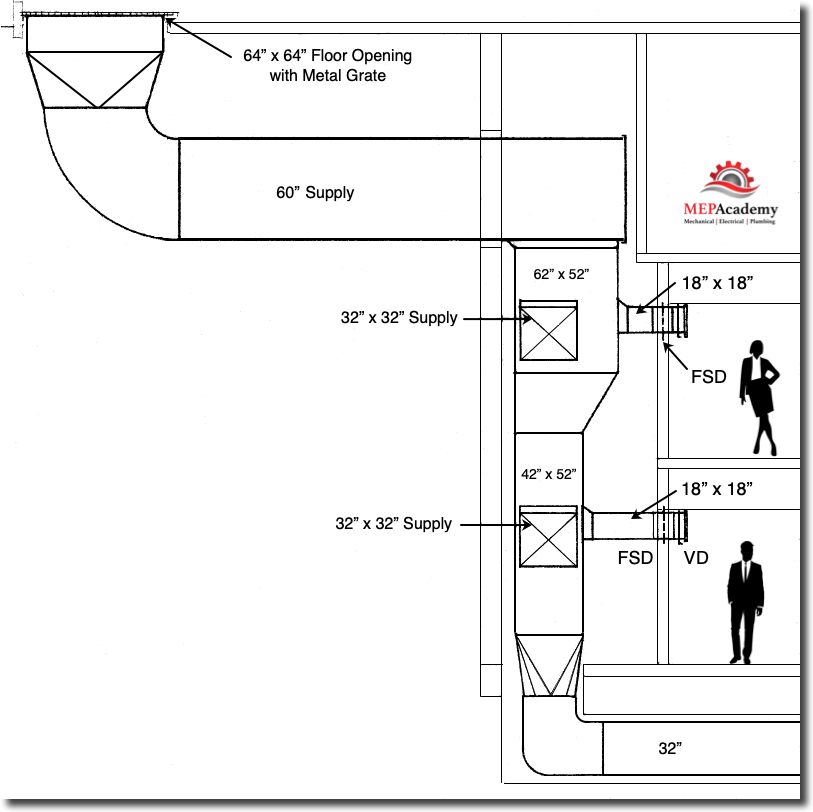

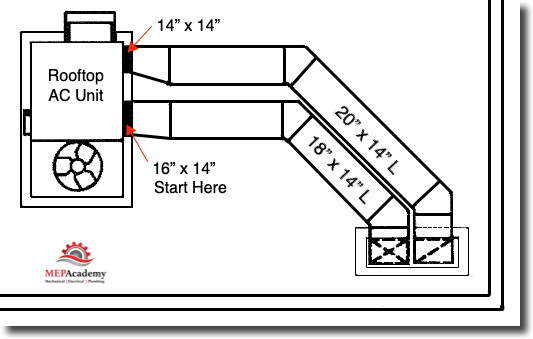

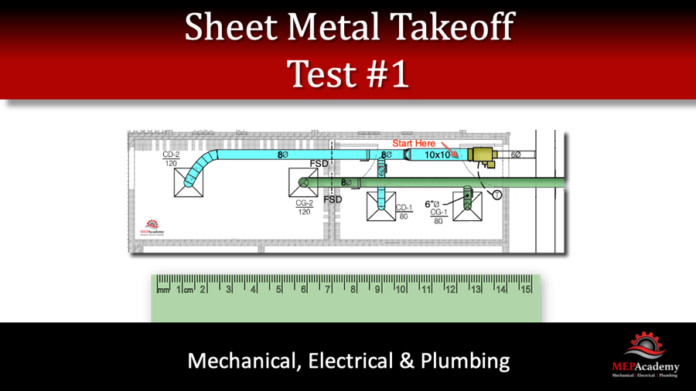

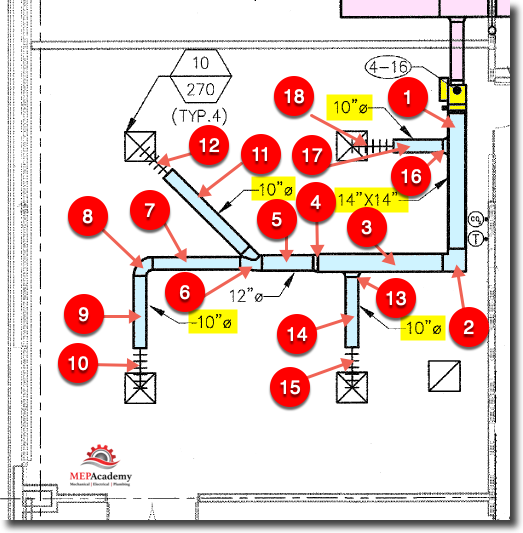

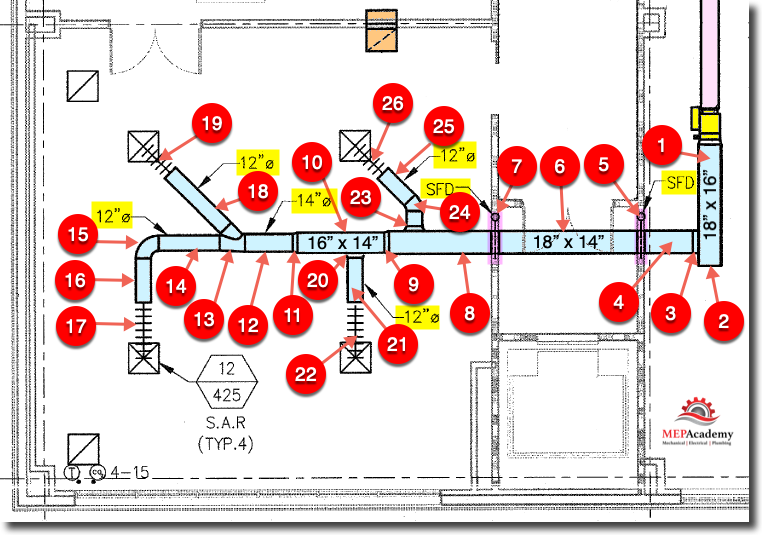

In the next two test you will be required to measure the lengths of the ductwork using the bar scale shown on each drawing. Print the enclosed drawings or use a distance measuring software program like Bluebeam so that you can accurately measure the distances for each duct length based on the bar scale shown on the drawings, or if you have an estimating program you can import the drawing and do your takeoff.

Another method is to measure the drawing on your computer screen, which can be done by increasing the magnification of the drawing until the bar scale on the drawing matches the hand held scale you hold up to the computer screen.

