Chapter #9 – Air Distribution

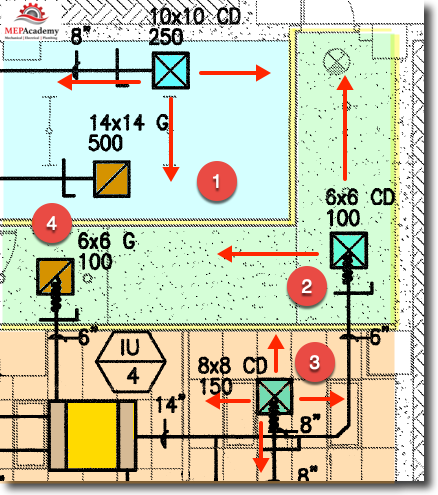

The fan blows or sucks air through a duct and exits or enters a piece of air distribution. There are different types of air distribution devices based on types of ceilings and the engineer’s preference. In the image below there are three different ceiling types (1, 2, 3) shown for the Supply Air Diffusers.

Ceiling Types

#1 – No ceiling (There is no ceiling in this room because it’s used for the engineering dept.)

#2 – Gypsum board ceiling.

#3 – Acoustical tile (2’ x 4’)

Remember that the Architectural Reflected Ceiling Plan shows the type of ceiling for each area. The Mechanical engineer may use that reflected ceiling plan has the starting background image before they design the HVAC system over it.

Supply air grilles and registers have options on the directional throw as shown in the image above, you have Supply Ceiling Diffuser (#1) shown as a 3-way throw, hence the three arrows. Supply Ceiling Diffuser (#2) is shown as a 2-way throw, and Supply Ceiling Diffuser (#3) is shown as a 4-way throw.

Have you ever been in a restaurant or other place of business and felt a draft drop down over you while you were sitting eating or conducting business? This is poor air distribution design, as you should never feel the air, it should just blend in without any draft on you.

Linear Diffusers

Linear diffusers are used in areas that require a more aesthetically pleasing look due to the ceiling design or layout.

The plenum will be installed first and then once the sheet rock is installed, the sheet metal field technician will return to install the actual linear diffuser.

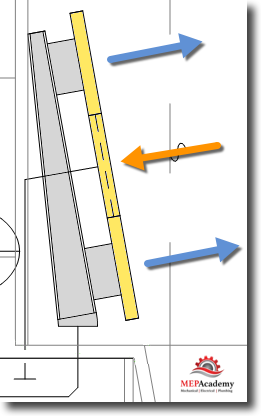

Shown below is what a linear supply and return diffusers looks like on the actual drawings. Each engineer draws them slightly different, but it should show as a skinny long grille. The blue arrows show the supply linears and the orange arrow shows the return linear.

In this design, the return air is ducted as shown by the single line duct leading from the center of the back of the linear. Often in commercial buildings the return air will be non-ducted, in which case the air will travel back to the HVAC equipment through the attic space.

HEPA and ULTRA HEPA Filter Grilles

HEPA filters are used when cleanliness is a requirement for a space. This could be a pharmaceutical or micro-chip manufacturer, hospital or laboratory. There are various levels of cleanliness from ISO-1 through ISO-9, or Class 1 through Class 100,000. You don’t have to worry about this right now, but you will need to get pricing and provide labor to install. Watch the video below to see what a 2’ x 2’ HEPA filter grille looks like.

Fan Powered HEPA Filters

This is a special type of air distribution device where a fan is located within the housing that supply’s air through a HEPA filter to provide clean air to a critical space such as a cleanroom or operating room. You would request a quote from the manufactures representative and provide the appropriate labor to install them. It takes much longer to install these special air distribution devices than a normal diffuser, possibly 2 to 4 hours each depending on the type and hanging requirements.

Flexible Duct Connections

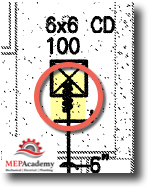

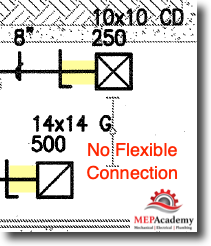

The majority of air distribution connections from branch ducts are made with a flexible duct connector. This is represented by a little squiggly mark between the duct and the air distribution diffuser.

