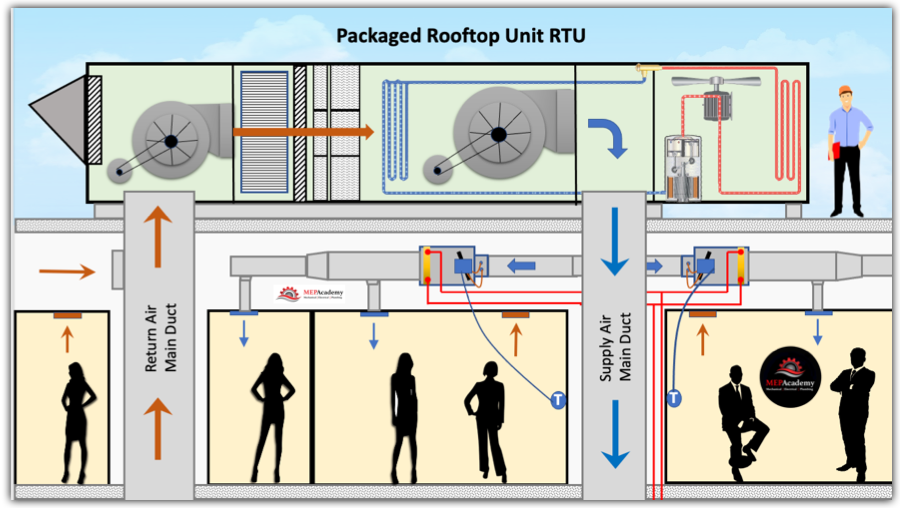

We’ll cover Packaged Rooftop HVAC Units from 2-Tons to 162-Ton, and discuss their components and when to add a return or exhaust fan into the unit.

If you prefer to watch this presentation see our Animated Version on YouTube by scrolling to the bottom this article.

You’ll find Packaged Rooftop HVAC Units everywhere in small to medium sized Commercial buildings, including office buildings, restaurants, schools, entertainment centers, retail, grocery stores, condominiums, and shopping centers.

These units are often referred to as RTU’s (Rooftop Units), which cover everything from very small tonnage to over 100 tons, the Intellipak™ 2 from Trane goes up to 162-Tons. These larger ones are often called “Box Car’s” in the USA because they’re as large as a railroad box car.

They provide the same benefits of heating and cooling as does your home air conditioner, they are just a little more sophisticated and contain additional features and functions which we’ll cover. Some of these features are required by code because they serve a commercial building.

There are many types of Rooftop Units (RTU’s) including 100% Outside Air Units (DOAS), Gas/Electric, Heat Pump, Straight Cooling, VAV or constant volume. Besides how they provide heating or cooling, all other components are similar.

Physical Size

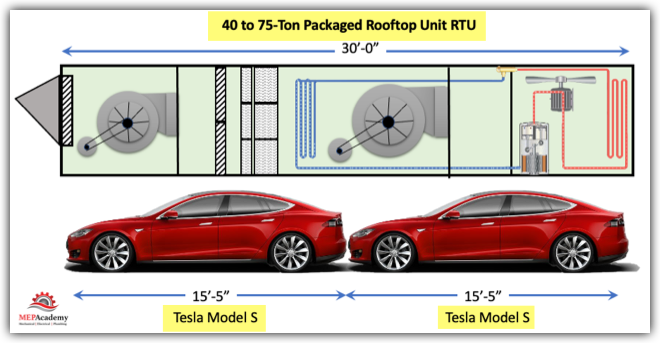

Most of us are familiar with small tonnage units from 2 to 15 tons, but how big is a 150-Ton unit. Here is a quick size comparison between a 40-Ton to 75-Ton Rooftop Unit and a 2020 Tesla Model S.

As you can see these Packaged Rooftop Units can be very long in length. RTU manufacture will use similar cabinet sizes for various ranges of Air Conditioning Tons, as the above cabinet will hold anywhere from a 40 to a 75 Ton unit. The differences is in the size of the various internal components, such as coils, fans, compressors, dampers and filters, but the cabinet is large enough to accommodate this range of sizes.

