Chapter #2 – Round Ductwork and Fittings

In order to do a takeoff, you will need to be able to understand what rectangular duct and fittings look like and how they are represented on the drawings.

Round fitting types and methods of construction can vary by region and between companies.

Engineers use software programs that have standardized duct and fitting symbols, in addition to the ability to create their own representations of what duct and fittings look like on the drawings, but once you know what to look for you can identify the slight differences between designs.

Depending on the situation ducts either start at some cooling or heating source air conditioner, air handler or an HVAC accessory like a VAV terminal, or transition from a rectangular duct as in a square to round fitting.

If the round doesn’t start from a piece of equipment or from a square to round, then it will need some form of starting fitting. Manufactures make various types and connection methods, so you need to become familiar of what is commonly used in your area.

Round Duct Types

Round duct is manufactured with various seam types, the most common being spiral or snap lock.

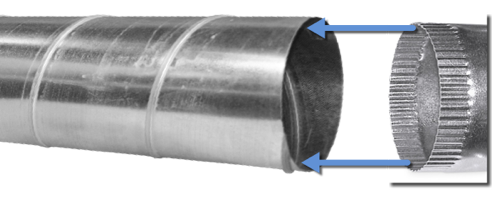

Spiral Round Ducts

Round duct is used to connect between fittings, accessories and flex duct. Manufactures usually stock standard lengths, but if you have your own spiral machine you can fabricate any length.

Spiral duct is not limited in length, except as required to fit on a truck or in an elevator, or as needed for the insertion of a fitting. Reinforcement rings are generally not required for positive pressure and low negative pressure round ducts. The use of rings helps maintain the roundness of the duct as the sizes get larger.

Longitudinal Seam Round Duct

In addition to the spiral seam there are various other types of seams that run straight from one end to the other (longitudinally), such as a longitudinal welded seam as shown in the video below. The video quality isn’t the best but it shows how you can weld galvanized and stainless steel round ductwork, and how to adjust the machine for various sizes.

Welded Longitudinal Seam

There is also a snap lock version of the longitudinal seam as shown in this next video. This particular type of round duct has an internal gasket that makes the seal.

Snap Lock Longitudinal Seam

Sheet Metal Rollers

When the use of round spiral is not allowed the use of longitudinal welded round duct is required, a piece of fabrication equipment that can roll a piece of flat stock into the required round size.

Specialty exhaust systems that require a secure seam without ridges can be made with a longitudinal seam.

Watch this Sheet Metal Roller video to see a sheet metal roller in action.

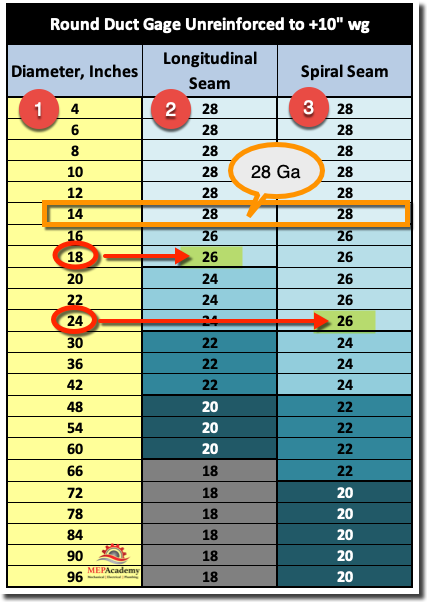

Longitudinal vs Spiral Seam

Spiral allows for lighter gages then longitudinal seams when using Unreinforced Round duct as shown in the SMACNA table below. You can see that from 4” to 14” round (Column #1), both Longitudinal Seam (Column #2) and Spiral Seam (Column #3) require the same 28 gage minimum. But, spiral seam can use 26 gage from size 16” to 24” round, while longitudinal seam is limited to a maximum of 18” round when using 26 ga. This indicates that the spiral seam is stronger and more rigid then a longitudinal seam.

You can also see in the table that the larger the round size the greater or thicker the metal gage required.

Special Round Ducts and Fittings

There are various manufactures that make proprietary systems that are meant to save labor such as the Eastern Sheet Metal’s gasket fitting system. The rubber gasket provides a tight seal, making additional sealing unnecessary. Watch the enclosed video to see how easy the ductwork goes together. They also have a double-wall version, in addition to a single and double-wall flanged system, and one for oval.

