Chapter #9 – Sheet Metal Shop Fabrication Productivity

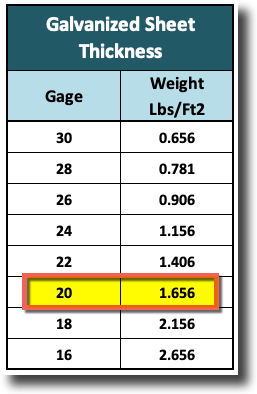

You must be able to determine the productivity rate of your shop as measured in pounds per hour. How many pounds per hour of galvanized rectangular fittings can your shop produce? How many pounds per hour of coil line ductwork can your shop produce? If you fabricate round ductwork and fittings the same question would apply.

You must have some measure of productivity in order to measure whether or not your shop is becoming more or less productive over time. This measure of productivity will allow you to focus on those areas of your shop that need improvement to be more productive.

Also, does your shop ship its duct KD (Knocked Down, Unassembled)? The main reason ductwork is shipped to the jobsite knocked down is to be able to nest (stack) more ducts onto the trucks, or because access into the building is limited

The fabrication shop is the best place to assemble the duct and fittings because it’s done under a controlled environment, although this may increase your trucking cost.

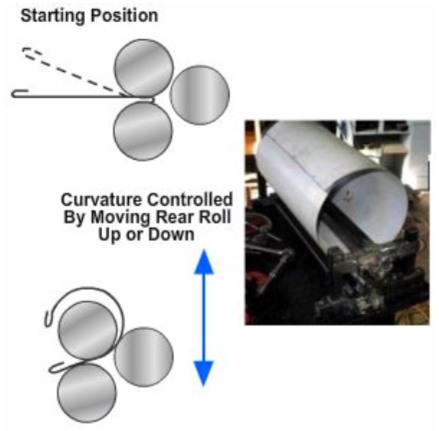

Coil Line Productivity

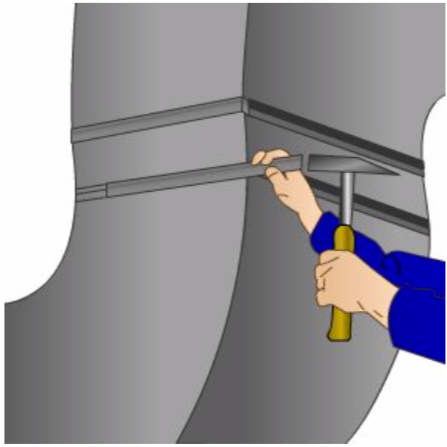

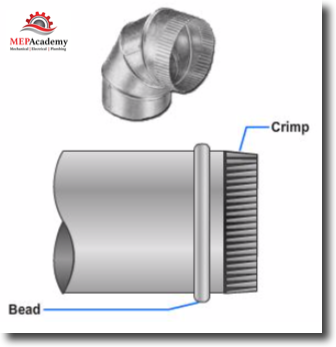

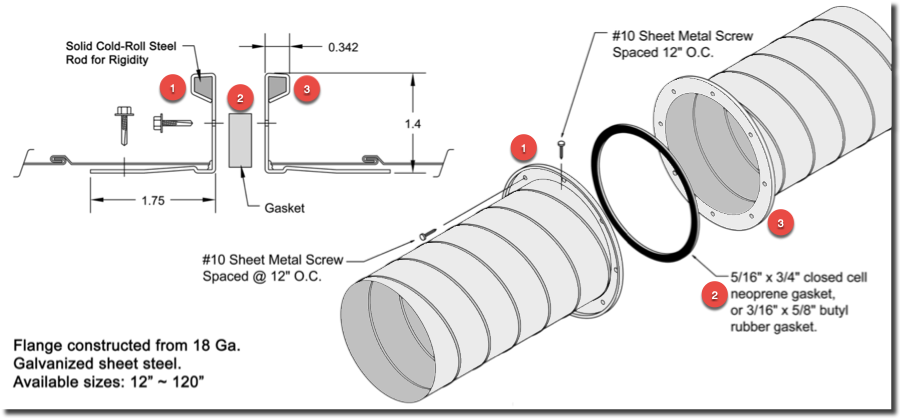

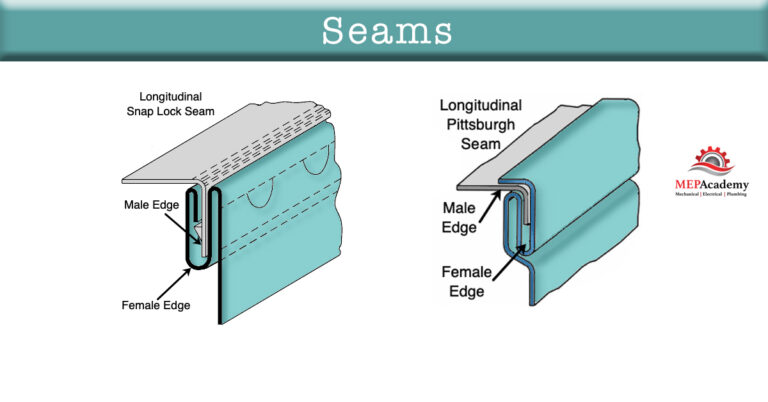

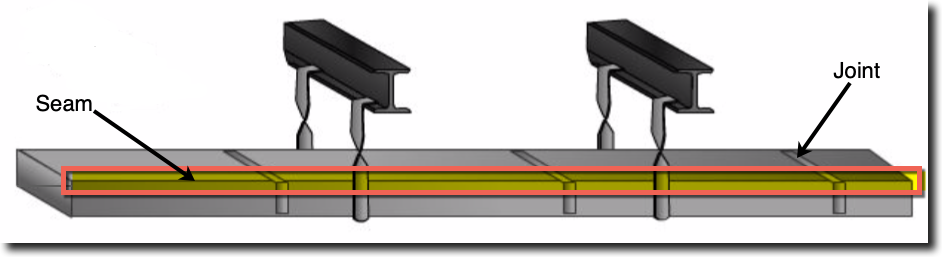

