Chapter #3 – Subcontractors (MEP Estimating Spreadsheet)

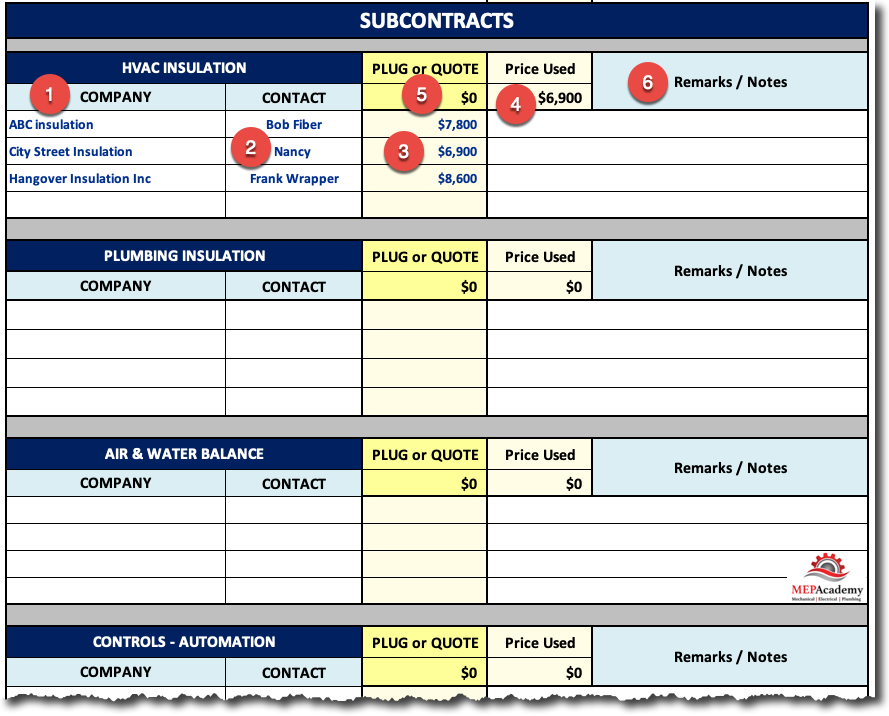

There will be certain task you will have to subcontract to companies that specialize in areas that your company doesn’t. For example, most companies don’t have their own insulators or controls division. Let’s look at the different requirements and needs for a subcontractor. On your subcontractor tab of your estimating spreadsheet we find the following.

Company (#1)

List all the companies that you normally do business with for each of the categories of subcontractors, as this will save you time on bid day when you need to contact them.

Contact (#2)

List the salesperson that you normally deal with, or the inside sales desk person, or the bid or quote desk person that is responsible for issuing quotes at bid time. Preferably you will have received the quotation without having to call on bid day to request it, as you have given them notification earlier in the process.

Recording the phone number of the vendor can save valuable time on bid day, by not having to look for phone numbers of key vendors that you require a quotation from.

Quote (#3)

Record each subcontractor’s quoted value under the Quote column.

After analyzing the bids for each category of subcontractors you will record the lowest responsible bidder in the Quote column. This is the price that will get carried forward to your front summary sheet called “Final Bid”

Price Used (#4)

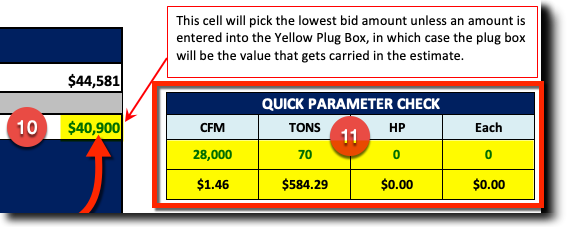

This is the price that actually gets used. If you are using the MEP Academy Estimating Spreadsheet then the lowest quote is automatically chosen from all the quotes listed.

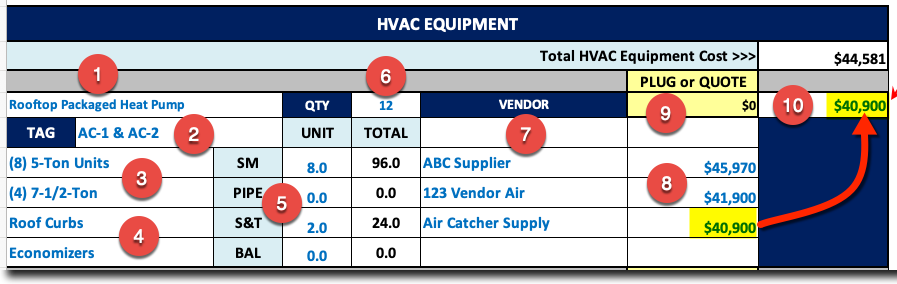

Plug or Quote (#5)

If you don’t want to use the lowest quoted value then you can overwrite this value by entering the price you want into the dark yellow cell entitled “Plug or Quote”

Remarks (#6)

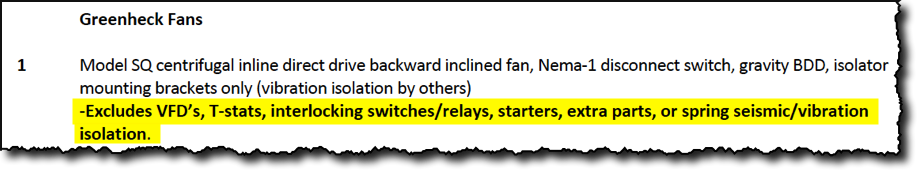

This is a small area for you to document those items that may help you in making a decision as to which subcontractor to pick. Such items may include exclusions or additional scope of work that is identified on their quotation.