Some air distribution diffusers won’t need a flexible connector as they maybe located where there isn’t a ceiling as shown in the below image. In this case you would use a hard 90-degree elbow. In some jurisdictions, the use of a 90-degree elbow is mandated by code, so check your local code authority.

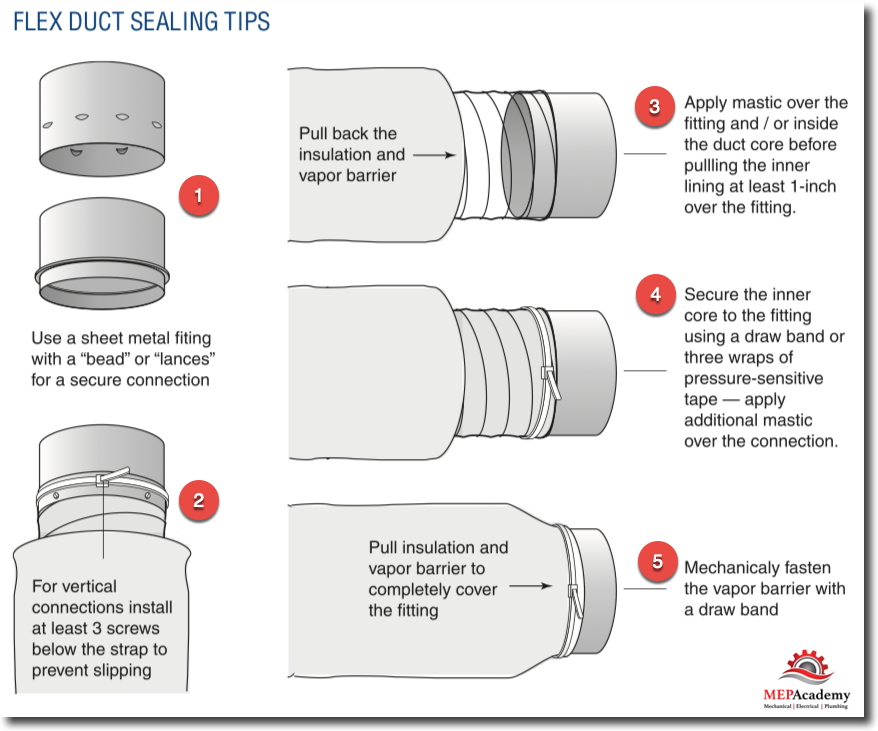

The following shows the proper method of attaching flexible duct to either the can or collar on the Air Distribution Diffuser or the branch duct.

Item #1 shown in the image below shows that a bead or lances provide the best method for keeping the flex secured in place. If the flex will be hanging vertically with gravity and its own weight pulling down, then its recommended to add sheet metal screws (#2) to hold it from slipping off.

Estimating Spreadsheet

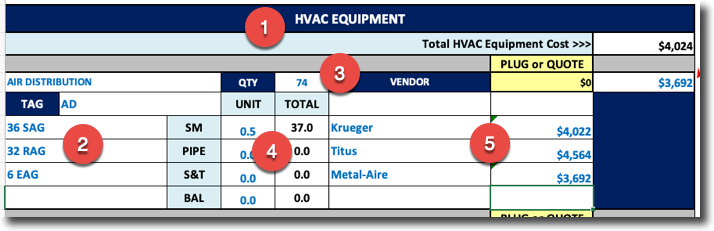

Enter the information on your estimating spreadsheet under the HVAC Equipment Tab. Indicate the Quantity of each type (#2), the Total Quantity (#3), Unit of Labor per each (#4), the Vendor Name and Pricing (#5). This estimating spreadsheet from MEP Academy automatically picks the lowest bidder, but can be overwritten by the estimator by entering a different value in the “Plug or Quote” box highlighted in yellow.

Sheet Metal Field Installation Course

- Chapter #1- Rectangular Duct and Fittings

- Chapter #2 – Round Ductwork and Fittings

- Chapter #3 – Sheet Metal Duct Hangers

- Chapter #4 – Sheet Metal Field Labor Productivity

- Chapter #5 – Labor Crew Sizes

- Chapter #6 – Sheet Metal Duct Sealer

- Chapter #7 – Sheet Metal Details and Specialties

- Chapter #8 – Grease Exhaust

- Chapter #9 – Air Distribution

- Chapter #10 – Rental Equipment

- Chapter #11 – Conditions Affecting Field Labor

- Chapter #12 – HVAC Equipment Labor