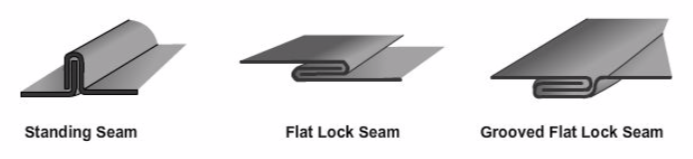

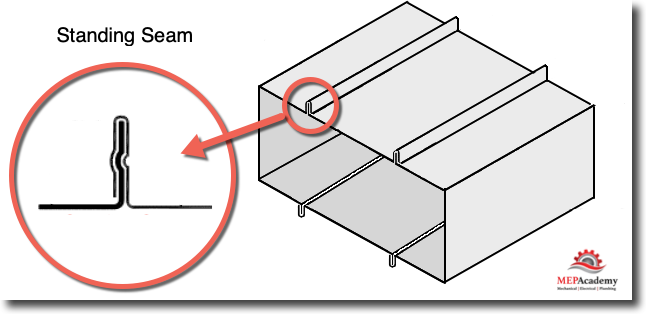

Sheet Metal Coil Lines usually feed other pieces of equipment in a fully automated shop such as a Beader, Shear, Snap Lock or Pittsburgh Seamer, TDC/TFC Flange Roll Former, Duct Liner with Glue and Pins, and lastly a Break that bends the finished duct into the size required.

The sheet metal gets cut from the coil and then goes through all the processes of beading and forming seams and joints before being finished with liner if required, then bent into shape (Either as one piece or as two halves that get assembled together).

Productivity will vary according to how much of the work is being done by the equipment and how much has to be done by hand. How many pounds per hour can your coil line produce lined and unlined ductwork? For an example maybe the shop did 20,000 lbs. this week and incurred 160 hours of labor. This would equate to 125 Lbs./Hr. (20,000 Lbs. / 160 hrs. = 125 Lbs./Hr.)

Rectangular Fittings

If your sheet metal fabrication shop has been fortunate enough to have a plasma cutter you can avoid the time consuming method of hand layouts and cutting. If you don’t own some form of automation cutter, your productivity will probably be at least half of that of those that do. Either way you should know how many pounds of fittings your shop can produce per hour.

