Chapter #5 – Field Labor Crew Sizes

The size of your labor crew depends on the project schedule, the amount of work required to be completed within that time frame, and the production rate of your crew.

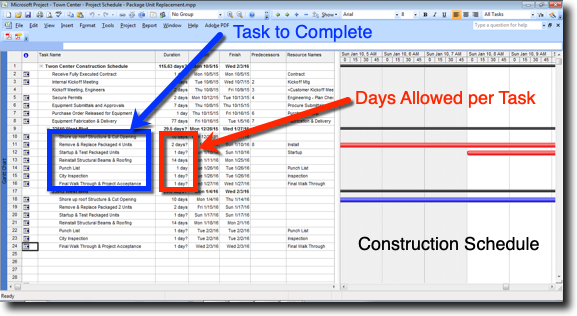

It’s imperative that you understand the project schedule and the sequence of construction or phasing. In order to optimize your labor productivity you will want to maintain a consistent crew size, but this is not always possible as different phases or sequences of the project require varying amounts of labor.

You will need to determine how many workers are required at various stages of the project. Your crew size will vary depending on how much work is required at any point in the project within the window allowed by the project schedule.

Watch this video and pay attention to how many works are required at each stage of this small project requiring a helicopter. From the warehouse workers who load the HVAC units onto the truck for delivery, to the workers on the ground at the building site who attach the new unit to the rigging cables and then to the workers on the roof who set the unit in place. How large was the crew at each stage of the process?

It’s also possible that one or two of the crew members you see in the video are part of the Helicopter companies rigging and safety personnel. The fact that the HVAC units sit so far from the edge of the building makes it feasible to hire a helicopter than the oversized crane required to reach such far distances.

Factors Affecting Crew Size

- Project Schedule (Duration)

- Scope of Work per Scheduled Duration and Allotted Area (Quantity of Material & Equipment to be Installed)

- Productivity Rate for Each Item to be Installed

Productivity Rate

How much work can get done in a day based on the project schedule and the project area available for your team? Projects are phased according to the most critical trade that needs access to the area. After reviewing the project schedule and determining the quantity of equipment and materials that you have to installed within that area you can determine the crew size with your productivity rate.

Your productivity rate is based on your company’s historical data from completed projects. The productivity rate will tell you how much of a certain item can be installed within a certain time frame. Units of measure usually include LF/Day (Linear feet / Day), Hours/Each, Lbs/Hr (Pounds per Hour).

The productivity values are collected from cost codes that your company uses to track various project tasks. The cost codes are broken down to be useful when analyzing future projects, such as keeping track of how long it takes to install round duct or small copper piping per foot, per hour.

Remember to review the chapter on Factors Affecting Labor Productivity.

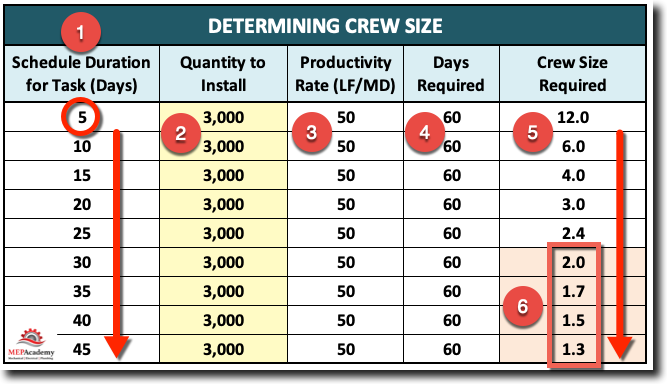

Project Schedule

Let’s Look at various project durations as shown in column #1 in the above chart for a fictious project. We show a schedule of 5 days through 45 working days for a certain area of the project. If we have a certain amount of sheet metal to install within this area, and we know the quantity as shown in column #2 as 3,000 feet, and we have a productivity rate (column #3) from our historical labor feedback, this will determine the quantity of days (column #4) required to install this particular item. From here we can determine the crew size required as a simple formula as follows;

3,000 Feet / (50 Feet/Day) = 60 days / 5 Day Schedule = 12 Crew Members

3,000 Feet / (50 Feet/Day) = 60 days / 10 Day Schedule = 6 Crew Members

3,000 Feet / (50 Feet/Day) = 60 days / 15 Day Schedule = 4 Crew Members

3,000 Feet / (50 Feet/Day) = 60 days / 30 Day Schedule = 2 Crew Members (Item #6)

3,000 Feet / (50 Feet/Day) = 60 days / 45 Day Schedule = 1.3 Crew Members (Minimum 2 Crew)

As can be seen in the chart above, that from a 30 to a 45 day project schedule, the minimum required crew size is 2. As the project schedule gets longer a smaller crew size will be required to get the same amount of work done.

