Essential Tools for Every Refrigeration Technician: A Comprehensive Review

Are you intrigued by the inner workings of refrigeration systems and the vital role they play in our everyday lives? Whether you’re an aspiring refrigeration technician or a seasoned pro, understanding the tools of the trade is essential.

In this comprehensive review, we delve into the top tools that every refrigeration mechanic should have in their arsenal. These tools are not mere conveniences; they are the very instruments that empower technicians to diagnose, repair, and maintain refrigeration systems efficiently and effectively.

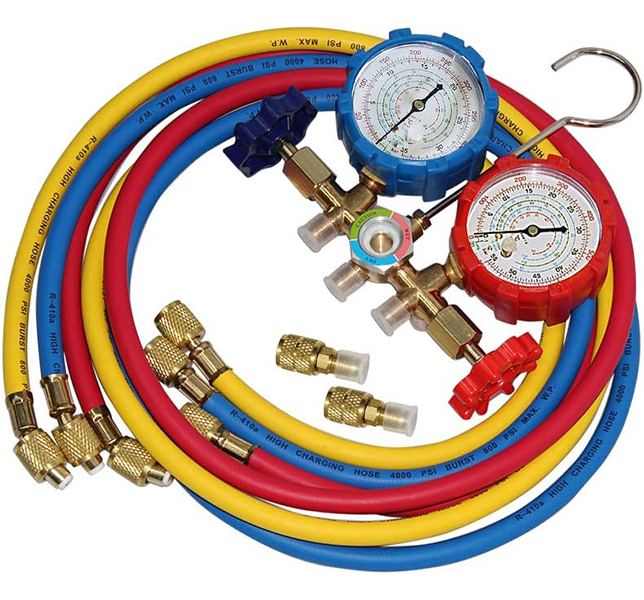

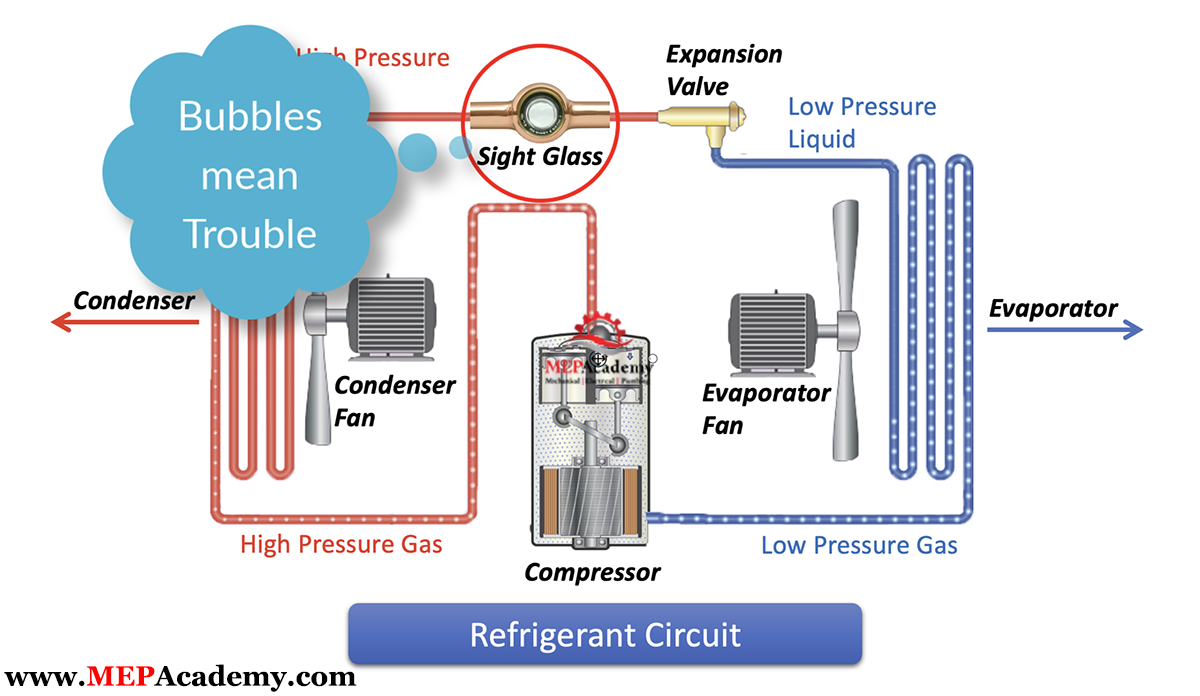

1. Manifold Gauge Set: Refrigeration mechanics rely on manifold gauge sets to simultaneously measure high and low side pressures in refrigeration systems. These sets are like the eyes of the technician, providing critical insights into the system’s condition. By providing real-time data, refrigerant gauges are essential for diagnosing issues and ensuring optimal system performance.