Also, any short straight pieces that are not run on the coil line should be figured as a fitting. As an example you might have 10,000 Lbs of metal run through the plasma cutter and have spent 250 hours of labor. (10,000 Lbs. / 250 Hrs. = 40 lbs/hour).

Round Ductwork

If your sheet metal fabrication shop owns a spiral machine, then you will want to know the productivity of this machine. This can also be figured in pounds per hour, or feet per hour per size depending on how the shop prefers to inventory materials. As an example if you produced 20,000 Lbs in 100 hours, you would get a productivity of (20,000 Lbs. / 100 Hrs. = 200 Lbs./Hr.)

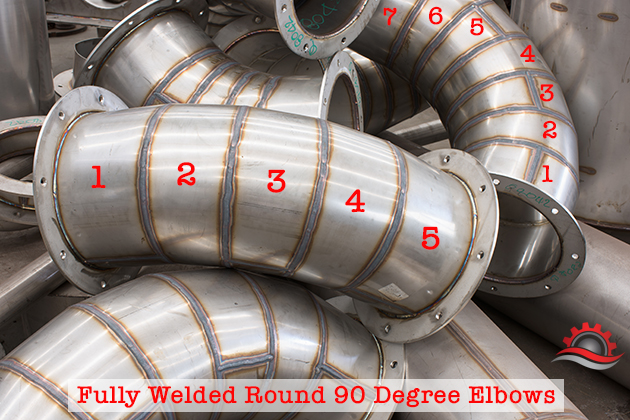

Round Fittings

If you cut and assemble your own round fittings it is imperative that you keep track of the cost to fabricate. How would you know if it is cheaper to fabricate then to purchase them? The only way to know for sure the true cost of fabricating is to measure the cost.

Also it can be very difficult to compete against a shop that uses Blue Label Workers; these are production, assembly line type of workers that have limited work task and a lower pay scale.

If a sheet metal fabricator is only in the business of fabrication and not contracting, they might have an advantage of being able to combine multiple orders from many contractors into to one fabrication run that helps optimize efficiency and increase productivity, making their prices highly competitive.

Remember that the examples here are just that, examples! Do not use these values for your adjustments. Each fabrication shop produces at various levels of productivity based on the machinery they own and the talent and experience of their shop labor. You must know your shops productivity factors in order to make the appropriate adjustments based on your unique circumstances.

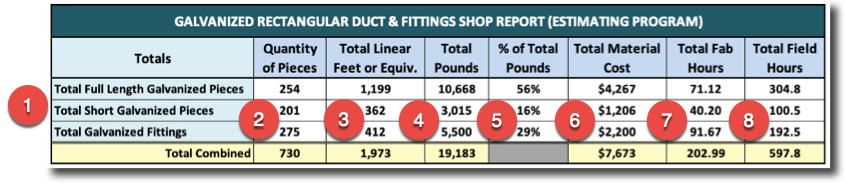

Above is a rectangular duct & fitting report from a popular computer estimating program. This report shows the total full-length pieces which can be considered from your coil line, plus the total quantity of short pieces and fittings (#1). From this report we can analysis the fabrication shops productivity. If your computer program summarizes these numbers in the format you need, you’re a step ahead.

The first thing to do is to determine what type of productivity the program is coming up with. If you rely 100% on the database numbers that printout of your estimating program then you can skip this step, but you should still verify the numbers from time to time.

If you notice from the report above there is no way of using the numbers without doing some type of calculation to get it into the format that is comparable to your shop reports of Lbs./Hour. Your Estimating program or if by manual takeoff you should obtain the following information.

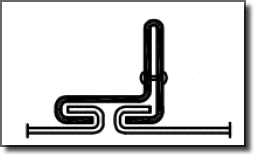

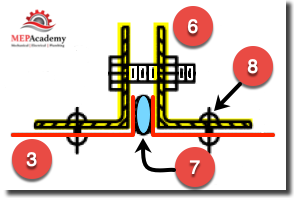

#1 (Total Full Length Pieces, Total Short Pieces and Total Fittings)

#2 (Quantity of Pieces). This will help you determine how many hours it takes to fabricate or install each piece.

