Chapter #4 – Sheet Metal Material and Labor Summary

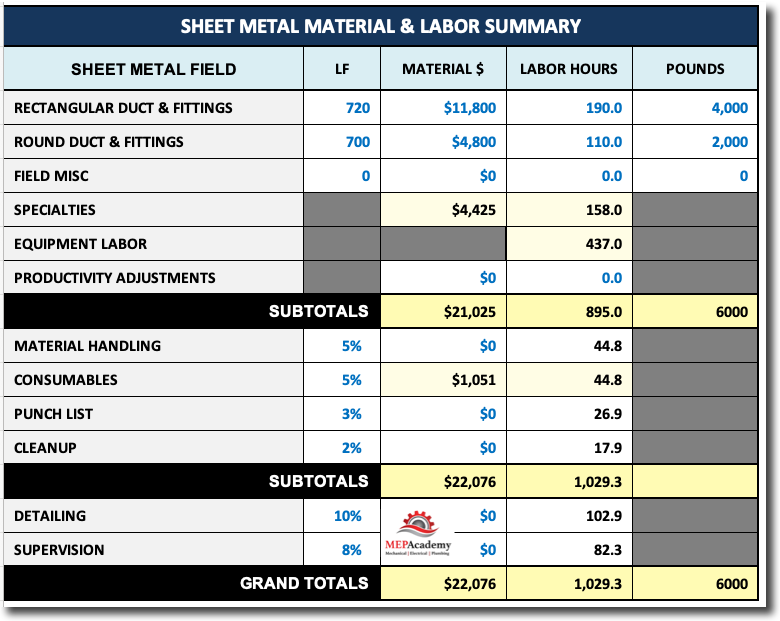

On the MEP Academy Estimating Spreadsheet you will find a page that summarizes all the sheet metal material and labor in a neat format for your review. No matter what type of estimating software or program you use to analyze your estimate, you should have some form of summary review. This page is a snapshot of all the sheet metal material and labor required for this project.

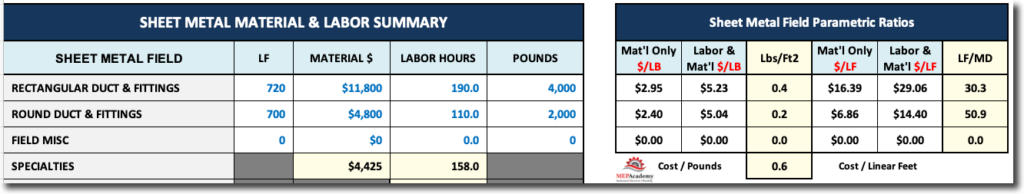

Sheet Metal Field Material & Labor Summary

The upper portion of the sheet metal summary covers the Field Material and Labor, while the lower half covers Shop Fabrication for those companies that have their own shop.

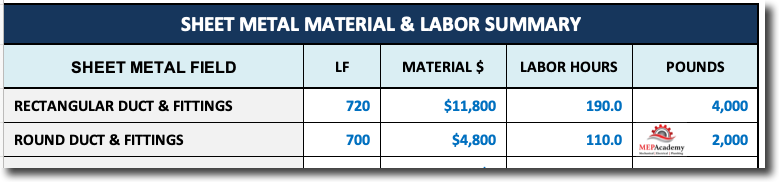

Rectangular and Round Duct & Fittings

Whenever you do a takeoff for sheet metal it’s always preferable to keep rectangular duct and fittings separate from round for better analysis.

If you are using an estimating software program for your takeoffs then this information should be readily available. This is where you put the summary of the information from your takeoff. Items like the total linear feet and pounds of ductwork and fittings for rectangular and round, along with the material cost and labor hours.

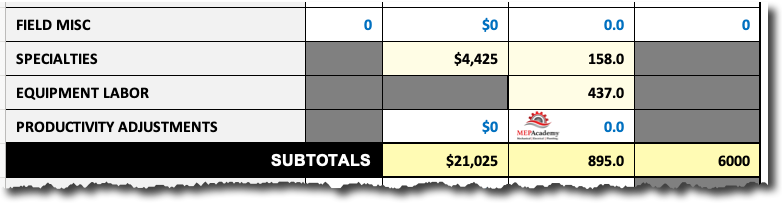

Field Misc

This is an extra line item on the estimating spreadsheet to allow for anything not previous covered, as various projects may require something not covered.

Sheet Metal Specialties (See separate Estimating Tab)

Sheet Metal Specialties were covered in the Field Installation chapter and this provides a line item summary of those items. Also, see below for the actual Sheet Metal Specialties page of the MEP Academy estimating spreadsheet for an explanation of that page.

