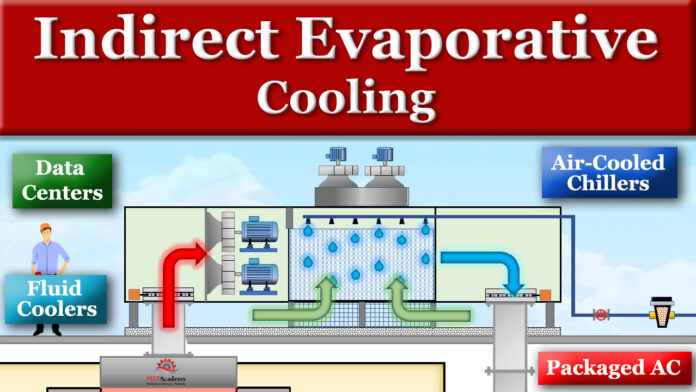

We’ll learn how indirect evaporative coolers work. By using indirect evaporative cooling some buildings can eliminate mechanical refrigeration-based systems while reducing environmental impact. Indirect evaporative coolers use air to air heat exchangers to optimize approach temperatures. We’ll show you four systems that use the indirect evaporative cooling method.

If you prefer to watch the Video of this presentation than scroll to the bottom or click the following link. How Indirect Evaporative Coolers Work

The difference between a direct evaporative cooler and an indirect evaporative cooler is that a direct evaporative cooler will add moisture to the air, thereby increasing the humidity, and the indirect evaporative cooler doesn’t add moisture to the space.

Checkout these Indirect Evaporative Coolers hereWhen water evaporates from a liquid to a vapor by the process of the heat of vaporization, sensible heat is absorbed from the air causing the air temperature to drop.

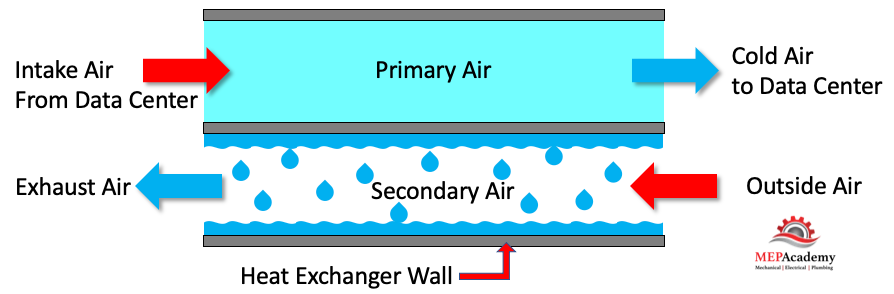

Indirect evaporative coolers use two separate air streams separated by the heat exchanger walls. The secondary air stream uses the evaporative process where water trickles down over air being exhausted from the building or by the use of outside air. This causes some of the water to evaporate and absorb heat from the primary air stream through the heat exchanger wall.

The heat exchanger keeps the wet air stream separate from the primary dry air flow to the space. Indirect evaporative coolers work best in low humidity areas with design wet bulb temperatures below 70F, allowing for an energy savings over mechanical refrigeration cooling.

The use of air conditioners contributes to the largest consumption of peak demand on the US electricity grid and is the primary cause of blackouts and grid failures. The problem is increased on high ambient temperature days when air conditioners are least efficient and the demand for cooling is the greatest. Indirect evaporative coolers use less energy than Variable Air Volume or Direct Expansion (DX) rooftop packaged units.

How indirect Evaporative Coolers Work

There are various configurations that can be used with indirect evaporative coolers, including additional stages of cooling using direct evaporative cooling and chilled water or DX cooling for additional capacity. We’ll explain the basic Indirect Evaporative Cooler only application.

The secondary air can be Return air from the space or outside air that enters the indirect evaporative cooler and passes over a wetted Heat Exchanger medium where the water is evaporated before its discharged outdoors. On the primary side the Outdoor air is brought into the indirect evaporative cooler where it crosses the Heat Exchanger medium without mixing with the return air and is indirectly cooled by encountering the cool heat exchanger before being supplied to the space.

If additional cooling is required, then a second or third stage of cooling can be added with an direct evaporative section and a chilled water or DX coil to drop the supply air temperature further. Since the primary air never mixes with the secondary wet air, the humidity of the space is not increased.

