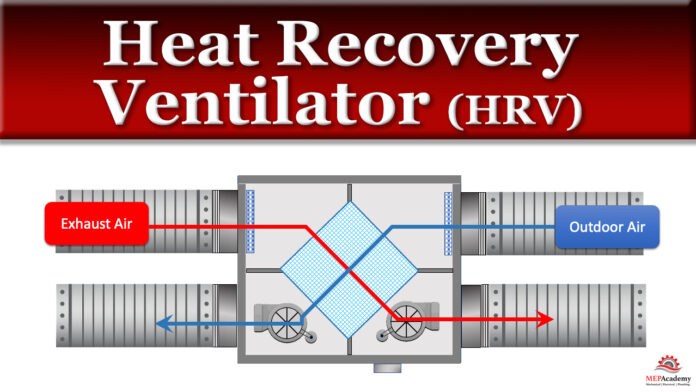

Learn how a Heat Recovery Ventilator works. The purpose of the Heat Recovery Ventilator is to transfer sensible heat between the incoming and exhaust air streams, and to increase indoor air quality. Instead of wasting the heat, it’s recovered from the exhaust stream in cold climates and in warmer climates the incoming hot air is cooled down by giving up some of its heat by the cooler exhaust leaving the building.

If you prefer to watch the video of this presentation scroll to the bottom or click this link ” Heat Recovery Ventilator and How They Work“

Ventilation air is required for human health and indoor air quality. The conditioning of this outdoor air takes lots of energy. By using a heat recovery ventilator, the load on the air conditioner can be reduced, thereby creating a more efficient system.

Checkout these Heat Recovery Ventilators hereWe’ll explain how they’re built, how they work, how to size them, and the three different ways that they can be used with or without air conditioning.

How a Heat Recovery Ventilator is Constructed

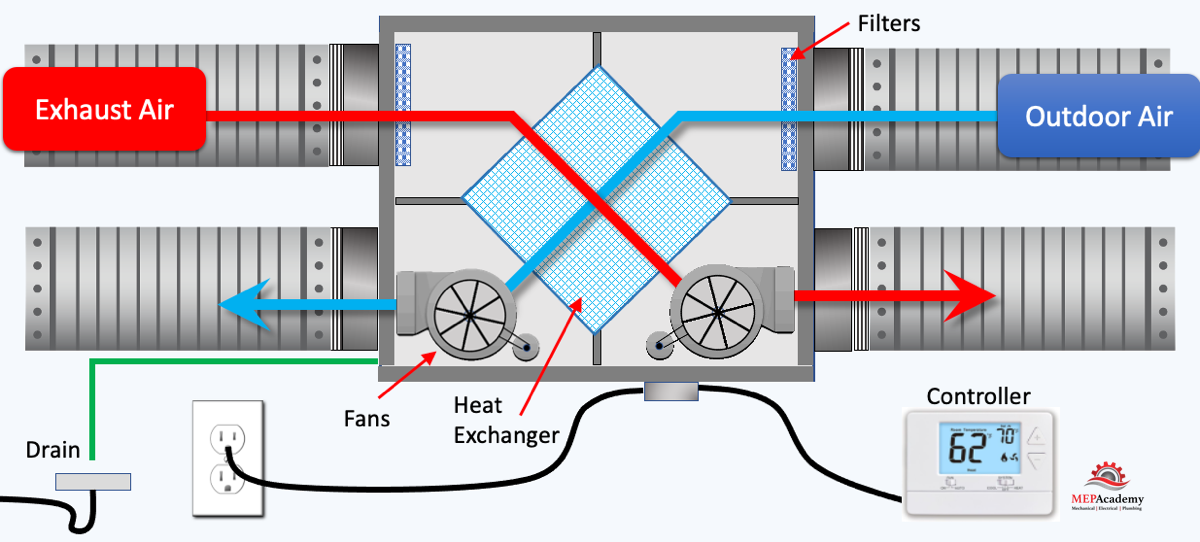

The heat recovery ventilator is made of a painted galvanized steel housing. There is a supply and exhaust fan capable of multiple speeds. There should be washable and/or disposable filters at the intake to both fans to keep the fans and heat exchanger clean. Some commercial HRV’s allow for final filters, which is a second set of filters of higher quality.