Equipment Labor (See Equipment Labor Chapter)

This line item is a summary of all the labor required to rig, set and install all the equipment and accessories as explained in the chapter on Equipment Labor in the Sheet Metal Field Installation course.

Productivity Adjustments ( See Field Labor Adjustments Chapter)

This is the line item that summarizes all the labor adjustments to the benchmark labor. This line is a quick reference to how much labor was adjusted from your database standard. See the chapter in the Sheet Metal Field Installation course for more details on adjusting field labor.

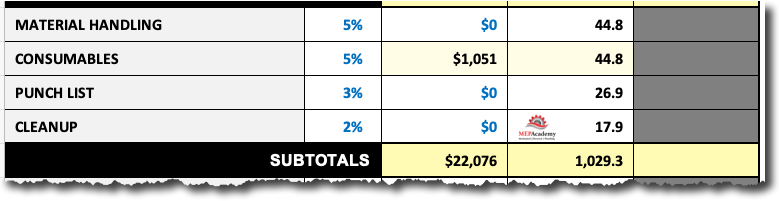

Material Handling

Sheet Metal material handling can take considerable time depending on the project conditions. If you are working on a high-rise building and need to get your sheet metal from the truck located at the truck dock on the first floor at the back of the building all the way up to the 20th floor, then you will need to add additional labor for this, as this is not considered part of the installation hours.

If you have the MEP Academy Estimating Spreadsheet then just add a percentage value and the spreadsheet will automatically calculate the hours based on the total field hours, if not, then add the appropriate hours to your own spreadsheet.

Consumables

When installing sheet metal there will be items that get consumed in the process, such as duct tape, sheet metal screws and duct sealer to name a few. If your estimating software doesn’t cover these items then you will want to add a small percentage here to cover these consumable items.

Punch List

At the end of the project there is a punch list generated by the owners representative, whether that is a general contractor or other intermediary, that will list those items that need to be corrected before the project gets a final signoff from the owners perspective. This will allow you to issue a final billing less any required retention.

Cleanup

The cost for cleanup can go under general conditions or under the specific trade that is performing the work, such as sheet metal or HVAC piping. Add the cost for a laborer to sweep up daily trash accumulated by your crew during the day. Usually this includes shipping boxes and scrap material from the installation materials.

The specifications often have a requirement that you clean daily, and if not, then the general has the authority to cleanup your mess and back-charge you for their cost.

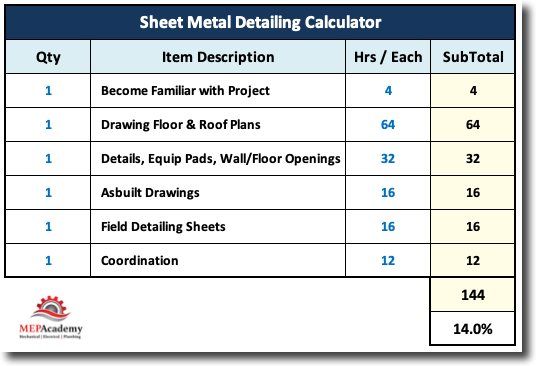

Sheet Metal Detailing

Most new construction projects of any significant size will require some form of detailing. This is where you will have a sheet metal detailer draw up shop drawings for the fabrication and installation of the sheet metal. Their responsibilities include reviewing all the other trade drawings to ensure that the ductwork and equipment will fit in the allotted space, and to coordinate with the other trades to resolve any conflicts.

Your company should have historical data on how long it takes to detail a project based on the size of the project your working on. One way to determine the hours required is to consider the following;

How many drawings will be required by the detailers to create the shop drawings and detail pages required?

- How long will it take to familiarize themselves with the project?

- How many floor plans and roof drawings will need to be created and how long does it take for each?

- What other specialty drawings will need to be created? Some specialty drawings could include detail pages, equipment pad sizes and locations, wall/floor/roof opening drawings, seismic point locations.

- How many asbuilt drawings will be required. This should match the quantity of floor & roof plan drawings, as these are the drawings where you will indicate how the ductwork was actually installed as opposed how they were originally drawn on the construction drawings.

- You will require some form of field detailing. If you have a software program that integrates the detailers and the fabrication shop then some of this will be automated as the system will just transfer files from the detailer to the shops computer.

- Coordination will be required to work out the different trades and the clashes that normally occur. If you are using clash detection software like NavisWorks, then this will be made a much similar operation, but still required.