Double-Wall Duct & Fittings

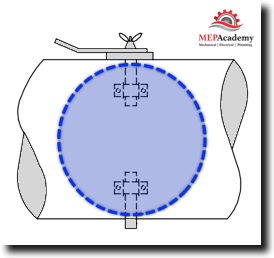

In some cases engineers will specify double-wall duct, often when noise is an issue, but it also provides thermal properties. Double-wall duct comes in round or oval sizes with either a solid inner wall or a perforated inner liner, with insulation sandwiched in between the inner and outer wall.

The outer duct can be purchased with three different seams, spiral lockseam, spiral lockseam with a standing rib, and longitudinal seam.

This next video shows how one shop fabricates double-wall duct with a perforated inner wall and lined with fiberglass insulation. The perforated inner wall is made from a skinny coil of material similar to that of spiral duct.

Engineers will also specify that the duct be made by a particular manufacture so that a certain level of quality can be assured to the owner.

Lined Round Spiral Duct and Fittings

In order to provide acoustical properties, which is the ability to attenuate or reduce sound transmission, lined round spiral duct can be used by adding liner to the interior of the duct. Watch the video below of the John Mansville Spiracoustic Plus liner material being added very easily to spiral duct and fittings.

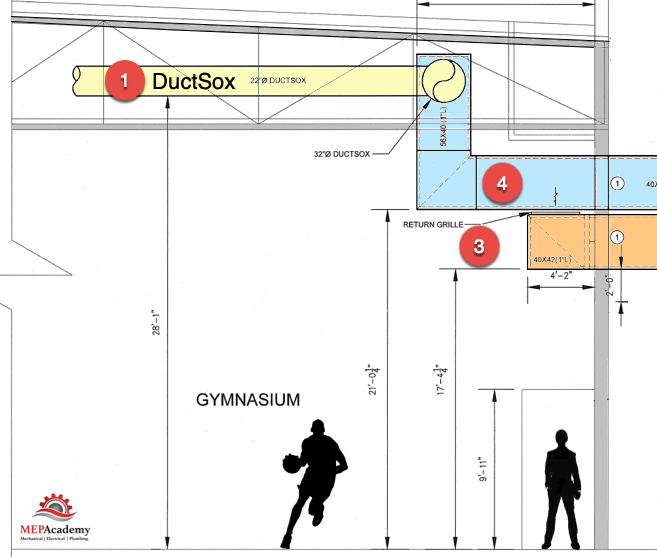

Fabric Duct

There are special cases where instead of sheet metal you can use fabric ductwork such as made by DuctSox. Where you have long straight runs of exposed ductwork the application of DuctSox may make sense, such as gymnasiums and indoor pools.

You have the option of having the air dispersed through linear vents, fixed orifices, fixed nozzles or adjustable nozzles.

They can come in various color options, and can have zippered sections. Companies can also have their logo imprinted on the fabric or pick from various patterns.

The fabric can be supported by an internal metal ring which provides tension to keep the fabrics shape, or without any internal metal ring in which case when the air is shutoff, the fabric will collapse.

Fabric Duct Hanging Methods

You can use an external cable to suspend the fabric sox or a channel that allows you to pull the fabric like a curtain along the suspended railway.

Applications

Fabric ducts can be used in Gymnasiums, Warehouses, Manufacturing Facilities, Indoor Pools, Auditoriums, Schools, Malls, Restaurants and other exposed locations.

In a lot of these facilities the use of some form of man-lift or scissor lift will be required to reach the heights at which these fabric ducts get installed. Remember to always check the height at which your ductwork needs to be hung.

As shown below the DuctSox (#1) is used in a Gymnasium and is installed at 28’-1” above the floor, which would require some form of man-lift for the installation. The main supply air duct (#4) is run in galvanized rectangular ductwork, including the return air duct (#3).

The video below is another brand of fabric ductwork which shows workers installing the duct using a scissor lift.

