In hospital construction, isolation rooms play a crucial role in preventing the spread of infectious diseases and protecting both patients and healthcare professionals. There are positive and negative pressure room designs depending on the patient’s condition.

If the patient needs to be protected from possible contamination because of a compromised immune system, the room is put under positive pressure. If the patient has a contagious disease, then the room will be under negative pressure to prevent the spread of that disease. We’ll show you four different isolation room configurations. Here are key aspects of how a hospital isolation room typically works:

If you prefer to watch the video version of this presentation, then scroll to the bottom.

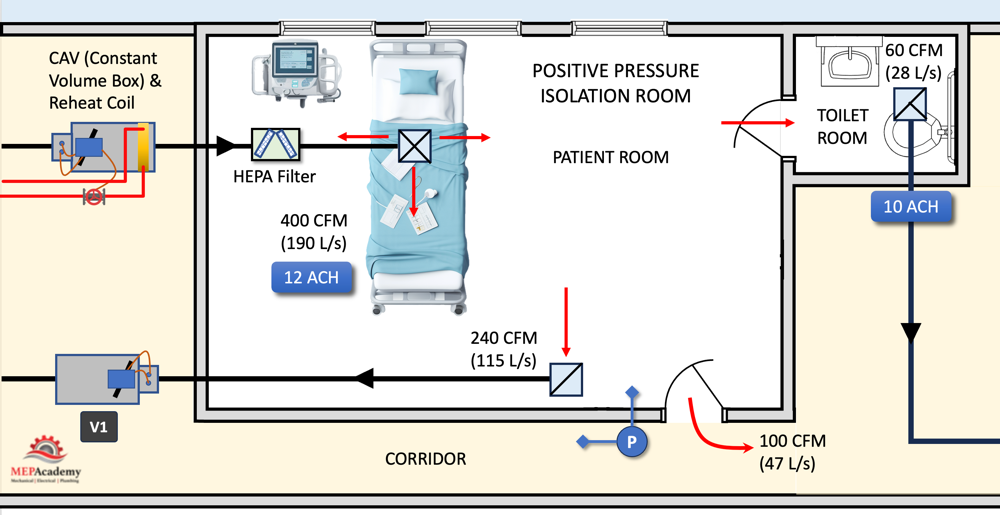

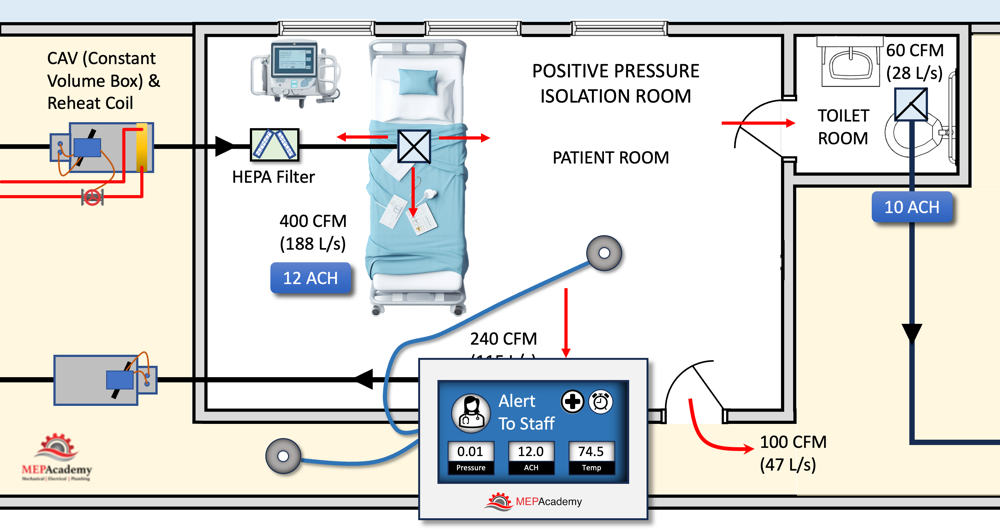

Positive Pressure Isolation Room

In hospital construction, positive pressure isolation rooms are designed to protect patients who are particularly susceptible to infections because of a reduced immune system.

The key characteristic of a positive pressure isolation room is that the air pressure inside the room is maintained at a higher level than that in the surrounding areas. This prevents external contaminants from entering the room.