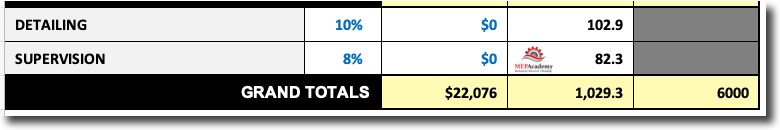

Sheet Metal Supervision

This is the cost for project labor supervision that is not part of the field installation crew. This person supervises the labor but doesn’t actually install anything themselves. Smaller companies may use the project foreman to provide double duty, but the supervisor will be required to visit all the other projects that are under construction at the same time, and to make sure that the field labor has what they need to accomplish their work and resolve any issues that may arise. Smaller non-union companies may use various other personnel to handle this work, such as a project manager or roving field foreman.

Figure how many hours per week that they might visit the project site and how many weeks the project will be under construction. You can also just use a percentage for the total labor

Option 1 (hrs per Week)

6 Hrs/week x 12 weeks = 72 hours

Option 2 (Percentage of Total Labor)

Total Field Hours x Percentage

720 Hours x 10% = 72 Hours

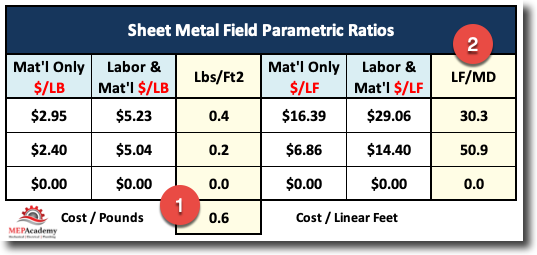

Sheet Metal Material & Field Metrics

One of the important duties of an estimator is to keep track of cost metrics. In order to do this, you’ll need to start collecting data based on projects that have been completed. In addition to completed projects, you will measure estimates that are currently being proposed. There are several metric calculators in the MEP Academy Estimating Spreadsheet that tracks various values. Make sure that the spreadsheet you use can track metrics that are important for your company’s success.

Some of the metrics that the estimating spreadsheet measures is the cost per pound and cost per linear foot. You should know what you are paying per pound for the rectangular and round sheet metal that you are purchasing, especially rectangular.

Material – Cost per Pound

Material & Labor – Cost per Pound

Material – Cost per Linear Foot

Material & Labor – Cost per Linear Foot

Another good metric to look at is how many pounds per square feet the rectangular and round are determined to be. This can be used in budgeting future projects that are not yet completely designed.

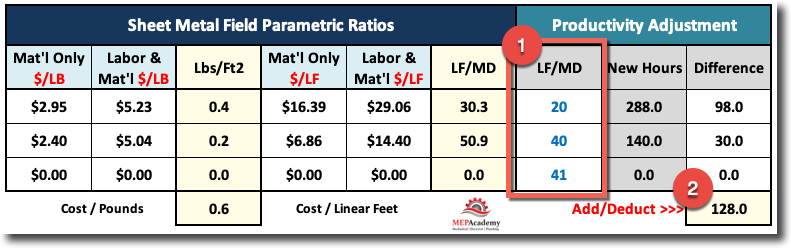

Labor Productivity – Linear Feet per Man Day

Labor Productivity is also measured as can be seen by item #2 in the above image which calculates the Linear Feet per Man Day. This is how fast the rectangular and round ductwork and fittings are going to be installed according to your current values in the spreadsheet. You can make adjustments to these values by calculating new productivities for each line item by using the MEP Academy Labor Productivity Calculator as shown below.

The productivity adjustment allows you to adjust the labor that you got from your estimating program, if not already adjusted within the program. Item #1 above shows that we adjusted the rectangular ductwork to 20 LF/MD, and the round to 40 Feet/MD, which gave us an overall add of 128 hours (item #2 in above image). This would be manually entered under the Labor Productivity line item.

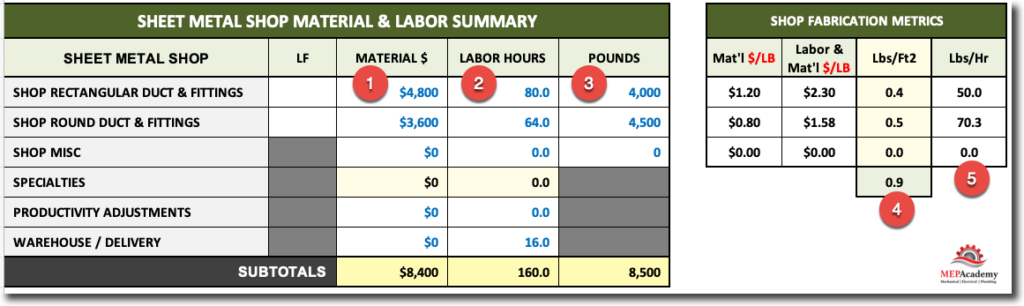

Sheet Metal Shop Material & Labor Summary

This section is for those that own their own sheet metal fabrication shop in addition to the Warehouse/Delivery line items. If you have an estimating program to do your sheet metal takeoff, then these values will be generated automatically.

