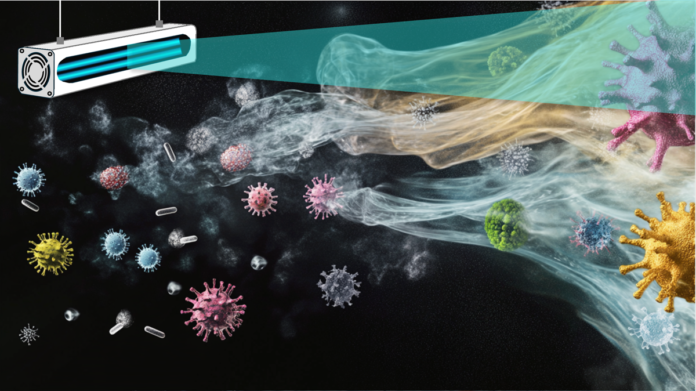

In this article we’re diving into one of the most popular topics in modern sanitization UV-C light and how it works to fight germs, bacteria, and viruses. UV-C technology is gaining a lot of attention for its ability to disinfect homes, businesses, and even industrial spaces, but with all this interest comes plenty of questions.

In this article, we’ll be answering some of the most frequently asked questions about UV-C sanitizers. Can you safely use UV-C light in your home? Is it effective against viruses like COVID-19? How do you know if a UV-C device is working properly, and what should you look for when choosing one?

Can I use UV-C lights while I’m in the room?

In most cases, it is not safe to be in the room when a UV-C light is in operation, as direct exposure to UV-C rays can harm your skin and eyes. Many devices come with safety features, such as motion detectors that turn off the light when someone enters the room. If you’re using Far UV-C (200 to 230 nanometer), this can be safe for occupied rooms, but standard UV-C lights should only be used in unoccupied spaces.

Portable Shielded UV-C Light Air Purifier

A portable shielded air purifier with an internal UV light won’t kill germs that are on surfaces within the room as the light is shielded. This type of air purifier pulls air into the housing where it’s exposed to the UV light that kills the germs as they pass through. This type of shielded UV light can be used when the room is occupied. If you want full room coverage, you’ll need to use an open lamp type that requires that the room is unoccupied when in use.

Open Lamp UV-C Light

This open lamp UV Light has a timer that can be set for 15, 30, or 60 minutes of run time. It will beep for 15 seconds to allow the person to exit the room. This type of open UV lamp will shine in a 360-degree radius effectively sanitizing the area within its reach. You want to set this in the middle of the room if possible and leave the room while the light is on. You don’t want anyone looking at the light while it’s on as this can damage their eyes.

Hospitals and Healthcare Facilities. UV light systems are installed in operating rooms, patient rooms, and high-touch surfaces to prevent the spread of infectious diseases. Portable UV sanitizers are also used to disinfect medical equipment and tools, providing an extra layer of protection against hospital-acquired infections.

Food and Beverage Processing. UV-C light is used to sterilize surfaces, packaging materials, and even air in food processing plants. It helps prevent contamination and ensures food safety, commonly applied in meat, dairy, and beverage industries.