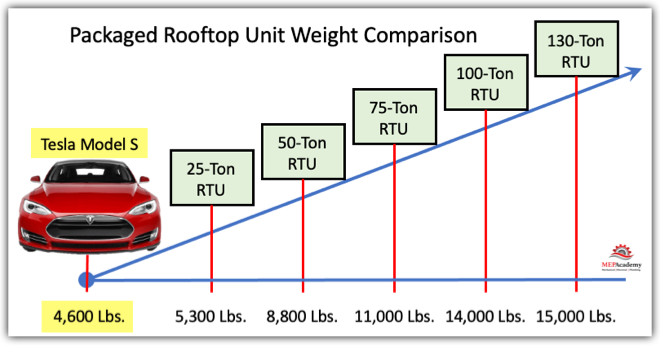

The other thing to consider is the weight of these units. So for reference here again is a quick look at a comparison based on weight. Can you guess what is heavier, a Tesla or a or a 25-Ton Rooftop Unit?

As you can see these RTU’s can get very heavy when put on a roof. It’s like parking many cars on your roof. This is why a structural engineer needs to make sure that the structure is designed to hold the weight.

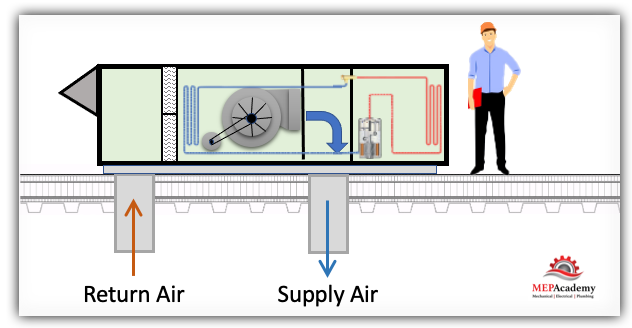

Supply Fan Only Configuration

A Rooftop Unit with just a Supply fan is the most common configuration for small tonnage units. This can be used for small spaces, maybe a single classroom. To relieve building pressures a barometric damper can be installed in the space or within the RTU. This damper will allow excessive pressure to be relieved outdoors. The buildup of building pressure occurs during the economy cycle, when all that outside air is being pulled in from outdoors and sent to the space with no return coming back. The air has to go somewhere, so it looks for the path of least resistance such as crakes under the doors or open windows.

Using only a supply fan with an economizer in a large building will make building pressure control difficult to maintain. Everyone has been in some building where the doors blow open, whistle or are hard to open because of the pressure relationship created by the HVAC system fans. That’s why on large systems is important to think about building pressure and adding a return or exhaust fan to the Rooftop unit.

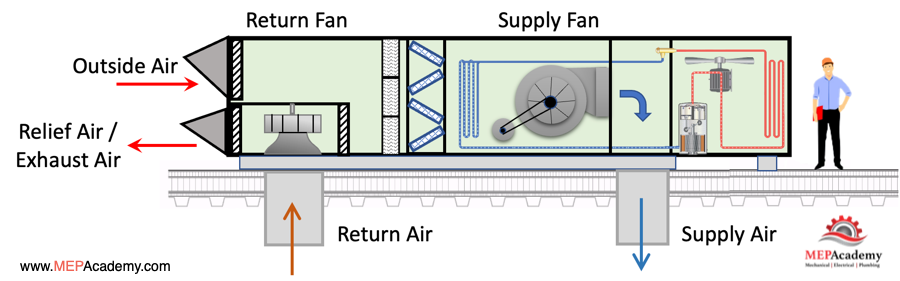

Supply and Return Fan Configuration

Better control of building pressure is accomplished by adding a return fan. In this configuration the return fan can handle the static pressure of the ducted return, and the supply fan can handle the supply duct static pressure. There will be three sets of dampers that control the follow and volume (CFM) of the three air streams, Outside Air, Return Air and Exhaust Air.