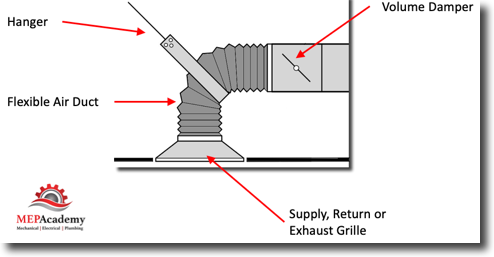

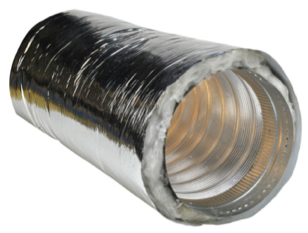

Round Flexible Ducts

Flexible ducts come in various arrangements that include insulated and uninsulated, metallic and nonmetallic. The insulated version would be used to carry conditioned air or for the reduction of noise, while the uninsulated metallic would be used for non-condition exhaust air. The use of flexible duct should be kept to a minimum to avoid excessive pressure drop. Aluminum is the most commonly used material for metallic flexible ducts. Flexible ducts come in various lengths depending on manufacture.

The R-values of the insulated flexible ducts range from R4.2, R6 to R8. Flexible duct comes in lengths of 3, 6 and 25 feet with some manufactures, others may vary.

Flexible ducts need to be supported according to the manufactures recommended method but not less than every 5 feet, including the maximum sag of 1/2” per foot between support hangers. This would allow maximum sag of 2-1/2” between two support hangers spaced 5 feet apart. The portion of the hanger that the flexible duct rest upon needs to be at least 1 inch wide to avoid the reduction of the internal diameter. This can be accomplished by a 1 inch wide hanger strap or by providing a saddle for the flexible duct. The size of the saddle would need to be half the circumference of the outside diameter of the flexible duct and sit at the bottom half.

Draw bands must be used to secure nonmetallic flexible ducts to a sheet metal sleeve or collar.

The most commonly used piece of flex duct is for the last 6 feet (2m) where a connection is made to a piece of air distribution. Some projects allow all of the low side ductwork to be run in flex. This is not the best approach due to many factors, one of them is static pressure loss.

Watch this video for the correct methods of supporting flexible ductwork.

Insulated Aluminum Flex

Some projects may allow long runs of insulated aluminum flexible duct, but this is not good engineering practice due to the higher resistance created from through inner surface, which creates more static pressure losses and increased energy cost.

Uninsulated Aluminum Flexible Duct

Often used for exhaust system that require a short run of duct.

Start Collar

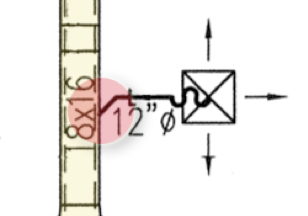

A round hole is cut into the side of a rectangular duct and the dove tails of the start collar are alternately bent perpendicular, one inside, one outside, and fasten with sheet metal screws and then sealer is applied.

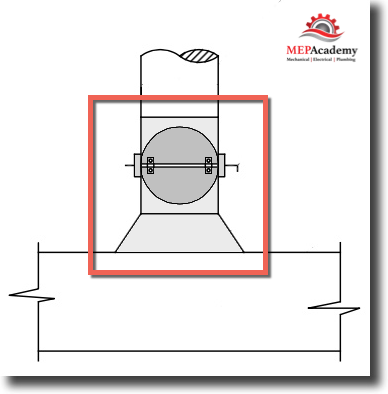

Start Collar with Volume Damper

Often the start collar will have a volume damper included. Keeping the volume damper in the start collar and as far away from the air distribution will help reduce noise transmission through the grille into the room.

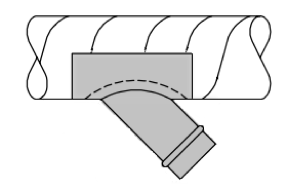

Flat Saddle Tap

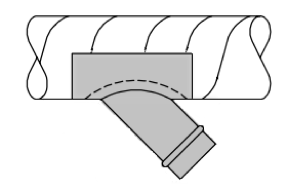

Instead of a spin-in or similar starting fitting, a flat saddle tap can be used to get round duct started from the side of a piece of rectangular duct. Available with a 45 or 90-degree branch.

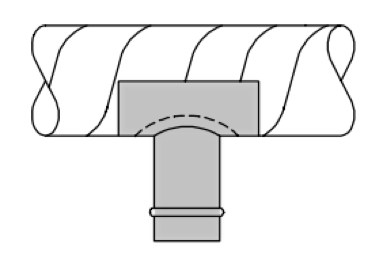

Radius Saddle Tap

This fitting is used in lieu of some form of a tee fitting. This will save having to cut the main round duct to install a Tee. This is a round on round fitting. Available with a 45 or 90-degree branch.

Here is a short video on the basics of installing a saddletap. There are electric shears that would work much better than the manual shear that this gentlemen uses in this video. You can stop the video after 2 minutes 38 seconds.