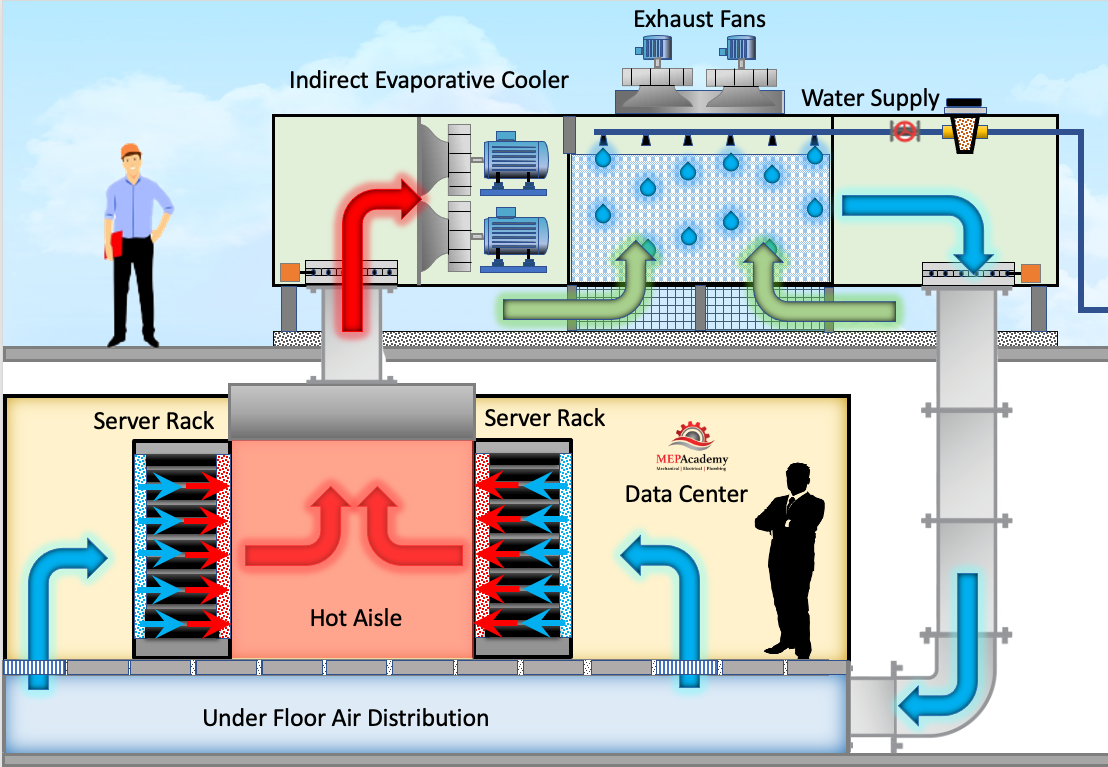

Indirect Evaporative Cooling in a Data Center

An indirect evaporative cooler can be used to cool a data center while saving large amounts of energy. See our video on Data Centers for a better explanation of the systems used for cooling data centers. Hot air from the servers is captured in a Hot Aisle and brought into the indirect evaporative cooler where it travels through the primary side of the heat exchanger where it gives up its heat to the secondary side. See our video on Heat Exchangers for a better understanding of Plate and Frame Heat Exchangers.

The cold air is then sent back to the data center through an underfloor distribution system. The cold air exits through floor grilles and travels back into the server racks where it picks up the heat of the servers and begins the cycle again. On the secondary side of the indirect evaporative coolers heat exchanger, there are fans mounted on top of the unit that pulls outside air through the heat exchanger as water is sent trickling down causing the water to evaporate and absorb heat through the walls of the heat exchanger.

Checkout these Indirect Evaporative Coolers hereIf the indirect evaporative process can’t meet the load because of unfavorable outdoor ambient conditions, a second phase of cooling can be added. This secondary cooling can be achieved by using a DX or Chilled Water coil.