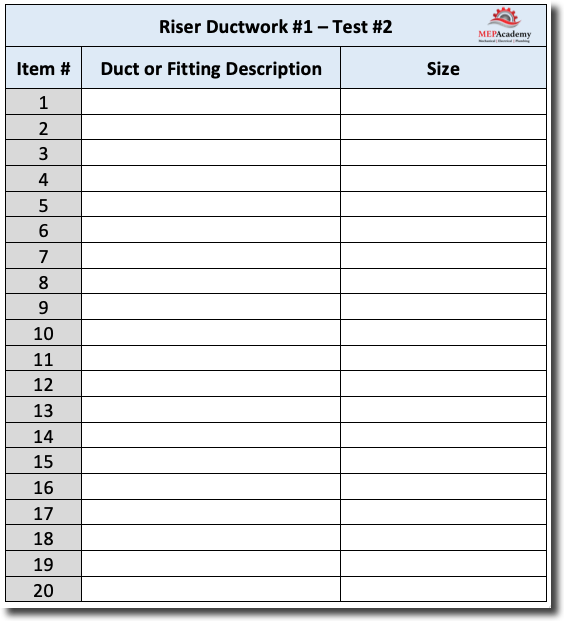

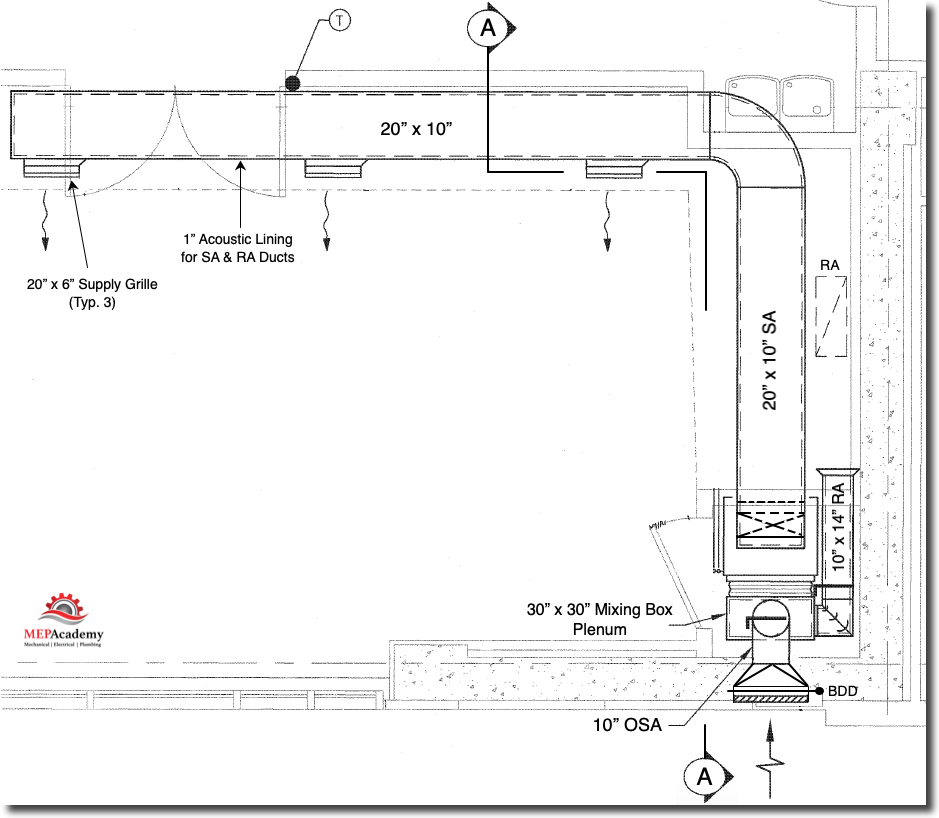

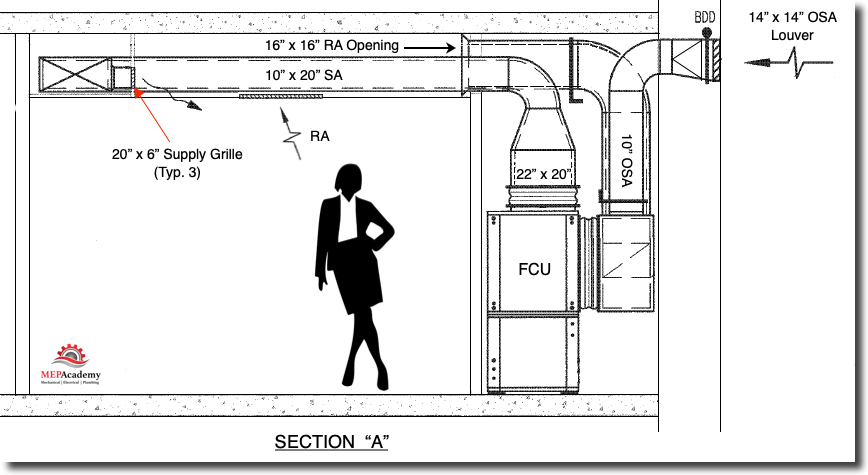

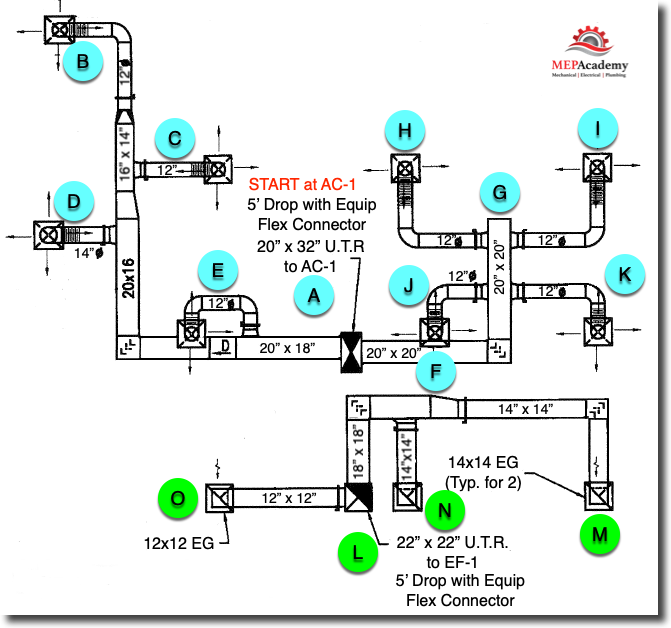

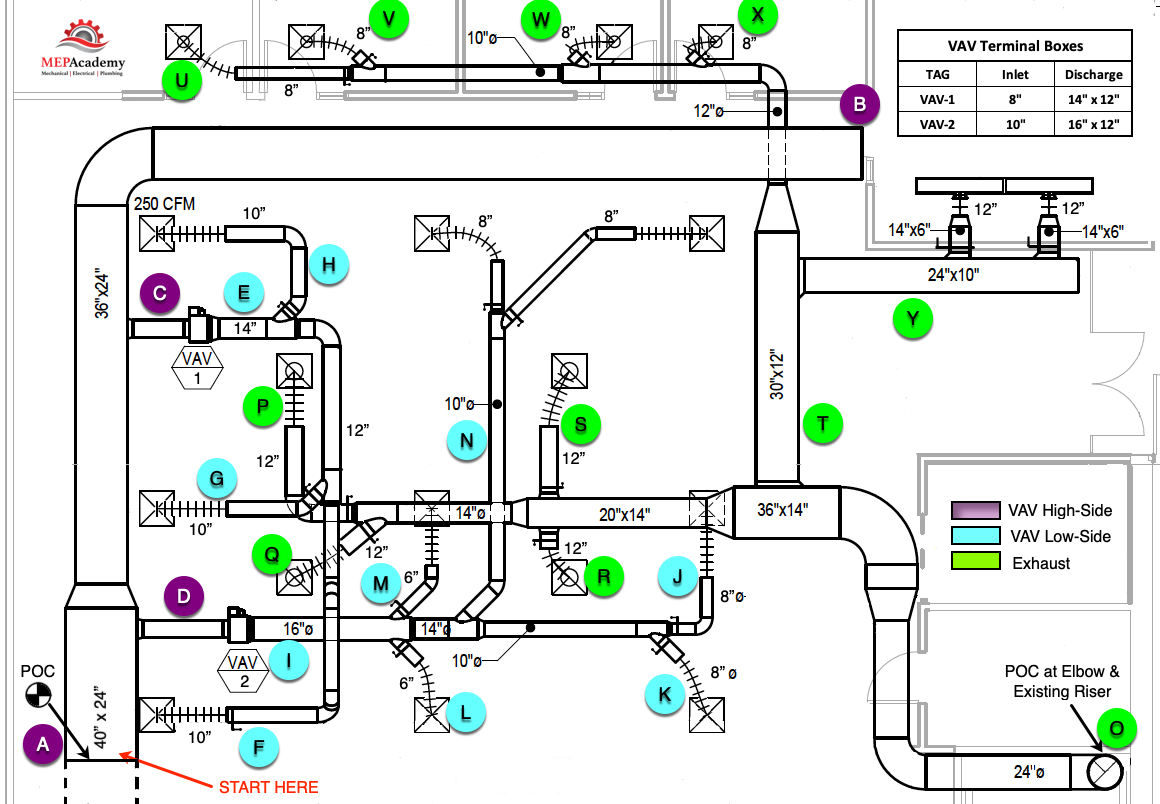

In the following series of test there will be no numbered items given. It will be up to you to determine what you need. Start as always at the source or the largest duct in this case we have outlined the path to take for you, so that the answer sheet given will follow the same path. Start at the letter “A” on the diagram and proceed in alphabetical order until you finish filling in the takeoff form.

Make sure that you have completed all the practice test, including Test 1 & 2 before proceeding.