Then there is the air-to-air heat exchanger which is made of polypropylene or aluminum. There will be a 120-volt power cord that plugs into any nearby outlet or hard wired to a circuit breaker in a nearby electrical panel. A low voltage control wire will be routed from the controller to a connection on the ventilator.

A drain pan and drainpipe will be needed to carry away any water that accumulates during heat transfer or the defrost cycle. There will need to be two holes cut in the exterior wall to allow for the ventilation intake and exhaust grilles. Ductwork will be routed from the grilles to the heat recovery ventilator. The ductwork can be pre-insulated flexible duct or rigid round with insulation.

HRV manufacturers position their fans and filters differently. Some will have the filter before the fan and some after. Some will configure the fans in a blow through arrangement while others use the draw through method.

How a Heat Recovery Ventilator Works

First its best to remember that heat moves from a warmer object to a cooler one as defined by the second law of thermodynamics. Heat will always seek to equalize itself with any cooler objects it meets. Therefore, you wear a jacket in winter, to retain the heat in your body and avoid it from equalizing with the cold outdoor air.

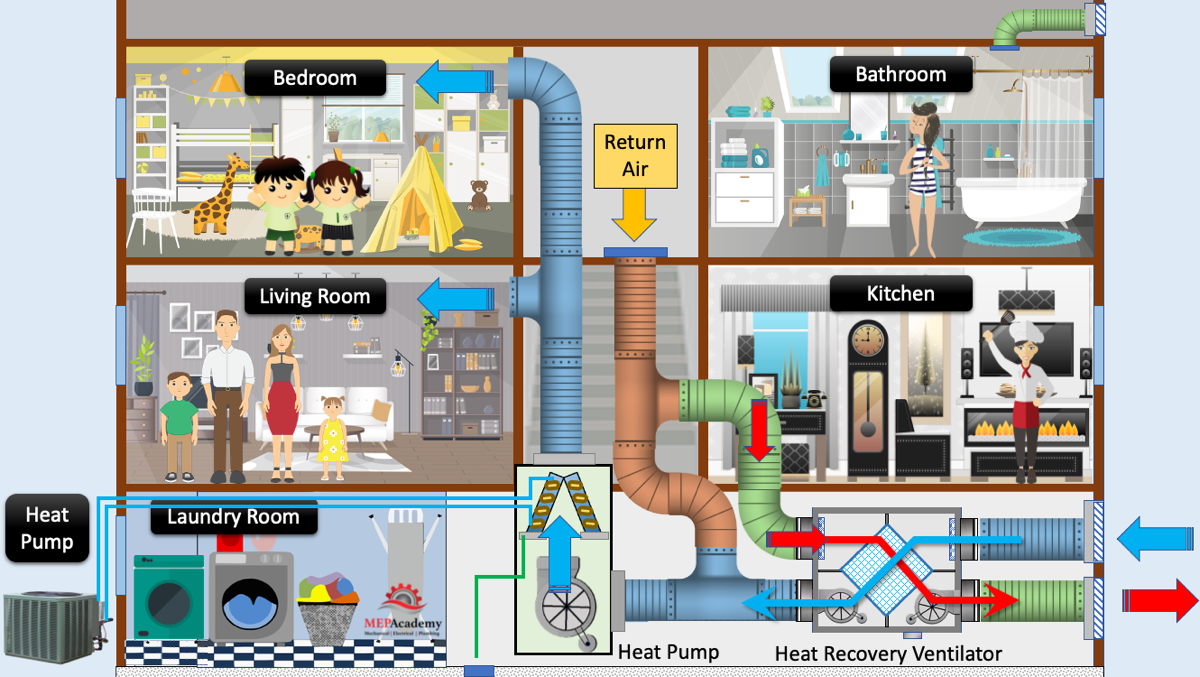

Now we’ll explain three common methods of using a Heat Recovery Ventilator. One method is used without an air conditioner or furnace, the next one with an integrated A/C system, and the final one integrated with all connections on the return duct feeding an air conditioner.