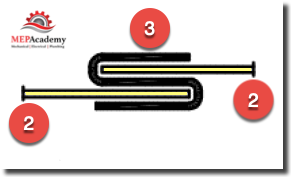

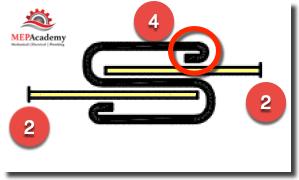

#3 (Total Linear Feet). Again we use these values to measure productivity.

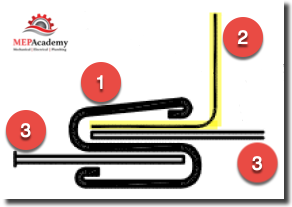

#4 (Total Pounds). You will use the total pounds for each category to determine how many pounds of metal can produced within an hour.

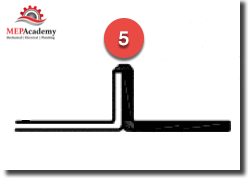

#5 (% of Total Pounds). This is important to analyze the fitting ratio when thinking about field labor. Projects with more fittings will take longer and thereby have a slower productivity value.

#6 (Total Material Cost). The sheet metal material cost that is in your computer program or that you calculate by hand.

#7 (Total Fabrication Hours). These should be your unadjusted values from your computer estimating program or if you have already put the net values into your database for shop labor, then those values are represented here.

#8 (Total Field Hours). Just like the shop hours, these are based on your labor database values unadjusted or net. If they are net labor units, then you should still review them to ensure they still make sense.

Sheet Metal Fabrication Shop Analysis

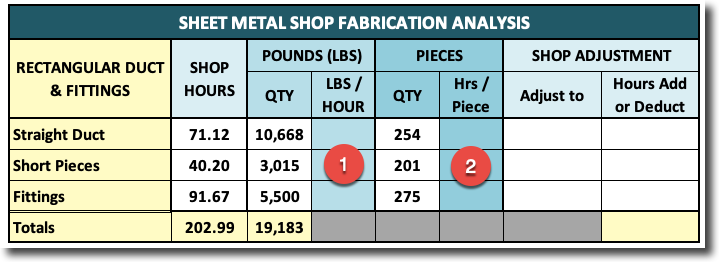

Put the numbers from the report above into the Shop Fabrication Analysis portion of the Sheet Metal Labor Review form shown below and calculate the productivity of the report without adjustment. The spreadsheet will automatically calculate LBS/HOUR (#1) and HRS/PIECE (#2) after you enter the information from the estimating program. You’re fortunate if your program provides these metrics as this will help avoid these extra steps.

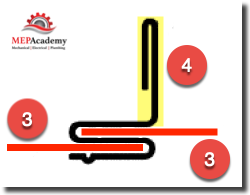

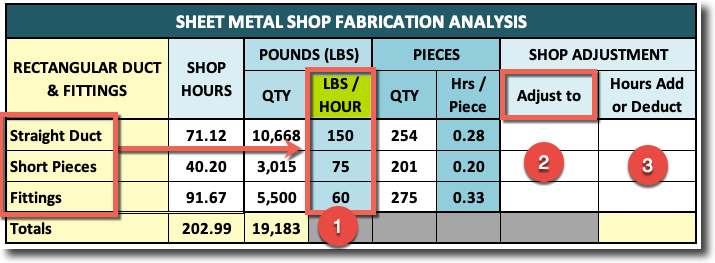

After you complete filling out the form and doing the calculations compare it to the form shown below. You can see that for each item (Straight Duct, Short Pieces, Fittings) there is now a calculated productivity metric shown by item #1 in the chart below. Straight Duct has a productivity of 150 LBS/Hr, while Short Pieces 75 LBS/HR. and Fittings 60 LBS/Hr.

This is the value that has come from the computer estimating program, now its time to adjust these values (#2) to that which is derived from your companies historical data or performance metrics. This will provide you with an Additive or Deductive Hours (#3) which you will enter into your estimating spreadsheet.