In our example the supply air is delivered by a constant volume terminal with a reheat coil. The supply air has been calculated at 12 air changes per hour in accordance with ASHRAE Standard 170, which equates to 400 CFM (190 L/s). The toilet room will consume 60 CFM of that, while the return air will use a valve to ensure that there is always a 100 CFM difference. This additional 100 CFM creates a positive pressure within the room and ensures that nothing enters from the corridor.

Positive pressure rooms have a dedicated air supply system that provides filtered and clean air into the room. The ventilation system often includes HEPA filters to remove airborne particles and pathogens, ensuring that the air entering the room is of high quality.

The direction of airflow is carefully controlled to maintain positive pressure. Air generally flows from the isolation room towards adjacent spaces, minimizing the risk of contaminants entering the room.

Monitoring Systems

Pressure Monitoring: Continuous monitoring of air pressure differentials is essential. If the pressure drops, alarms are triggered to alert healthcare staff to take corrective action. The monitor can be connected to a building automation system.

Located in the hallway outside the room is a monitor that reveals what is happening with the pressure differential, temperature, air changes per hour, and many other metrics. The monitor will have sensors located in the room and in the corridor to track the pressure differential.

Access to positive pressure isolation rooms is restricted to authorized personnel to minimize the risk of contamination.

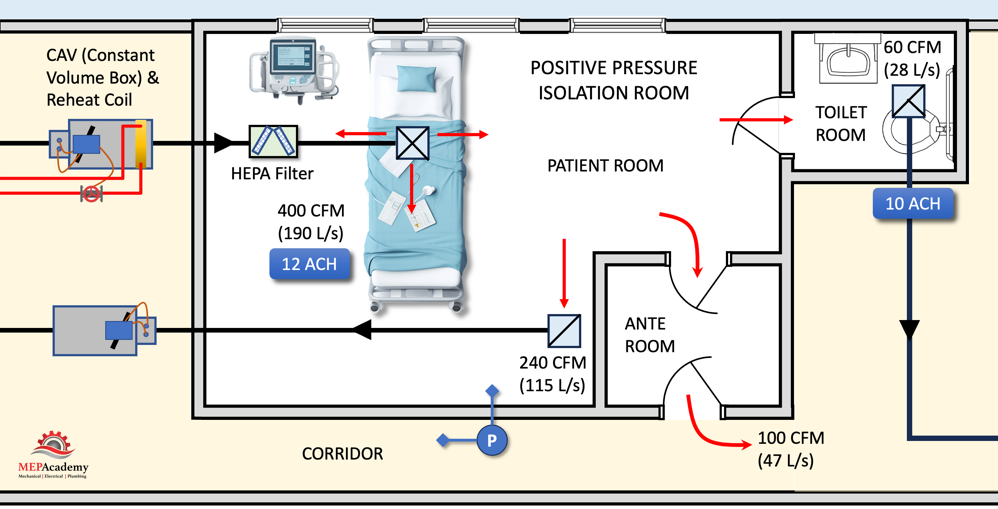

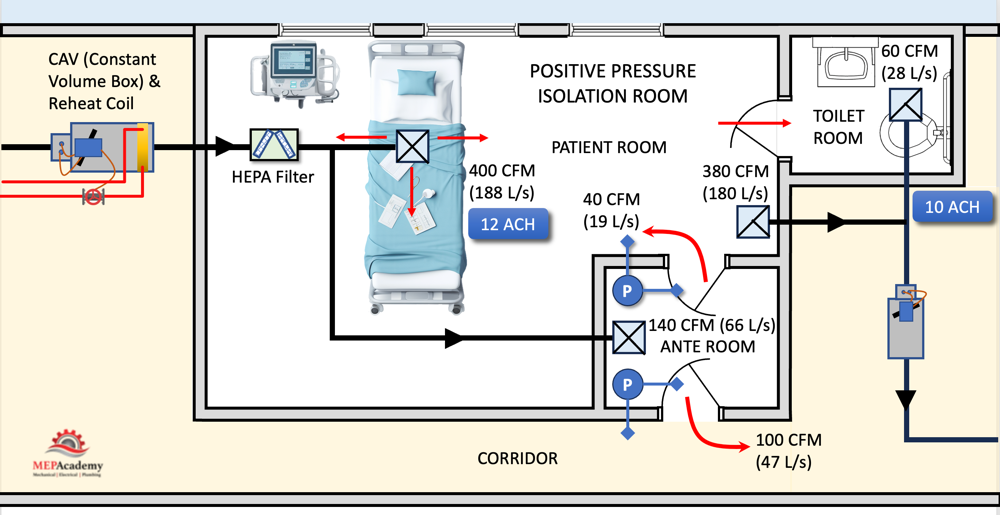

Anterooms

Some positive pressure rooms may have an airlock system with two sets of doors to further reduce the risk of air exchange with the external environment. You can see that the volume of air is the same, except now there is an extra door and small ante room.