Checkout these Heat Recovery Ventilators hereHeat Recovery Ventilator (Non-Integrated System)

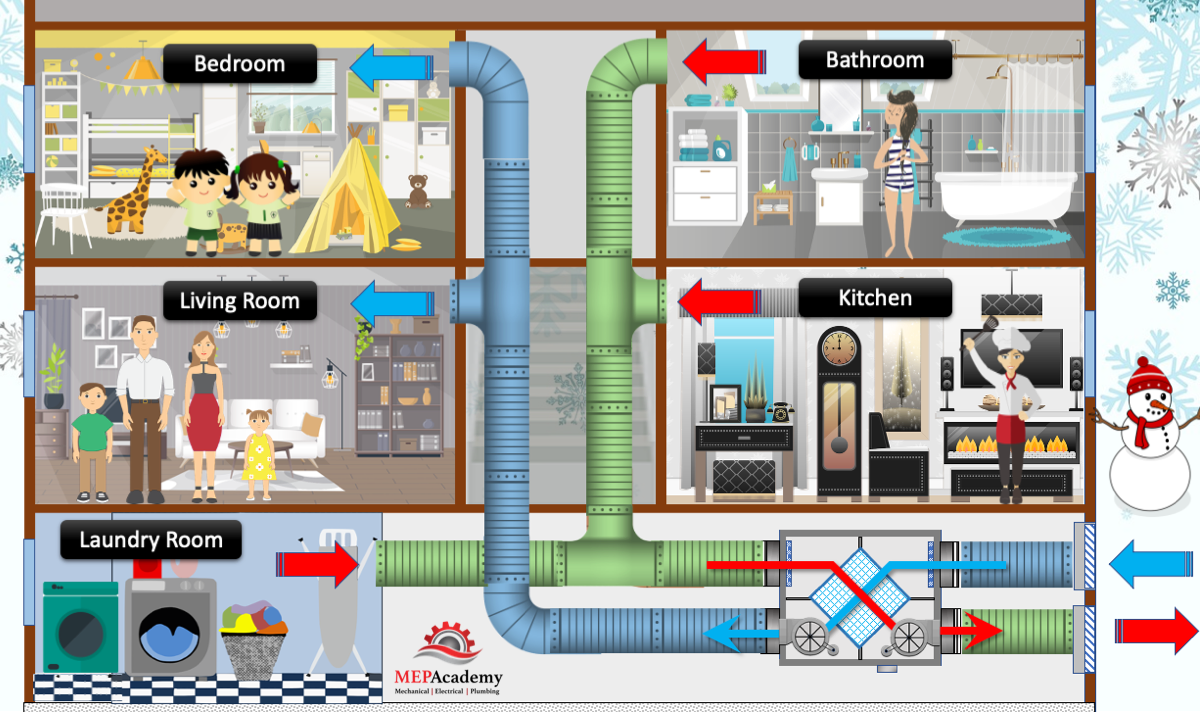

Ventilation air Ductwork will be routed from the outdoors through the heat recovery ventilator to various rooms, like bedrooms, living rooms and family rooms. It’s recommended to design the airflow so that the fresh air is routed from clean spaces to rooms where the air is to be exhausted because of odors. This would have the fresh air travel into the bedroom and then be exhausted through the bathroom, kitchen or laundry room where smells are generated.

This will provide a good path for fresh air to enter spaces where occupants are sleeping and living, while exhausting areas that generate smells or have stale air. This moves fresh air from clean areas through dirty areas. Now let’s add an air conditioning unit to the space.