HVAC Subcontractors

Make sure to review their scope letters for complete coverage of the project requirements. Did they include all of the systems required to be insulated? Sometimes subcontractors will exclude a system because of an outdated material spec or they will be missing scope because they didn’t do a thorough job of reviewing the plans and specifications. It is your job to make certain that they have included all that is required for this project.

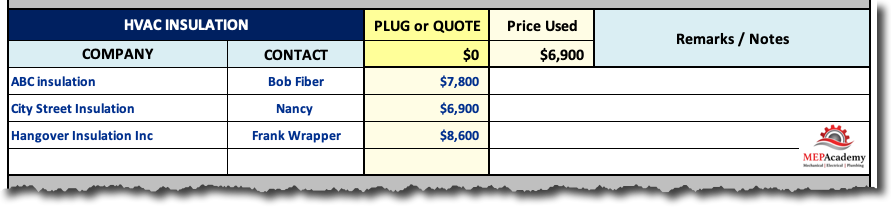

Insulation Subcontractor

The first category of subcontractors is the insulators. Record their bids for the cost to insulate the ductwork and piping if you’re bidding both trades. Note any exclusions or additional scope. For those living in an intensive energy code environment be sure to note any code changes in the thickness required for insulation, as jurisdiction keep increasing the thickness to meet state mandated energy savings.

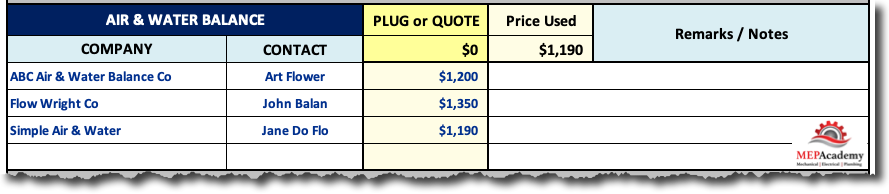

Air and Water Balance

It is often the requirement of the specifications that the Air and Water Balancing be done by an independent contractor, one that is unaffiliated with your company. This would mean that your company couldn’t do the air or water balance on their own. If the specification don’t require an independent contractor and your company has the capabilities to do their own, then you would need to add labor for each of the HVAC systems that would require balancing. For company provided balancing, enter the labor values on the HVAC Equipment tab of your estimating spreadsheet.

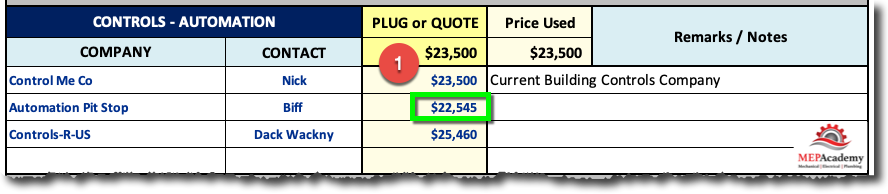

Building Automation Systems

Building automation is often specified to be done using a particular controls manufacturers product line, and that the installers be trained technicians of that manufacture. This eliminates a lot of contractors from doing their own controls. If the project is located within a larger facility of buildings or campus, then there is most likely one controls manufacture that has been used on this multi-building campus. This would require you to contact the approved BMS (Building Management System) contractor to get their quote for the project.

Open Protocol for the Building Automation Systems allows for any controls contractor to bid on the project using hardware and software that is compatible with the existing open protocol system.

Sometimes the best choice isn’t always the lowest bidder, as shown in the image above you can choose to go with a higher if it makes sense. In this case the bid of $23,500 is the 2nd lowest bidder, but they are the existing controls contractor in the building which will probably mean less of a management problem because of their existing knowledge of the building and its building automation system.

The small premium of $955 over the low bidder, is worth having a knowledgeable subcontractor. These are some of the decision you will have to make. Also, it will look better on your proposal to the owner that you are using the existing buildings controls contractor. This is all based on the project not being awarded solely on low price, as not all projects are. Some projects are awarded based on a combination of price and best value.

There will be times when the controls portion of the scope of work will be under the general contractors contract with the requirement for the HVAC contractor to coordinate and cooperate with the controls contractor.

Fire Caulking

Anytime you penetrate a rated wall or floor you might be required to seal that penetration with fire caulking. Fire caulking maintains the fire rating of the rated assembly. Some of the insulators also have a division that does this type of work.

Excavation and Backfill

If the project requires you to dig a trench to bury pipes or sometimes ductwork, there will be a requirement for excavation and backfill. Identify in the specifications who is responsible for this scope of work. Usually the responsible party is the one requiring the trench. You have two choices if the requirement is yours to perform; hire someone or do it yourself. Most HVAC contractors are not setup to do their own excavation and backfill.

If you hire an excavation and backfill subcontractor make sure to review their proposal for completeness and any exclusion, like rock or virgin soil.

Self-Performed Excavation

If you do your own excavating, there is a simple method on the form to calculate the cubic yards required for a straight trench with no sloped sides. If your trench goes deeper than 5 feet you may be required to provide shoring. Check the requirements in the local jurisdiction of the property.

Put the length, width and depth of the trench in unit values of feet. The total cubic yards will be calculated automatically along with the total cost based upon what you enter for the cost per cubic yard to excavate and backfill. It’s always best to allow a professional excavator to figure the required amount of excavation and backfill, as they do this for a living and will protect you from making a mistake.

Get a copy of the MEP Academy Spreadsheet here >> MEP Academy Spreadsheet

Understanding the MEP Estimating Spreadsheet (Free Course)

- Chapter #1 – HVAC Equipment

- Chapter #2 – HVAC Quotations

- Chapter #3 – Subcontractors

- Chapter #4 – Sheet Metal Material and Labor Summary

- Chapter #5 – Labor Rates

- Chapter #6 – Rentals

- Chapter #7 – General Conditions

- Chapter #8 – Finalizing the Estimating Spreadsheet