2. Vacuum Pump: A vacuum pump may seem unassuming, but its role is monumental. It evacuates air and moisture from refrigeration systems before the introduction of refrigerant, ensuring that the system operates efficiently without unwanted contaminants.

List of Vacuum Pumps

1- Xtremepower 3 CFM 1/4 HP (see image)

3. Leak Detection Tools: Finding elusive refrigerant leaks is a challenge without the right tools. Leak detection tools, including electronic detectors and bubble solutions, play a crucial role in environmental protection and system efficiency by pinpointing these leaks.

List of Leak Detectors

1- Elitech ILD-200 Infrared (see image)

4. Digital Multimeter: An HVACR technician’s electrical diagnostic prowess relies heavily on a digital multimeter. This tool measures voltage, current, and resistance in electrical components, making it indispensable for troubleshooting electrical issues.

List of Digital Multimeters

1- KAIWEETS Digital Multimeter (see image)

2- AstroAI TRMS 6000

4- Astro 2000

5- Klein MM325

5. Pipe Cutters and Flaring Tools: Copper pipes are the lifeblood of many refrigeration systems, and pipe cutters and flaring tools ensure these essential components are accurately cut and shaped for the job.

List of Flaring Tools

4- Rigid 41162 377 3/16″ to 3/4″

6. Pipe Benders: The importance of smooth, kink-free bends in copper pipes cannot be overstated. Pipe benders are the secret to achieving these precise bends without compromising the integrity of the pipe.

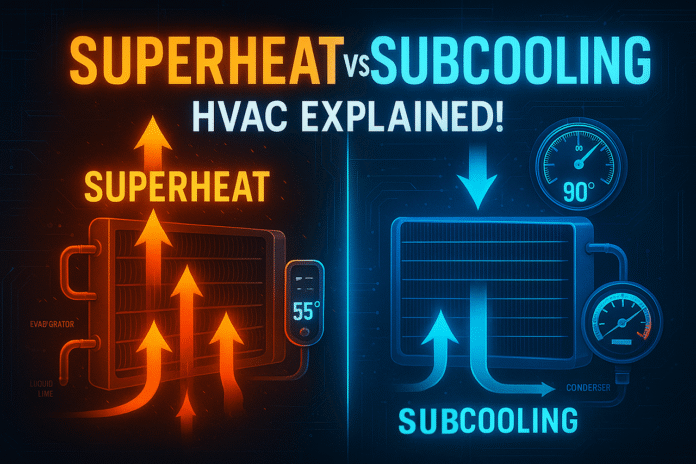

7. Thermometers and Thermocouples: When it comes to temperature measurement, accuracy is key. Thermometers and thermocouples help technicians monitor temperatures at various points in the system, assisting in both diagnostics and cooling optimization.

8. Tubing Tools: Properly preparing tubing for installation is a fundamental step in any refrigeration project. Tubing tools, such as deburrers and reamers, ensure that tubing is ready for action.

9. Hex Key Set: Hexagonal screws and bolts are commonplace in refrigeration systems. A set of hex keys is a technician’s trusty companion for swiftly disassembling and reassembling components.

10. Oil Pump and Oil Injector: Lubricating oil is the lifeblood of compressors. Oil pumps and injectors ensure that the compressor functions optimally by delivering the right amount of lubrication.

11. Torque Wrench: Precision matters in refrigeration systems. Torque wrenches guarantee that bolts and nuts are tightened to precise specifications, safeguarding components and maintaining proper seals.

12. Digital Scale: In the intricate world of refrigeration, precision is paramount. This is where a digital scale steps in as a silent but indispensable partner for refrigeration mechanics. Why? Because refrigerants, lubricants, and various chemicals must be added to systems with meticulous accuracy.

A digital scale ensures that the right quantities are added, helping maintain the system’s efficiency, performance, and, perhaps most importantly, the environment. It’s not just about getting the job done; it’s about getting it done right, and that’s where the digital scale shines. So, let’s weigh in on the importance of this often-overlooked tool in the refrigeration technician’s toolkit.

These tools are the cornerstone of any refrigeration technician’s toolkit. Stay tuned as we dive deeper into each of these essential instruments, unveiling the art and science behind their usage, and why they’re indispensable for refrigeration technicians around the globe.