In this article we’ll discuss the dual duct system and mixing boxes. Dual duct mixing boxes help regulate the temperature and airflow in buildings by mixing hot and cold air to achieve the desired conditions.

If you prefer to watch the video of this presentation, than scroll to the bottom.

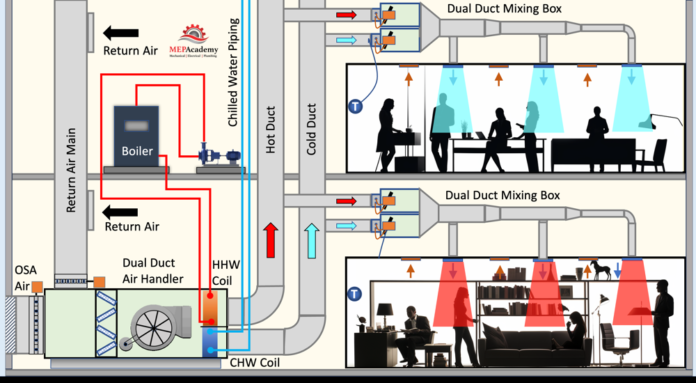

Here’s how a dual-duct system works.

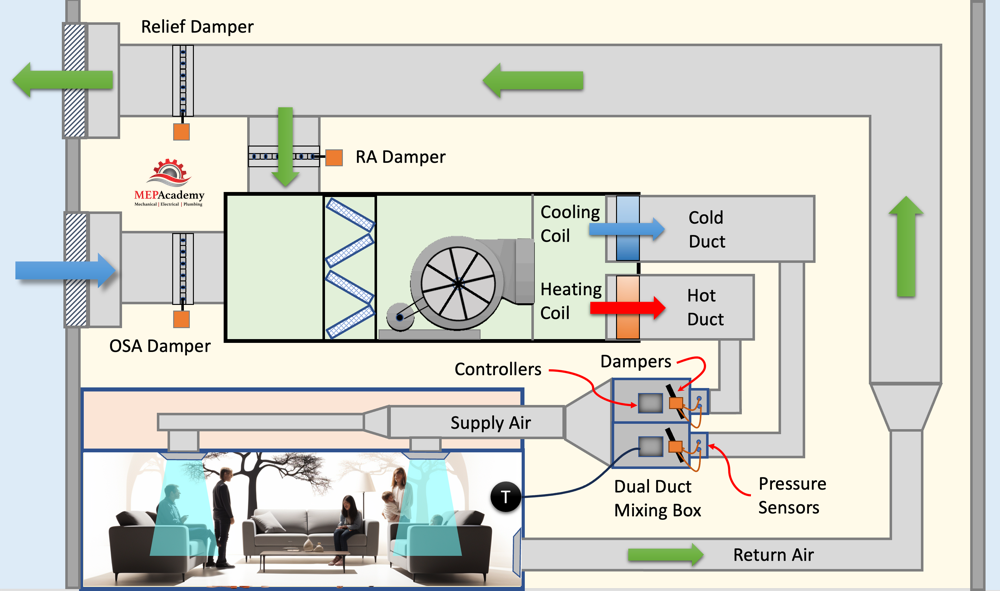

Depending on the configuration, an air handler can be provided with one or more fans. Next, there will be a heating coil and boiler to provide heat, while a chilled water coil and chiller will provide cooling. There are also other sources available for heating or cooling.

There will be two main ducts leaving the air handler. One for heating, and the other for cooling, which makes this a dual-duct system.