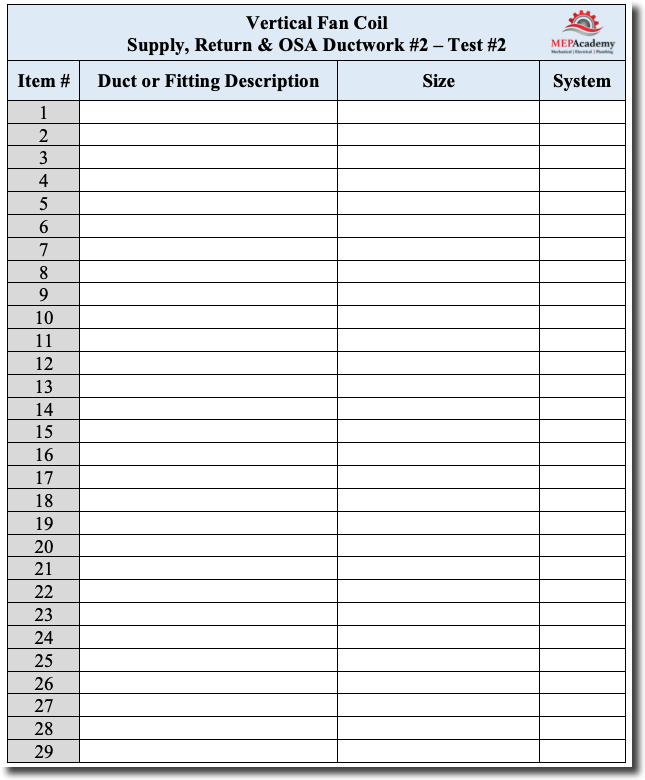

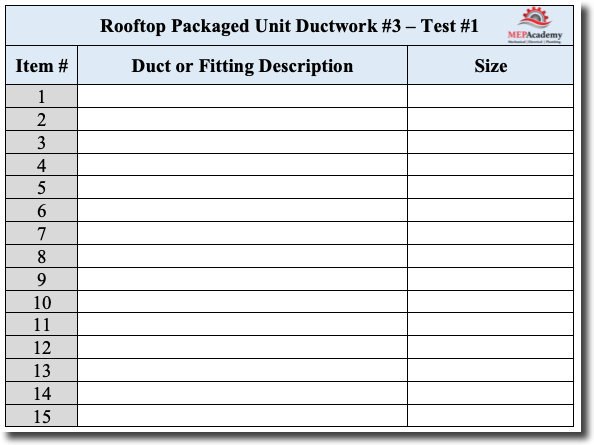

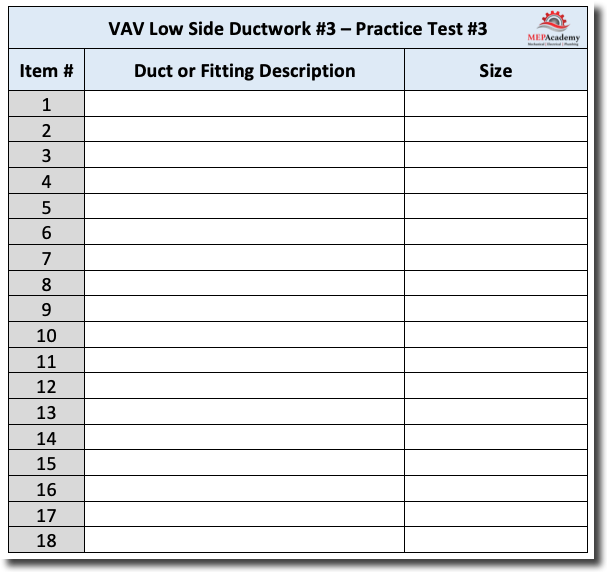

Download the PDF Drawing and Takeoff form or use your own tablet or computer to record your answers that match the list for each of the following takeoffs.