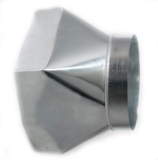

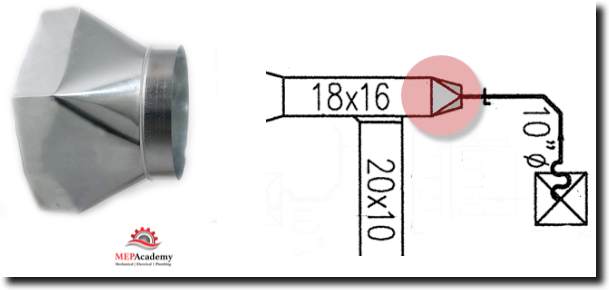

Square to Round

When rectangular duct transitions to round duct on the straight run its called a square-to-round.

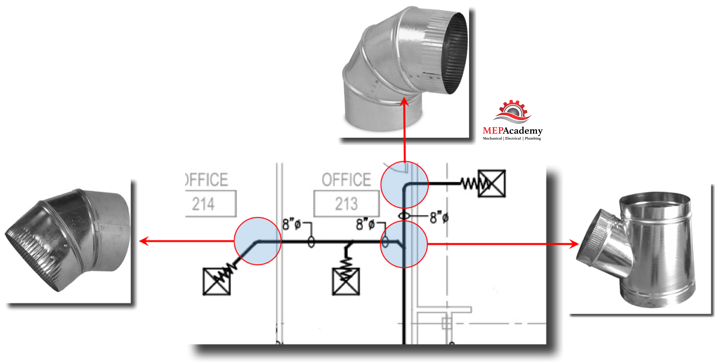

90 Degree Elbow

Most turns will either be 90 degrees or 45 degrees. You don’t see a lot of odd angle elbows as they would be more of a custom made fitting and more expensive. Notice the crimped end on one end of the fitting.

Elbows can come in many variations, from adjustable, stamped, pleated, spot welded or fully welded. Here is a video on how an adjustable elbow can be manipulated to create various angles.

Sheet Metal Spiral Elbow Machine

There are machines that lock segments or sections of a fitting together to make a complete fitting. Some of these machines are referred to as Gore Lockers. Two segments are butted together and are spun around as their seams are locked together by the gore locking machine. For a multiple gore elbow this occurs with each piece until you get the quantity of gores required. This is common for adjustable gore elbows. It’s a good time to discuss the different types of elbows.

45 Degree Elbow

There are several different types of elbows based on seam and joint types. As you can see this fitting also has a crimped end allowing it to slip inside the next piece of duct.

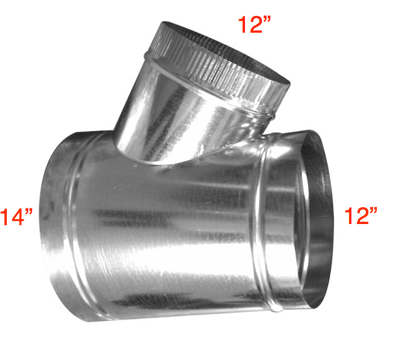

Tee-Wye (T-Y)

These are used to make 45-degree branch connections. See the image above where the T-Wye reduces the main branch from 10” x 8” x 8”. Also shown above but not highlighted is an 8” x 8” x 8” Tee-Wye, can you find it. Also note that the acronym used for a this fitting may be spelled many different ways, but they all refer to the same fitting type such as; T-Y, T-Wye, Tee-Wye, etc .

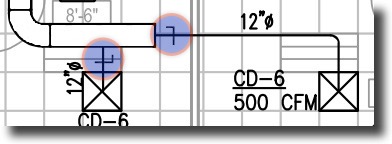

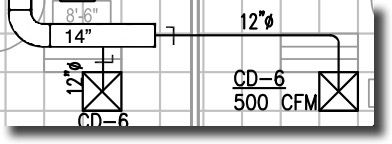

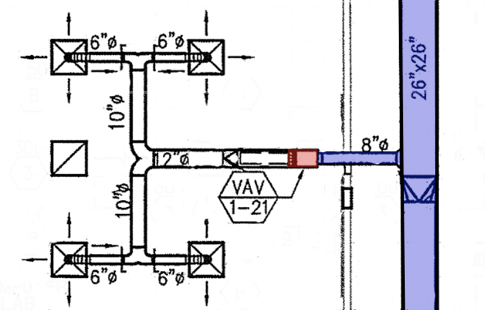

Volume Dampers

Dampers are used to adjust the volume in ducts. These will be used by the air balancing personnel to set the CFM needed for the branch or main that has a manual volume damper.