Dual-Duct Mixing Box

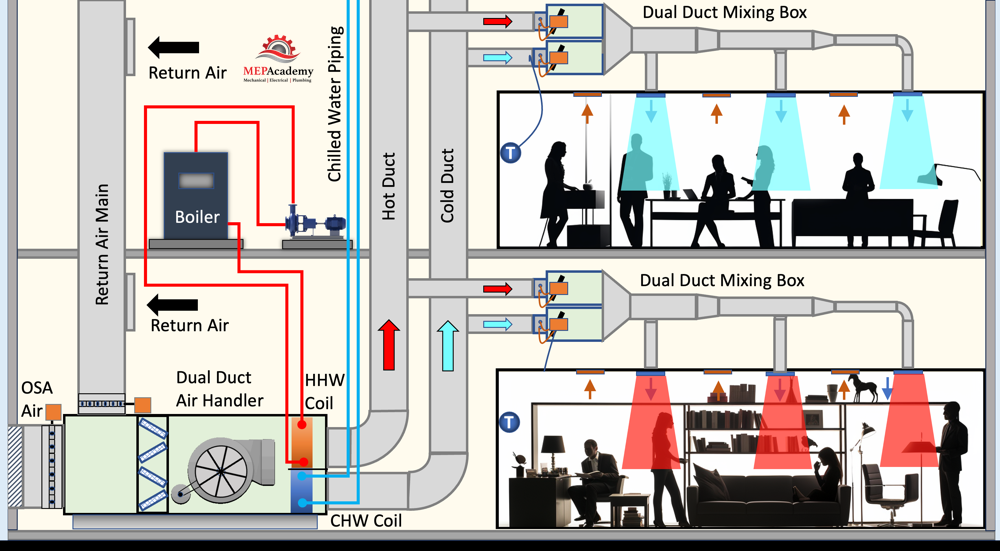

Each zone will have its own dual-duct Mixing Box, that can be either constant or variable volume. This allows one zone to be in cooling, while another zone can be in heating. Dual duct boxes are made of galvanized steel and contain two dampers. Each damper has a controller located on the outside of the box. A flow sensor is in the hot and cold inlets of the box allowing for accurate measurement of the air flow.

A room-based temperature sensor or thermostat will continuously monitor the indoor temperature. These sensors provide feedback to the HVAC control system. The control system analyzes the temperature data and determines the required airflow and temperature to maintain the desired conditions.

The dual duct mixing box operates by adjusting dampers within the box. These dampers control the amount of cold and hot air that is mixed before being distributed to different zones within the building.

Mixing Box Operation

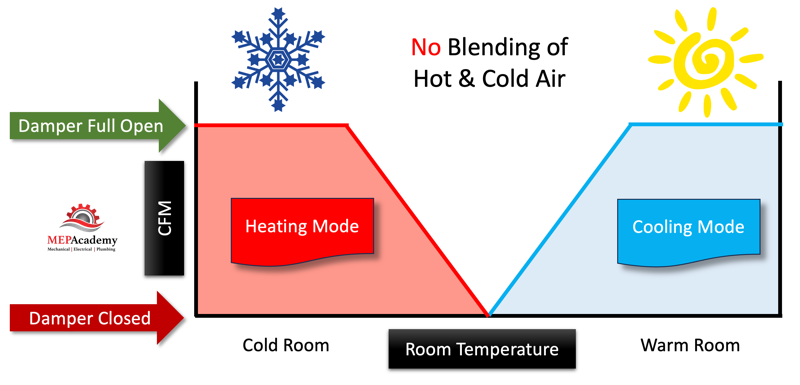

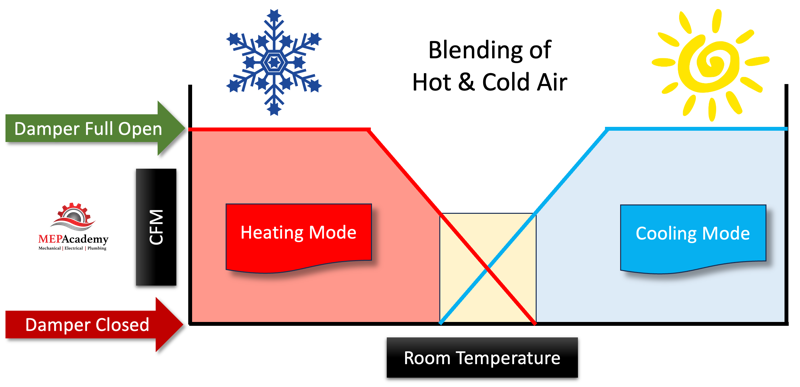

There are various control strategies for dual-duct boxes. One strategy is for there to be no blending of the hot or cold air, which looks like this.

When the thermostat calls for cooling, the damper on the hot air duct closes, and the cold air damper modulates from zero to maximum. This allows cold air to enter the mixing box.

Conversely, when heating is needed, the damper on the cold air duct closes, and the damper on the hot air duct opens.

Then there are various blending strategies where a mixture of cold and warm air will mix during certain conditions.

As the temperature sensor approaches the setpoint in cooling mode, the cold air damper will modulate from maximum to a minimum setpoint. When the temperature continues to drop the hot air damper begins to open creating a mixed air flow. While the temperature continues dropping, the cold air damper completely closes, and the hot air damper modulates to maximum open position.

There are two separate ducts for supplying air. One duct carries cold air, while the other carries hot air. After mixing, the conditioned air is distributed to various areas of the building through separate ductwork.

Each zone may have its own mixing box, allowing precise control over the temperature and airflow in different parts of the building. Again, this allows any zone to be in either heating or cooling mode.