As shown above, the coil line or straight duct pieces are reporting out at 150 Lbs./Hour or 0.28 Hrs./Piece. However you analyze your productivity, now is the time to adjust the factor to your shops productivity. The Computer Estimating program may be setup with SMACNA labor units and your fabrication shop may be doing better or worse than these values, so an adjustment will be required.

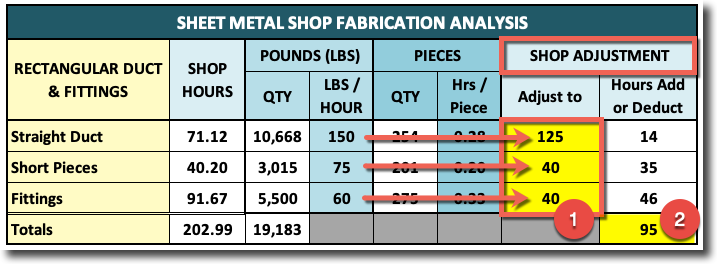

After you have entered the numbers from your computer estimating report, it’s time to decide what factors to apply for the shop adjustment. Let’s use the numbers in the examples shown above at the beginning of this chapter of 125 Lbs./Hour for straight pieces and 40 Lbs. / Hour for short pieces and fittings as shown below by item #1. After these new adjustment factors (#1) you will either have additional hours to add to your estimate or hours to deduct (#2).

As you can see we have adjusted the straight pieces to 125 Lbs. / Hour, and the short pieces and fittings to 40 Lbs. / Hour. This gives us a shop add of 95.22 hours, which equates to a 47% add. (95.22 / 202.99 = 47%)

Other things to consider when adjusting the shop are how many pounds are on this one project compared to your average job. Is this considered a smaller job than usual? Will it be penalized at fabrication time because the shop is slow? Will the foreman submit cut sheets one at a time or in complete batches to improve productivity? Some of these factors are out of your control, but it is good to be aware of those things that have an impact on productivity.

If your productivity numbers are as those shown in our example at the beginning of this chapter, your adjustment might look as shown below.

Shipping

How do you figure the cost of transporting the ductwork from the fabrication shop to the job site? Does your company use an independent trucking company, or do they own their own trucks, or do you purchase your duct FOB job site?

If you fabricate your own ductwork and fittings you will have to determine the cost to ship it from the shop to the jobsite. A common way of figuring shipping is by determining the amount of pounds that can be shipped per truck load. If you know that you have 20,000 lbs of ductwork and that your truck can deliver 4,000 lbs per trip, the formula would look like this; (20,000 Lbs. / 4,000 Lbs. = 5 Truckloads.

The next thing to consider is what the cost to the company is for operating and maintaining the truck. This will include items such as fuel, lease payments, insurance, maintenance, all other burdens in addition to the labor for the truck driver, warehouse loading and delivery time.

The charge can be handled in many different ways, such as a burden rate added on top of the shop labor hourly rate, or by the hour for the labor and a fixed rate of recovery for the truck for each trip or miles driven.

For example you might figure using 12 hours per truckload at a rate of $50/hr. Based on our previous example of 5 truckloads, this would equal (5 Truckloads x 12 hours/Truckload = 60 hours) = (60 Hours x $50/Hr = $3,000). Or, you could use a combination of the two, where you separate the labor cost from the truck cost. Whichever method you use, be sure to consider all cost associated with shipping.

Remember to consider whether you are shipping your ductwork KD (Knocked Down) or if it is pre-assembled by the shop. You should be able to get a little more than twice the pounds per truckload in K.D. form.

Watch the below video to get a sense of the magnitude of the work required in a sheet metal shop. This shop by McCorvey Sheet Metal Works will give you an idea of what a large sheet metal fabrication shop entails. Most fabrication shops will not be this large, but this will give you an idea of what is capable on a larger scale and how productivity is also related to how well a shop is organized and professionally operated.