In the example above the volume damper controls the amount of air that air distribution diffuser CD-6 receives, in this case it indicates 500 CFM (cubic feet per minute)

Reducers

A reducer is used to change size of the duct run. The reduction in size can also be accomplished by using a reducing tee.

Round Joint Types

Most low pressure round fittings will either have a crimped end or be coupling sized.

Crimped Ends

Crimped ends reduce the overall diameter just slightly so that the fitting or duct can slip into the next piece.

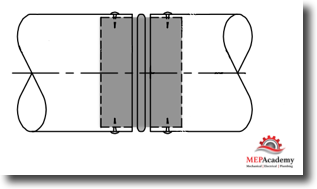

Round Couplings

Couplings slip inside the ends of two round ducts to be joined together and then sheet metal screws are fastened to hold it in place. Couplings could be required at a certain size such as connections 18” and larger. The shaded area in the image below is the coupling.

Flanged Connections

There are many manufactures that provide various types of flanged connections like Ductmate™ Spiralmate™, see their website for more information and videos for various connections.

Welded Connections

The requirement for a welded duct connection can be found for kitchen grease exhaust systems or some industrial processes and laboratory exhaust systems. Some of the more commonly welded duct materials are galvanized steel, stainless steel and black iron. Joints are often butt welded or flanged.

Often welded kitchen exhaust systems will use stainless steel where exposed to view and black iron for the hidden duct to the grease exhaust fan. Grease exhaust ducts need clean-out doors every so often as required by code for access for cleaning. (Also see chapter on Grease Exhaust Systems).

FRP – Fiberglass Reinforced Duct

Used in industrial processes to exhaust corrosive fumes such as solvent or acid exhaust systems. You can spend your life in the HVAC business and never be involved in a project that requires this material, but watch the enclosed short video so you understand what is involved.

The Proper Use of Round Fittings

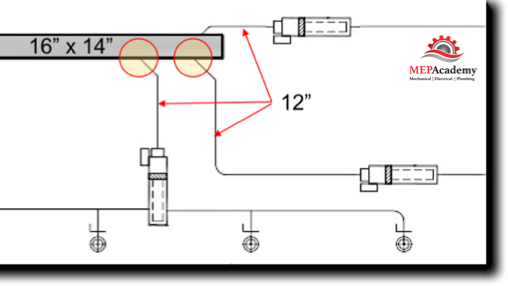

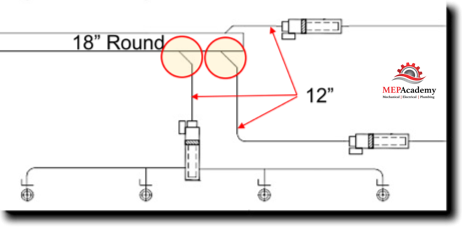

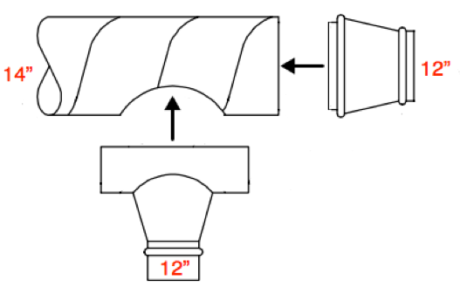

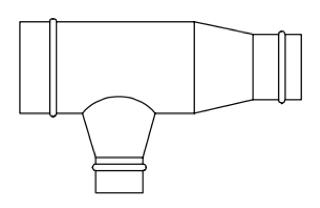

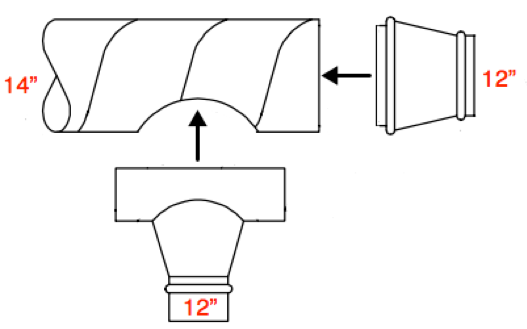

There is more than one way to make a reduction or branch connection. As the following example shows you can use two different ways to accomplish the same thing. In the example we have a round main duct that branches into two 12” round branches. You can either use a 14” x 12” x 12” Tee-Wye or you can use a 14” – 12” reducer with a 12” saddle-tap.