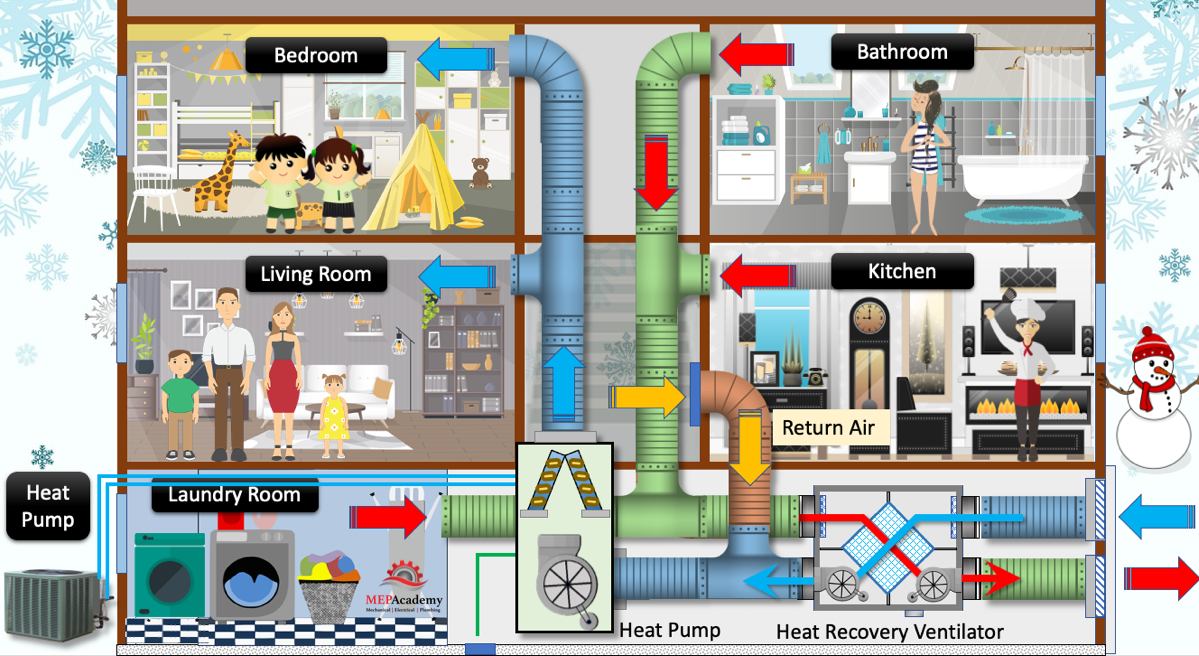

Heat Recovery Ventilator integrated with Air Conditioning System

This will require an outdoor unit and an indoor air handler. See our video on “How Split System Air Conditioners or How Heat Pumps Work” for an explanation of these systems. The indoor and outdoor units are connected with refrigerant piping.

The heat recovery ventilator works the same way but is connected directly to the return air duct of the heat pump unit. The fresh air duct will need a manual volume damper to balance the air volume. The fresh air will be distributed through the existing air conditioning or furnace supply air ductwork. This requires that the air conditioner is running any time the heat recovery unit is running. There is an interlock between the two systems to ensure that one is not running without the other.

A backdraft damper should be provided in the return air duct upstream of the fresh air connection. This will avoid the heat recovery ventilator from pushing air backwards through the return air ductwork if the air conditioner was off or failed. Also, the distance from the return air connection to the air conditioner to where the fresh air tap into the return air is dictated by code, check your local code for distance requirements. Some manufacturers require at least 10 feet (3 m)

If the building has more than one air conditioner, there will need to be a separate Heat Recovery Ventilator for each.

Checkout these Heat Recovery Ventilators hereHeat Recovery Ventilator integrated with Return Duct of A/C System

The heat recovery ventilator works the same way but once again is connected differently. Both the fresh air intake and exhaust are connected to the return air ductwork. Instead of taking air directly from the bathroom, kitchen or laundry areas, this system arrangement just exchanges enough return air with the required amount of fresh air.