We could also pressurize the Ante Room by putting a supply air grille in the room. An additional exhaust grille is added to the isolation room. The V-1 terminal valve will adjust as needed to maintain the required pressure differential.

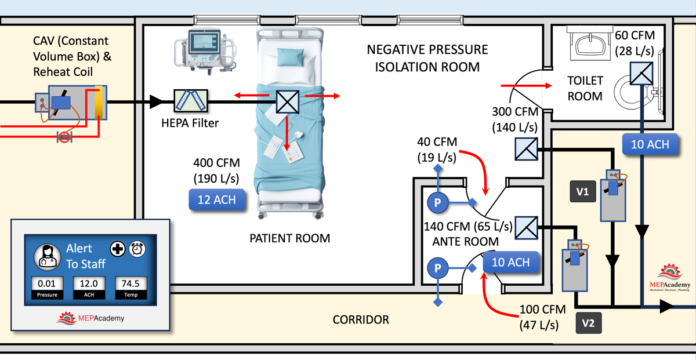

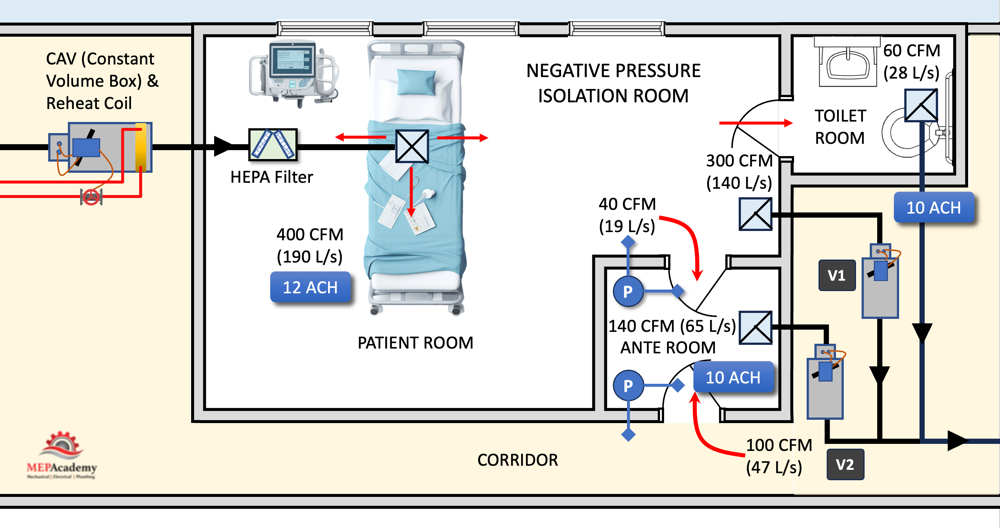

Negative Isolation Room

A negative isolation room is also referred to as Airborne Infection Isolation (AII) Room. Negative Pressure Isolation rooms are designed with negative air pressure relative to surrounding areas to quarantine patients with infectious disease. This helps prevent small airborne contaminants from escaping the room and spreading to other parts of the facility.

High-efficiency particulate air (HEPA) filters are used to capture and filter out airborne pathogens. The ventilation system ensures a controlled flow of air to maintain the required air changes per hour (ACH) for the specific isolation room.

Exhaust valve V2 is used to pull air in from the corridor and the patient room into the Ante Room. This provides an additional barrier to contamination when entering or exiting the room. The Ante Room is provided with 10 air changes per hour to create a negative pressure. Valve V1 will maintain the proper pressure differential.

Monitoring and Alarm Systems

Continuous monitoring of temperature, humidity, and pressure differentials ensures that the isolation room is operating within the specified parameters. An alarm system alerts staff to any deviations from the desired conditions, prompting quick response and correction.