Various Fitting Options

In the case above it would be best to use the T-WYE as it is one less connection. Use a T-Wye when the main duct changes sizes, and use saddle-taps when the main remains the same size as shown below. Using the saddle tap and the reducer in the above scenario would require and extra cut of the duct and two fittings, instead one T-Wye fitting.

In lieu of a full body fitting you can use a saddle-tap which allows the main duct to remain the same size without having to cut-in a fitting. A saddle-tap does just as its name implies, it saddles the main round duct. This is accomplished by cutting a hole in the main duct where the branch is to occur and then the saddle-tap is fastened with sheet metal screws and then sealed to provide an airtight assembly.

Round Starting Fittings

Whenever you have a piece of duct tapping into the side of another duct you will need a starting fitting if you are not using a whole body fitting of the same shape.

Round on Rectangular Duct

So, if you have a round duct branching off of a rectangular duct you might use one of the following;

Options for branch connections

- Spin-in

- Spin-in with damper

- Dove-tail spin-in

- Scoop tap-in

- Flat 45 Degree Saddle-tap

- Flat Straight Saddle-tap

Each of these starting fittings will get you connected to the side of the rectangular duct and then capable of connecting another round piece to that fitting, such as a length of spiral duct.

Round on Round Duct

- Straight Saddle-tap

- 45 Degree Saddle-tap

- Tee-Wye

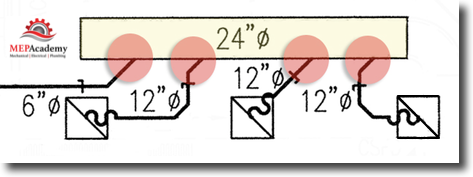

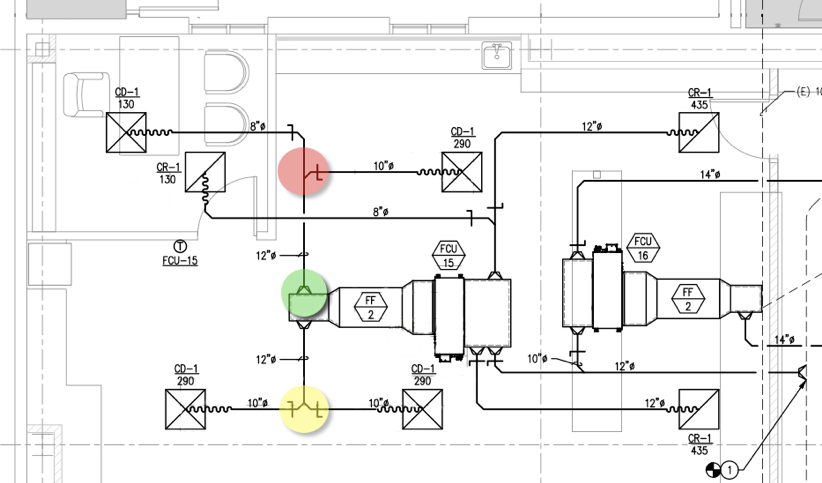

Single Line Duct Design

Most often you will find that the duct design is done in a single line style, where the actual scale width of the duct is not represented.

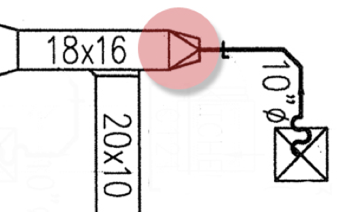

In the above example the yellow dot highlights a fitting that may not be feasible to fabricate and what could be a better selection is a Tee-Wye instead of a bullhead tee as shown.

In the above example the Red dot highlights a typical Tee-Wye except that is usually preferable if possible to have the branch that angles off in a 45 degree to be the same size or smaller then the reducing run dimension, in this case the Tee-Wye is a 12” x 8” x 10”. It would be better to use a 12” x 10” x 8” if possible.

In the above example the Green Dot highlights an expensive fitting as opposed to a simple spin-in. What is actually represented by the symbol is a type of tap/Square-to-Round all in one fitting.

There are many different ways to make a branch connection in round duct from a full body fitting like a Tee to a saddle-tap which only requires a hole in the side of the duct big enough for the connection outlet size.