When in 100% economizer mode, the Return Damper will be 100% Closed because all the building air is being replaced with outside air, so the Outside Air Damper is 100% Open, this leaves the exhaust damper 100% open sending all the return air out of the building. This is where the use of an Energy Wheel can be applied, which we’ll discuss later.

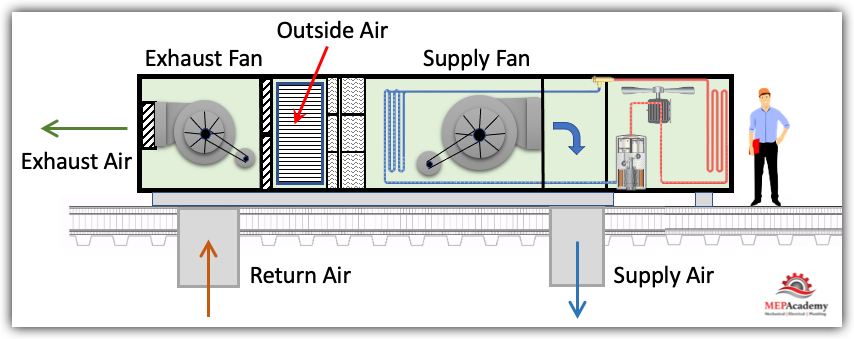

Supply and Exhaust Fan Configuration

On larger units there is the ability to add an Exhaust Fan. In this configuration the Exhaust Fan will be used for building pressurization control. There will be a building pressure control sensor that will provided feedback on when to run the fan. The Supply Fan in this case will be responsible for the static pressure of the supply and the return system.

Since the Supply fan is responsible for the return air static pressure, this configuration works best with low static pressure return systems, like un-ducted return (attic return).

The exhaust fan will operate to maintain building static pressure by modulating its damper opening or fan speed, while the economizer (OSA Damper) is modulated to support ventilation requirements.

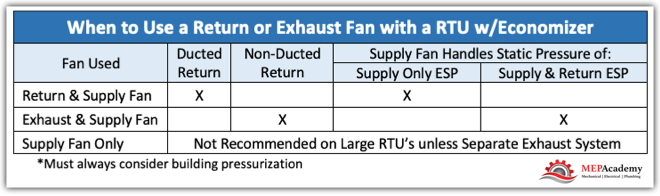

Here is an example of when to use a Return Fan versus and Exhaust Fan with an economizer.

Return Air Fans (Ducted Return Air Systems, external static pressure ESP exceeds 0.40”sp.)

Exhaust Air Fans (Non-ducted Return Air Systems, low external static pressure ESP return)

Economizers

In many jurisdictions the use of an economizer is mandated to save energy when the outside air conditions are cool enough for conditioning the space. Economizers use the outside air to cool a building when the air outside is cold enough to assist or do all of the cooling. This allows for a reduction, or a total shut down of the refrigeration equipment (compressor), allowing for energy savings. In California, under Title-24 of the Energy Code, the requirement for an economizer is for any unit larger than 54,000 BTU’s, basically above a 4-1/2-Ton unit.

The amount of fresh air (Outside Air) is code driven and usually referenced in ASHARE Standard 62.1. The ASHRAE standard provides recommendations on how much outside air should be provided based on space usage type. For instance, an office space would require less outside air when compared to a conference room.

An economizer is basically a set of dampers and some control logic that opens and closes the outside air damper to allow more or less outside air into the building based on demand or code minimums.

An important consideration when using an economizer in a commercial building is building pressure, which relates to the fan arrangement in the Rooftop Unit. On small tonnage units you can get away with just a Supply fan and a barometric relief damper. On larger units you may need to add a return or exhaust fan, especially if there is extensive return air ductwork.

