Chapter #7 – Sheet Metal Details and Specialties

Most engineered drawings have a section for details, which allow for additional information to be provided. It is easier for the Mechanical Engineer to provide a detail showing exactly all the components required for a particular piece of equipment, duct specialty item or other building component that requires more information than what can be but on the plan view.

If the engineer was to put all the detail information on the building plan view, then this would make for a very messy and crowded drawing. It’s important that you review all the details as this is where cost impacts are usually incurred because of special requirements not identified anywhere else on the documents.

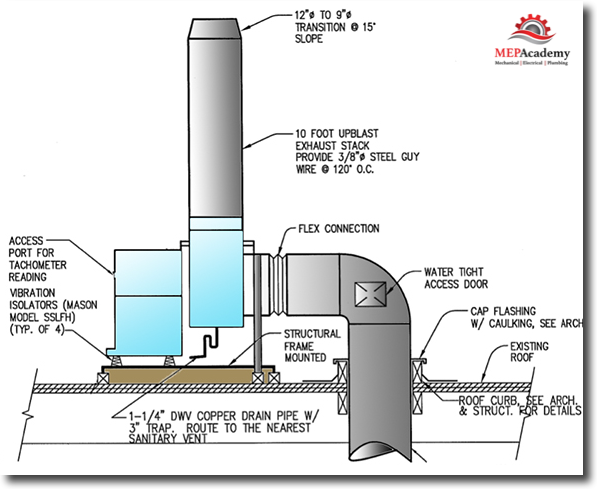

Utility Fan Exhaust Stack

Utility fan will often require that you install a length of sheet metal off the discharge side of the exhaust fan to ensure that the exhausted air doesn’t get entrained back into any of the building intakes. Often this stack will need independent supports like guy wires attached to a ring near the top of the exhaust stack and the other end of the wire attached to the roof structure. This will prevent the stack from being blown away on windy days.

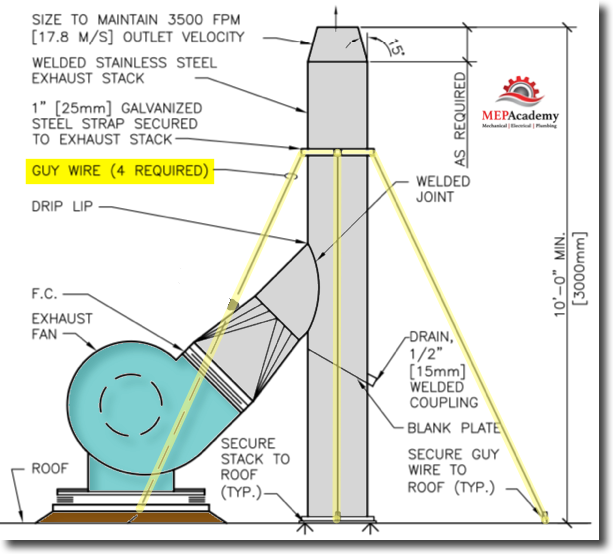

Utility Fan Exhaust Stack

The two most common ways that Utility Exhaust fans support their discharge ducts or stacks are shown here. Above the discharge duct is support by the fan housing, while the exhaust stack (duct) shown below is support by the roof and has guy wires for additional stability during stormy weather. Of course, the detail below is going to have a greater cost impact. This is why its important to review the details.

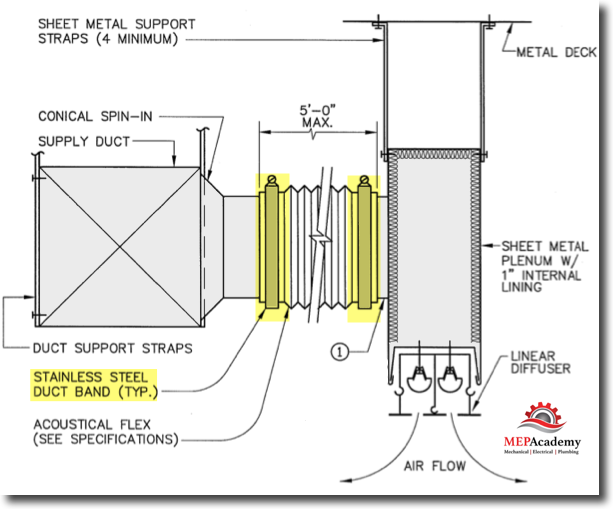

Linear Diffuser Detail

Linear diffusers are used to provide a more pleasing look as envisioned by the architect, then the traditional square diffuser. Linear diffusers also cost more than the standard diffuser or grille. In this detail the engineer has also specified “Stainless Steel” duct bands (highlighted in yellow) which are more costly than the standard plastic pandit type. You would add this item to your sheet metal specialties page to include the additional cost. These bands hold the flexible duct securely in place to avoid becoming detached or so as to prevent leaking.