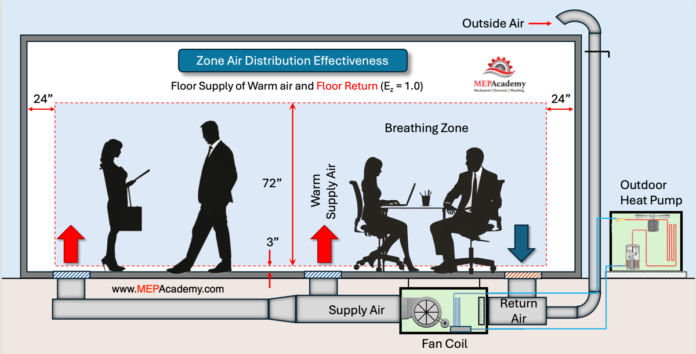

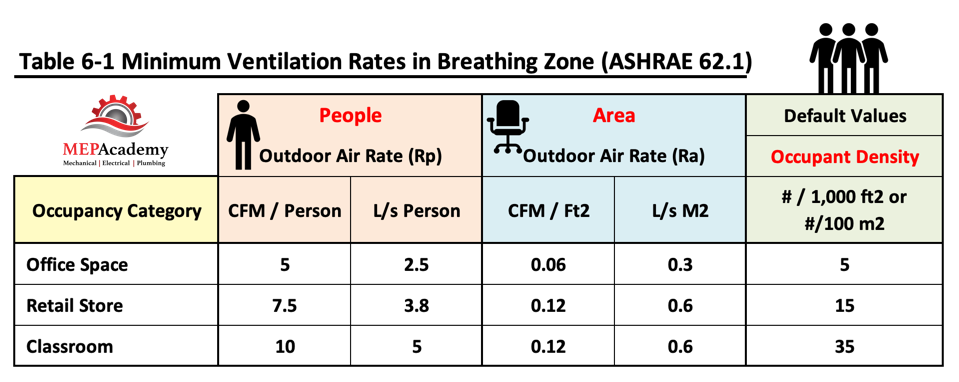

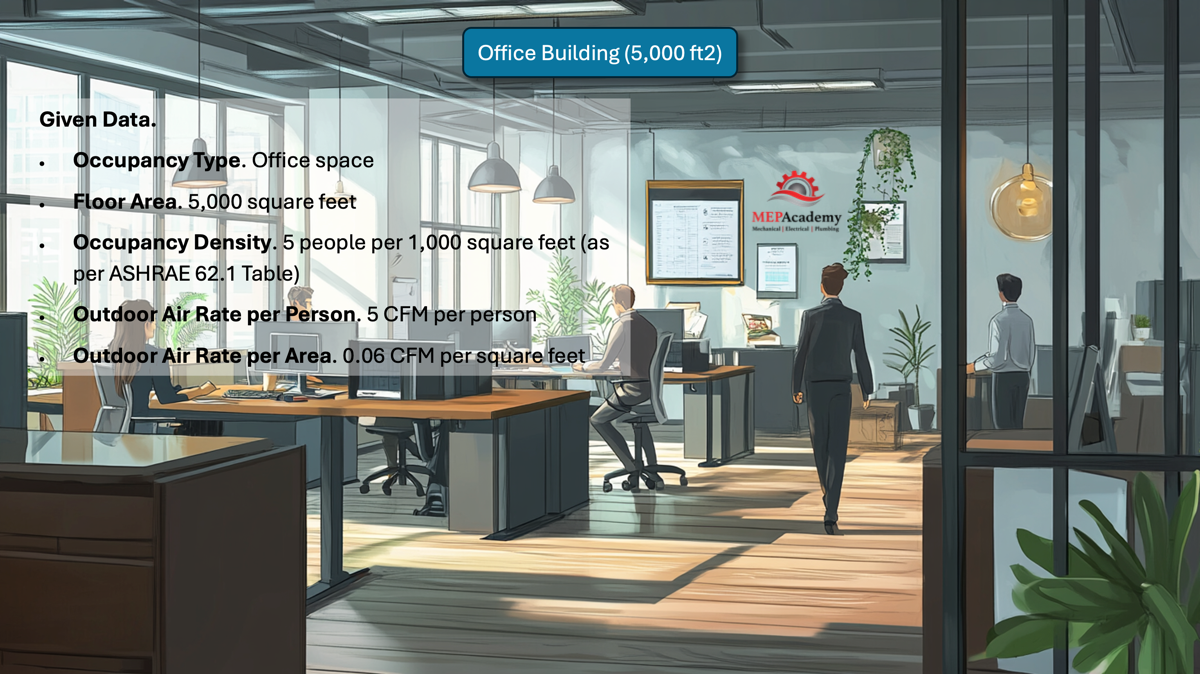

HVAC Systems in Buildings. UV lights are installed in HVAC ducts and air handling units to disinfect the air by killing airborne bacteria, viruses, and mold spores. This improves indoor air quality in large commercial buildings, such as offices, hotels, hospitals, and schools.

How does UV-C light work to kill germs?

UV-C light works by emitting ultraviolet light at a specific wavelength (typically 254 nanmeter) that penetrates the cell walls of microorganisms, such as bacteria, viruses, and mold. This light damages their DNA or RNA, which prevents them from reproducing or functioning, effectively killing or inactivating the germs. UV-C lights can inhibit the growth of mold or mildew on cooling coils, ducts, and other moist surfaces in HVAC systems reducing unpleasant odors. This can be useful for people with allergies, asthma, or other respiratory conditions.

Is UV-C light safe for humans, pets, and plants?

Direct exposure to UV-C light is not safe for humans, pets, or plants. It can cause skin burns and eye injuries, such as photokeratitis (like sunburn of the cornea). However, certain forms of UV-C, like Far UV-C (200 to 230 nanometer), are considered safer for occupied spaces. Most UV-C devices should only be used in unoccupied areas or enclosed systems to avoid exposure.

A person should not look directly at UV-C light, as it can cause serious damage to the eyes and skin. UV-C light is harmful because it emits high-energy ultraviolet radiation.

How long does it take for UV-C light to disinfect a room or surface?

The time required depends on the power of the UV-C light, the size of the room or surface, and the specific microorganisms being targeted. On average, it can take anywhere from 10 to 60 minutes to disinfect a room or surface. Manufacturers usually provide recommended exposure times based on their devices’ specifications and the area being disinfected.

