chiller, thereby taking load off the chiller.

We add a plate and frame heat exchanger to the system and a pump which will pull water out of the chilled water return and send it through the heat exchanger, where it will give up some of its heat and be sent back into the chilled water return on its way to the air-cooled chillers.

Then a cooling tower is added to the system for heat rejection along with a pump to pull cool water from the basin and send it into the heat exchanger where it will pick up heat from the chilled water return system. Then it will exit the heat exchanger warmer and be distributed at the top of the tower where it will give up the heat to the atmosphere.

Non-Integrated Waterside Economizer

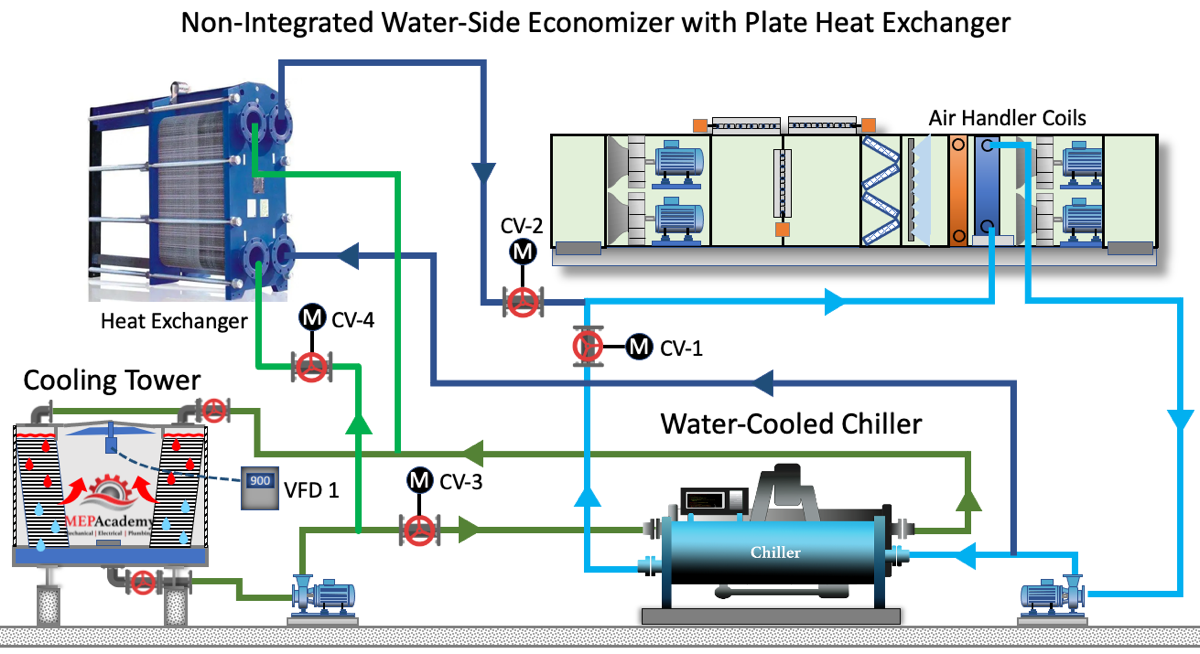

The use of a non-integrated economizer strategy provides for the economizer to be either on or off, there is no simultaneous chiller function. When the economizer is operating the chiller is 100% off. The condenser water from the cooling tower will satisfy the cooling load without assistance from the chiller.

Here we have a water-cooled chilled water plant served by a cooling tower that we can add a waterside economizer to in a non-integrated method just for you to see the difference.

We install a plate and frame heat exchanger and then tap into the chilled water return piping and connect to the inlet on the warm side of the heat exchanger. From the outlet on the warm side of the heat exchanger we connect into the chilled water supply feeding the load in the building, in this case we show one air handler, but this could be dozens of air handlers.

Next we tap into the condenser water supply coming from the cooling tower basin and feeding the chiller. This will be our inlet on the cold side of the heat exchanger. Then on the cold water outlet of the heat exchanger we’ll connect to the condenser water return piping leaving the chiller and entering the tower.

To make this all work there needs to be control valves that reroute the water when the economizer is activated. Remember this is a non-integrated economizer, so there is no simultaneous running of the chiller. This is why the piping is routed around chiller. Control valves CV-1 and CV-2 will be installed on the chilled water side of the economizer, so that when the economizer is activated and the chiller shuts off, CV-1 will close, and CV-2 will open. This allows the water from the air handler or building load to bypass the chiller and go directly to the heat exchanger.