Supply, Return and Exhaust Fans and Volume Control

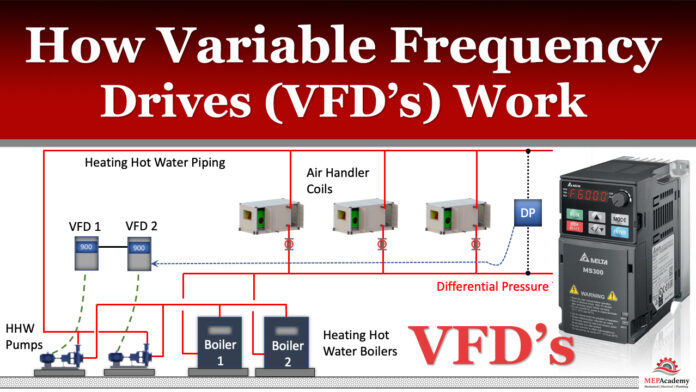

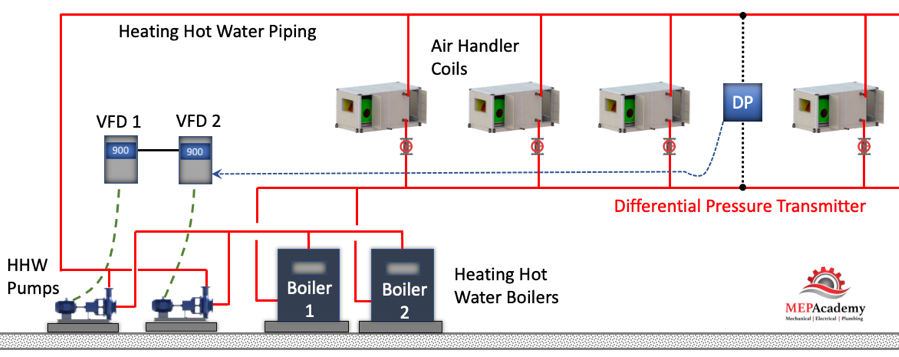

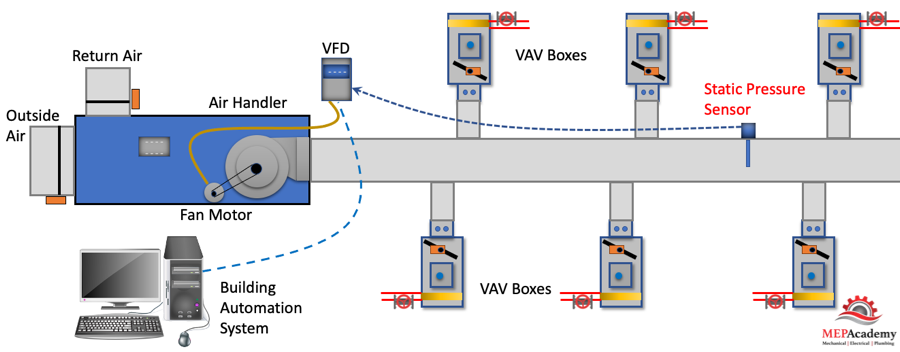

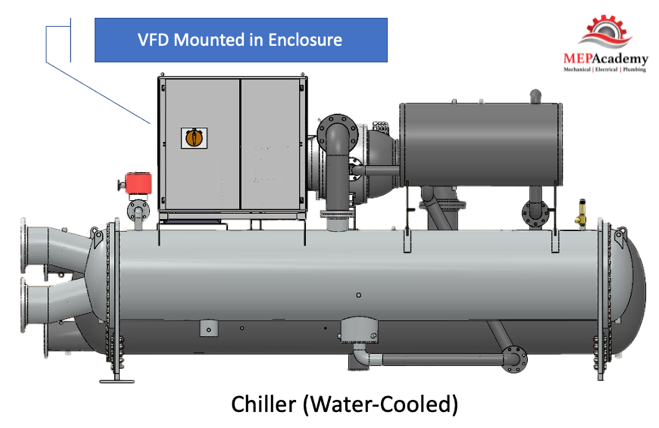

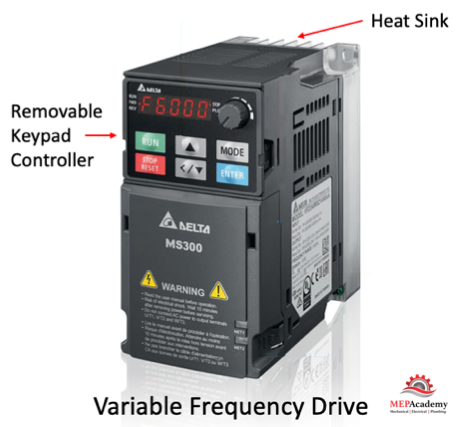

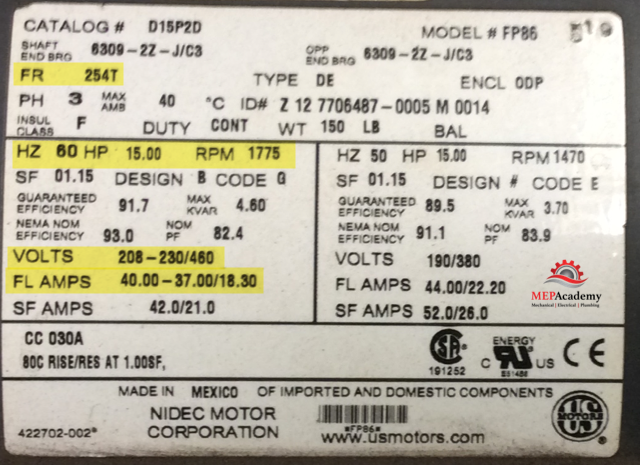

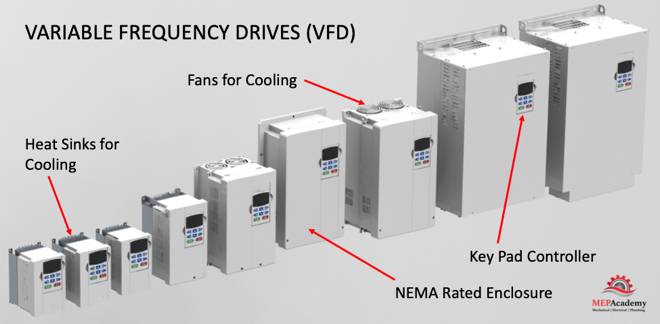

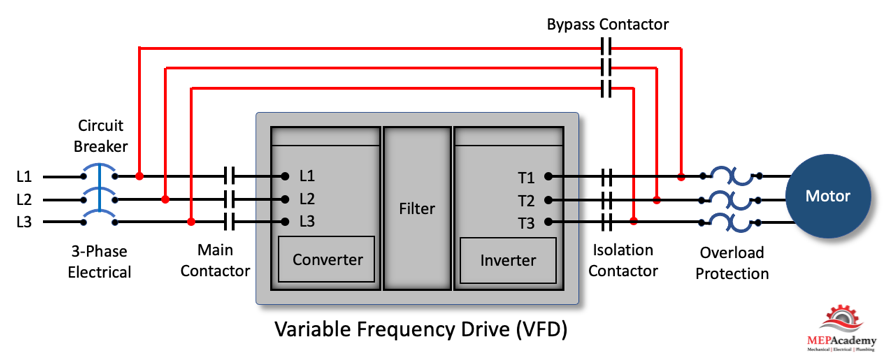

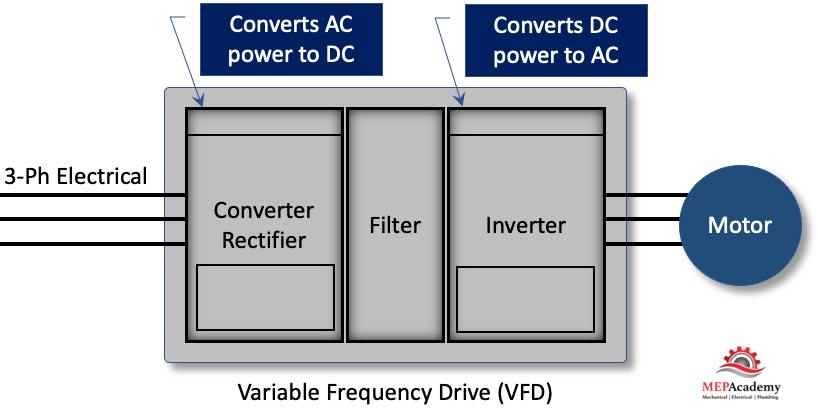

Depending on the size of the rooftop unit there may be a code requirement to have a variable speed fan. Using a VFD or ECM motor to reduce the volume (CFM) of air when the demand for cooling is reduced will save energy. This is often mandated by energy codes. (See our video on VFD’s to get a better understanding of how they work).

The fans can be a belt-driven Centrifugal Type or a direct drive plenum style fan. Centrifugal style fans should be sitting on spring isolators to dampen any vibration from the motor. The supply fan is the other major energy consuming device in the Rooftop Unit besides the compressor.

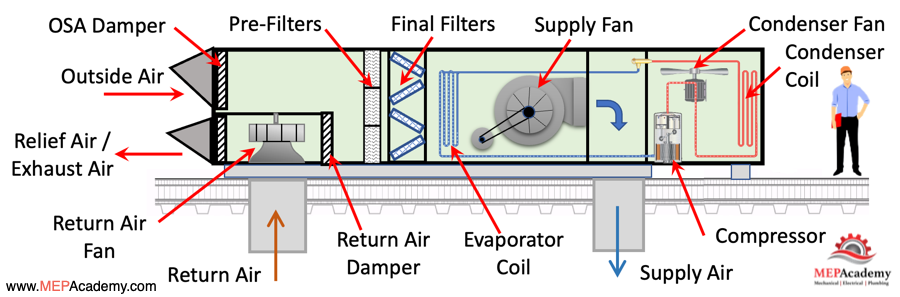

Outside Air (Intake), Return Air and Exhaust Air Dampers