- Chapter #1 – Introduction to Sheet Shop Fabrication

- Chapter #2 – Sheet Metal Materials

- Chapter #3 – Sheet Metal Coil Line

- Chapter #4 – Plasma Cutting Table

- Chapter #5 – Spiral Machine

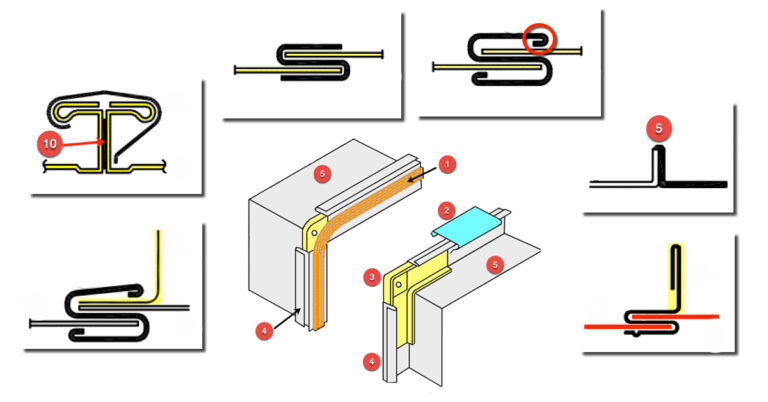

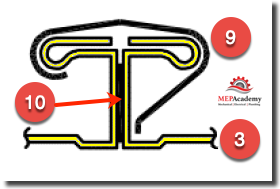

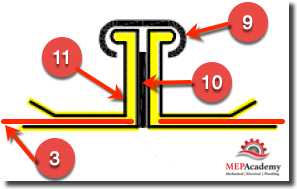

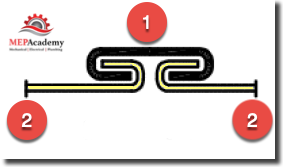

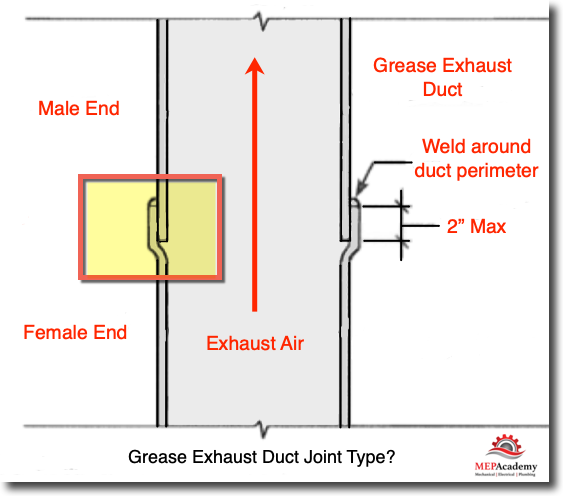

