Chapter #6 – Sheet Metal Duct Sealer and Leakage

Duct Leakage

Duct leakage is a factor of the static pressure in the ductwork that allows for leakage to occur through holes, seams, joints and penetrations. Leakage is a loss of energy, which means a loss of money. This is why it’s so important to seal the ducts and to prevent leakage. Leakage can also occur at equipment and accessories that are installed into the system including dampers, smoke/fire dampers, VAV Boxes and access doors.

SMACNA Duct Seal Classes

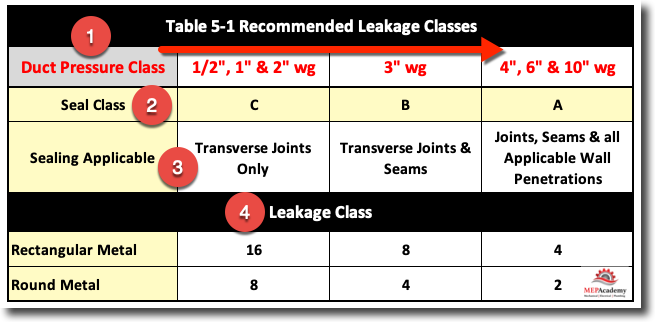

Ducts are required to be sealed according to SMACNA Table 5-1 based on the duct pressure class (#1), which is broken down into three categories of pressure. Depending on the pressure class of the duct, there will be a corresponding Seal Class (#2) from C to A.

As the pressure increases in the ductwork the applicable sealing requirements (#3) will apply to various aspects of the ductwork, starting with Transverse Joints Only (Seal Class “C”), then Transverse Joints & Longitudinal Seams (Seal Class “B”) and finally All Transverse Joints, Seams and Wall Penetrations (Seal Class “A”).

Duct Sealing

There are various sealing requirements.

This video shows how duct sealer is applied with a brush. It appears to be a messy job, but the idea is to make sure that all the joints and seams are air tight so as to avoid duct leakage, including brushing sealer over all screws used in fabrication. Ducts that leak are wasting energy and preventing the conditioned air of doing its job of providing a comfortable environment for the occupants.

There are various types of sealer including some that are required to be of low or no VOC (Volatile Organic Compounds) when a building is seeking to get LEED (Leadership in Energy and Environmental Design) certified or when requested by an environmentally conscious owner. The IEQ Credit 4.1: Low Emitting Materials is worth 1 point in the LEED certification program. This LEED credit applies to various sealants and adhesives used on the interior of construction projects in addition to duct sealer, items such as carpet and floor adhesives.

The Adhesives, Sealants and Sealant Primers must comply with South Coast Air Quality Management District (SCAQMD) Rule #1168.

Joint Sealing

Joints are sealed with Butyl Gasket to prevent leaks at the connection points between ducts, fittings and accessories.

Duct Leakage

SMACNA doesn’t recommend pressure testing on duct pressure classes of 3” wg and less, as its not economically feasible. Be sure to check the specifications and your local or state energy code for this requirement. Leakage testing could be shown in the Testing & Balancing or the Ductwork section of the specifications.

Some states, like California require pressure testing on small systems (spaces 5,00 Ft2 or less) when 25% or more of the ducting is located in a non-conditioned space, one not intended to be occupied by people. This applies to both new and renovated projects.

Also some of the utility companies that offer energy saving incentives or rebates require pressure testing to confirm a maximum level of leakage in order to qualify for their program.

Duct Leakage Allowed

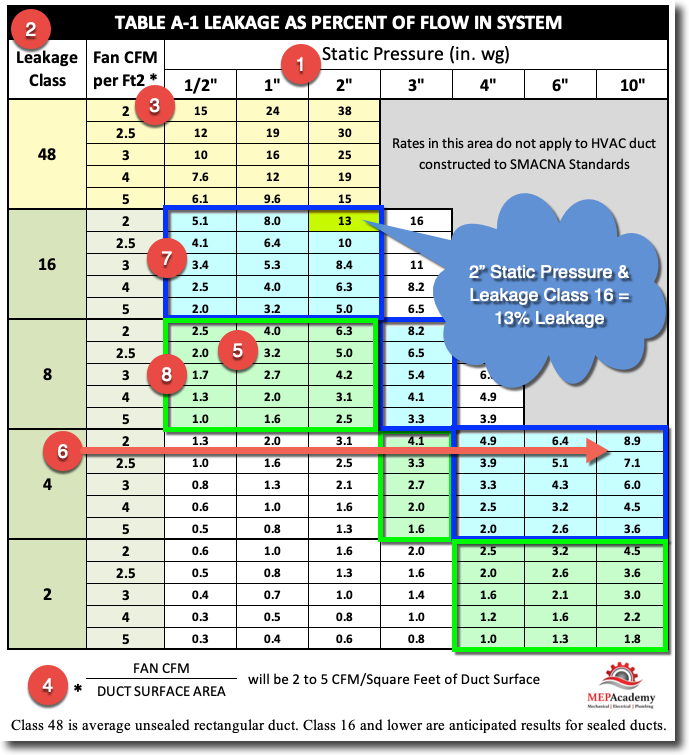

SMACNA publishes Table A-1 “Leakage as Percentage of Flow in System” that if specified in your local code or the design specifications, shows the percentage of leakage (#5) at various Static Pressures (#1) and Leakage Classes (#2). This is also effected by a calculation (#4) of the Fan CFM divided by the Ducts Surface Area (#3), shown as; CFM/Duct Surface Area. The product of the calculation is available at 2, 2.5, 3, 4 & 5 (#3).

Note that as the pressure increases (#6) so does the percentage of duct leakage. As an example, if you had a duct rated for 2” static pressure and the specifications called for a leakage class of 16, you would get a rate of 13% leakage, assuming your calculation (#3) for Fan CFM divided by Duct Surface Area equaled 2 or less.

Item (#7) above shows what the Table 5-1 “Recommended Leakage Classes” above would look like on this leakage rate chart. Item #7 shows for rectangular duct (highlighted in blue), while item #8 on the chart above is reflective of round duct (highlighted in green).

Sheet Metal Field Installation Course

- Chapter #1- Rectangular Duct and Fittings

- Chapter #2 – Round Ductwork and Fittings

- Chapter #3 – Sheet Metal Duct Hangers

- Chapter #4 – Sheet Metal Field Labor Productivity

- Chapter #5 – Labor Crew Sizes

- Chapter #6 – Sheet Metal Duct Sealer

- Chapter #7 – Sheet Metal Details and Specialties

- Chapter #8 – Grease Exhaust

- Chapter #9 – Air Distribution

- Chapter #10 – Rental Equipment

- Chapter #11 – Conditions Affecting Field Labor

- Chapter #12 – HVAC Equipment Labor