There will be an outside air opening for the intake of ventilation air as required by code to provide occupants with fresh air. This is often defined by ASHRAE Standard 62.1 for the ventilation requirements. The outside air opening may have an economizer depending on its size. Some codes require any rooftop unit over 36,000 BTU’s to have an economizer (check your local code). If the unit is provided with an economizer there will either be a relief air opening (barometric relief) for air leaving the building (not returned to the space) or a powered exhaust module to exhaust return air when the economizer is in operation.

The quantity of air is controlled by dampers with actuators (small motors) to turn them from closed to open based on demand. These dampers will modulate their volume (CFM) based on the space requirements. The outside damper should never fully close because the code requires a minimum of outside air for the occupants.

Barometric Relief Dampers are usually used on smaller systems or buildings. As the pressure builds up in the building, this increase in pressure will force open the barometric relief damper located in the return section of the RTU or in the space, such as a classroom. There are no sensors, controls or motors to open the barometric relief damper, it’s opened strictly based on building pressure. These are usually used on small systems when the return air is non-ducted, such as in open ceiling plenum return.

On larger units look for the added feature of Outside Air measurement for better control. There will be aa means for measuring the volume (CFM) of air entering the RTU.

Refrigeration Circuit

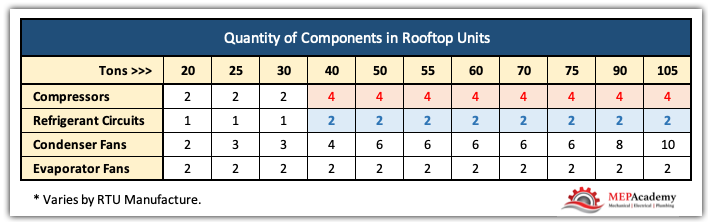

One of the benefits of a Packaged HVAC Rooftop unit is that all the refrigeration components are in one cabinet, as compared to split systems where you’ll have an indoor and outdoor section connected by refrigerant piping. As the Rooftop HVAC units get larger, around 30-Tons or more you’ll find that there are two refrigerant circuits instead of one. This allows for better capacity control. If you’re not familiar with how a Refrigerant Circuit works, see our video explaining the Refrigerant Cycle. We will go over the location of the various components of the a complete Packaged Rooftop HVAC unit.