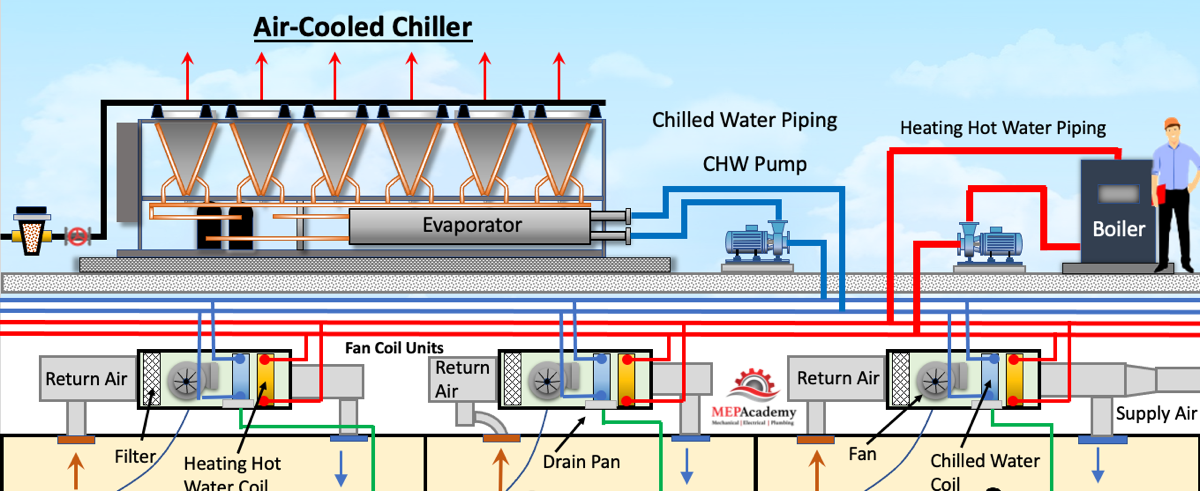

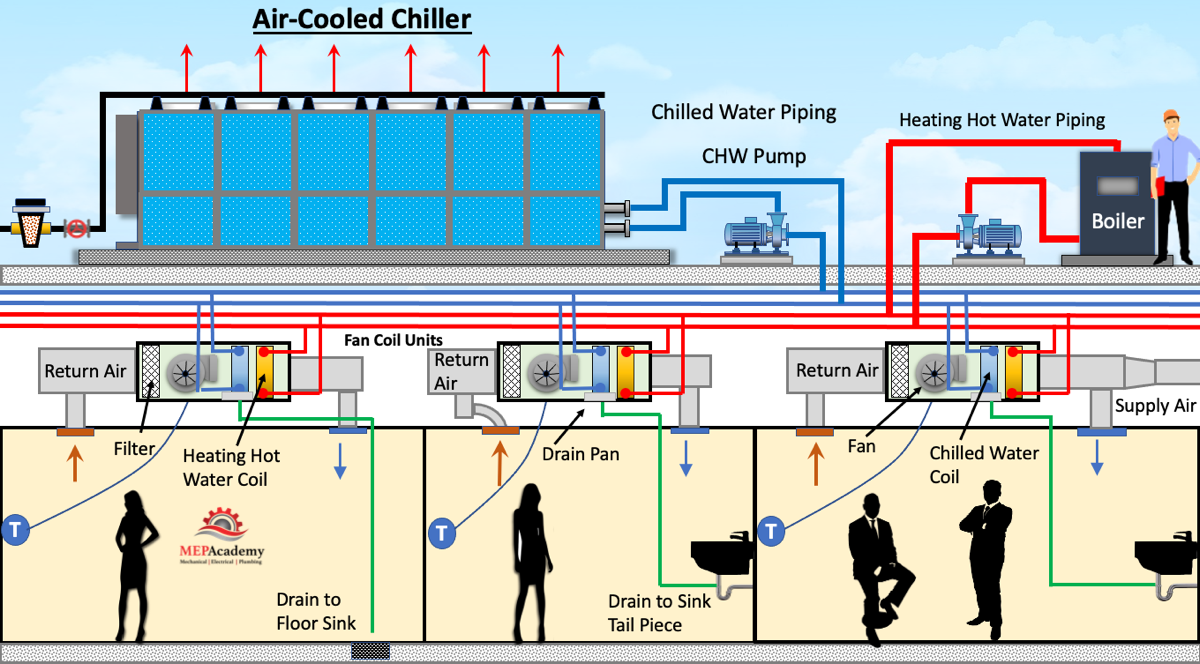

Indirect Evaporative Cooling of Air-Cooled Chillers

Indirect evaporative cooling is also used to cool down the condenser coils of an air-cooled chiller.