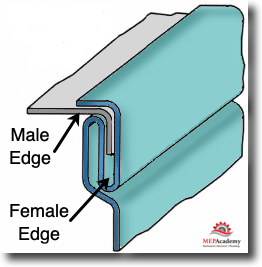

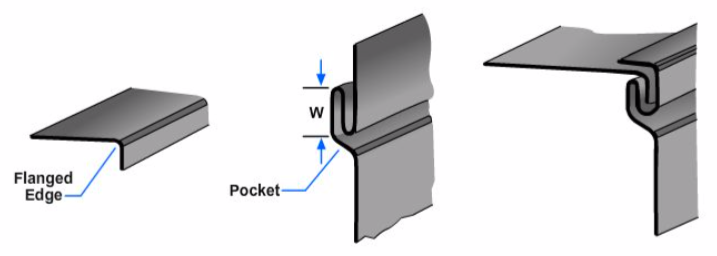

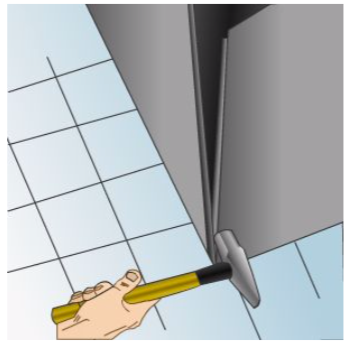

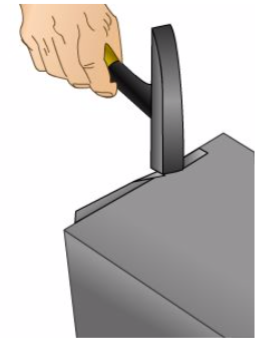

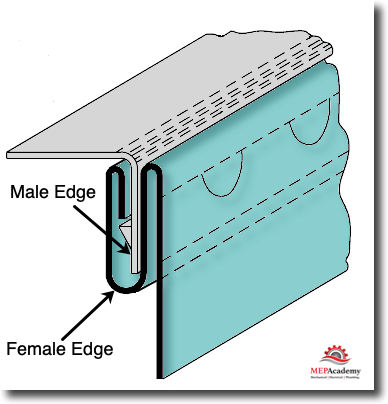

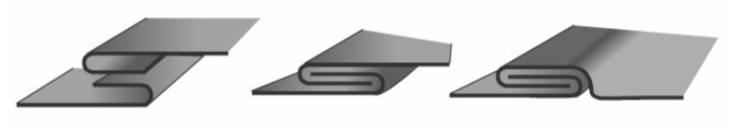

- Chapter #6 – Sheet Metal Seams

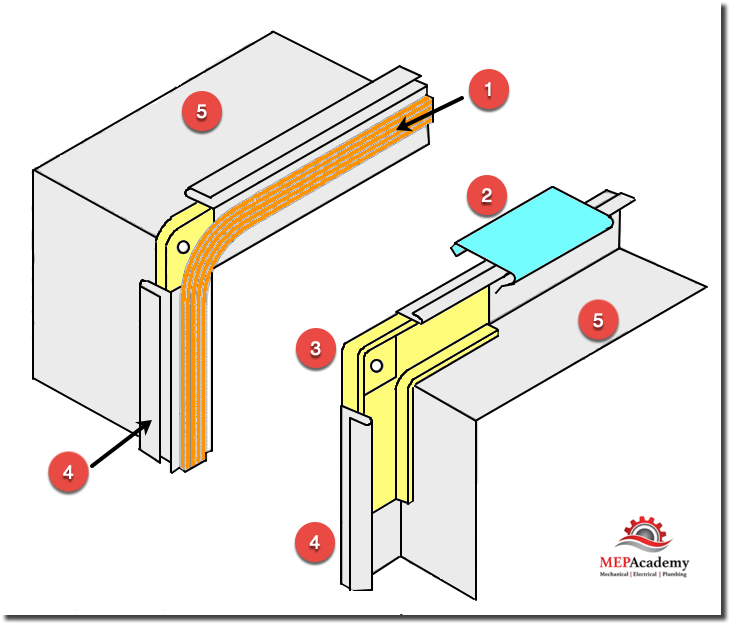

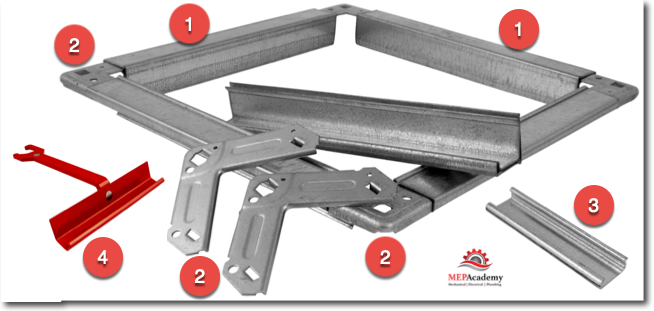

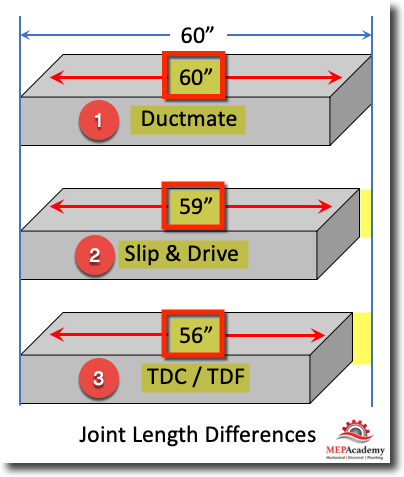