The bathroom and laundry rooms can have their own exhaust fan while the kitchen will have a range hood to exhaust air when cooking on the stove.

How to Size a Heat Recovery Ventilator

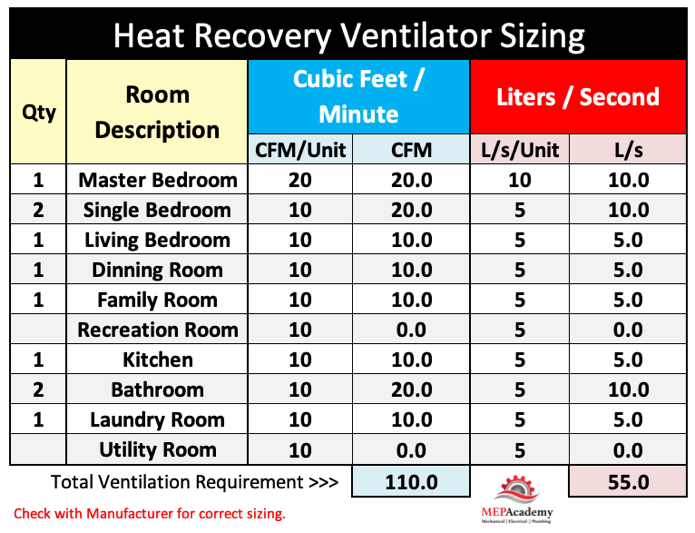

For small residential properties various equipment manufacturers provide convenient charts based on a quantity of cubic feet per minute (CFM) or Liters per Second (L/s) for each room in the home. Bedrooms receive the greatest amount of CFM (L/s), followed by all other rooms. One manufacture recommends 20 CFM (10 L/s) for Master Bedrooms and 10 CFM (5 L/s) for each of the other bedrooms and spaces within the home.

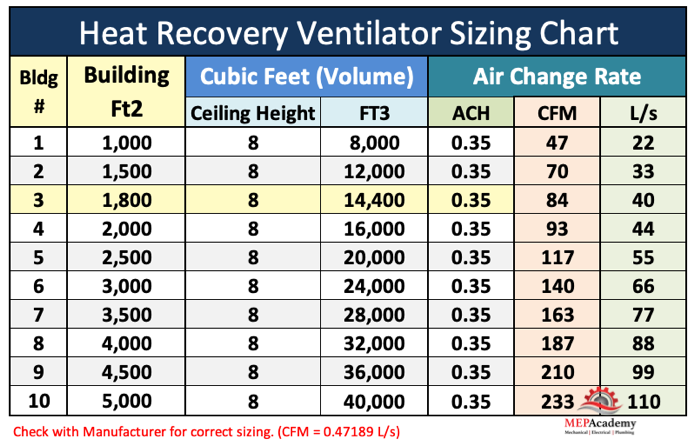

Another sizing method uses Air Changes per Hour (ACH). See our video on Air Changes per Hour for a better explanation. One manufacturer recommends 0.35 ACH. The formula would look like this: Total Ft3 of building x 0.35 ACH / 60 Minutes/Hour.

Example: A 30’ x 60’ home

1,800 Ft2 x 8’ Ceilings = 14,400 Ft3

14,400 Ft3 x 0.35 ACH = 5,040 Ft3

5,040 Ft3 / 60 minutes = 84 CFM (40 L/s)

Winter Mode

Cold fresh air is brought into the ventilator through a filter by a blower fan. The blower sends the cold air into the heat exchanger where it absorbs heat from meeting the material of the heat exchanger. The heat exchanger is warmed up by the exhaust air leaving the building. The exhaust air is brought in from the spaces within the building. The exhaust is filtered before the blower and then sent across the heat exchanger, before being thrown outdoors.

A heat recovery ventilator brings in ventilation air through one end and exhaust air through the other end. They cross paths internally within the ventilators heat exchanger, but the air streams never physically mix, so there is no contamination of the fresh air by the stale exhaust air. Instead, they transfer heat between heat exchanger surfaces that keep the two air streams separated.