Linear Diffuser Detail

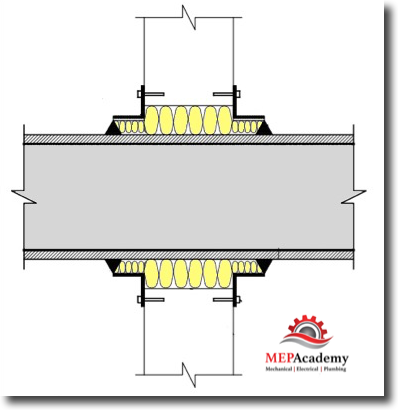

Acoustical Wall Penetration

When penetrating a wall that is acoustically rated to prevent the transmission of sound you would need to include the cost to sound proof your duct penetrating the wall. If you had a noisy room adjacent to a private office then you would want to make sure that none of the noise was transmitted from one space to the other.

Acoustical Sealing of Duct Penetration

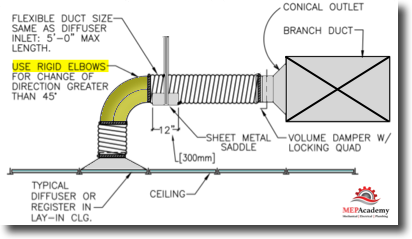

Elbows at Diffusers or Registers

Engineers, certain facilities and various jurisdictions require that you install a 90 degree elbow at each piece of air distribution. This was most likely in response to projects where flex was installed incorrectly, causing kinks that reduced airflow to the space. To ensure proper airflow a 90-degree elbow is installed at the point of the diffuser or register as shown below. The traditional method is shown in the next detail where a flexible duct connection is used to attach the ductwork to the diffuser.

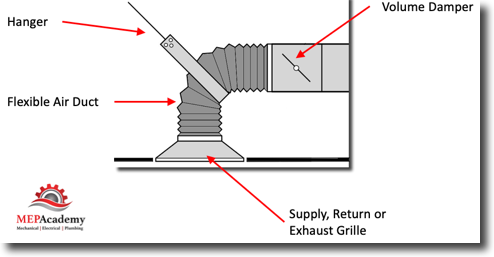

Air Distribution Connection Detail

There are several items that makeup a connection to a piece of air distribution. Each piece of air distribution should have a Balancing/Volume Damper to adjust the volume of air coming out of or into the air distribution. Some jurisdiction will allow a piece of flex duct to make the final connection between the duct and the air distribution grille.

Air Distribution Connection Detail

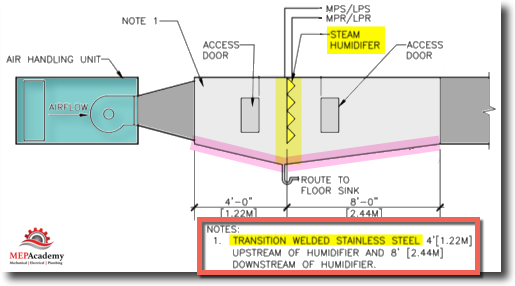

Steam Humidifiers

There are certain rooms that require that the RH (Relative Humidity) remain within a range, such as between 40% & 70% RH. A humidifier is installed in the duct to ensure proper humidity to the space. Since steam (moisture) is added to the air stream by the humidifier to maintain the required RH levels, the need for a non-corrosive duct material within a certain distance before and after the humidifier will be required, in addition to a drain.

As shown in the detail below, the engineer has specified that 4 feet before and 8 feet after the humidifier shall be constructed of welded stainless steel. Also, there are two access doors shown, one on each side of the humidifier to allow for easy viewing of the internal components of the humidifier.