Next there will need to be control valves on the condenser water side of the heat exchanger to bypass the chiller. Control valves CV-3 and CV-4 are installed on the condenser water supply to the chiller and the inlet piping to the heat exchanger. During waterside economizer mode, CV-3 will close preventing water from entering the chiller, and CV-4 will open allowing the flow to be diverted from the chillers condenser to the heat exchanger.

ASHRAE 90.1 (2019 Section 6.5.1.2.1)

If your local building code has adopted ASHRAE 90.1 then the use of a waterside economizer could be mandated by code under certain conditions or as one of several options to achieve energy saving goals. When the temperature drops below a set value, such as 50 F dry bulb/45 F Wet bulb or (10 Celsius DB/ 7.2 Celsius WB) mechanical cooling would shut down and 100% full waterside economizer would be active.

For those that live in the state of California, in the United States, the temperature requirement thresholds are the same as mandated in the Title-24 Energy Code. When starting up the central plant the control logic will determine whether to activate the economizer mode based on the two approach values being able to meet the chilled water supply temperature setpoint.

Important Temperatures

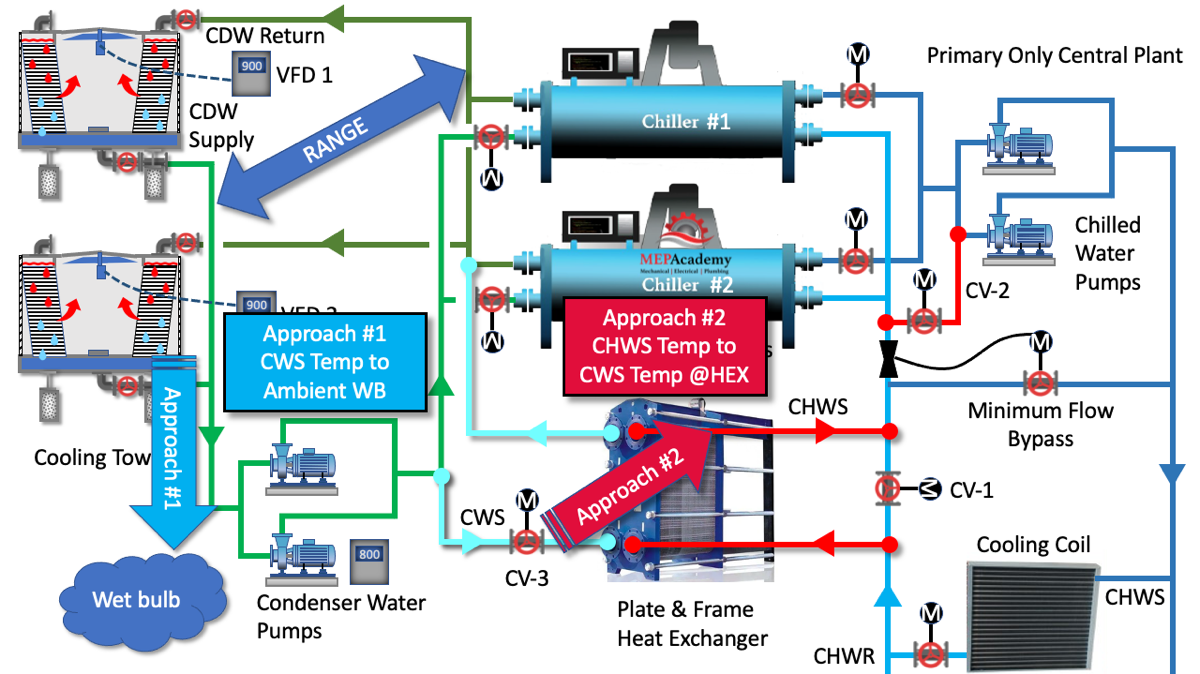

Some of the key temperatures to look for when determining if an economizer will work in your location is what they call the Approach Temperatures. This would take another video for an in-depth explanation but we’ll get you started with two approaches important for the integrated economizer systems we have explained in this video.

There is the Cooling Tower or Condenser Water Approach, that defines the condenser water supply temperature in relationship to how close it gets to the ambient wet bulb temperature. Then there is the Heat Exchanger Approach that compares the condenser water supply temperature to the chilled water supply temperature across the heat exchanger.

Another important value would be the temperature range of the condenser water, that’s the difference between the condenser water return minus the condenser water supply.

The three important factors in sizing the water-side economizer are the wet-bulb temperature, the temperature range, and the approach.