If frost accumulates then a defrost cycle could be implemented whereby the supply fan shuts off, while the exhaust fan speed increases. This allows the warm exhaust time to defrost the system when no supply air is brought in. The defrost cycle is turned on by measuring the temperature of incoming ventilation air. If the air is too cold the defrost cycle commences for a fixed time.

Summer Mode

The process is the same as in winter except that warm air is now brought in with the ventilation air. The blower sends the warm fresh air into the heat exchanger where it rejects heat as it crosses paths with the cooler exhaust air. The heat exchanger is warmed up by the ventilation air entering the building. The exhaust air is from the bathroom, kitchen and laundry as we showed before. The cooler exhaust air is filtered before the blower sends it across the heat exchanger where it picks up heat, before being exhausted outdoors.

Heat Recovery Ventilator versus an Energy Recovery Ventilator

First, we need to explain that there is a difference between a Heat Recovery Ventilator (HRV) and the Energy Recovery Ventilator (ERV). An Energy recovery ventilator removes both sensible and latent heat (humidity), while a heat recovery ventilator removes only sensible heat. Remember that sensible heat involves raising or lowering the dry bulb temperature of the air and doesn’t include the energy required for water vapor to change state. Latent heat is associated with water vapor and humidity.

Heat Recovery ventilators are cost effective at reclaiming heat during winter and are used in colder climates, while energy recovery ventilators are used in warmer humid climates to help control humidity.

Heat Recovery Ventilator Control

There are various methods for activating the heat recovery ventilator.

Thermostats can turn the unit off and on based on temperature or fan only status. Remember if the ventilator isn’t running, there won’t be any fresh air coming into the building by this method.

If used with Carbon Monoxide Detectors, some manufactures offer an interface connection that would allow the fan to go into high-speed mode. This would assist with CO dilution and exhaust.

These units can also use a humidistat to control the speed of the fan. When humidity levels get too high within the space the humidistat can call for the fan to go into high-speed mode. Humidistats can be in bathrooms, laundry rooms or kitchens where moisture is generated. But remember, this is a heat recovery unit, it does not remove latent heat or moisture.

A remote timer can be used to allow occupants to turn the heat recovery ventilator on for the duration that they plan to occupy the space. There are also programmable fan timers that can be set to allow the system to come on and off throughout the day based on a schedule.

A simple switch could be used to allow occupants to turn the unit on and off as they wish, or the switch can allow for high-speed fan operation.

The recovery ventilator could also be connected to a building management system in a commercial application.

Heat Recovery Ventilator Maintenance

- Remember to disconnect the power before performing any maintenance or hire a professional to avoid unintended accidents.

- As with any air moving equipment, filters will need to be cleaned or replaced every quarter or based on usage.

- Clean the fans of any dust or grease that may have attached itself to the fan blades and fan housing.

- Check the drain opening and connected piping to ensure that the pathway is clear for condensate to flow unobstructed.

- Inspect the ventilation intake grille to ensure that the opening isn’t clog with debris like leaves and trash.

- Have the air ducts inspected and cleaned, if need be, or replaced if in poor conditioned. A dirty or leaking air duct will reduce the performance of the heat recovery ventilator.

- Clean the heat exchanger of any dust that may have accumulated. Some units allow for the easy removal of the heat exchanger and allow cleaning with a warm water/detergent solution. Check the manufacturers literature for maintenance and cleaning requirements.

- Make sure to maintain all clearance requirements for the removal of the core and fans. The manufacturers literature will indicate the required clearances.

- Do not exhaust clothes dryers, flammable fumes, dusty environments, or appliances.

1 CFM = 0.47189 L/s

1 L/s = 3.6 m3/Hr.

The heat recovery ventilator is designed to recover or reject heat in homes, hotels, offices, meeting halls and just about anywhere except where the air contains coarse dust, soot, flammable, or explosive mixtures, or any dangerous or harmful substances.