Chapter #8 – Grease Exhaust Duct

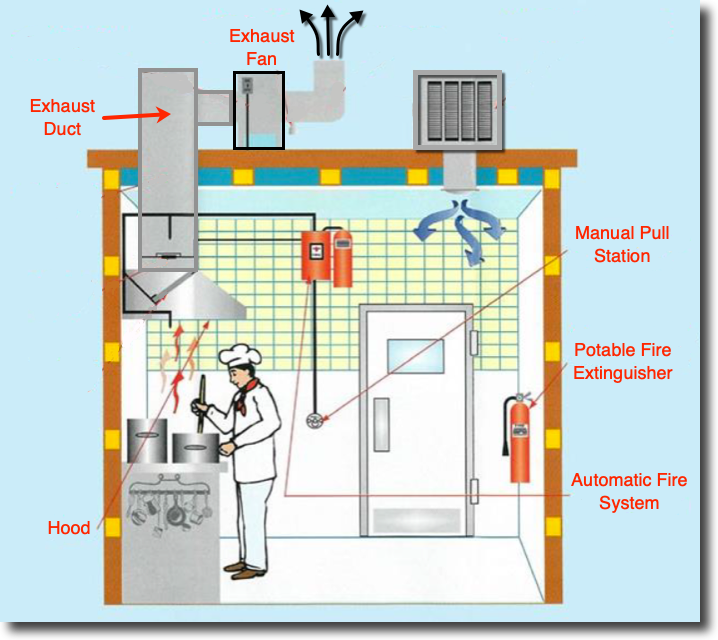

Grease duct is welded in order to prevent fires caused by the flammability of the hot grease igniting construction materials surrounding the duct and fittings. The ducts and fittings need to be supported by hangers of non-combustible materials designed to carry the weight and seismic load if applicable.

No fasteners or support screws are allowed to penetrate the duct as this would provide a point of possible failure and fire. The grease duct must contain access doors for inspections and cleaning, so don’t forget to include them in your estimates.

The grease duct is required to slope to prevent the accumulation of grease in horizontal installations.

Grease duct is either routed through a fire rated shaft enclosure or wrapped with an approved fire insulating blanket that allows for zero clearances, such as that manufactured by 3M.

Grease duct can be made out of Black Iron, Galvanized or Stainless Steel material depending on the code of jurisdiction the project falls under. Areas that are exposed are usually made out of stainless steel because of its aesthetic properties.

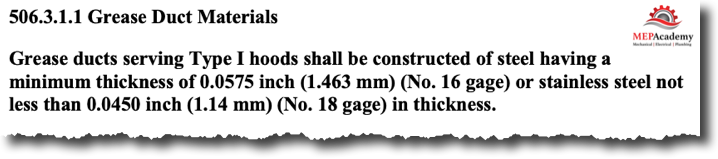

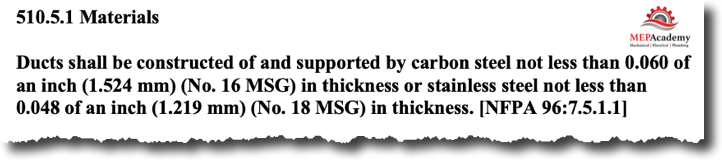

In all cases the joints and seams will be welded, the only exception are those factory manufactured duct systems as defined latter in this chapter. The minimum duct thickness is defined by whatever code jurisdiction that the project is located in. Below are two code references related to the required thickness and material type for grease ducts.

IMC – International Mechanical Code 506.3.1.1

CMC – California Mechanical Code 510.5.1

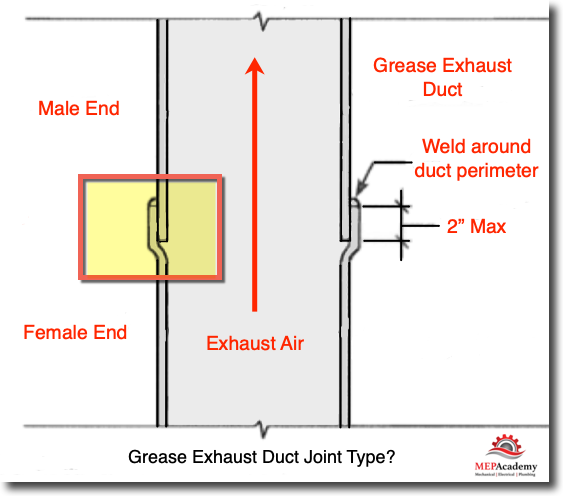

Grease Duct Joints

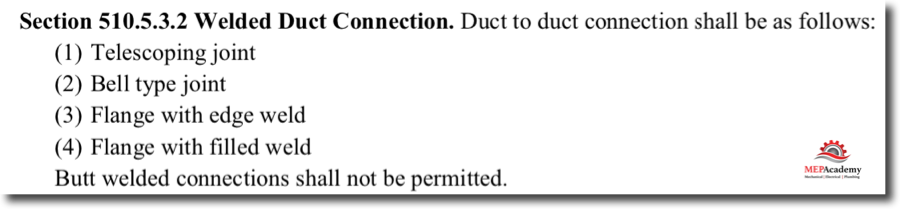

There are several approved methods of making a welded joint for grease exhaust ductwork. The choices will depend on the code for your jurisdiction but should include flanged, telescoping, Bell type or overlapping joints. Flanged joints are made by bending the end of the raw duct or fitting to make a ¼” flange. Below is the code section for the International Mechanical Code for the allowed welded duct connections types.