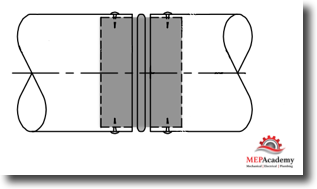

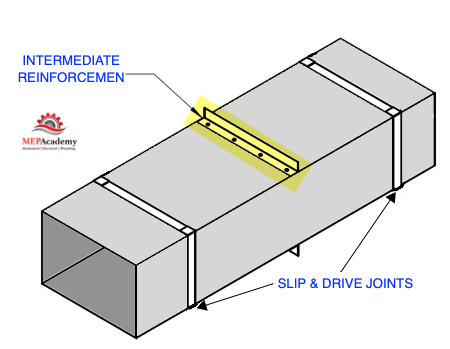

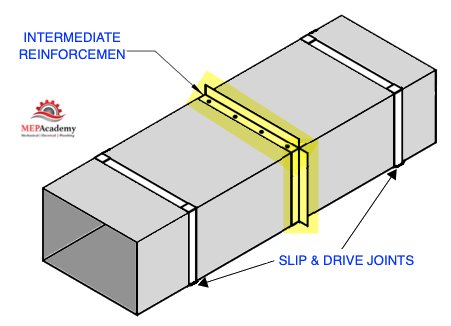

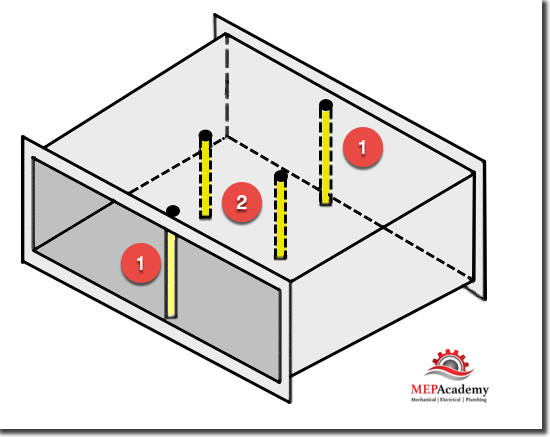

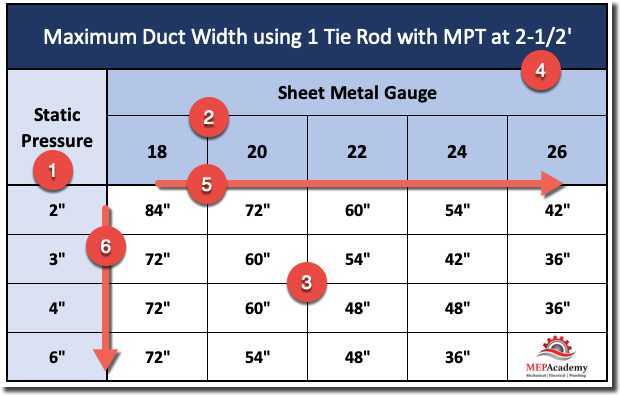

- Chapter #7 – Sheet Metal Joints

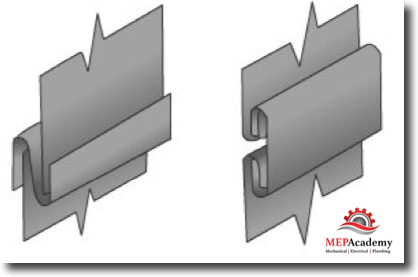

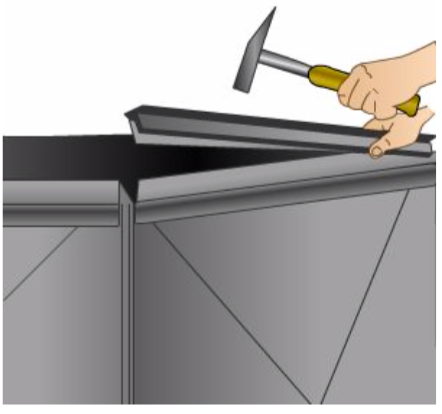

- Chapter #8 – Casings and Plenums

- Chapter #9 – Sheet Metal Shop Fabrication Productivity