What types of pathogens can UV-C light kill?

It is effective against a wide range of microorganisms, including bacteria (coli, MRSA), viruses(influenza, SARS CoV-2), mold, and fungi. It is also commonly used to control airborne pathogens and allergens in HVAC systems and surfaces.

Is UV-C effective against COVID-19?

Yes, UV-C light has been shown to be effective at inactivating the SARS CoV-2 virus, which causes COVID-19. Studies have confirmed that UV-C light can destroy the virus by breaking down its RNA, making it unable to replicate. However, it should be used as part of a comprehensive strategy that includes proper ventilation, cleaning, and other precautions.

Can UV-C light penetrate through surfaces or fabrics?

No, UV-C light does not penetrate through solid surfaces or opaque materials like fabrics, glass, plastic, or metal. It only disinfects what it directly shines on. This means that any objects or areas that are shaded or blocked from the light will not be disinfected.

What is the difference between UV-A, UV-B, and UV-C light?

UV-A (315 to 400 nanometer) and UV-B (280 to 315 nanometer) are longer wavelength forms of ultraviolet light that primarily cause skin aging, sunburns, and DNA damage leading to skin cancer. These are present in sunlight.

UV-C (200 to 280 nanometer) has the shortest wavelength and is the most effective for germicidal purposes because it can inactivate pathogens. Unlike UV-A and UV-B, UV-C is filtered out by the Earth’s atmosphere, so it’s not naturally present in sunlight.

Only UV-C is commonly used for disinfection.

How do I know if a UV-C light is working properly?

Some UV-C devices include indicator lights or built-in sensors that show whether the UV-C lamp is functioning. Since UV-C light is invisible to the human eye, you can’t see it. Regular maintenance, such as cleaning the lamp and replacing bulbs when necessary, will ensure proper functioning. You can also use UV intensity meters to measure the output of the light.

What’s the lifespan of a UV light bulb?

The UV light bulbs typically last between 9,000 and 12,000 hours, depending on the manufacturer and usage conditions. However, even though the bulbs may still light up after this period, their germicidal effectiveness diminishes over time, so it’s recommended to replace them after reaching their rated hours.

Are there any risks of UV-C light damaging materials or electronics?

Prolonged exposure to UV-C light can cause some materials to degrade over time, especially plastics, rubber, and certain fabrics. UV-C light can cause discoloration, brittleness, or weakening of these materials. However, properly installed and used UV-C devices do not typically cause harm to electronics.

Do I need to clean surfaces after using UV-C light?

UV-C light does not leave any residue, so there’s no need to clean surfaces after use. However, UV-C light only disinfects surfaces, so if there is visible dirt or grime, cleaning is necessary before disinfection, as UV-C does not penetrate dirt or organic matter effectively.

How much area can a UV-C sanitizer light cover?

The coverage area depends on the power of the UV-C device and its design. Most devices specify the maximum area they can effectively sanitize. Smaller units may only cover a few square feet, while larger units can disinfect entire rooms or HVAC systems. For general reference, high-powered UV-C units can cover areas of up to several hundred square feet.

The physical area that the UV-C device can effectively disinfect, is often expressed in square feet or cubic feet. Larger spaces require more powerful or multiple UV-C devices to ensure full coverage. Compare devices based on the size of the area they can disinfect effectively, especially if you’re considering them for larger rooms, air ducts, or water systems.

Are UV-C sanitizers portable and easy to install?

Yes, many UV-C sanitizers are portable and designed for easy installation. Portable units are often plug-and-play, allowing you to move them between rooms as needed. Some devices, such as those used in HVAC systems or mounted for air or surface disinfection, may require professional installation.

Is UV-C light energy-efficient?

UV-C lights are relatively energy-efficient, especially when used for shorter disinfection cycles. Most UV-C devices have low power consumption compared to the energy required for constant air filtration or chemical disinfection methods. Devices typically range from 10 to 200 watts, depending on their size and capacity.

Does UV-C light affect air quality or release harmful chemicals?

Properly designed UV-C devices do not release harmful chemicals or fumes. However, some UV-C lamps can produce a small amount of ozone, especially if they emit wavelengths below 240 nanometers. Ozone can be harmful in high concentrations, so it’s important to choose ozone-free UV-C lamps or ensure proper ventilation in the space.

Can UV-C light replace traditional cleaning methods?

No, UV-C light should not completely replace traditional cleaning methods. It is most effective when used as a supplement to cleaning. For example, you should still clean surfaces to remove dirt and debris before using UV-C to disinfect. Similarly, combining UV-C with good ventilation and air filtration enhances overall disinfection.

These answers provide a comprehensive overview of the most common questions about UV-C sanitizer lights.