Below is a sample of the Bell type joint. The male side of the joint belongs on the uphill side of a sloping duct so that the grease will drain back down. The female side of the duct contains the bell portion for which the male portions slips into, and then it gets welded completely around its perimeter.

Canopy hoods have requirements to extend at least 6” beyond cooking surface, this is to ensure the entrainment of any heat and smoke.

Factory Built Grease Ducts

These duct assemblies are required to be in accordance with UL 2221. CaptiveAire makes a double wall grease duct that has insulation between two metal walls. The duct sections are constructed of an inner duct wall and an outer wall with insulation in between. The inner duct wall shall is constructed of .036 inch-thick, 430 type stainless steel and is available in diameters 8″ through 36″. The outer wall is constructed of stainless steel at a minimum of .024 inch-thickness.

Watch the two video’s below of CapitiveAire’s single wall system which requires no welding.

The duct, based on model number, shall include layers of Super Wool 607 Plus, Insulfrax Elite Blanket insulation, or Unifrax S16 Bulk Fiber insulation between the inner and outer wall. Grease duct joints are held together by means of formed V clamps and sealed with 3M Fire Barrier 2000+.

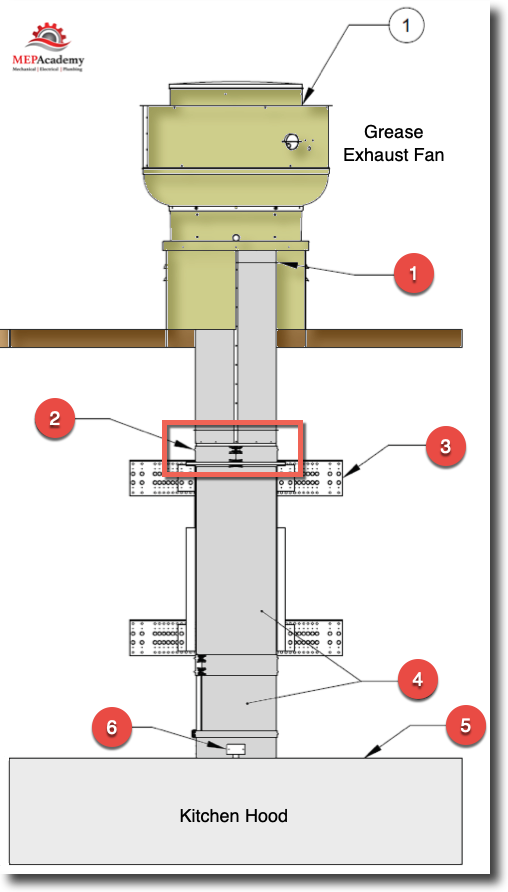

#1 Adjustable Grease Duct Section

#2 Double V-Band (Connects two duct sections together)

#3 Vertical Support – Installed under V-band

#4 Standard Length of Grease Duct

#5 Kitchen Hood

#6 Duct Sensor

Double wall grease ducts are listed for a continuous internal temperature of 500 degrees F and intermittent temperatures of 2000 degrees F.

Hood Types

There are several ratings for hood types, Type I and Type II.

Type I hoods are rated for use with Deep Fryers, Char Broilers, grills, Pizza Ovens and all solid fuel appliances (wood, Charcoal, Briquettes and Mesquite).

Type II hoods are rated for use with Steamers, Dishwashers

Grease Duct Wrap

Using a fire blanket like that made by the 3M company allows you to eliminate the need for rated gypsum board enclosures, which take up valuable space. These fire blankets are rated to be installed with zero clearance, which means they can be touching building materials and don’t require a rated enclosure. and be safe from fire.

3M’s Fire Barrier Duct Wrap 615+ protects ducts for up to 2 hours. The fire duct wrap is applied in a single layer for protecting ducts from an external fire, and requires two layers of the Fire Barrier Duct Wrap for grease ducts.

- 1-Layer (External Fire Protection)

- 2-Layers (Grease Duct)

The single layer can be used for life/safety systems like stairway pressurization ducts which provide for the pressurization of stairways in order to keep smoke from infiltrating into the stairwell every time someone opens a stairwell door.

Grease Duct Access Doors

Access doors in sheet metal are used to provide a means of accessing the inside of a duct or an internal component.

Access doors provided in grease ducts are required by code to allow for the periodic cleaning and inspection of the interior buildup of grease on the walls of the duct and fittings.

Sheet Metal Field Installation Course

- Chapter #1- Rectangular Duct and Fittings

- Chapter #2 – Round Ductwork and Fittings

- Chapter #3 – Sheet Metal Duct Hangers

- Chapter #4 – Sheet Metal Field Labor Productivity

- Chapter #5 – Labor Crew Sizes

- Chapter #6 – Sheet Metal Duct Sealer

- Chapter #7 – Sheet Metal Details and Specialties

- Chapter #8 – Grease Exhaust

- Chapter #9 – Air Distribution

- Chapter #10 – Rental Equipment

- Chapter #11 – Conditions Affecting Field Labor

- Chapter #12 – HVAC Equipment Labor