Panels containing wetted medium can be attached around the air-cooled chiller, effectively closing off the pathway for the condenser fan inlet air. This causes the condenser inlet air to travel through the media which is sprayed with water based on the ambient temperature and the compressors liquid line temperature.

This precools the incoming air before it travels over the warm condenser coils, allowing for increased energy efficiency. Before attaching the panels the condenser coils should be cleaned to ensure the best performance.

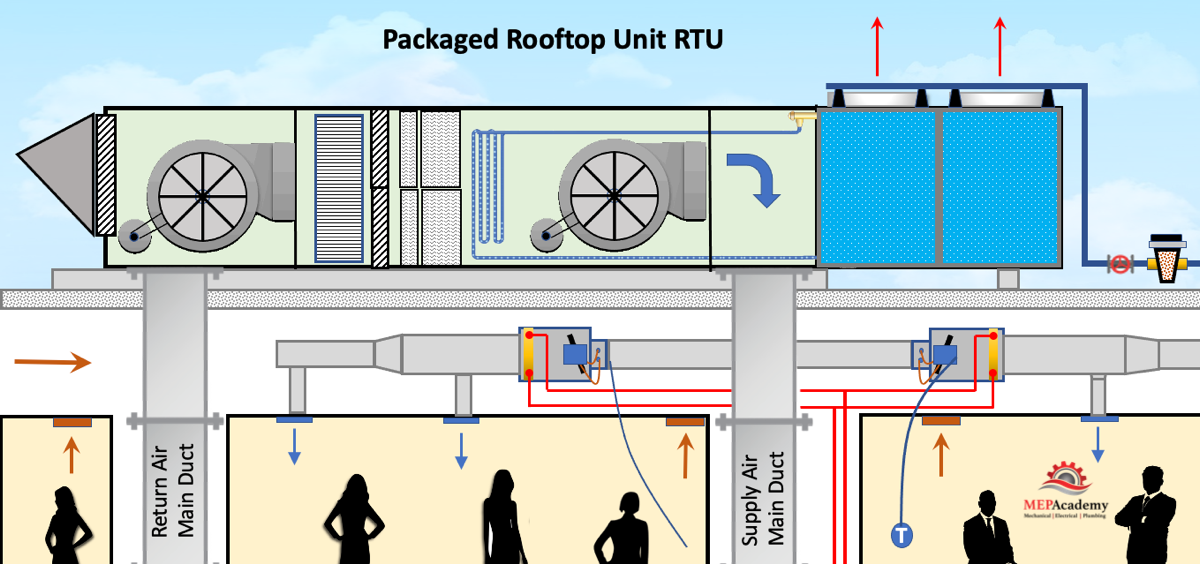

Packaged Air Conditioners and Indirect Evaporative Cooling

This is another method of using indirect evaporative cooling to pre-cool air before it enters the condenser coil of a packaged DX unit. This also allows for increased efficiency.