Fabricated Rectangular and Round Duct & Fittings

If you fabricate your own ductwork or use an estimating program that provides raw material and labor data then this is where you would put it in order to get the metrics needed for analysis. With the material cost, labor hours and total pounds of sheet metal fabricated the MEP Academy Estimating Spreadsheet will automatically calculate the Material Cost per Pound, and the Labor & Material Cost per Pound.

Sheet Metal Fabrication Shop Specialties

This line item cost is carried forward from the specialties sheet covered below.

Shop Fabrication Productivity Adjustments

This is the line item that summarizes all the labor adjustments to the benchmark labor. This line is a quick reference to how much labor was adjusted from your database standard. See the chapter in the Sheet Metal Shop Fabrication course for more details on adjusting shop labor.

Warehouse / Delivery

All those materials that are fabricated in your sheet metal shop must be trucked out to the jobsite. This category is provided to cover that cost. You may calculate your cost based on the amount of sheet metal pounds one truckload can carry or by some other means. Whatever means you use, put the cost here on the delivery line item.

Your warehouse cost will include shipping and receiving material and equipment related to the operations of the business and for the project your bidding.

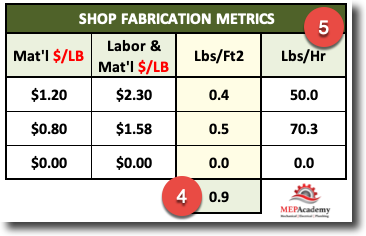

Shop Fabrication Metrics

Just like the field metrics there should be the equivalent fabrication metrics. How many pounds per hour is the shop fabrication productivity (item #5 in below image). This is something that your fabrication shop should know and be tracking. You will adjust these values to match what your shop can actually produce. Use the Productivity Adjustment line below to make adjustments to the shop labor productivity.

Another good metric to track is how many pounds of ductwork per square feet does this particular project require (See item #4 in image). This is useful if you are budgeting a project that hasn’t been completely designed, but one where the owner or general contractor would like a budget on.

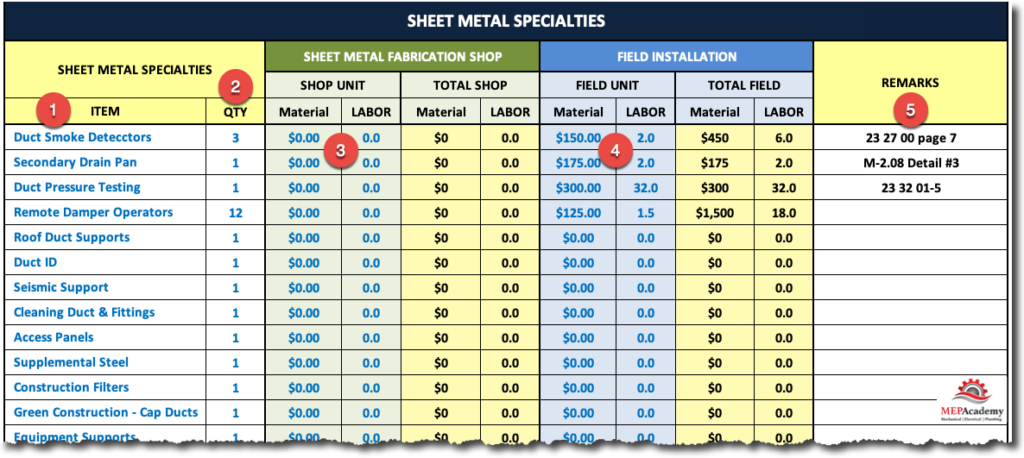

Sheet Metal Specialties

We covered the various types of sheet metal specialties you might encounter in our Sheet Metal Field Installation Course. Here we want to show you how to record and provide cost for those items.

The above image is from the MEP Academy Estimating Spreadsheet.

Item #1 is where you would list the sheet metal specialties

Item #2 is the quantity required for the project your bidding

Item #3 is where you provide the unit cost for material and labor for the Fabrication Shop

Item #4 is where you provide the unit cost for material and labor for the Field Installation

Get the MEP Academy Estimating Spreadsheet here >> MEP Estimating Spreadsheet

Understanding the MEP Estimating Spreadsheet (Free Course)

- Chapter #1 – HVAC Equipment

- Chapter #2 – HVAC Quotations

- Chapter #3 – Subcontractors

- Chapter #4 – Sheet Metal Material and Labor Summary

- Chapter #5 – Labor Rates

- Chapter #6 – Rentals

- Chapter #7 – General Conditions

- Chapter #8 – Finalizing the Estimating Spreadsheet