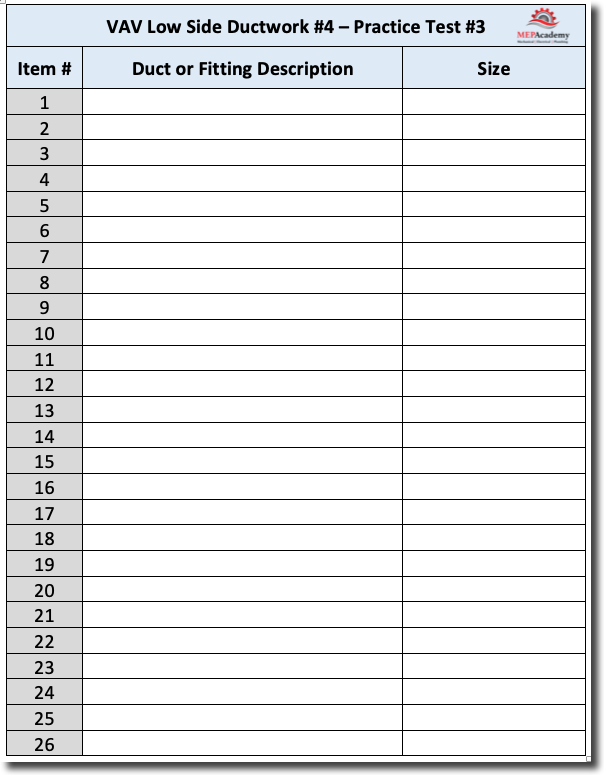

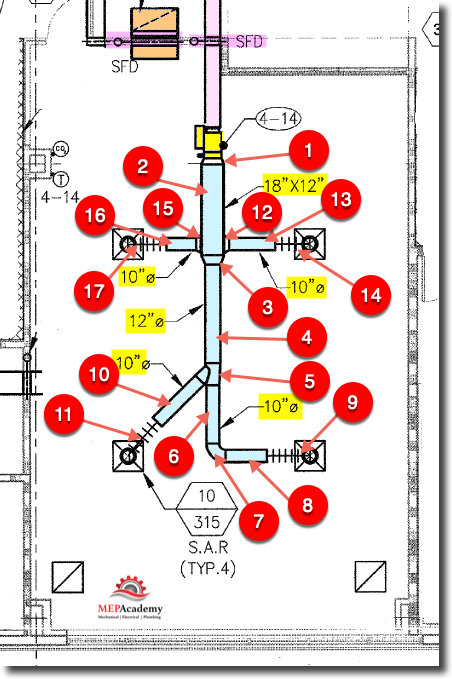

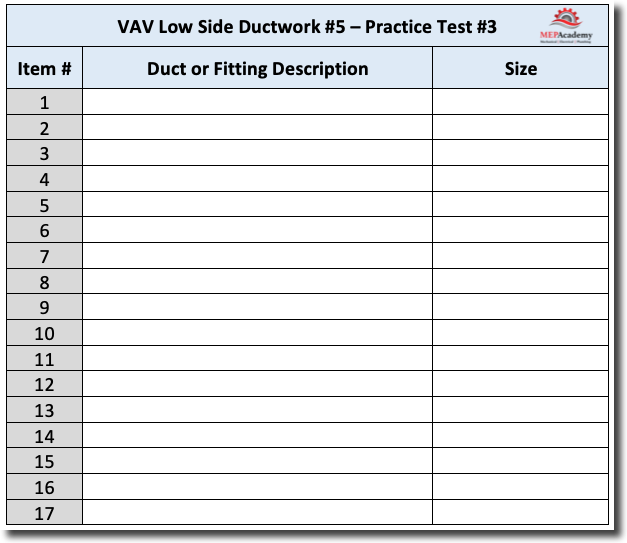

Write down a description of the duct or fitting along with the appropriate size shown. After you have completed your takeoff, check your answers with the online answer sheet. Don’t worry if the lengths are slightly different. The lengths should be close, at least within 6” or so, depending on your method of measuring.

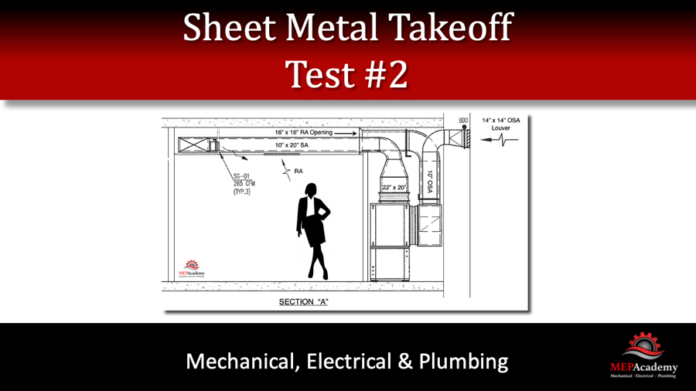

Air Conditioning Unit Ductwork #1

Fill in the PDF Takeoff Form with answers to Air Conditioning Unit Ductwork #1 Image Above.