Weather

Extreme weather can be a cause for a restricted crew size as productivity is affected. Remember to review the chapter on those conditions which affect labor.

Consistent Crew Size

As mentioned above, it would be nice if you could maintain a consistent crew size, but this is unlikely as projects require varying amounts of field labor depending on the amount of task to be accomplished within the window of time allotted on the project schedule.

Crew Composition

Determining the mix of skilled and unskilled labor that will comprise the crew can be dictated by Union ratio requirements for union contractors and the availability of labor and skilled set required to accomplish the task at hand.

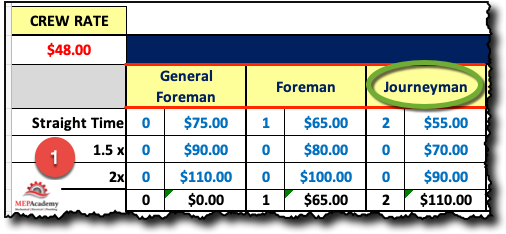

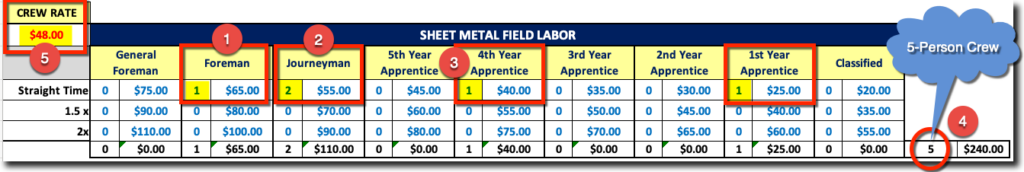

Having a method to pick your average crew size for the project will help you estimate the correct average hourly rate for the project. Most union labor rates use the Journeyman rate to determine all other rates.

Above and below we have inserted portions of the Labor tab of the MEP-Academy Estimating Spreadsheet where you pick the crew size and whether any of their time is at time an a-half (1.5x) or double-time (2x).

In the Sheet Metal Field Labor table above, you can see that there are various categories of labor including General Foreman, Foreman (#1), Journeymen (#2), and Apprentices (#3) of various levels of experience.

Step -1 Pick how many of each of the categories of field labor you want based on the total crew size determined above and the ratio of journeymen to Apprentices allowed by your local union if you’re a union contractor. The crew size will be indicated as shown in the example above by (#4), which in this case is a crew of 5 workers at a crew rate of $48.00/Hr. (#5)

Summary

Think of crew size in simple terms of you being told that you need to get a fence painted that is 300 feet long, the length of a football field. You figure based on your past experience of painting that you can paint at least 30 feet a day yourself. This would mean that if you were to do the project yourself and pocket all the money it would take you 10 days to paint the entire 300 feet of fencing.

300 feet / 30 feet per day = 10 Days

Now what if the owner said that he needed it painted in 5 days, and that he couldn’t wait 10 days. You have a choice, you could work two shifts a day yourself (16 hours a day or 60 feet/day), or you could hire another person to assist you.

30 feet per day / person x 2 Workers = 60 feet per day

300 feet / 60 feet per day = 5 days

The results would require two people work 5 days to complete the project per the owners schedule.

Project Schedule = 5 Days

Scope of Work = Paint 300 feet of fence in 5 Days. 300 feet/5 Days = 60 Feet / Day

Historical Productivity per Worker = 30 feet/Day per worker.

Workers Needed = Productivity Required (60 Ft/Day). (60 Feet/Day) / (30 Feet/Day/Man)

Now think of how many feet of sheet metal duct could be hung in a day instead of how many feet of fence you could paint in a day. Your companies historical data should be able to tell you how many linear feet of duct can be hung in a day based on differing size breakdowns.

Sheet Metal Field Installation Course

- Chapter #1- Rectangular Duct and Fittings

- Chapter #2 – Round Ductwork and Fittings

- Chapter #3 – Sheet Metal Duct Hangers

- Chapter #4 – Sheet Metal Field Labor Productivity

- Chapter #5 – Labor Crew Sizes

- Chapter #6 – Sheet Metal Duct Sealer

- Chapter #7 – Sheet Metal Details and Specialties

- Chapter #8 – Grease Exhaust

- Chapter #9 – Air Distribution

- Chapter #10 – Rental Equipment

- Chapter #11 – Conditions Affecting Field Labor

- Chapter #12 – HVAC Equipment Labor