Filtration

The amount of filtration goes from the minimum required to more extensive filters for the removal of contaminants that maybe harmful to the process the rooftop units is serving. Filters are rated by their MERV number, which is usually a minimum of MERV-13. There are special filters like HEPA filtration that increases the removal of dust and smaller particles in the air than a standard filter, but these are more expensive. There are also carbon filters for gas removal, and UV filtration to kill bacteria. Standard units will come with standard filtration, but these other options may be available upon request.

It’s important to keep the internal components clean, especially the coils where the heat transfer occurs. Dirty coils will reduce the effectiveness of the unit to coil or heat the building. Therefore, filtration is always before the coil.

There maybe several sections of filtration, including cheaper 2-inch thick MERV-8 pre-filters to the more expensive 12-inch thick MERV-14 filters.

Cooling Section

This section of the unit is where the heat transfer occurs between the refrigerant or heating fuel source. With a Heat Pump or Straight Cooling unit the refrigerant circuit feeds the coil with refrigerant from the compressor.

Coils can be made with copper tubing and aluminum fins, or be all-aluminum microchannel coils. Other options are available like copper fins or coated coils. Coils are where the heat transfer occurs, so they should be kept clean by regular maintenance.

Heating Section

Heating can be provided by Heat Pump (Electric), Gas, Hot Water or Steam. Most smaller RTU’s are going to be either a Heat Pump or Gas. The larger RTU’s provide options for various other method for heating, such as Hot Water or Steam. If using Gas for heating than there will be a stainless steel heat exchanger for transferring heat from the gas that is burning to the air going over the heat exchanger, the two never mix. The gas burners will be able to modulate the volume at some ratio like 4:1 in order to match the current demand of the space.

Preheat and Reheat Section

For colder climates there may be a need to provide reheat when the air leaves the cooling coil to ensure the supply air is within the target temperature setpoint.

Compressors

This is the heart of the refrigeration cycle and where a lot of the energy is consumed providing heating or cooling for a space. Compressors can be inverter duty rated, allowing for variable speed and capacity control along with energy savings. There may be more than one compressor depending on the size of the unit, and there could be more than one circuit. The largest units, those around 40-tons and larger will have 4 compressors or more depending on manufacture. The compressors could be a mix of fixed and variable speed.

Condensers

Depending on the size of the unit and the location of the installation there are two choices for the type of condenser: Air -Cooled and Evaporative. The Evaporative Condenser is usually available starting at over 20-Tons. The condenser is the section of the refrigerant circuit that rejects heat to the surrounding atmosphere. The condenser coils are available with corrosion protective coatings for corrosive environments like seawater air.

Smoke Detectors

Often duct-mounted smoke detectors are required over a certain size unit, like everything over 2,000 CFM requires a smoke detector to shut-down the rooftop unit when smoke is detected. This helps prevent the spread of smoke through-out the building. It may be possible to have the smoke detector mounted within the rooftop unit. This will save time and money by not having to mount and wire the smoke detector to the unit. There may be an additional requirement for remote monitoring at a fire control panel, which would be the scope of the Fire/Life Safety contractor.

Curb or Platform Mounted

The Rooftop Unit can either sit on a manufactured curb, which is often the case with down-shot units or they can sit on a platform, often with side discharge units. A down-shot unit is one where the supply and return ductwork come out of the bottom of the rooftop unit, and a side discharge is just as the name implies where the supply and return ductwork comes from the side of the unit.

A curb mounted unit will require holes in the roof to be cut beneath the curb to allow for the supply and return ducts to enter the building. A platform mounted Rooftop unit will have supply and return duct openings cut in the roof somewhere further away from the unit to enter the building.