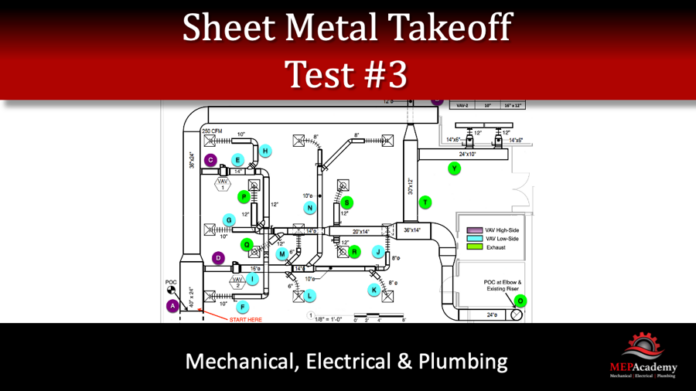

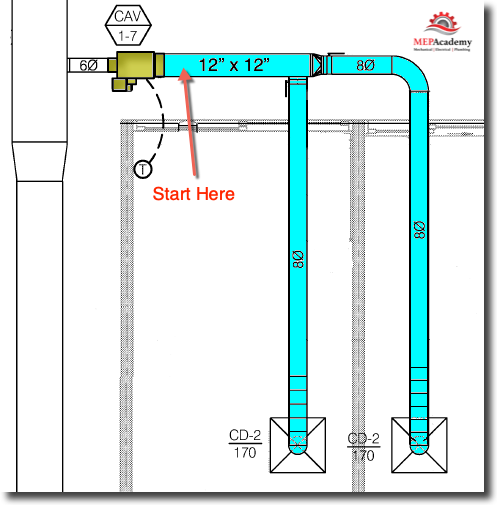

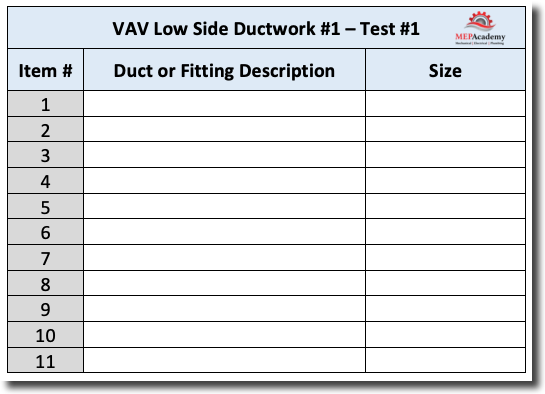

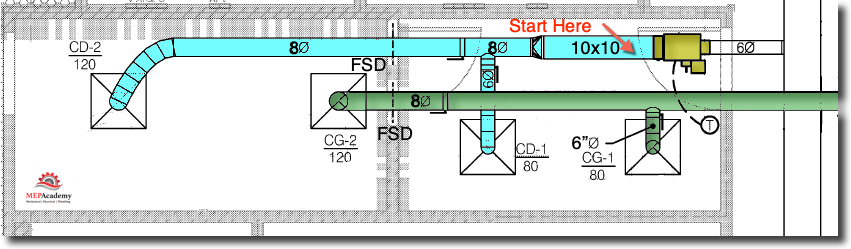

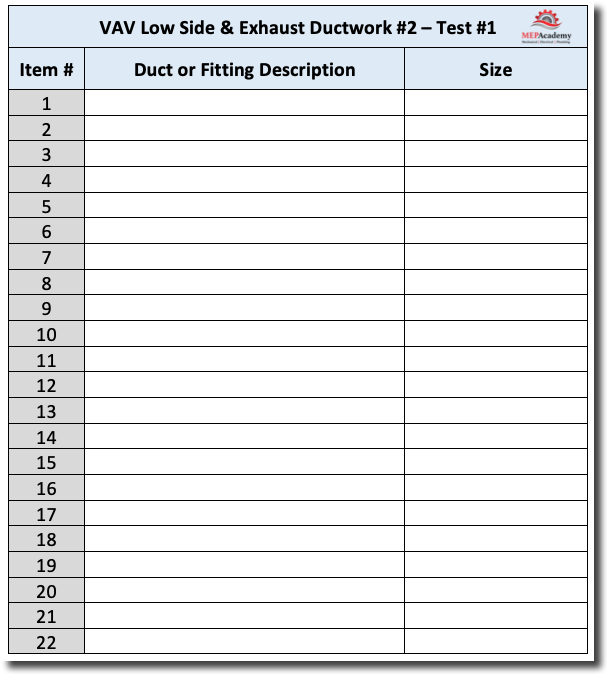

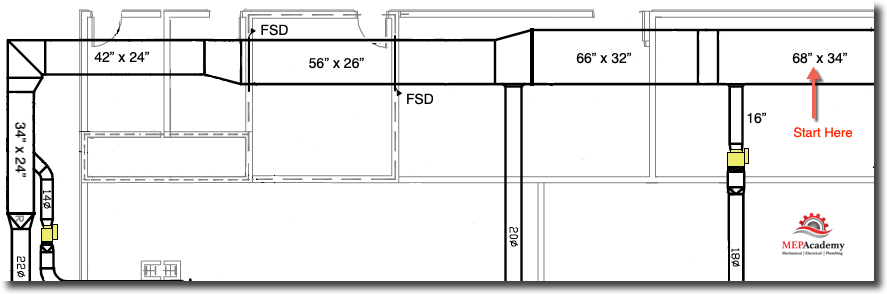

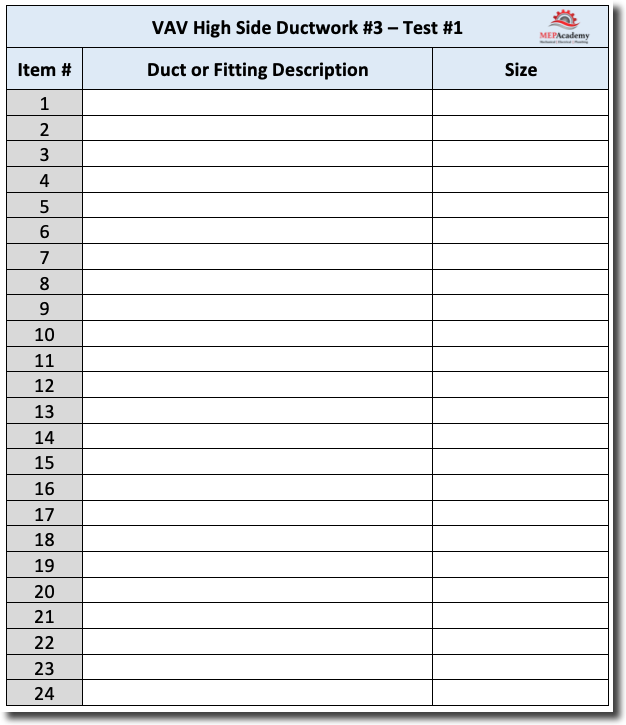

VAV High/Low & Exhaust Ductwork – Takeoff #2

Start with the High-Side Supply Mains, then the branches to VAV-1 & 2, followed by the Low Side Supply and then finish with the Exhaust ductwork. Do your best to identify every piece of duct or fitting. Be sure to follow your takeoff as shown starting at the letter “A” and progressing to “B”, then to “C”,, “D”, etc. Make sure to takeoff all the duct and fittings shown for each letter in alphabetical order so that the answer sheet will make more sense to you.

In this exercise you will be required to provide the duct lengths, so be sure to download the drawing and confirm your scale using the bar scale on the drawing before proceeding. If for some reason you can’t measure the ductwork, then proceed as in previous exercises by just indicating a section of ductwork without the length.

Download the PDF Takeoff Form if you haven’t already or use your own tablet or computer to record your answers.

Resources

Additional Sheet Metal Takeoff Chapters

- Rectangular Sheet Metal Takeoff

- Round Sheet Metal Takeoff

- Duct Riser Takeoff

- Sheet Metal Assembly Takeoff

- Sheet Metal Takeoff Practice Test #1

- Sheet Metal Takeoff Practice Test #2

- Sheet Metal Takeoff Practice Test #3

- Sheet Metal Takeoff Test #1

- Sheet Metal Takeoff Test #2

- Sheet Metal Takeoff Test #3