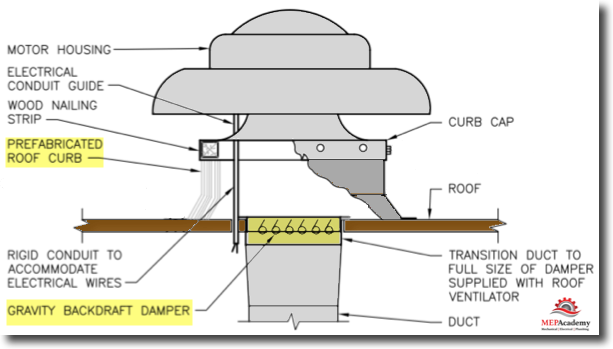

Roof Mounted Exhaust Fans

There are many types of roof mounted exhaust fans that require a curb to sit on. In addition there will be a Gravity Backdraft Damper to prevent outside air from being forced into the building under increased pressure from outside due to winds and storms.

A sheet metal transition is often required because the duct drop is a different size then that which connects to the exhaust fan. Check the vendors quote to make sure that the exhaust fan comes with the rood curb and BDD (backdraft damper). This also applies to exhaust and intake hoods that don’t have a motor, but strictly operate on pressure differentials.

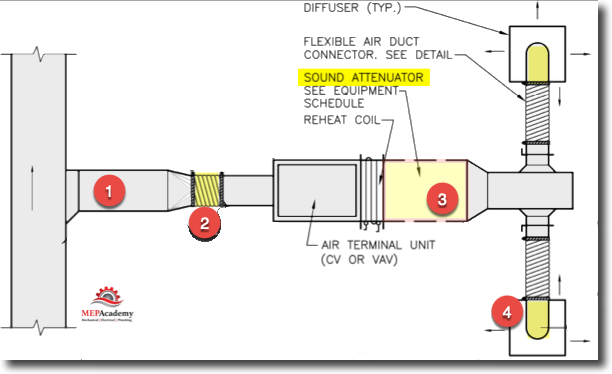

CAV or VAV Detail

CAV (constant air volume) or VAV (variable air volume) air terminals may come with a sound attenuator as shown in the below detail. This is usually something provided by the air terminal manufacture, so you won’t need to price this as a piece of sheet metal, but you will need to confirm that the vendor has included them in their proposal. The sound attenuator (#3 below) muffles any noise coming from the CAV/VAV.

Also, if the inlet duct (#1 below) to the air terminal unit exceeds a certain distance then a requirement to increase the duct one size may be specified as shown in this detail. This is to ensure that the proper amount of air reaches the air terminal. There may also be a requirement to provide a high side flexible duct (#2 below) on the inlet side of the air terminal. When you look closely you will also see that there is a 90-degree elbow (#4 below) at the diffuser.

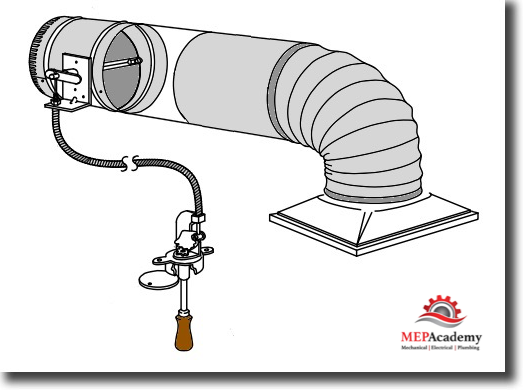

Remote Damper Operators

Used where dampers are concealed above inaccessible ceilings. The remote damper operator allows you to adjust the CFM (airflow) going through the duct by adjusting the damper position in the duct from a remote location like a wall or ceiling.

Sheet Metal Field Installation Course

- Chapter #1- Rectangular Duct and Fittings

- Chapter #2 – Round Ductwork and Fittings

- Chapter #3 – Sheet Metal Duct Hangers

- Chapter #4 – Sheet Metal Field Labor Productivity

- Chapter #5 – Labor Crew Sizes

- Chapter #6 – Sheet Metal Duct Sealer

- Chapter #7 – Sheet Metal Details and Specialties

- Chapter #8 – Grease Exhaust

- Chapter #9 – Air Distribution

- Chapter #10 – Rental Equipment

- Chapter #11 – Conditions Affecting Field Labor

- Chapter #12 – HVAC Equipment Labor