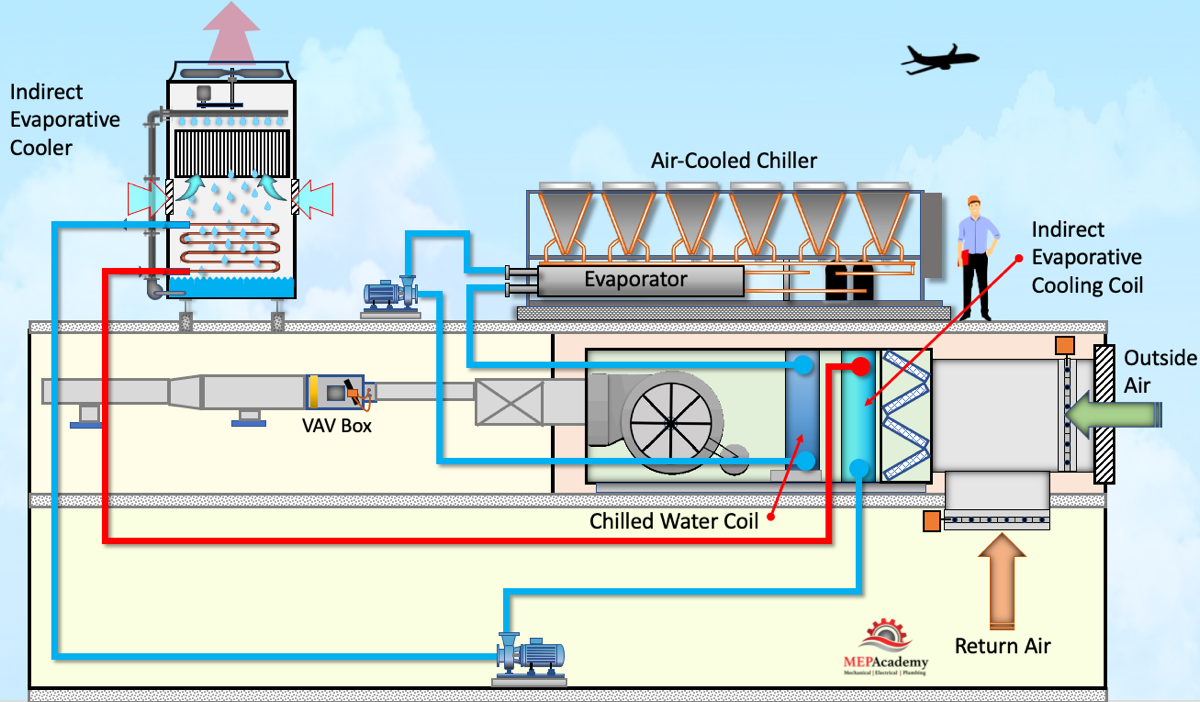

Indirect Evaporative Cooling using a Fluid Cooler

There is another method of providing indirect evaporative cooling by providing a fluid cooler that feeds a cooling coil within an air handler. The fluid cooler provides indirect cooling by spraying water over an enclosed coil that circulates water through an air handler. The coil in the air handler absorbs heat from the space or outdoor air and circulates it to the tower where it gives up its sensible heat to the cool moist air. The water circulated in the Indirect Evaporative Cooler never mixes with the water circulated in the air handler coil.

If this doesn’t provide enough cooling then a secondary system can be added, like an evaporative cooling section or a chilled water coil as shown here fed by an air-cooled chiller.

Benefits of Evaporative Cooling

- It can reduce or eliminate mechanical refrigeration or chiller usage.

- Overall energy savings

- Initial cost is less than refrigerated air conditioning

- Reduced maintenance cost with less skilled maintenance personnel.

- Works good in dry climates

- Can save water when compared to a water-cooled chiller plant.

- The ability to increase the amount of outdoor air for improved indoor air quality.

- Environmentally friendly as there are no refrigerants, CFC’s or HCFC’s.

Where are Indirect Evaporative Coolers Used

There is a wide application for the use of indirect evaporative coolers in schools, warehouses, offices, retail, industrial and some data centers.

According to a NREL study the use of a multi-stage indirect evaporative cooler there are “Three target market segments that have been identified for this technology: data center installations in ASHRAE climate zones 2B through 6B; outside air pre-conditioner retrofits for air-cooled RTUs in climate zones 2B and 3B; and new construction and facilities that do not currently have cooling systems in climate zones 4B, 5B, and 6B. In ASHRAE climate zones 1A through 7A, the increased outdoor humidity characteristic of these zones reduces cooling capacity and overall energy savings to the point that the multistage IEC will not provide a favorable return on investment.”

Calculating the Effectiveness of Indirect Evaporative Coolers

The following calculation is often used to inform the engineer about the effectiveness of using an indirect evaporative cooler in a particular climate. Remember that these units work best in hot and dry climates. The higher the value the more efficient the indirect evaporative cooler.

EF = T (DB) – SAT / T (DB) – T (WB)

EF= Evaporative Effectiveness

T (DB) = Ambient Dry Bulb temperature

T (WB) = Ambient Wet Bulb Temperature

SAT = Supply Air Temperature

The greater the difference between the ambient dry bulb and wet bulb temperatures, the better the chances for the efficient use of an indirect evaporative cooler.

Energy Use and Increased Temperatures

The typical air-cooled air conditioner loses efficiency the higher the outdoor temperature gets, while evaporative cooling usually gets more efficient.

Summary

Indirect evaporative coolers use less energy than a refrigerant based system, they provide better air quality when ventilation air is increased, they avoid the use of environmentally hazardous refrigerants, and the installed cost is less, including the reduced skill level required of maintenance personnel. The main disadvantage is that they perform best in hot and dry climates only.