Often there will be several methods to accomplish the same branch takeoff or reduction in size. Whether to use a fitting or some form of saddle-tap and reducer can depend on the specifications or your company preferences.

The above fitting accomplishes the provision of a branch connection and a size reduction in the run. This can also be accomplished by cutting an opening in the side of the main duct for a saddle-tap that provides for a branch connection and then a reducer to provide a reduction in size for the main run. The fitting is comprised of one piece while the other connection method requires two pieces, the saddle-tap and reducer.

Saddle-taps are an effective strategy when you have multiple taps on a main duct that doesn’t change in size on the run. For instance, if you had a main 20” spiral that had four 10” branches it would be best to use saddle-taps to avoid cutting the main for a Tee connection for each branches.

Round fittings will be represented on the drawings either in single or double line format. Either way the specifications will let you know what type of fittings are required.

Round fittings come in various construction seams and joints, which show be defined in the specifications.

We will show you where each of these fittings are used and the different ways they can be represented on engineered drawings.

Engineers or their CAD personnel may not show the fittings as you would actually build the duct. You have to read the specifications and look at the details to determine what is allowed.

Fully Welded Round Fittings

There will be projects that require a fully welded round system. This usually occurs where special an exhaust system contains flammable or noxious gases in the air stream.

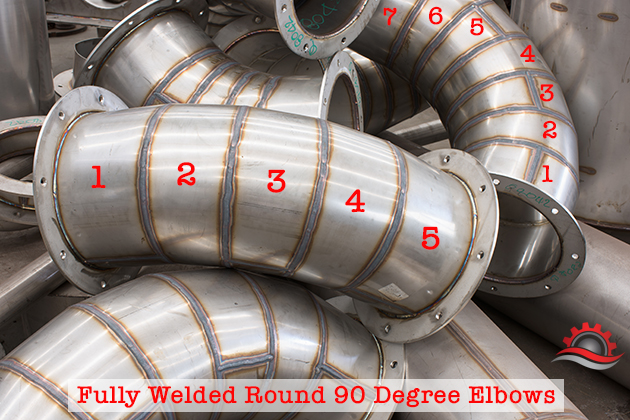

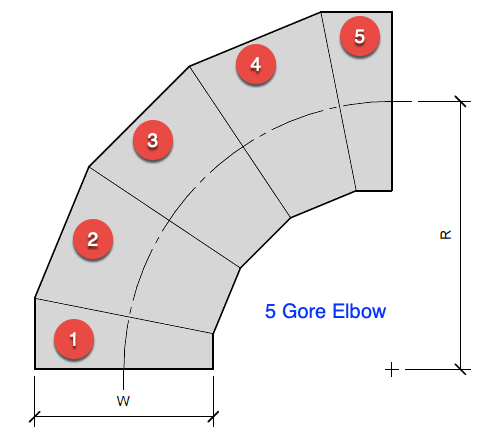

Gored Elbows

As shown in the image above these are fully welded 90 degree elbows with flanged joints. The seams are fully welded and the quantity of gores are indicated. There is a 5 and 7 gore elbow identified in the image above. When a greater radius turn is required the engineer will specify more gores for the elbow. This applies to any degree of elbow from the standard 45 and 90 degree elbows to custom angles such as 30 and 60 degrees.

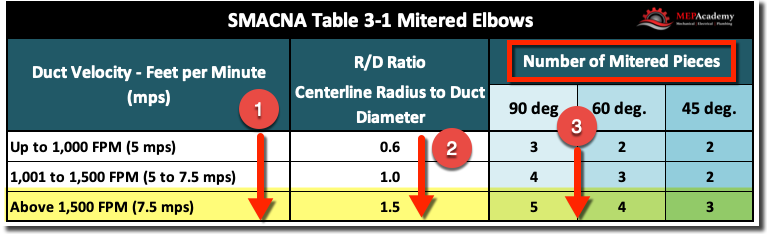

Mitered elbows should comply with SMACNA table 3-1 below which sets the number of mitered pieces based on the velocity (#1) in the ductwork. Unless the specifications call for something different or other limitations are stated, then this SMACNA table can be safely used to figure the quantity of miters (#3) to add to 90, 60 and 45 degree round elbows.

As can be seen from Table 3-1 as the velocity increases (#1) within the elbow, the greater the quantity of miters (#3), and the larger the Centerline Radius (#2) is required. The centerline radius makes the elbow take a wider turn, which allows for better aerodynamics and performance.