On the larger RTU’s the curb will not extend under the Condenser section. In these cases, the condenser will be provided with support rails. This is meant to mitigate any noise coming from the compressors and condenser fans being transmitted through the supply duct into the building.

Factory Startup and Training

On the larger RTU’s you might want to take advantage of the manufactures option for factory startup assistance and training. This will depend on how comfortable your technicians are with the type of RTU being installed. Make sure to add this cost to your estimate if you plan on using this option.

Controls

Controls can be fully integrated, and factory installed ready to go with an interface panel mounted on the Rooftop Unit. The larger units may have static over-pressurization protection on RTU’s with VFD’s. There will be communication interface modules for LonTalk, BACnet or manufactures proprietary interface to allow for connection to a building management system or remote monitoring. This allows for control of the unit from anywhere with an internet connection. Some RTU manufactures offer WiFi control of their units, which eliminates the need to hardwire the controls.

On larger RTU’s there is the ability to control the Supply, Return and Exhaust Fans with VFD’s.

The use of Fault Detection and Diagnostics (FDD) with RTU’s that have an economizer is to ensure that notice is given if the economizer or outside air damper is not working correctly. Economizers or outside dampers are notorious for not working, which has led to additional code requirements and testing. The FDD is meant to give notice if a fault occurs, because improperly functioning economizers are a waste of energy and or lack the necessary volume of ventilation air required for a space.

Humidifiers

There are various optional components that can be added to a custom RTU, such as a humidifier. The humidifier adds moisture to the air to maintain a certain range of Relative Humidity because of some process or space requirement.

Electrical

Some of the larger RTU’s come with more than one entrance point for the connection of the electrical. Most codes now require some form of electrical convenience outlet within a certain distance of the RTU for service personnel. The larger units may have the option of having a convenience outlet already installed on the unit.

Energy Recovery Wheel

Another option is to have an Energy Recovery Wheel installed in some of the larger Rooftop Units to increase the energy savings when using large amounts of outside air (Ventilation Air). The Energy recovery Wheel will capture heat and moisture that is being exhausted and transfer it to the incoming outside air that is being used for ventilation air. This will save from losing this energy because of the need to provide ventilation according to ASHRAE 62.1. An Energy Recovery Wheel can be used on 100% Outside Air Units or Rooftop Units with Economizers. Energy Recovery is mandated in most of the USA when you reach a certain minimum percentage of ventilation air and exceed certain flow rates (CFM)

Sound Attenuators

Some manufacturers off the option of sound attenuators to reduce the noise levels emanating from the rooftop unit. These are usually installed downstream of the supply air fans to reduce the transmission of noise from the fans into the building.

Rooftop Unit RTU Cabinet and Housing

Since these units are installed outdoors, they need to provide protection from the elements, whether that’s the sun, rain, snow, wind, or salty ocean air. The units come standard with zinc coated galvanized steel and painted to match the manufactures standard color. We’ve all seen cars that reside near the beach and how corrosive the salt air is to the paint.

There are special coatings for the housing and the internal components like coils if required because of coastal locations. They also need to provide for thermal integrity using interior thermal lining or optional double wall construction with foam injected insulation.

The Rooftop unit needs to be completely weatherproof but allow access when being serviced. This requires that various access doors are installed in key location around the unit. Often these doors are located to allow for filter changing and coil cleaning, in addition to access to controls, electrical and the compressor section.

The evaporator section will have a drain pan often made of stainless steel. The supply and return air duct connections come off the bottom with the option on some models to have a side discharge configuration.

The larger RTU’s come with lifting lugs for rigging using a crane.

SUMMARY

The use of a Rooftop HVAC Unit allows for easy installation within a wide range of sizes, from 2 to 160-Tons. With various options available for humidification, energy recovery, economizers, UV lights, sound attenuation, VFD’s, roof curbs coil and cabinet coatings for protection, and increased filtration. There are various fan arrangements for building pressure control when RTU’s serve larger buildings or multiple spaces. Adding a Return Fan provides better building pressure control with a ducted return.