Machine Made Gored Elbows

Watch the enclosed video to see how a version of the gored elbow can be made quickly in this sheet metal fabrication shop.

Adjustable Elbows

The most common 45 and 90 degree elbows are fabricated to have adjustable gores, so that you can spin the gores and make various angles out of the two types.

Spot Welded Elbows

For system and designs requiring a better fitting, you might find the requirement that the gores be SPOT WELDED. Every so often around the circumference of the seam a spot weld will be made to hold the two segments of the fitting together, giving it a stronger bind then that used for an adjustable elbow.

Continuously Welded Elbows

And for systems requiring a tight seal there are fully welded fittings with a continuous weld as opposed to a spot weld every so often around its circumference. This type of fitting will have a continuous weld at the seams and joints.

The cost of the fittings is usually related to the method of fabrication with adjustable type fittings being the least costly, then spot welded, and fully welded being the most expensive fitting type. Having to fully weld the seams of a fitting requires more shop labor and the use of a heavier gauge to allow for a clean weld without destroying the metal, this is why it is the most expensive type of seam and joint for a round fitting. There are other types of elbows used through-out the industry such as;

Stamped Elbows

This elbow is created from two pieces that were stamped out. This requires that the two half sections be welded together along there longitudinal seam with either a continuous weld or spot weld.

Pleated Elbows

Just as the name implies this elbow has a pleated appearance, almost appearing as if it was a piece of flex duct bent in the shape of a 90 degree elbow and then harden. I have personally never used this type of fitting, but just wanted to make you aware of the terminology in case you live in an area where they are used.

Standing Seam Elbows

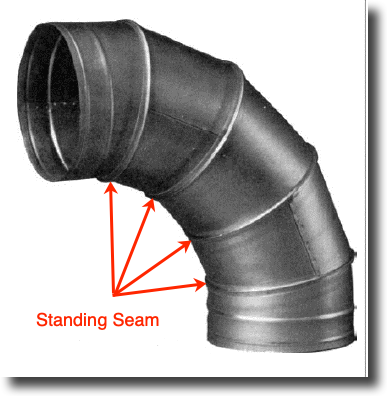

This fitting is fabricated with segmented pieces with standing seams that lock to an adjoining segment.

Oval Duct and Fittings

Not as commonly specified as round duct, but it has its application. Oval duct is made from a section of round spiral duct, that is ovalized, or stretched into an oval size. See the enclosed video to see this machine in operation.

Watch the below video to see the installation of oval duct and fittings. Notice that the reducer being used is undersized on its collar allowing the oval duct to slip over the collar. They are using Unistrut with threaded rods as hangers for the ductwork.

Round Industrial Classifications

This course doesn’t cover Industrial Construction standards, but you should be aware that duct is classified by the medium that is traveling through the ductwork.

Round Industrial Standards will cover round ducts that carry corrosive fumes or particulate matter, like that found in a dust collection system or industrial processes. The non-industrial standards cover ducts from +10” wg (2,500 Pa) to -10” wg, while the industrial standards cover ducts up to a negative -30 wg.

Class 1 – Includes non-abrasive applications: Makeup Air, General Ventilation, Gaseous Emission Control

Class 2 – Includes applications with Moderately Abrasive Material in Low Concentration: i.e., buffing and polishing woodworking, grain dust, etc.

Class 3 – Includes applications with Highly Abrasive Material in Low Concentration: i.e., abrasive cleaning operations, dryers, kilns, boiler breaching and sand handling, etc.

Class 4 – Includes applications with Highly Abrasive particulate in High Concentrations; i.e., materials conveying high concentrations of particulate in all examples listed under class 3 (usually used in heavy industrial plants such as steel mills, foundries, mining and smelting).

Sheet Metal Field Installation Course

- Chapter #1- Rectangular Duct and Fittings

- Chapter #2 – Round Ductwork and Fittings

- Chapter #3 – Sheet Metal Duct Hangers

- Chapter #4 – Sheet Metal Field Labor Productivity

- Chapter #5 – Labor Crew Sizes

- Chapter #6 – Sheet MetalDuct Sealer

- Chapter #7 – Sheet Metal Details and Specialties

- Chapter #8 – Grease Exhaust

- Chapter #9 – Air Distribution

- Chapter #10 – Rental Equipment

- Chapter #11 – Conditions Affecting Field Labor

- Chapter #12 – HVAC Equipment Labor